Sinar Technology 6095 AgriPro User manual

Sinar Technology, Unit 2, Old Station Business Park,

Compton, Berks, RG20 6NE, ENGLAND

Telephone : +44 (0) 1635 579940 Fax: +44 (0)1635 579941

email: office@sinar.co.uk Website: www.sinar.co.uk

Operator Manual

6,1$50RGHO$JUL3UR

SINAR

TECHNOLOGY

www.coffeelabequipment.com

TEL (804) 435-5522 TOLL FREE (866) 244-1578

Technical Specifications

Dimensions

21x7.5x7.5cm

Weight

1.5kg(includingcarryingcase)

Storage Temperature

-20 deg C to + 55 deg C; Humidity up to 98% non condensing

Construction

Non shock ABS Plastic

Measurement cell in polished Aluminium

Supplied with shock proof carrying case

Display

Direct digital display with accuracy to one decimal point

Power Supply

9 volt Alkaline Battery

Measurement range.

5 -45% depending on crop

Precision

+/- 0.5 %mc or better to Oven Method @ 135 +/- 2 deg C for I hour

Calibrations - individual calibrations for all Grain types including:

Wheat

Barley

Oats

Oil Seed Rape

Linseed

Peas

Beans

Repeatability

Standard Deviation of 0.05 to 0.15 (dependant on application)

Functions

Automatic temperature correction with calculation of average.

Warranty

2 years against component failure and faulty workmanship

Manufactured in the European Community

-1 -

Operating Instructions:

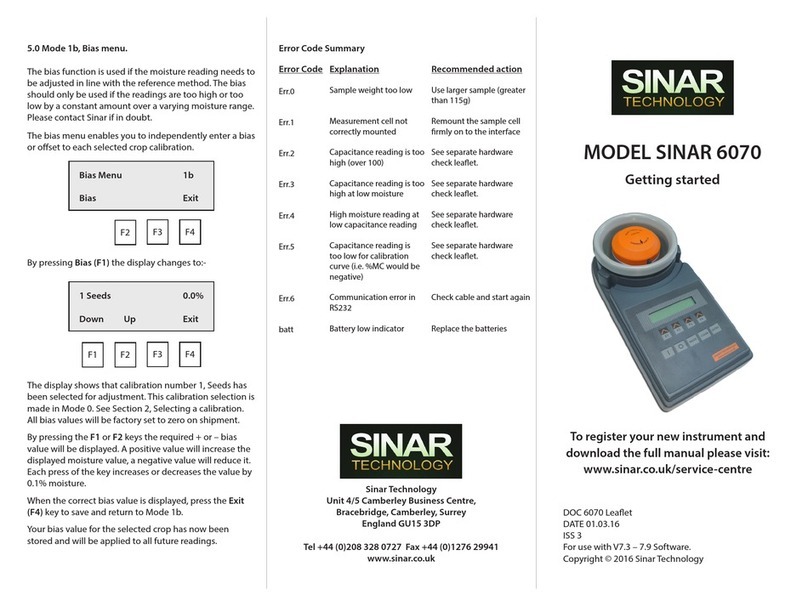

1. Measuring %mc

a) Inspect the cell to ensure it is clean and empty

b) Turn on the analyzer by pressing ON/TEST button. The >> MEASURE << menu will be

automatically displayed.

c) Accept mean by pressing the ON/TEST button.

d) By using the ©or ªarrows select the crop for measurement.

e) Using the scoop provided, fill the measuring cell evenly to the top, ensuring the crop is

level with the top of the cell. Screw on the cap and tighten until the stainless steel

pressure indicator is flush with the top of the cap. see figure 1a - 1 d.

f) Press the ON/TEST button. The word >> TEST << will be displayed for approximately

10 seconds before the moisture content result is displayed.

Theactual%mcwillbedisplayedontheleft-handsideoftheLCDe.g.14.9%andthe

right-hand will show the average of the last measurements, e.g. 14.7%.

g) The analyzer will remain with the chosen crop displayed and a new measurement can

be made by emptying the test cell and re-filling with a new sample.

Note: DO NOT RE-TEST THE SAMPLE WITHOUT EMPTYING AND REFILLING.

