TECHNICAL MANUAL 620074E04

Due to the continuous products improvement, the indications of the present manual can be modified without previous warning and in any case are a

contract commitment. The present information publishing does not represent resignation of intellectual property or patent.

Copyright ©2009-2021 S.A. Sistel -E 08211 BARCELONA Pag. 3

0. Before you begin ............................................................................................................4

1. Safety...............................................................................................................................4

1.1 Precautions against damage to people......................................................................4

1.2 Precautions against damage to the product ..............................................................5

1.3 Limits of the guarantee..............................................................................................5

2. Certifications...................................................................................................................6

3. Description and main features ......................................................................................7

3.1General features........................................................................................................7

3.2 Applications ...............................................................................................................7

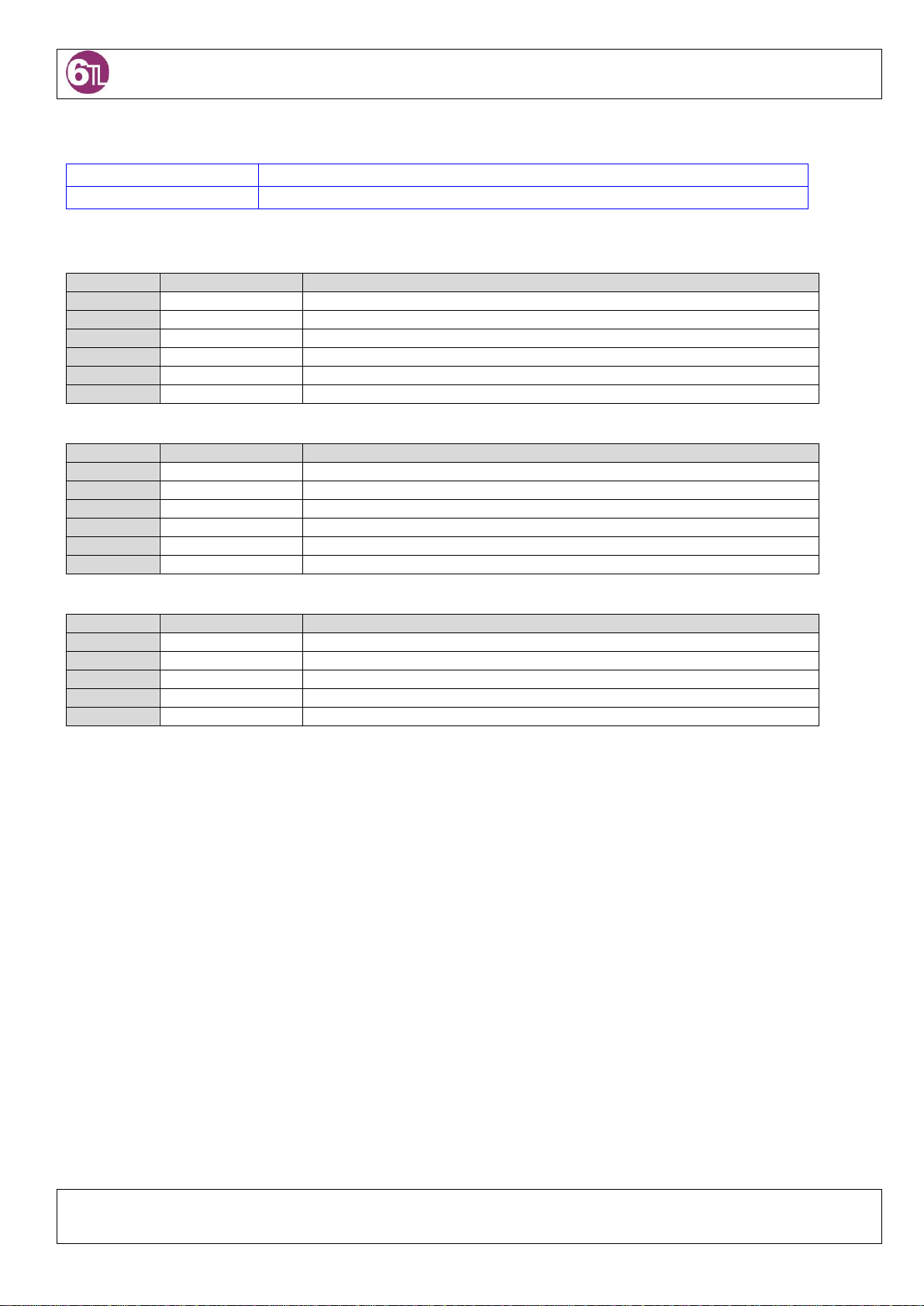

3.3 Ordering information..................................................................................................7

