8

CAUTION: Improper usage can cause serious injury to personnel and/or

damage to equipment and work area. For your own safety, please observe

the following precautions.

SAFETY PRECAUTIONS

●Check each component after opening the package to make sure

everything is in good condition. If there are any suspected

damage,donotusetheitemandreporttheissuetoyourvendor.

●Turn OFF the main power switch and unplug the device from

powersourcewhenmovingthedevice.

●Donotstrikeorsubjectthemainunit(andallitscomponents)to

physicalshock.Usecarefullytoavoiddamagetoanypart.

●Handlewithcare.

Neverdroporsharplyjolttheunit.

Containsdelicatepartsthatmaybreakiftheunitisdropped.

●Make sure the equipment is always grounded. Always connect

powertoagroundedreceptacle.

●Temperaturemayreachashighas480°CwhenswitchedON.

Donotusethedevicenearflammablegases,paperandotherflammable

materials.

Donottouchheatedparts,whichcancausesevereburns.

Donottouchmetallicpartsnearthetip.

●Disconnecttheplugfromthepowersourceiftheunit willnotbe

usedforalongperiod.

Turnoffpowerduringbreaks,ifpossible.

●Useonlygenuinereplacementparts.

Turnoffpowerandlettheunitcooldownbeforereplacinganypart.

●Theunitmayproduceasmallamountofsmokeandunusualodor

during initial usage. This is normal and should not yield any

negativeresultwhenreworking.

●Solderingprocessproducessmoke—useonwellventilatedplaces.

●Do not alter the unit, specifically the internal circuitry, in any

manner.

