3

PLEASE READ THIS MANUAL COMPLETELY BEFORE OPERATING EQUIPMENT

INTRODUCTION

For years nothing has equaled the appearance and quality of foil imprinting. Printing with ink does not offer

the vibrant color of foil. In addition, foil imprinting imparts a 3-dimensional effect that is not obtainable with

conventional ink printing. Foils are uniformly opaque, odorless, non-liquid and are smear free. The foil

imprinting process transfers the color of the foil to an item by the application of heat and pressure. The three

basic elements needed to create a quality foil imprint are the proper amount of heat, pressure and dwell (the

length of time the type and dies are in contact with the product.)

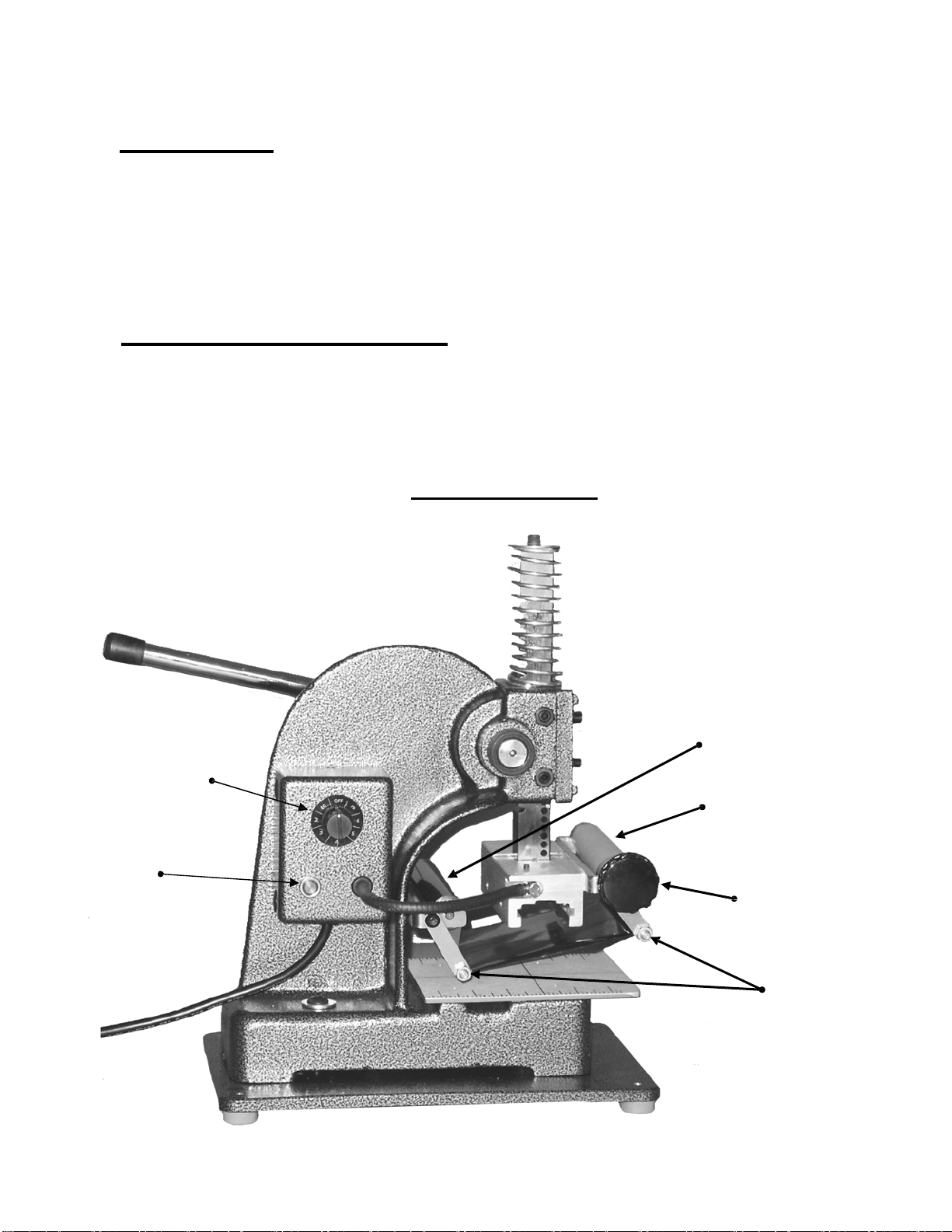

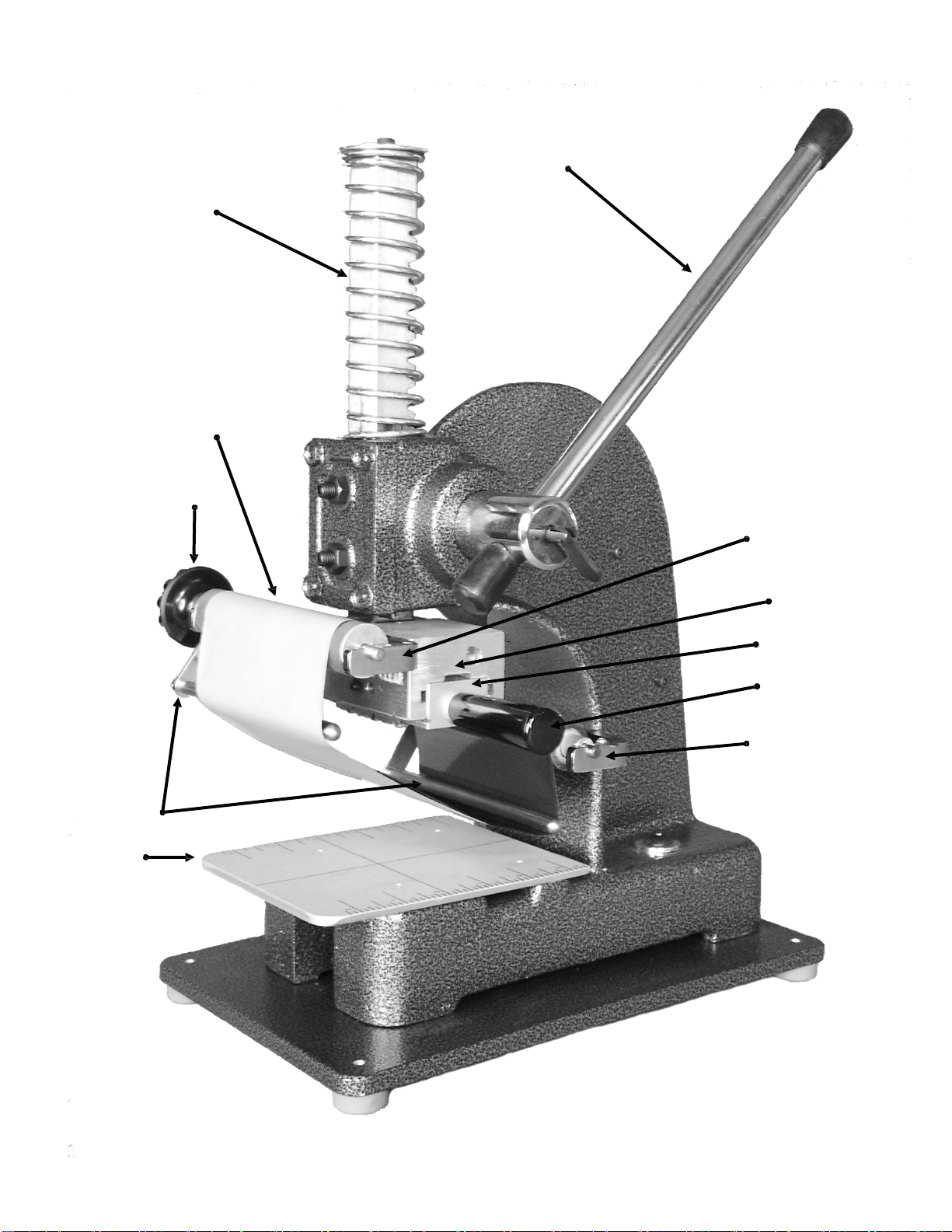

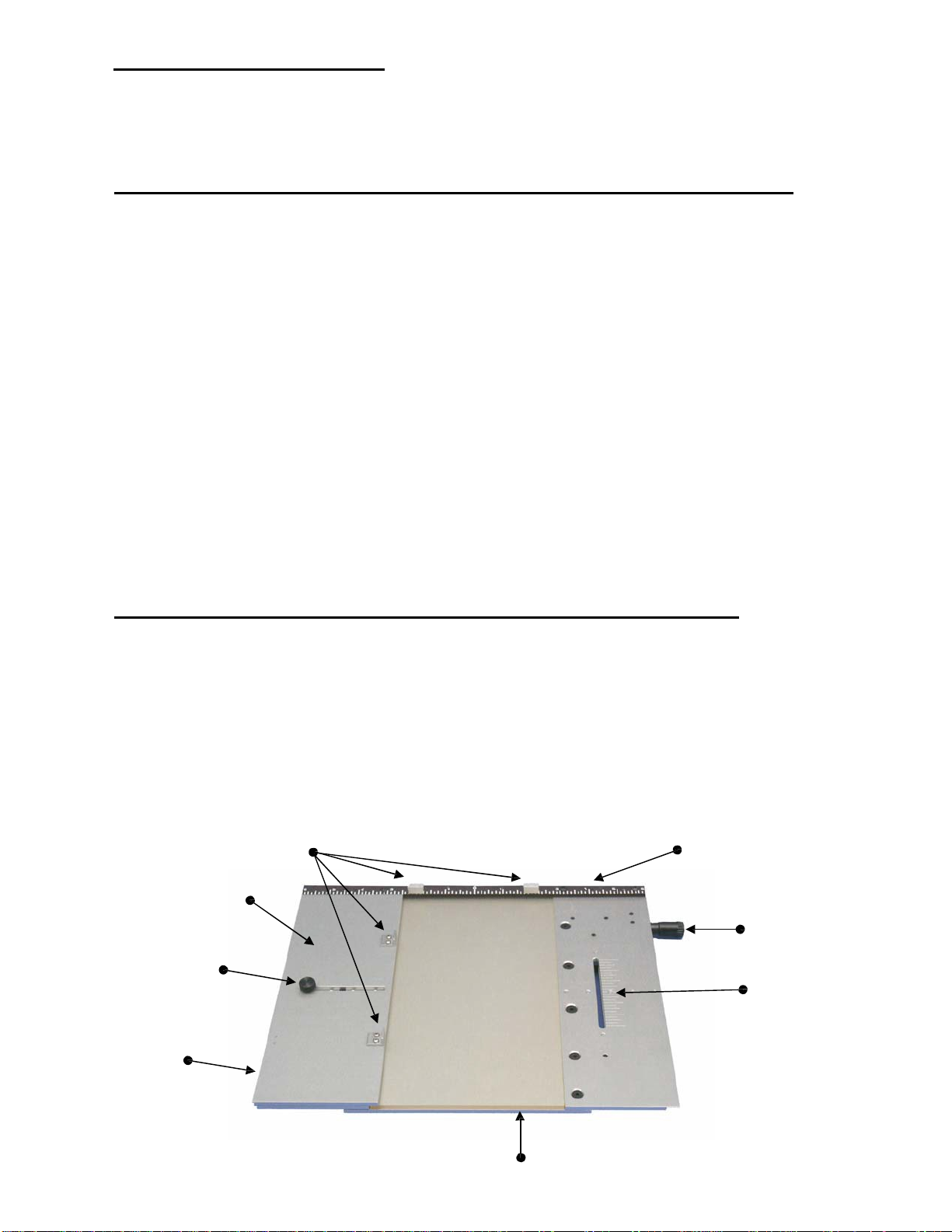

AAmstamp's personalizing machines are designed to give you the power of a big press in a table top

machine. The Sprite Machine and it’s accessories, type, dies, emblems and foils are the highest quality and

easiest to use products available today. This Equipment is not intended for use by persons(including

