4B - W4005 BÜHLER ELEVATOR MONITORING SYSTEM R9.6 –22 May 2020

Page 2of 48

TABLE OF CONTENTS

1. ABBREVIATIONS AND NOTATIONS USED........................................................................................................................... 4

2. WARNINGS........................................................................................................................................................................ 4

3. SYSTEM INTRODUCTION ................................................................................................................................................... 4

4. SYSTEM APPROVALS AND COMPLIANCE ........................................................................................................................... 4

4.1 W4005V46-SYS1 /B DECLARATION OF CONFORMITY .................................................................................................................... 6

4.2 W4005V46-SYS2 /B DECLARATION OF CONFORMITY .................................................................................................................... 7

5. TRANSPORTATION ............................................................................................................................................................ 8

6. SYSTEM COMPONENTS ..................................................................................................................................................... 8

6.3 SYSTEM COMPONENTS INTRODUCTION.......................................................................................................................................... 8

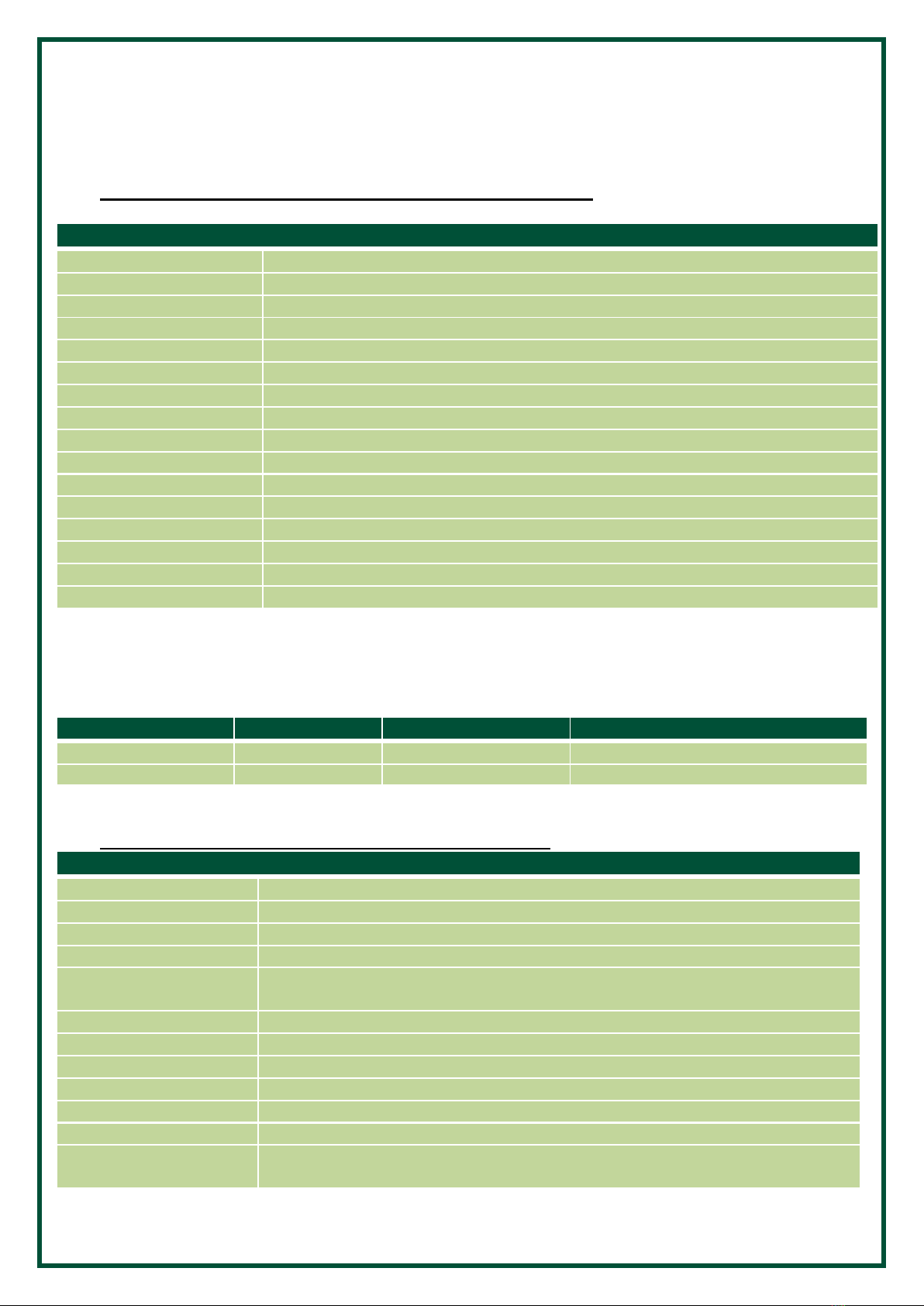

7. SPECIFICATIONS ................................................................................................................................................................ 9

7.1 OVERALL PACKAGING ................................................................................................................................................................. 9

7.2 AIRBORNE NOISE....................................................................................................................................................................... 9

7.3 W4005NV46AI /B –W400 SERIES ELEVATOR CONTROLLER ........................................................................................................ 10

7.4 TS1V4AI /B –TOUCHSWITCH™ALIGNMENT SENSOR ................................................................................................................... 10

7.5 P300V34AI /B –PROXIMITY SPEED SENSOR............................................................................................................................... 11

7.6 WG4A-BR /B –WHIRLIGIG®SPEED SENSOR MOUNTING.............................................................................................................. 11

7.7 ADB910V3AI /B -ADJUSTABLE DEPTH BEARING TEMPERATURE SENSOR......................................................................................... 11

8. MECHANICAL INSTALLATION............................................................................................................................................12

8.1 TS1V4AI /B –TOUCHSWITCH™ALIGNMENT SENSOR ................................................................................................................... 12

8.2 WG4A-BR /B AND P300V34AI /B –PROXIMITY SPEED SENSOR AND BRACKET INSTALLATION ............................................................ 15