17

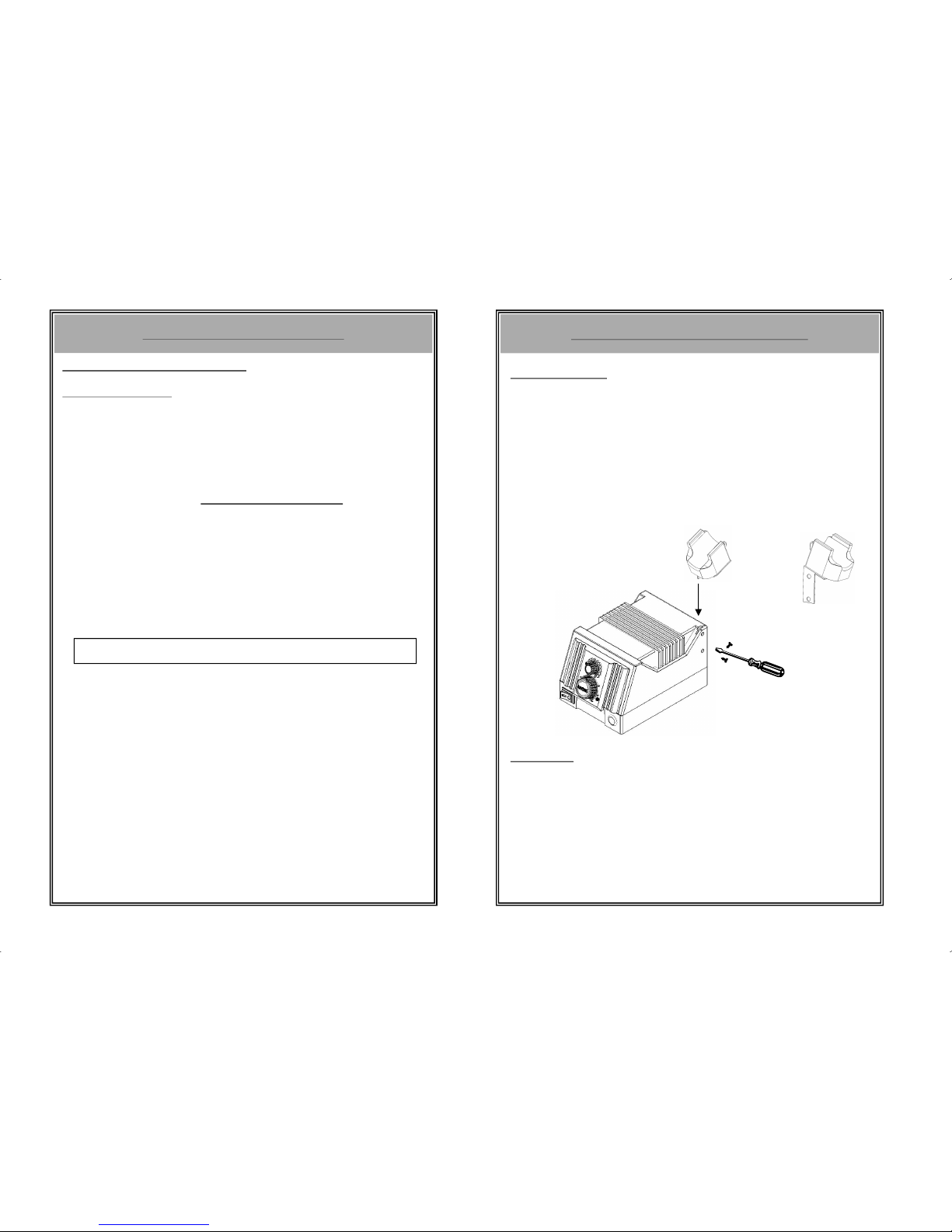

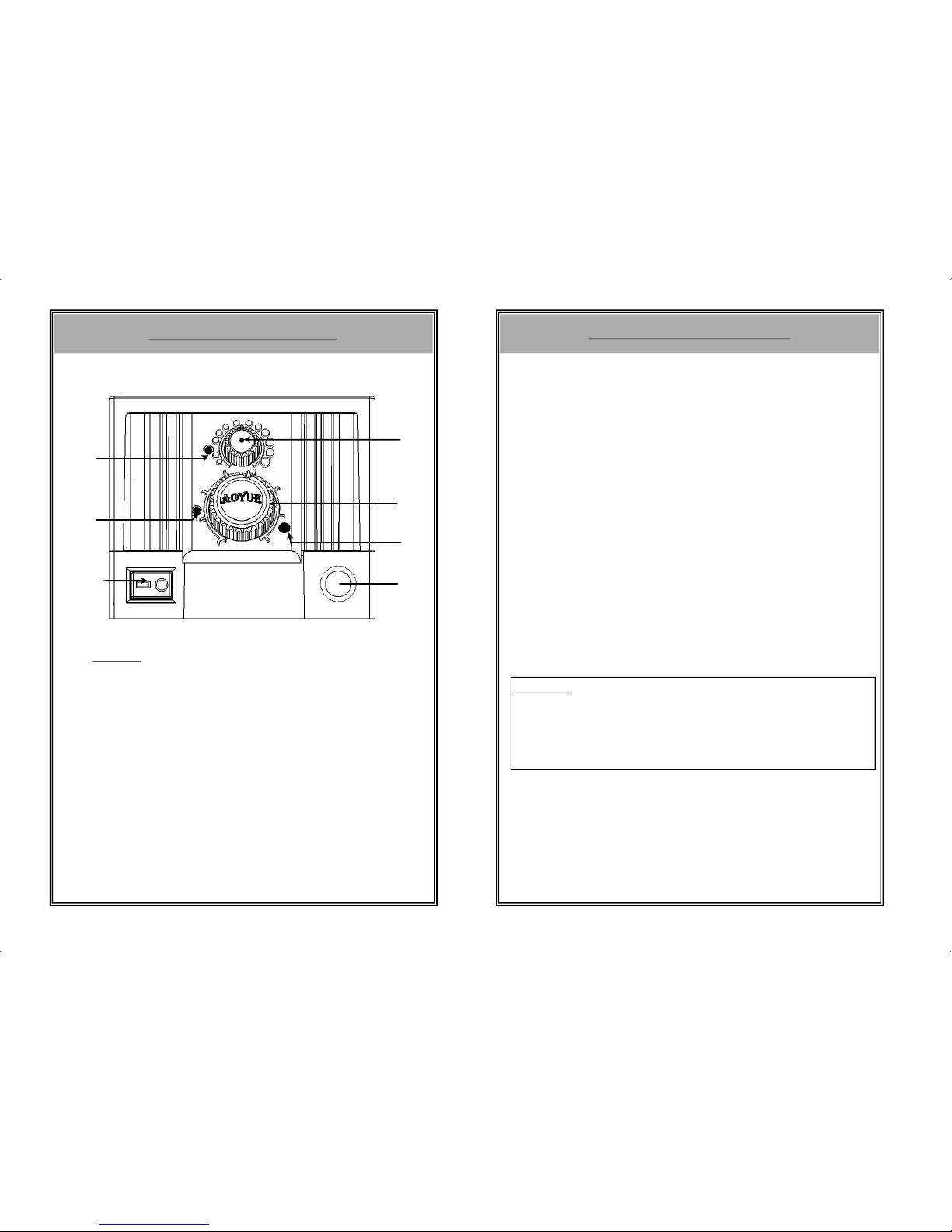

OPERATING GUIDELINES

Soldering:

1. Followproceduresin,“A.INITIALPROCEDURES”.

2. Prepare the unit to be worked upon on a stable elevated

surface. A working platform with locking mechanisms to

secure the PCB is highly recommended. Use a preheating

stationifappropriate.

