1. Never store unused material in spreader. Return

unused product to its original container.

2. Wash spreader thoroughly after each use and dry

completely in sun or heated area.

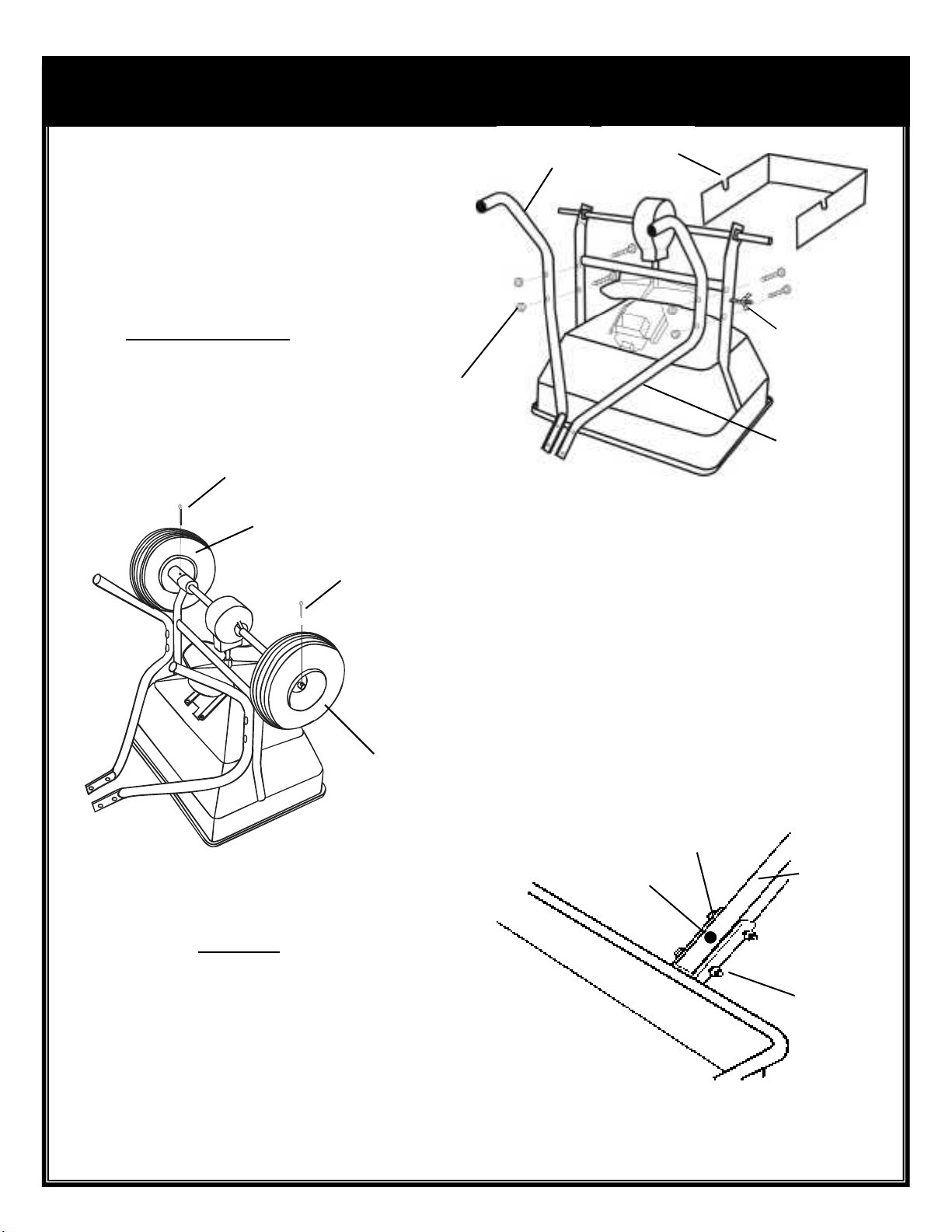

3. Oil the axle bearings, impeller shaft bearing in

hopper, control knob in T-handle.

4. Remove gear cover and wash gears thoroughly.

Oil all bearing areas and face of gear teeth. Re-

install gear cover.

5. Gear mesh should be checked on a regular basis

during high use periods. Clearance between the

axle gear and pinion gear should be minimal but not

tight. If adjustment is necessary, loosen axle collar

set screw and hold gears together. Slide axle collar

against the gear support and tighten axle collar set

screw. Spin drive wheel. Gears should run freely

and smoothly.