children) with reduced sensory or mental capabilities, or lack of experience and knowledge.Children should

not play with the equipment.

After reviewing this manual, please call our customer service department toll free, in USA (888) 375-8375

with any questions you may have.

SAFETY PRECAUTIONS - PLEASE READ CAREFULLY

AAmstamp's printing machine is anelectric tool and as such, basic safety precautions should be followed.

Taking these precautions will reduce the risk of fire, electric shock, or personal injury. The means of

disconnecting the power supply from the mains is by removing the plug from the socket-outlet.

1

Keep your area clean and clutter free.

2

Do not wear loose clothing or jewelry which could become entangled in the machine.

3

Machine for indoor use only. Do not use the machine in a damp or wet place, or

expose it to rain. Do not use the machine in the presence of flammable liquids or gases.

Maschine nur zur Verwendung im Innenbereich geeignet. Verwenden Sie das Gerät nicht in einer feuchten oder

nassen Platz, und setzen Sie es an zu regnen. Verwenden Sie das Gerät nicht in der Nähe von brennbaren

Flüssigkeiten oder Gasen.

4 Do not touch the Typehead/Ram Bar assembly. These parts of the machine

have operating temperatures that can cause serious burns.

Berühren Sie nicht die Kopf/Ram. Diese Teile der Maschine sind die Temperaturen, die zu schweren Verätzungen

führen kann.

5 If supply cord is damaged, it must be replaced by the manufacture, its service

agent or other qualified persons to avoid avoid hazards.

Wenn das Netzkabel beschädigt ist, muss es ersetzt werden durch die Herstellung, den Service Agenten oder andere

qualifizierte Personen zur Vermeidung von Gefährdungen.

6 Note the voltage on the power source. AAmstamp equipment runs on standard

230V~50Hz. in the EU. In the U.S. 120V~60Hz

Bitte beachten Sie die Spannung an der Steckdose. AAmstamp Ausrüstung läuft auf Standard 230V~ 50Hz

einstellen. In den USA 120V~ 60Hz

7 AAmstamp equipment should not be used while under the influence of alcohol or drugs.

AAmstamp Anlagen sollten nicht verwendet werden, während unter dem Einfluss von Alkohol oder Drogen.