Table of Contents

1 TubeMarker™ 2 Introduction ..........................................................................................................6

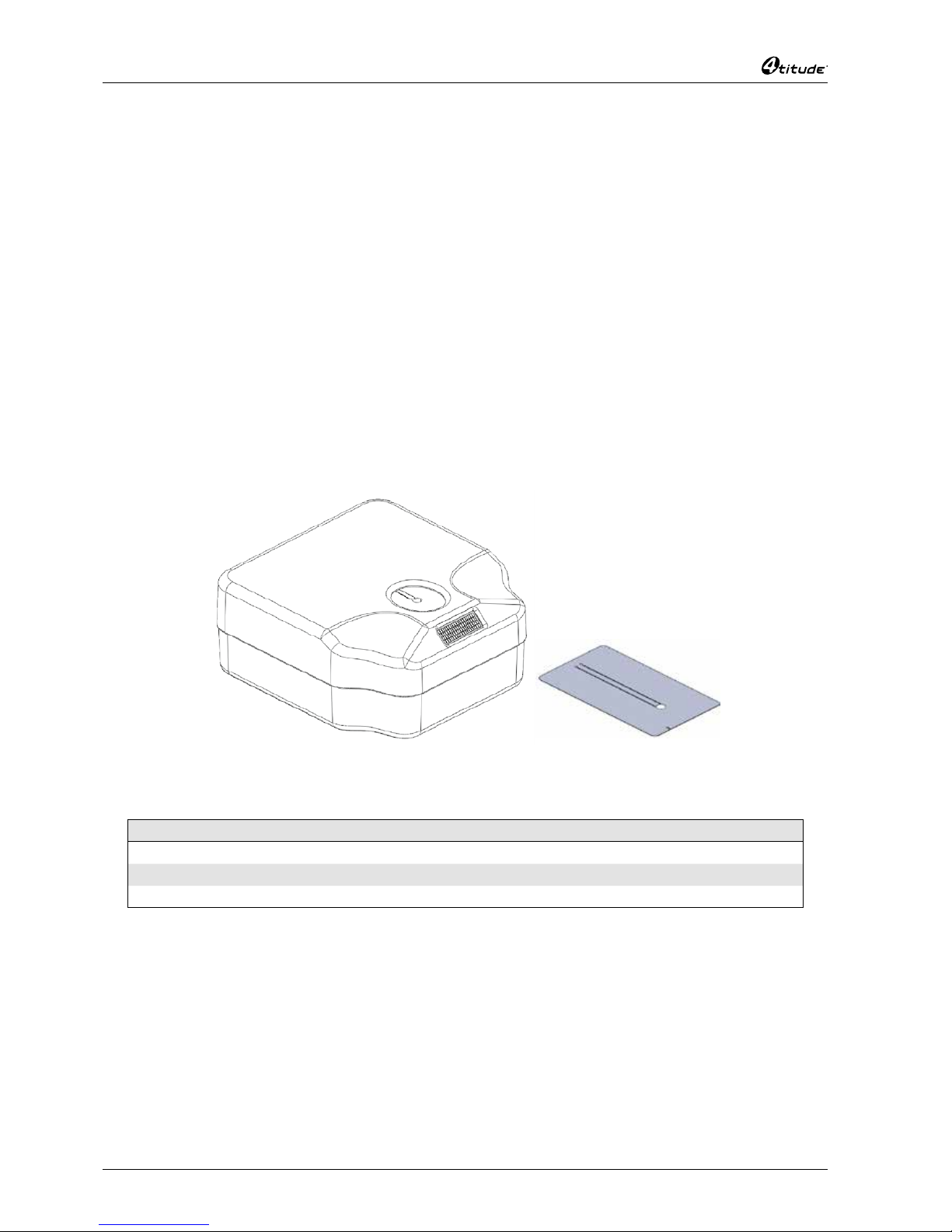

1.1 The Instrument…………………………………………………………………………………………………………6