3. ApplysolderpastetothePCB.

4. Pickupthehotairgun.

5. Setthetemperaturecontrolknobtoabout250°C.

6. Turntheairflowcontrolknobtoaminimumairflow.

7. WaitfortheheaterLEDtostartblinking.Thissignifiesthatthe

hotairtemperaturehasattaineditstemperaturesetting.

8. Place the hot air gun vertically on top of the target device.

Thiswillallowhotairtodirectlyheatupthetargetdeviceand

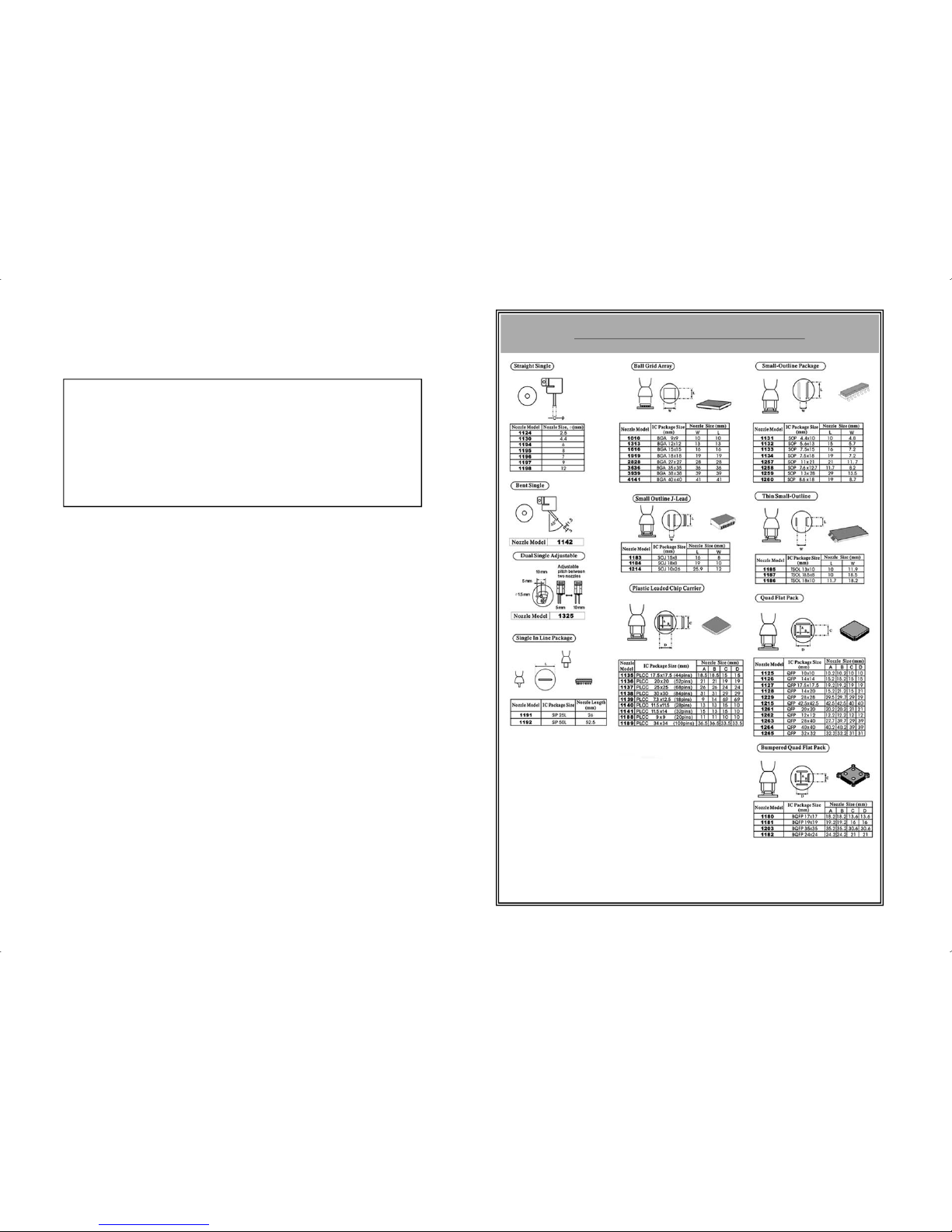

thesolderpaste.Useappropriatenozzleforbettersoldering.

9. SolderpastewouldmeltandsoldertargetdeviceandthePCB

together.

10. LetPCBcooldown.

Note:Airflowandtemperaturemayvarydependingonsizeofcomponents.

ATTENTION

● Temperature setting presented in these guides are provided

as reference only. Please refer to device manufactures data

for the tolerances of the items to be soldered.

● Actual temperature settings for soldering and reworking are

dependent on the size of the material to be soldered and

solder paste reflow temperatures.

● Very high reworking temperatures can damage sensitive SMT

materials.