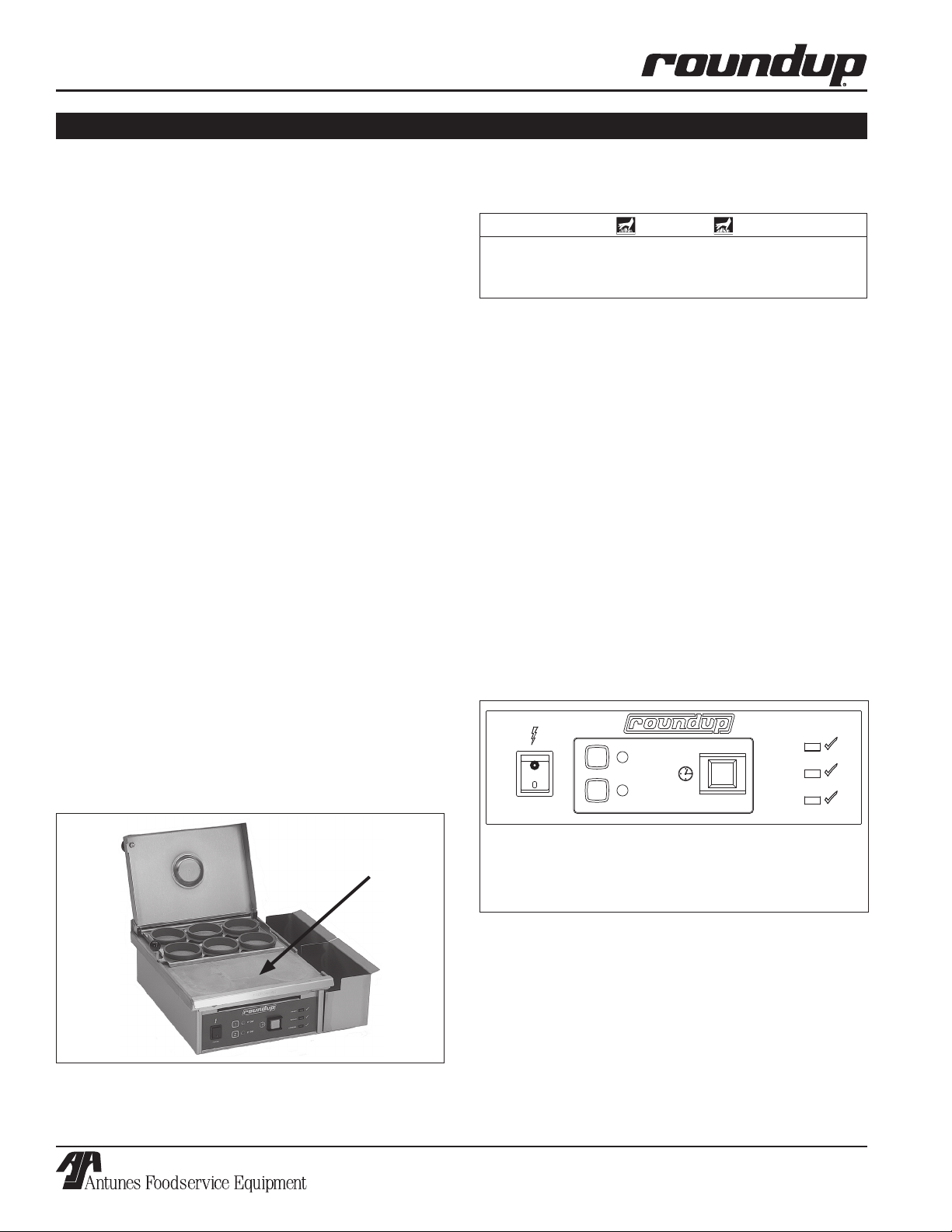

EGG STATION (ES-600 & ES-1200)

2P/N 1010883 08/05 Rev. A

General

This product cooks/steams a maximum of six or twelve

eggs (refrigerated) in approximately 150 seconds and

reheats sliced meat for sandwiches. Eggs within the

Egg Rings, are cooked with a combination of heat and

steam. With the cover closed, water is poured into a

trough on the cover and drips onto a hot Platen produc-

ing steam, cooking the eggs. The unit is equipped with

audio/visual signals for operation.

This manual provides the safety, installation and oper-

ating procedures for the Egg Station. We recommend

that all information contained in this manual be read

prior to installing and operating the unit.

Your Egg Station is manufactured from the finest mate-

rials available, assembled to Roundup’s strict quality

standards, and tested at the factory to ensure depend-

able trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty

printed on the back cover of this manual.

If the unit arrives damaged, contact the carrier

immediately and file a damage claim with them.

Save all packing materials when filing a claim.

Freight damage claims are the responsibility of the

purchaser and not covered under warranty.

OWNER INFORMATION

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference. If the unit changes owner-

ship, be sure this manual accompanies the equipment.

The warranty does not extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Installation, calibration, or adjustment.

• Normal maintenance outlined in this manual.

• Consumable parts such as Egg Rings, gas-

kets, rubber feet, labels, O-rings, light bulbs,

etc.

• Malfunction resulting from improper service

or maintenance.

• Damage caused by improper installation,

abuse, or careless handling.

• Damage from moisture getting into electrical

components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

• Damage caused by parts or components not

provided by A.J. Antunes & Co.

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................3

Specifications .............................................................5

Electrical Ratings .......................................................5

Model Designation .....................................................5

Electrical Cord & Plug Configurations .......................5

Dimensions ................................................................6

Shipping Weight ........................................................6

Net Weight .................................................................6

Installation ...................................................................7

Unpacking ..................................................................7

Equipment Setup .......................................................7

Operation .....................................................................8

Preparing Unit ............................................................8

Cooking Instructions ..................................................8

Bacon Timer* .............................................................9

Maintenance ................................................................9

Daily Cleaning ...........................................................9

Checking Cycle Times (Monthly) ............................ 10

Checking Grill Platen Temperature ......................... 10

Troubleshooting .......................................................11

Control Board LEDs ............................................... 12

Green LED Blink Codes ......................................... 12

Wiring Diagram .........................................................13

Replacement Parts ...................................................14

LIMITED WARRANTY ................................................16