1.2 Package Contents ……………………………………………………………………………………………………6

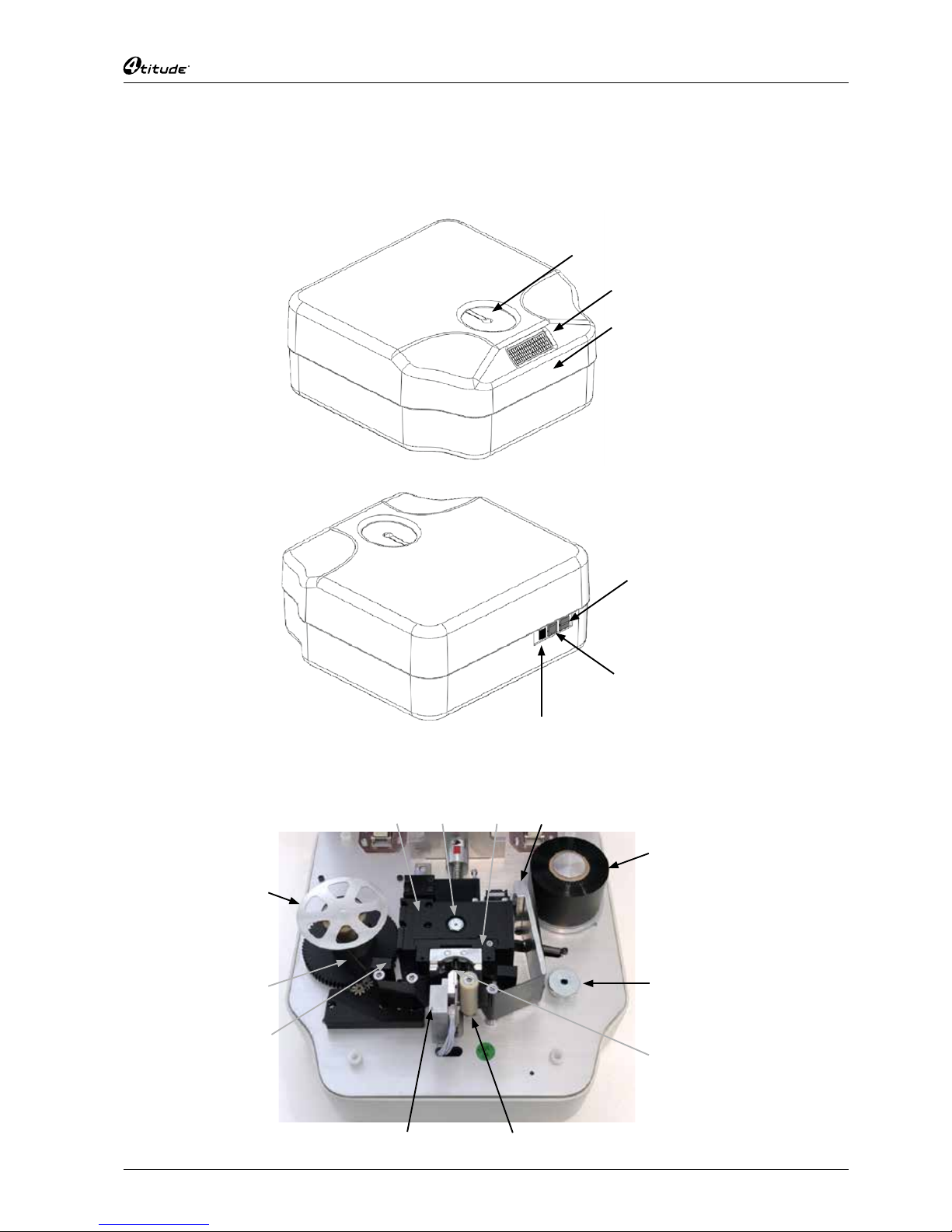

1.3 TubeMarker™ 2 Parts ………………………………………………………………………………………………7

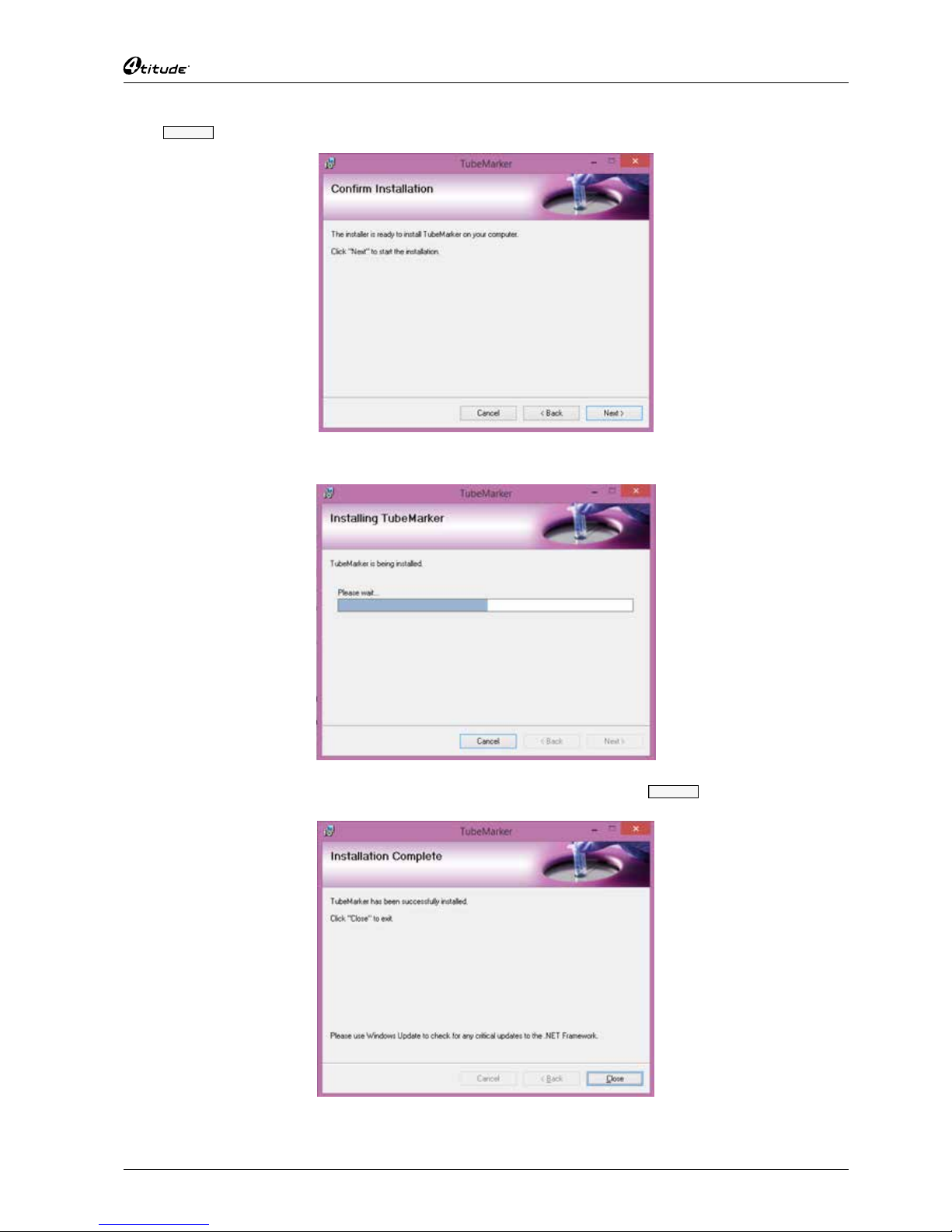

2 Software Installation........................................................................................................................8

3 Hardware Installation ....................................................................................................................10