2. To select crop or function

a) When pressing the ON/TEST the analyzer will show software version and the country

code, followed by the level of battery and lastly the >> MEASURE<< menu. If you wish

to accept this choice of menu press the ON/TEST button and the desired crop can be

selected by use of the ©or ªarrows. If you wish to return to the >> MEASURE<<menu

simply press the ESC/OFF button and use the ©or ªarrow keys to cycle through the

menus.

3. How to adjust a calibration

Each calibration can, if required be adjusted individually, up or down by 3.9%mc by

increments of 0.1%mc.

a) Turn the analyzer by pressing ON/TEST. The menu >>MEASURE<< will be

displayed.

b) Using the ©or ªarrow keys the menu >>CALIBRATION<< can be selected

c) Accept the menu by pressing ON/TEST.

d) By using the ©or ªarrow keys select the desired crop.

e) Accept this choice by pressing ON/TEST. The numeric value +0.0 is shown on the

display.

f) By using the ©or ªarrow keys the desired calibration can be adjusted up to a

maximumof-3.9to+3.9%mc.

g) Accept the adjusted value by pressing the ON/TEST button.

Note: Where an adjustment has been made to a factory installed calibration a * will

appear at the end of the crop name.

Some calibrations are factory biased on delivery and should only be changed with

extreme caution.

4. How to clear the calculated average values.

a) Turn on the analyzer by pressing the ON/TEST button. The menu>>MEASURE<< will

appear on the display.

b) By pressing the ©or ªarrow key the menu >>CLEAR AVERAGE<< is selected.

Figure 1a. Fill the measuring cell evenly

to the top, ensuring the crop is level with

thetopof thecell.Screwonthecapand

tighten until the stainless steel pressure

indicator is flush with the top of the cap.

-3-

µScrew cap under

tightened. Stainless steel

indicator sunken in cap

9Screw cap correctly

tightened. Stainless steel

indicator level with cap

µScrew cap over

tightened. Stainless steel

indicator proud of cap.

Figure 1 b Figure 1 c Figure 1 d

4. How to clear the calculated average values (continued)

c) $FFHSWWKLVFKRLFHE\SUHVVLQJ217(677KHZRUGLQJ³2.´ZLOODSSHDURQWKH

display followed by automatic return to >>MEASURE<<.

5 How to turn the unit off.

a) Press the OFF/ESC button and hold down until the analyzer is turned off.

Note: The analyzer will automatically turn off 45 seconds after the last operation to

conserve battery power.

5. Constructing a Calibration.

If you require a calibration for a particular crop not included in the analyzer, then this

FDQEHGRQHE\VHOHFWLQJWKHFDOLEUDWLRQZLWKQDPH³%,7´.

a) Turn on the analyzer by pressing ON/TEST. The menu>>MEASURE<<

will appear.

b) Accept the menu by pressing the ON/TEST .

c) By using the ©or ªDUURZNH\VVHOHFWWKH³%,7´VFDOH

d) Fill the test cell with crop of known moisture content, screw down the cap and make a

test as described in section 1.

e) Write down the value which appears on the display together with the known

moisture content value.

f) Repeat the steps d) & e) with different known moisture content samples. Preferably

at 0.5%mc change in sample over the moisture range of interest.

g) A calibration chart can be constructed by plotting the BIT values against %mc.

Unknown sample values can then be calculated by reading the BIT value and using

the calibration scale to look up the moisture content of the unknown.

6. How to read temperature.

6HOHFWWKH³%,7´FDOLEUDWLRQDQGSURFHHGDVGHWDLOHGLQD- 5.d) above.

The temperature is the value displayed on the right in ° C.

7. Error Messages

The following error messages may occur on the display:

Error Message Definition

Temperature ++ Temperature above limit

Temperature - - Temperature below limit

Hi %mc above upper limit of calibration

Lo %mc below lower limit of calibration

Change Battery Replace battery

-4-

8. Useful information

Note: 1 Some grains, such as grass seeds are too small to push up the pressure

indicator of the screw cap. In these circumstances screw down the cap all the way before taking a

reading. Do not attempt to add additional grain to the cell having once compressed the sample.

Note 2. High moisture grain will continue to compress in the test cell once the pressure

cap is screwed down. Higher readings than actual may result if the TEST button is not

immediately pressed after screwing down the cap.

