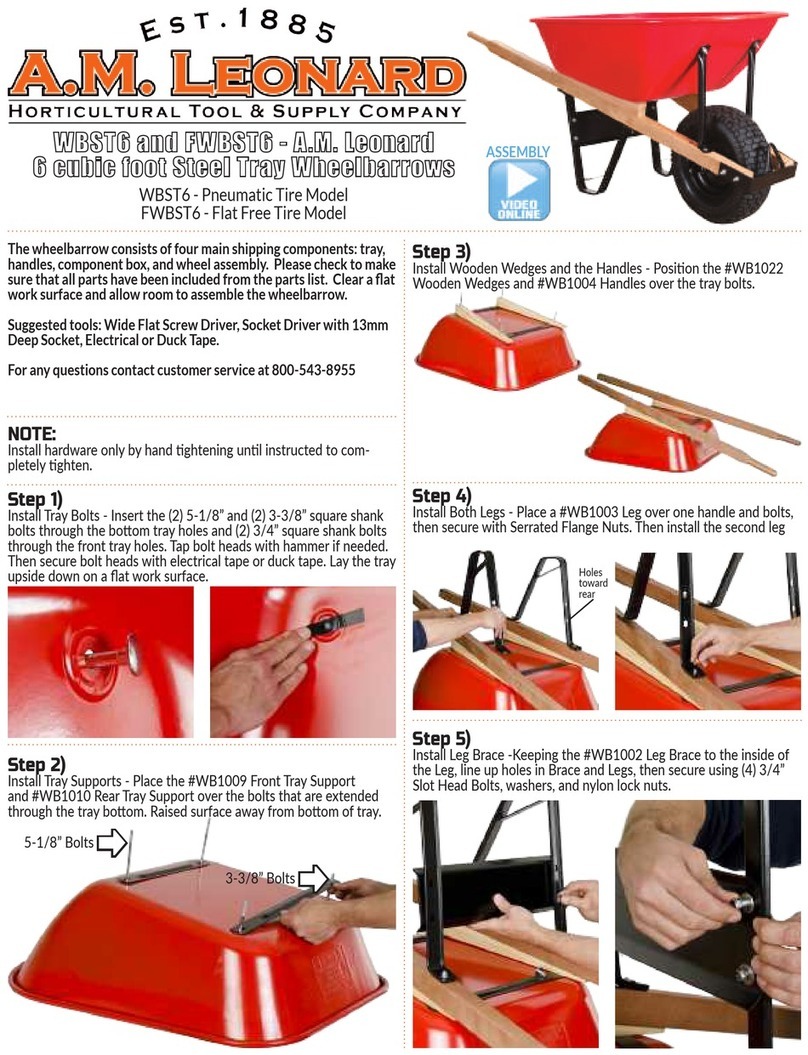

Step 12)

Align Wheel Assembly - IMPORTANT. Slide the axle brackets in-

ward unl they contact the wheel. Next slide the Wheel and Brack-

ets le & right unl the wheel is centered between the handles.

Keep the axle brackets against the wheel.

Step 13)

Tighten the Axle Bracket Bolts - Completely ghten the axle bracket

bolts/nuts at this me, while keeping wheel assembly centered.

Step 14)

Tighten Remaining Hardware - Flip the wheelbarrow upright on a

at surface. Completely ghten the (4) Cross Brace Bolts and (6) Tray

Bolts.

Step 15)

Check Tire Pressure and Grease Wheel - Check and adjust re pres-

sure per indicated PSI on re, using a re gauge. Install grease via

the 1/4” grease ng on the wheel hub. Wheelbarrow assembly is

now complete.

Note:

Flat Free Wheelbarrow Models - Flat Free Wheels will retain their

shape, however, if le under load for extended length of me, a

at spot can develop. The wheel will go back to original shape af-

ter use. But to avoid any inconvenience, do not store wheelbarrow

with materials in the tray for extended lengths of me.

Roune Maintenance:

• Hardware includes serrated ange nuts and nylon lock nuts

which resist loosening. It is best to rounely check hardware and

ghten as may be required.

• Install wheel grease periodically to keep axle and bearings

lubricated. This will also prevent rust formaon on the steel wheel

parts.

• Check re pressure with a gauge. Over inaon may cause

injury and re damage. Under inated res will cause premature

wear. Check and adjust pressure using a re gauge.

• Wood Handles are coated for weather resistance. Excessive ex-

posure to sun and weather will cause deterioraon. To maximize

handle life, recoat with a wood preservave as necessary.

WRONG

• Slide axle bracket

against wheel

• Center the axle

bracket/wheel assem-

bly between handles

• Completly ghten

remaining hardware

• Brackets not

against wheel

• Wheel not

centered

a

a