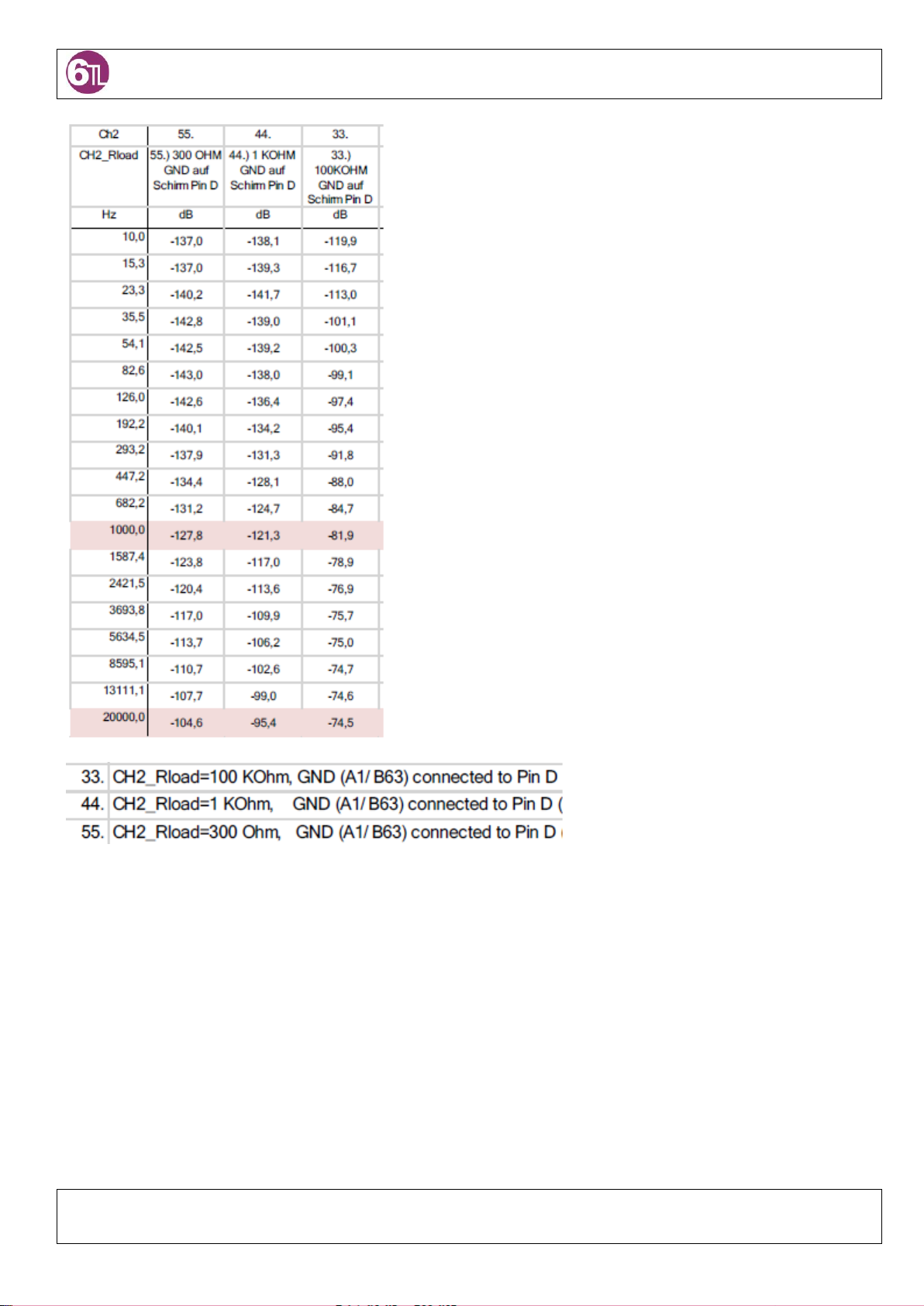

3.4 Device electrical Characteristics................................................................................8

3.5 Electric Diagram ......................................................................................................11

3.5.1 Connector X2.................................................................................................... 12

3.6 YAV boards Dimensions..........................................................................................13

4. YAV modules overview ................................................................................................14

4.1 YAV modules drivers...............................................................................................14

4.1.1 Phi6 LabVIEW driver........................................................................................ 14

4.1.2 SixTL_Driver..................................................................................................... 15

4.2 YAV modules common information..........................................................................16

4.2.1 SW1 DIP switch functionality............................................................................ 16

4.2.2 CAN bus communication speed. ...................................................................... 16

4.2.3 YAV module address........................................................................................ 16

4.3 YAV modules standard addressing & Virginia Panel Receivers ..............................17

5. Low level CAN commands...........................................................................................19

5.1 Example: Managing a YAV board using C language...............................................20

6. PHI6-Explorer panel......................................................................................................22

7. Operation.......................................................................................................................24

7.1 Outputs Activation....................................................................................................24

7.2 Soft Panel................................................................................................................24

8. Test ................................................................................................................................25