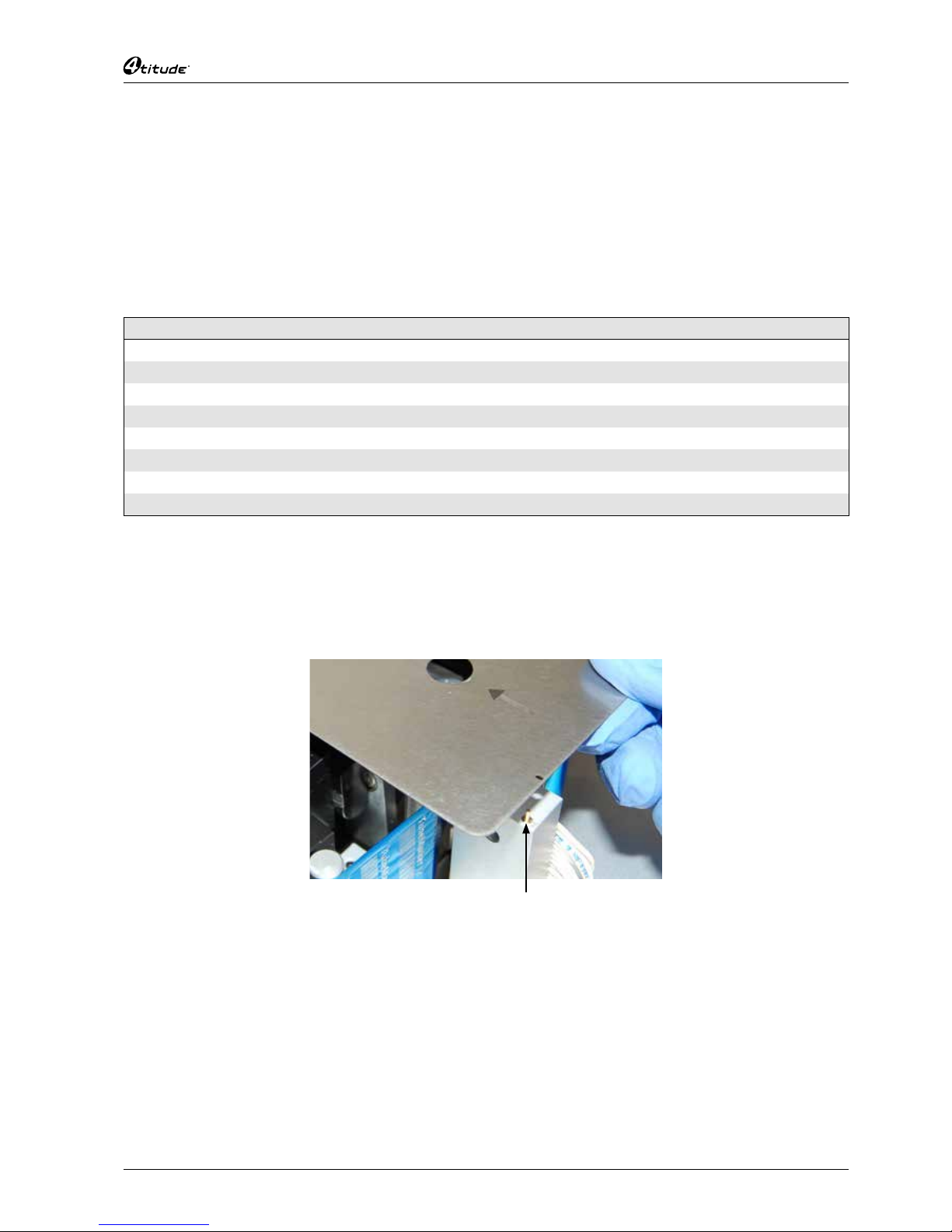

3.1 How to Install Ribbon for Printing ………………………………………………………………………………… 10

3.2 How to Set-up Tube Support……………………………………………………………………………………… 11

3.3 How to Connect Printer to PC …………………………………………………………………………………… 15

4 Preparation for Printing ................................................................................................................16

4.1 How to Create Label Content …………………………………………………………………………………… 16

4.2 How to Enter Data into the TubeMarker™ Spreadsheet ……………………………………………………… 27

4.3 How to Set the Printer Settings…………………………………………………………………………………… 29

5 Printing Modes...............................................................................................................................34

5.1 How to Use Print Mode – All ……………………………………………………………………………………… 34

5.2 How to Use Print Mode – Selected ……………………………………………………………………………… 35

5.3 How to Use Print Mode – Single ………………………………………………………………………………… 36

5.4 How to Adjust the Ribbon during Print Mode …………………………………………………………………… 37

6 How to Print using Multiple Printers............................................................................................39

6.1 How to Connect a Printer to Software …………………………………………………………………………… 39

6.2 How to Print using Multiple Printers ……………………………………………………………………………… 41

6.3 How to Disconnect a Printer from Software …………………………………………………………………… 42

7 Maintenance / Cleaning the Printhead..........................................................................................43

8 Error Messages / Troubleshooting ...............................................................................................44

8.1 Error Messages …………………………………………………………………………………………………… 44

8.2 Troubleshooting …………………………………………………………………………………………………… 44

9 AppendixA:TechnicalSpecications .........................................................................................46

10 Appendix B: Accessories / Ordering Information .......................................................................47

10.1 Accessories ………………………………………………………………………………………………………… 47

10.2 Ordering Information ……………………………………………………………………………………………… 47

11 Appendix C: Warranty ...................................................................................................................48

12 Appendix D: Shipping Instruction................................................................................................49

13 Appendix E: Disposal Information ...............................................................................................49