Note 3. Due to different size grains one can expect slight variations in measurement of

the same sample due to variation in packing. To compensate for this effect it is recommended

that 3-5 measurements are made of the same batch of grain and the average result is used as a

true %mc in the grain. Remember to use a fresh sample for each new measurement.

Note 4. If the sample temperature is greater than that of the measuring cell e.g samples

coming directly from a dryer, it is recommended to preheat the measuring cell as follows:-

a) Fill the measuring cell with the hot sample and wait for 40 seconds before emptying

the cell.

b) Refill the cell with a new hot sample and test as described in section 1.

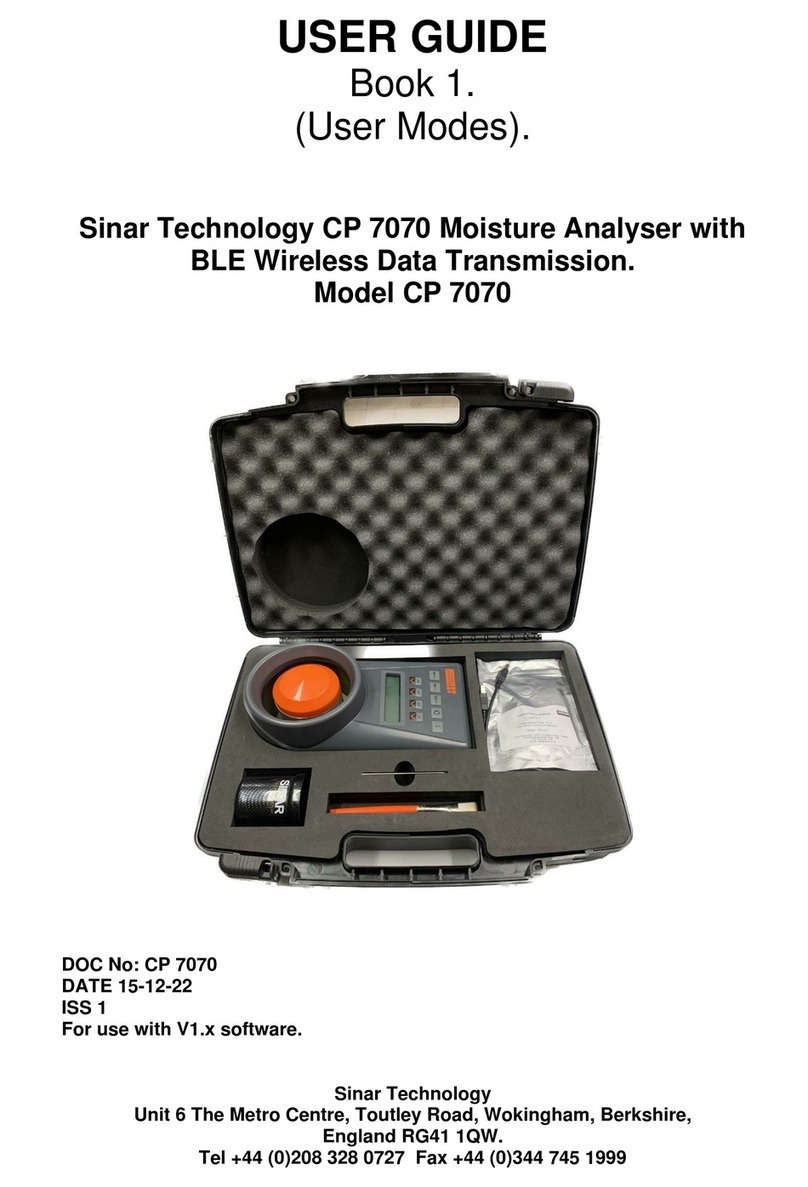

9. Storage and Use of the Analyzer

It is recommended that the analyzer is:

Always stored in the carrying case.

Not exposed to large temperature fluctuations.

Kept dry.

Allowed to acclimatise when taken from a cold storage location to a warmer testing

environment to prevent possible condensation.

Cleaned thoroughly on all surfaces with a clean damp cloth and the battery

removed before storage at the end of the season.

If the above instructions and guidelines are followed you can expect a long and excellent

performance from your Sinar Model 6095 AgriPro Moisture Analyzer.

-5-

Table of contents

Other Sinar Technology Measuring Instrument manuals