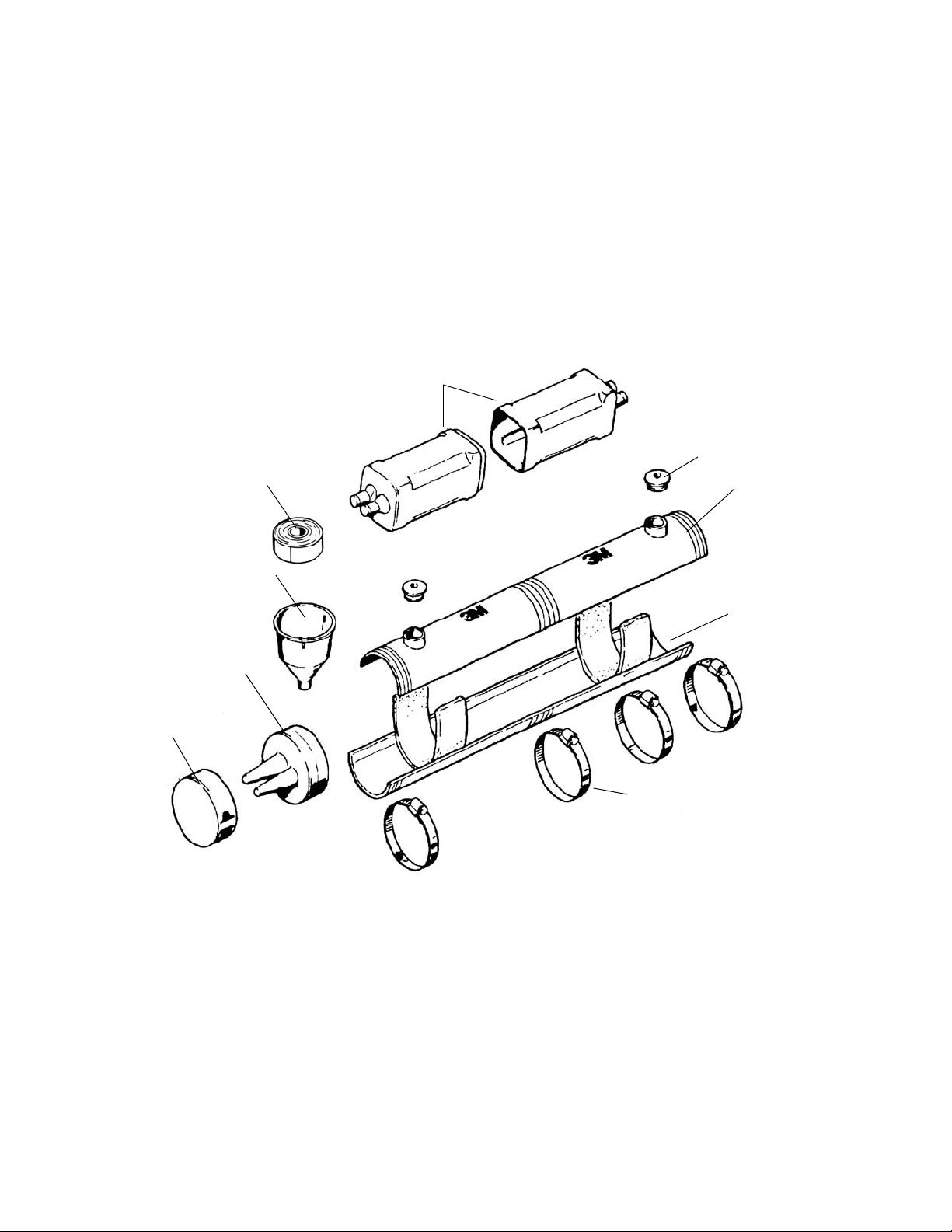

3.6 Splicing:

a. Attach cable organizer bracket (3M 2196 or

equivalent) to cable.

b. Place trays (3M 2522 or equivalent) and route

buffer tubes and fibers into the proper tray

following the instruction sheet.

c. Splice and test fibers per manufacturer's

instructions.

