3M Nano-Lok Edge Series User manual

Other 3M Security Sensor manuals

3M

3M 740 Guide

3M

3M DBI Sala EXOFIT XP Operator's manual

3M

3M 600 Series User manual

3M

3M DBI-SALA ExoFit NEX Operation and maintenance manual

3M

3M Dynatel 500 User manual

3M

3M SecureFit X5500NVE User manual

3M

3M Rollgliss User manual

3M

3M SEALED-BLOK Series User manual

3M

3M Dynatel 2210 User manual

3M

3M DBI SALA 8705 Series Installation instructions

3M

3M MACURCO GD-2 User manual

3M

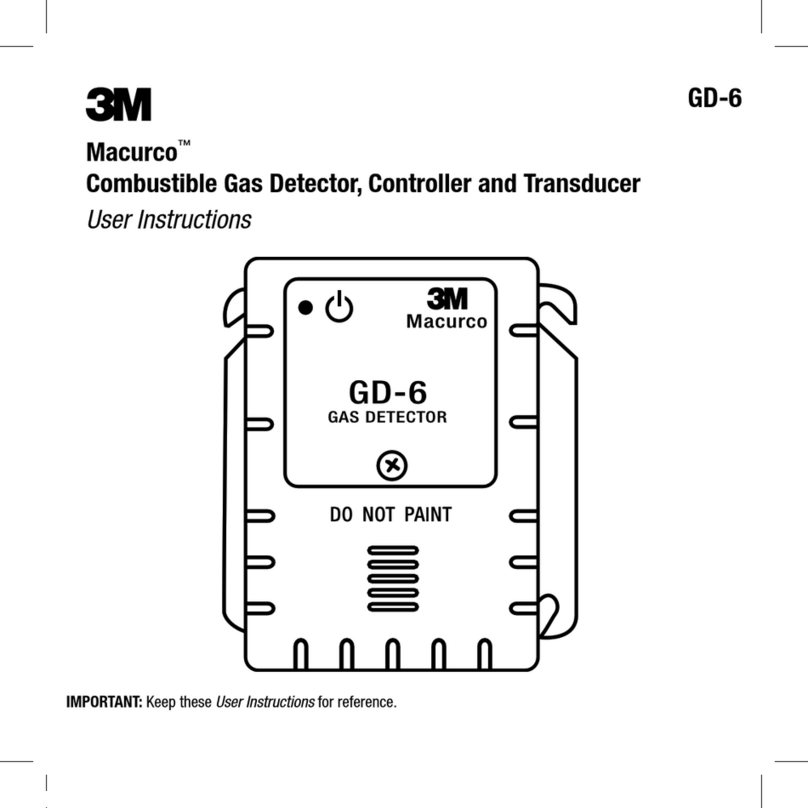

3M MACURCO GD-6 User manual

3M

3M Versaflo M-973 User manual

3M

3M DBI SALA LAD-SAF X3 User manual

3M

3M LAD-SAF User manual

3M

3M Petrifilm 6402 Instruction sheet

3M

3M SD-200 User manual

3M

3M DBI-SALA LAD-SAF User manual

3M

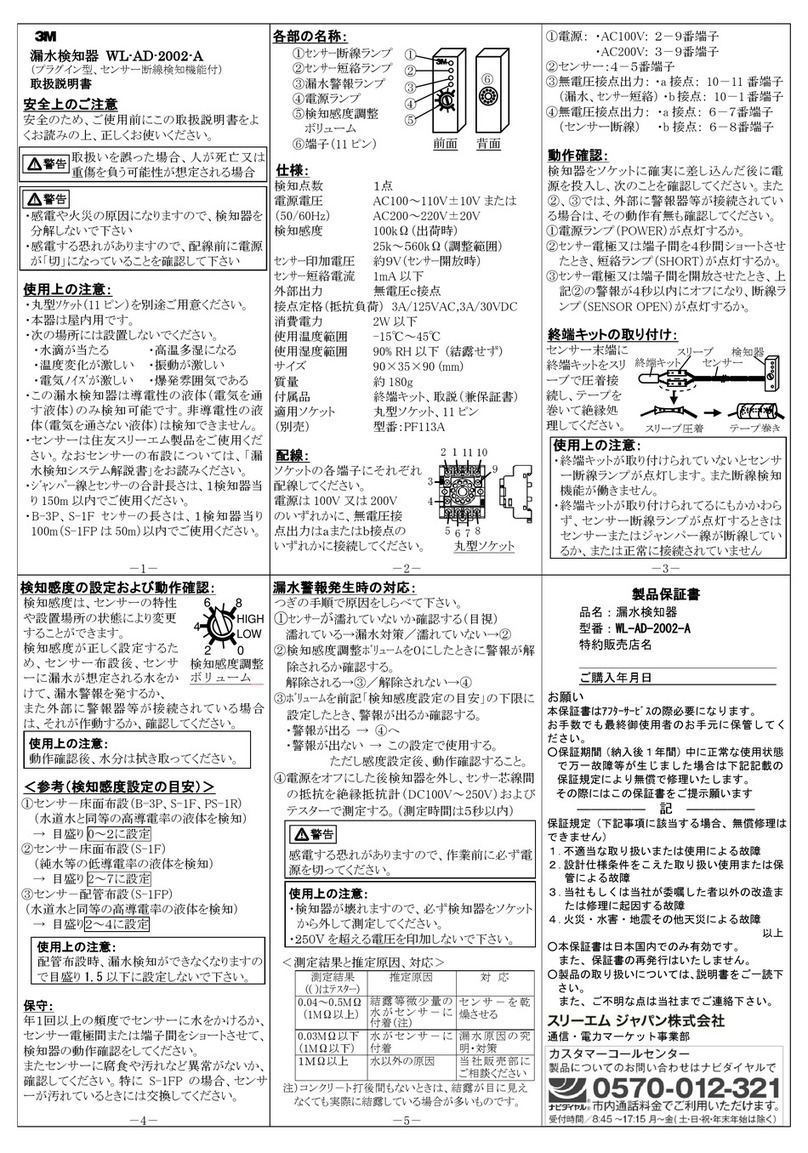

3M WL-AD-2002-A User manual

3M

3M DBI SALA 9506038 Operator's manual