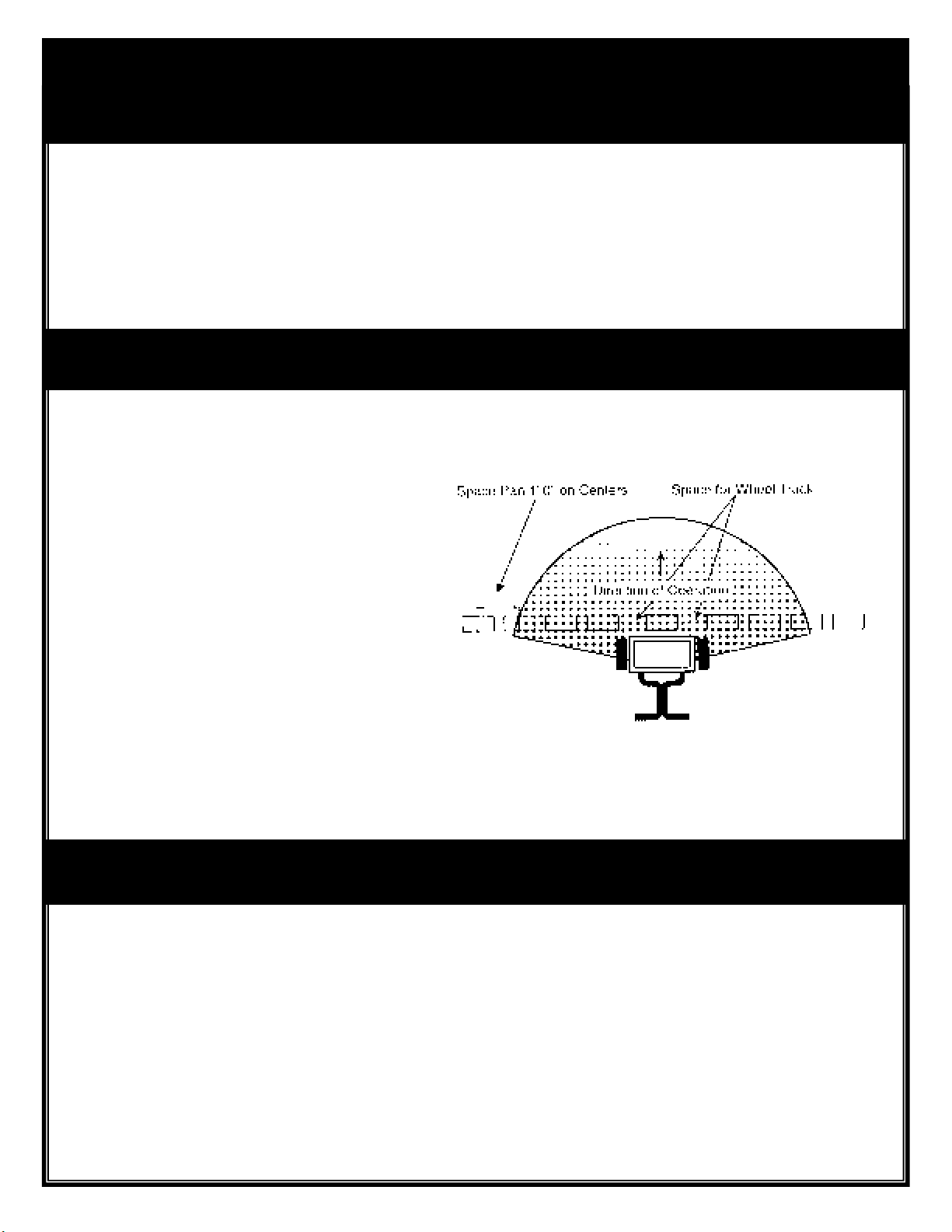

6. Impeller surface should be cleaned periodically to

remove build-up of product. Build-up can cause the

spread pattern to change.