3.7 Protective Shell Assembly:

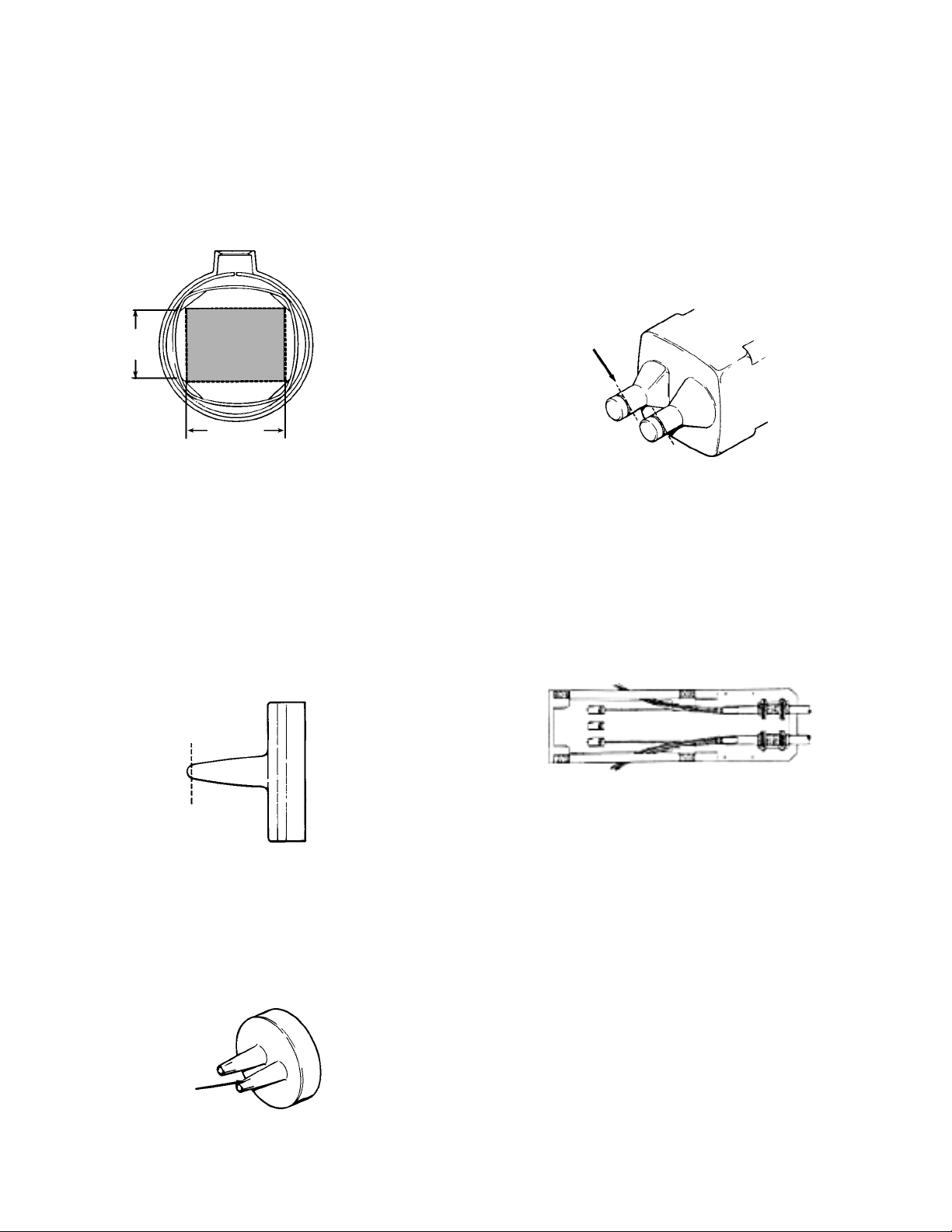

a. Remove plastic vinyl tape from cable sheaths.

b. Mark each cable 11" (279 mm) from the center

of the splice. At each location, wrap Foam

Tape around each cable. Taper sealant ends at

start and finish of wraps to prevent leakage.

See illustration for number of wraps.

Note: If external ground is required, embed the

ground wire within the Foam Tape Collar

wraps.

Foam Tape Wraps

Cable Diameter Required

.4" - .5" (10-13 mm) 2

.5" - .8" (13-20 mm) 1

.8" - 1.0" (20-25 mm) 0

c. Slide protective shell halves over splice area

and sheath collars (and external ground lead,

if applicable.) Push shell together until it

snaps into place. A 0.2" (5 mm) wide gap is

present when halves are correctly assembled.

d. Wrap center seam with foam tape and press

into place. Butt ends and trim excess.

e. Center shell, leaving approximately 1" (25 mm)

of Foam Tape exposed at each end.

f. Wrap 1 layer of Foam Tape at each shell port.

