A.O. Smith BTH 120 Series How to use

Other A.O. Smith Water Heater manuals

A.O. Smith

A.O. Smith DURA-Power DRE-52 User manual

A.O. Smith

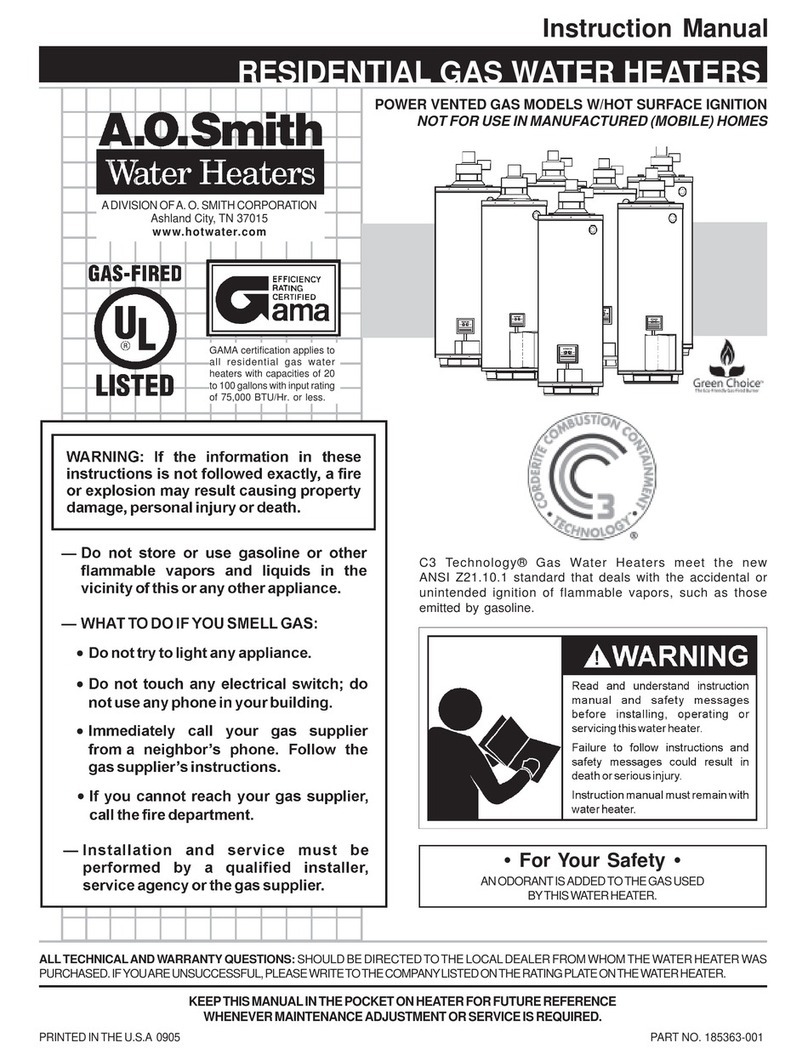

A.O. Smith POWER VENT GAS User manual

A.O. Smith

A.O. Smith COF 199 Troubleshooting guide

A.O. Smith

A.O. Smith MEV 50 EC User manual

A.O. Smith

A.O. Smith ARESS00606 User manual

A.O. Smith

A.O. Smith T-D2-OS User manual

A.O. Smith

A.O. Smith DVE-10.000 User manual

A.O. Smith

A.O. Smith ADMR - 40 Troubleshooting guide

A.O. Smith

A.O. Smith BTH 120 - 250 User manual

A.O. Smith

A.O. Smith Jaguar HSE-SNJ-015 User manual

A.O. Smith

A.O. Smith Conservationist BTP-139/A User manual

A.O. Smith

A.O. Smith EWS 10 User manual

A.O. Smith

A.O. Smith 101 Series User manual

A.O. Smith

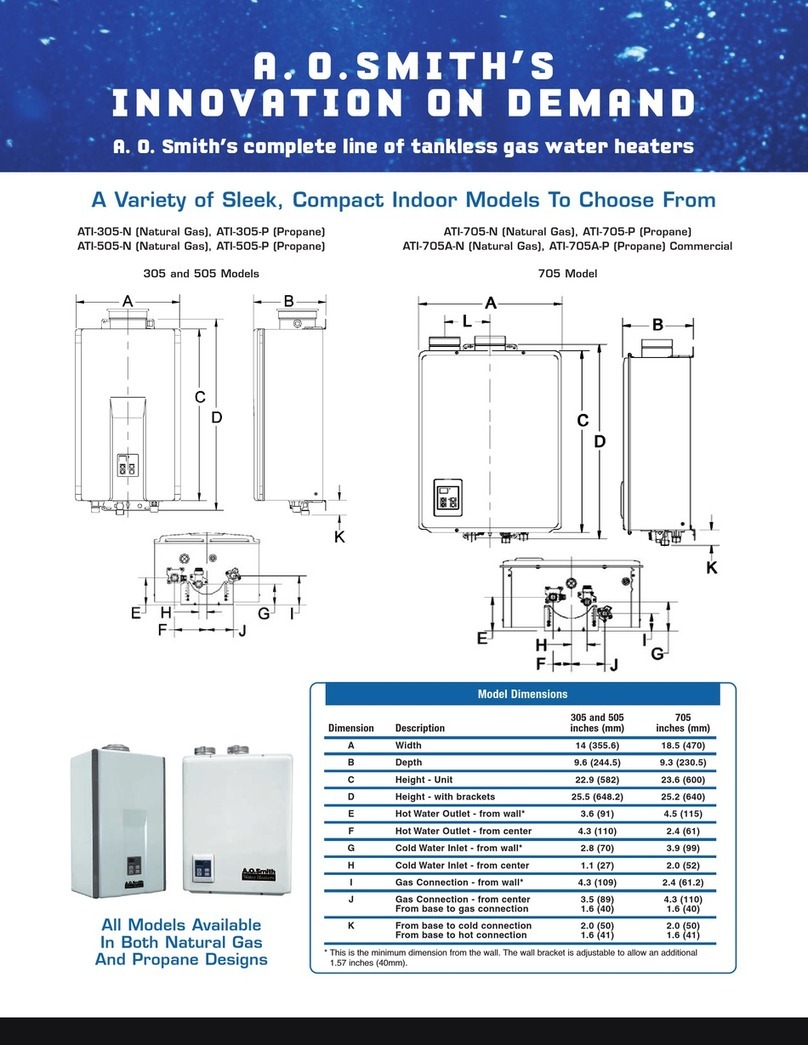

A.O. Smith 305 User manual

A.O. Smith

A.O. Smith 185363-001 User manual

A.O. Smith

A.O. Smith HSE-SES-015 User manual

A.O. Smith

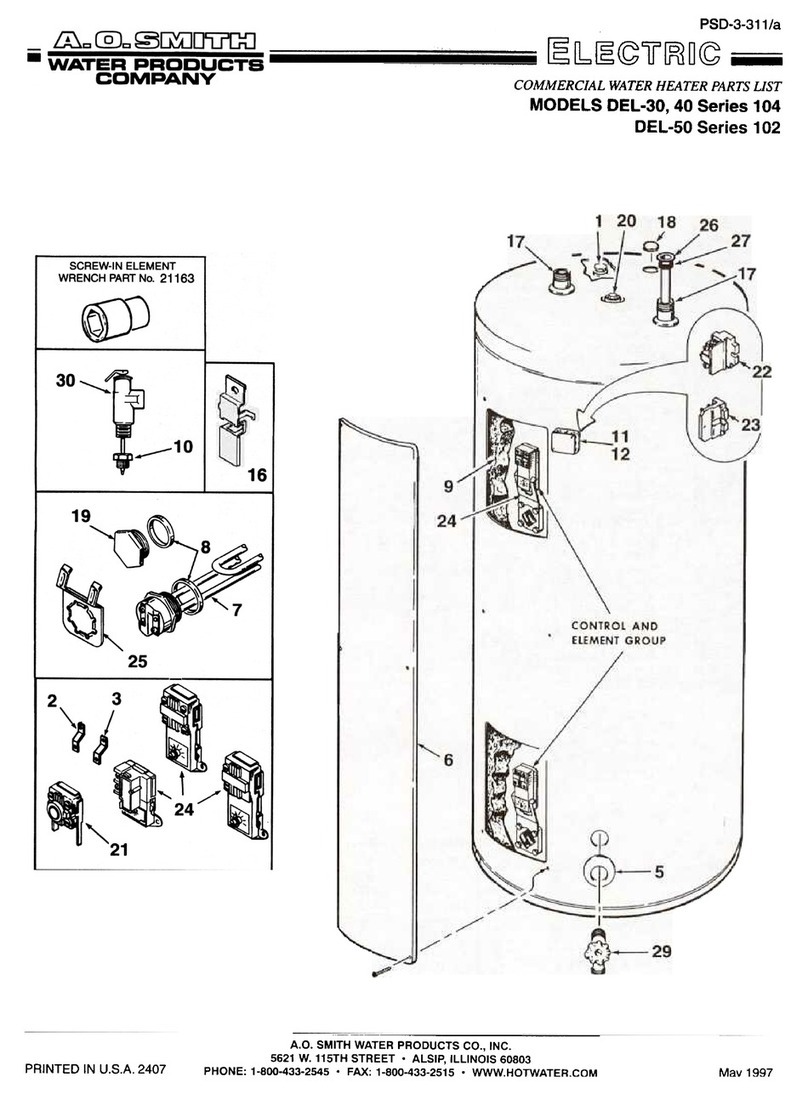

A.O. Smith DEL 30 User manual

A.O. Smith

A.O. Smith HSE-SBS 6 User manual

A.O. Smith

A.O. Smith GPVH 40 Guide

A.O. Smith

A.O. Smith CYCLONE Xi BTH 400A Manual

Popular Water Heater manuals by other brands

Kenmore

Kenmore 153.582400 Use & care guide

STIEBEL ELTRON

STIEBEL ELTRON Eltronom SHU 5 S Operating and installation instructions

clage

clage E-Mini Series Operating and installation instructions

Toyotomi

Toyotomi Oil Miser OM-180 installation manual

Bradford White

Bradford White EF Series Service manual

Eccotemp

Eccotemp 40-H Use & care manual

Dimplex

Dimplex ECSd125-580 Installation and user instructions

Dux

Dux 32FCR6N installation manual

Noritz

Noritz N-132M Owner's guide and installation manual

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions

Koryo

Koryo KWHZF15Y user manual

Pentair

Pentair PSC-14-4-02 Installation and operation manual

GE

GE 40M06AAG Energy guide

Thermor

Thermor AEROMAX SPLIT 2 Instructions for use

American Hometec

American Hometec AHQ-B03X Installation and operation manual

PVI

PVI MAXIM Specifications

Sunerg Solar Energy

Sunerg Solar Energy Calor Top 200D Installation & owner's manual