7. Tire pressure should be 20-25 PSI.

MAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE

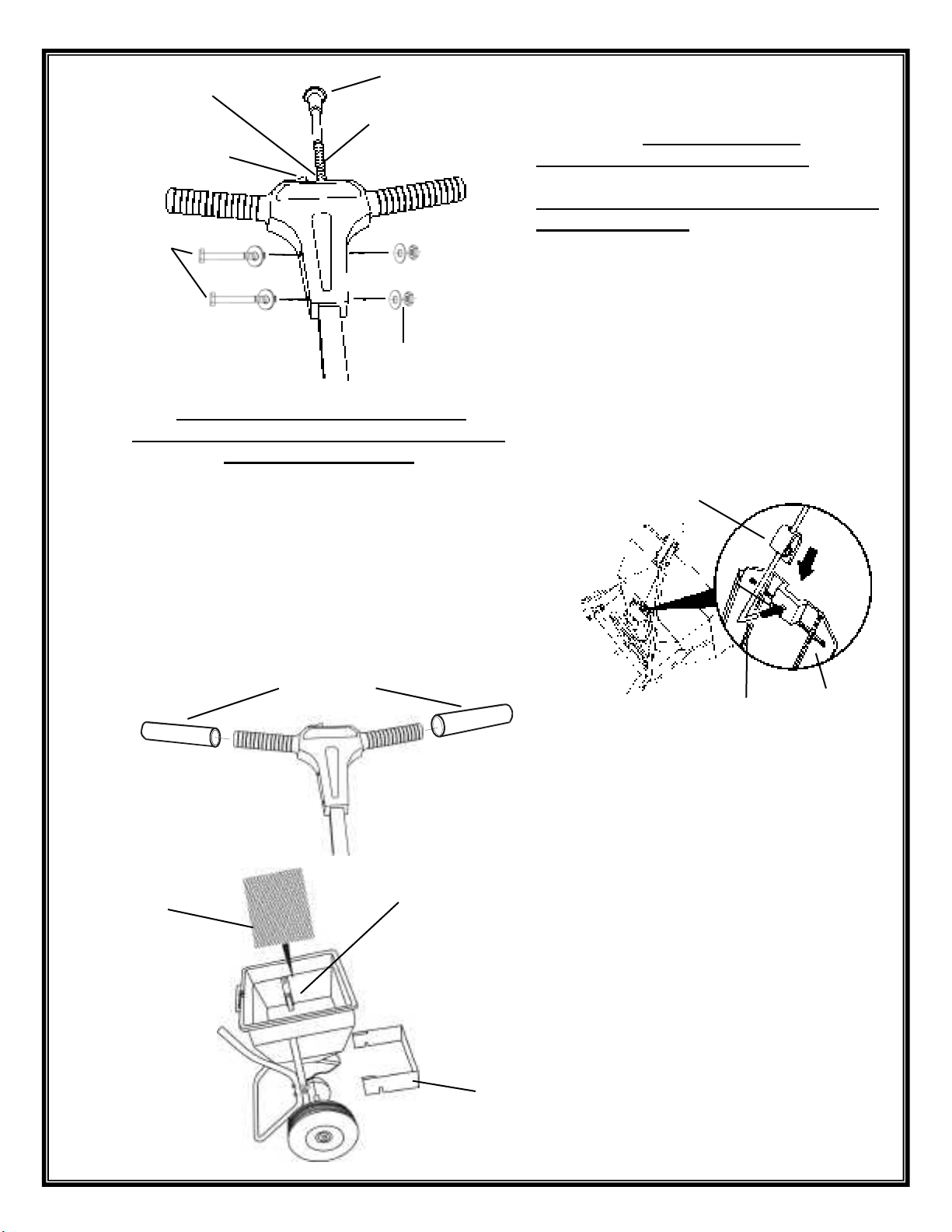

Oil

Oil Impeller Shaft

Bearing In Hopper

Axle Collar

Oil

Oil

Oil

WARRANTY

WARRANTYWARRANTY

WARRANTY

7

A.M. Leonard warrants to Purchaser the following:

1. Product will be free of defects in materials and workmanship.

2. A.M. Leonard will decide in its reasonable discretion if the part(s)/unit is defective.

3. The spreader or part(s) will be shipped to A.M. Leonard at the customer expense with a written description of defect.

4. All Unit and part replacement will be performed at the reasonable discretion of A.M. Leonard.

A.M. Leonard’s sole obligation under this warranty is limited to repairing or replacing the defective part. Upon replacement of any Product or Product part, the replacement

item shall become the property of A.M. Leonard. If A.M. Leonard determines that the Product covered by this warranty requires service, A.M. Leonard shall prepay return

shipping charges from A.M. Leonard. In all other instances, such charges shall be paid by Purchaser. Except for loss or damage caused by A.M. Leonard negligence,

Purchaser relieves A.M. Leonard of responsibility for all risks of loss or damage to the Product and its parts during the period the products are in transit to and from A.M.

Leonard .

This warranty does not extend to any Product or parts thereof that have been allowed to corrode,

subjected to misuse, neglect, accident, or modification by anyone

other than A.M. Leonard or that have been affixed to any nonstandard accessory attachment or that have been used, stored, installed, maintained or operated in violation

of A.M. Leonard’s instructions or standard industry practice. No agent, employee or representative of A.M. Leonard has any authority to bind A.M. Leonard to bind

A.M. Leonard to any affirmation, representation or warranty concerning the Product and any affirmation, representation or warranty made by any agent, employee or

representative shall not be enforceable by Purchaser.

THIS WARRANTY EXTENDS ONLY TO THE ORIGINAL PURCHASER AND IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS OR INTENDED USE FOR A PARTICULAR PURPOSE

AND OF ANY OTHER OBLIGATION ON THE PART OF A.M. LEONARD.

A.M. LEONARD SHALL NOT BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL LOSS, DAMAGE OR EXPENSE DIRECTLY OR INDIRECTLY

ARISING FROM THE USE OF ANY OF THE PRODUCT INCLUDING, BUT NOT LIMITED TO, DAMAGE OR LOSS OF OTHER PROPERTY OR EQUIPMENT,

LOSS OF PROFITS OR REVENUE, COST OF CAPITAL, COST OF PURCHASED OR REPLACEMENT GOODS, OR CLAIMS OF CUSTOMERS OF PURCHASER.