Center the tape on the protective shell port rim.

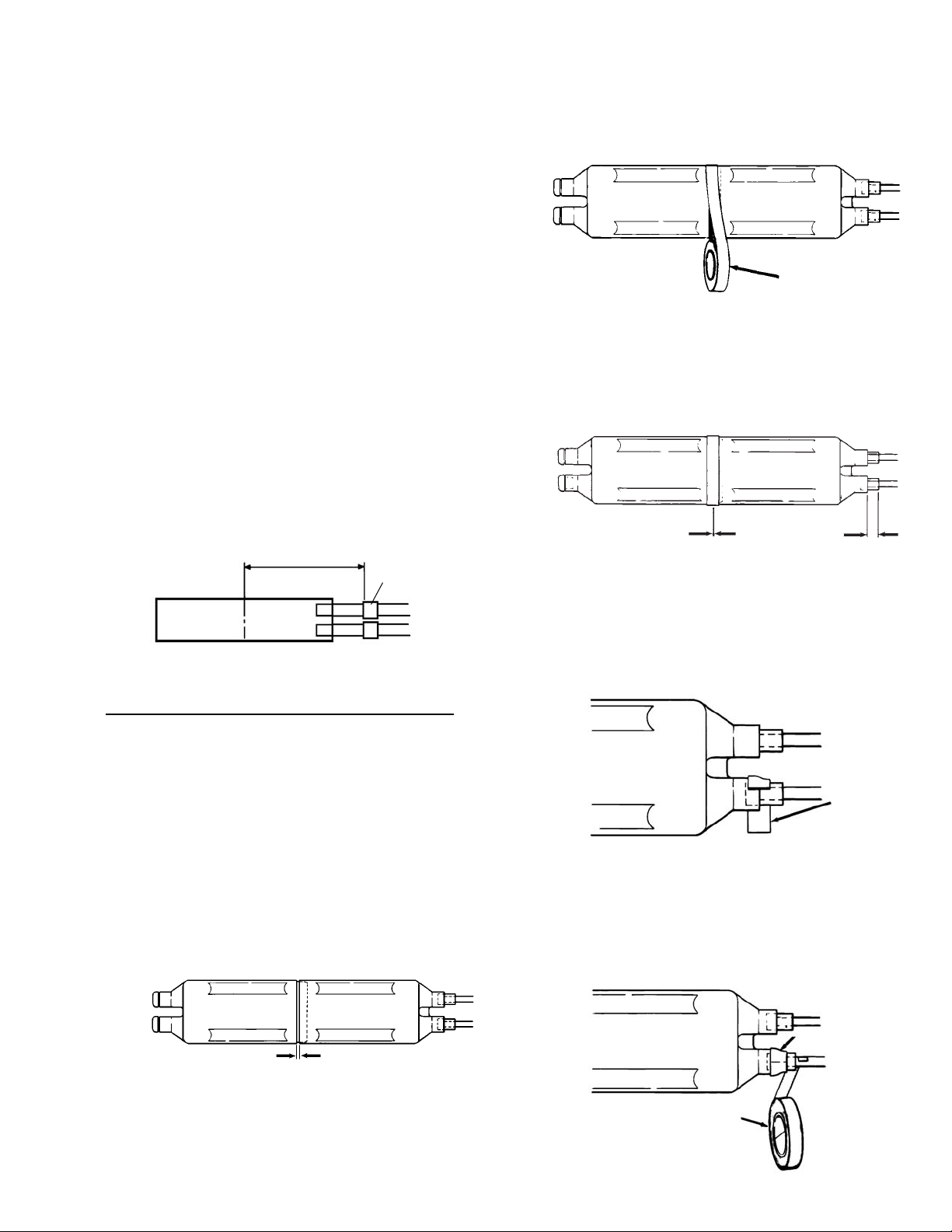

g. Completely overwrap Foam Tape with 2 half-

lap layers of highly stretched 3/4" (19 mm)

DR Tape white side out. Start DR Tape 1/2"

(13 mm) outside Foam Tape and continue to

taper of port.

11" (279 mm)

B Sealing Tape

0.2" (5 mm) Gap

Foam Tape

3/4" (19 mm) DR Tape

1 Layer of

Foam Tape

11.5" (292 mm)

11.5" (292 mm)

1" (5 mm)

1 Wrap Foam Tape