8.3 ADB910V3AI /B -ADJUSTABLE DEPTH BEARING TEMPERATURE SENSOR......................................................................................... 16

8.4 W4005NV46AI /B –W400 SERIES ELEVATOR CONTROLLER ........................................................................................................ 17

9. ELECTRICAL INSTALLATION AND WIRING .........................................................................................................................17

9.5 WARNINGS............................................................................................................................................................................. 18

9.6 TS1V4AI /B –TOUCHSWITCH™ALIGNMENT SENSOR ................................................................................................................... 18

9.7 P300V34AI /B –PROXIMITY SPEED SENSOR............................................................................................................................... 21

9.8 ADB910V3AI /B -ADJUSTABLE DEPTH BEARING TEMPERATURE SENSOR ........................................................................................ 21

9.9 W4005NV46AI /B –W400 ELEVATOR CONTROLLER.................................................................................................................. 22

10. W4005NV46AI /B CONTROLLER OPERATION DESCRIPTION..............................................................................................26

10.10 OVERALL OPERATION DESCRIPTION........................................................................................................................................ 26

10.11 W4005NV46AI /B CONTROLLER LEDS................................................................................................................................. 26

10.12 W4005NV46AI /B CONTROLLER BUTTONS ........................................................................................................................... 27

10.13 SETTINGS SWITCHES............................................................................................................................................................ 28

10.14 W4005NV46AI /B CALIBRATION ........................................................................................................................................ 30

10.15 ALARMS AND SHUTDOWN .................................................................................................................................................... 30

10.16 TEST FUNCTIONALITY........................................................................................................................................................... 32

10.17 NORMAL MACHINE START /STOP.......................................................................................................................................... 32

10.18 ALARM SHUTDOWN RESTART................................................................................................................................................ 33

11. COMMON MISUSE WARNINGS.........................................................................................................................................33

12.COMMUNICATION OPTIONS ............................................................................................................................................33