IS--1627

IS--252LRJS--IEC

Revision: 0

Page 1 of 5

Installation Instructions: 252LRJS--IEC

Deadbreak Elbow Connectors with Jacket Seal

CONTENTS: Elbow Connector Housing, Compression Lug, Probe, Probe Wrench, Lubricant, Hold--down Bail,

Installation Instructions.

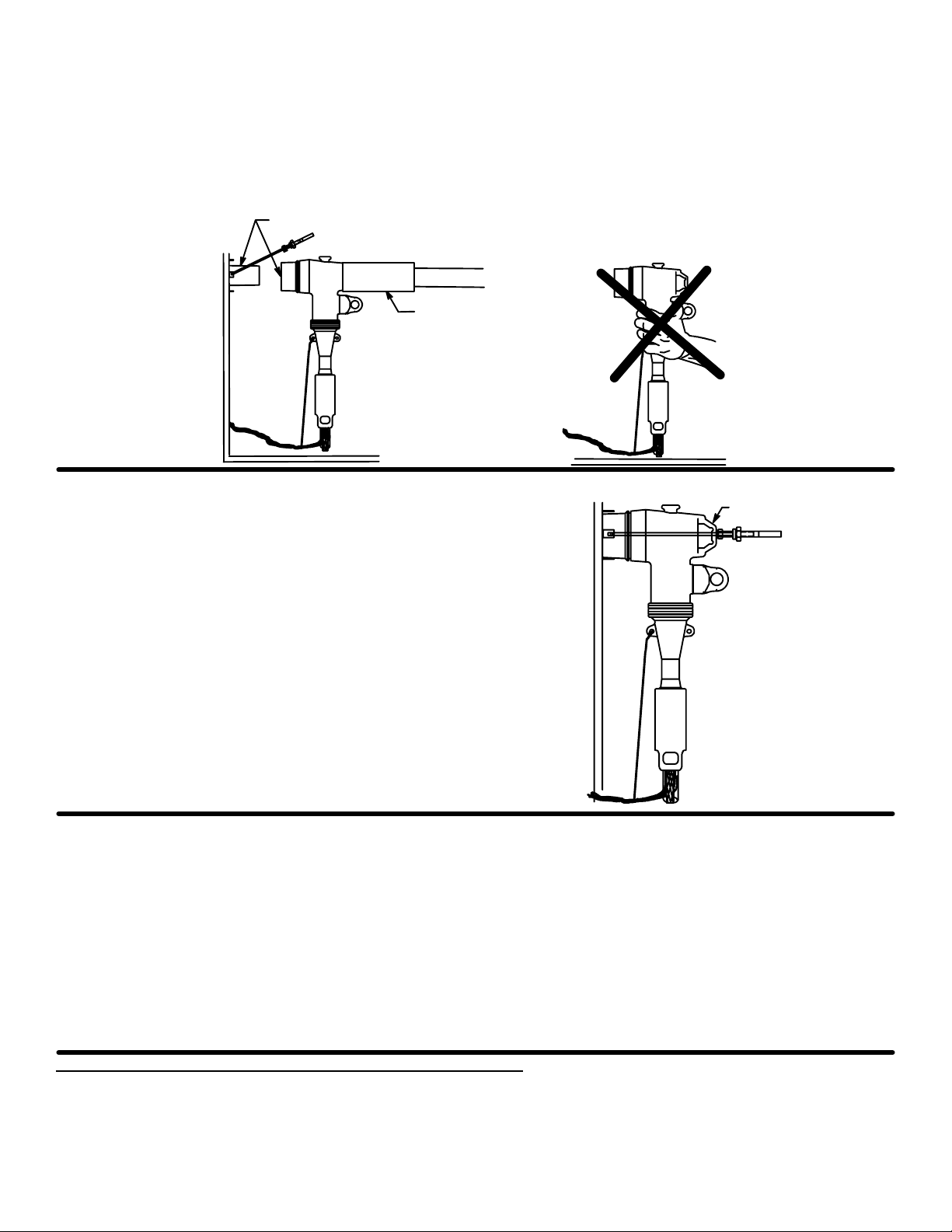

The 252LRJS is designed to terminate UD jacketed and non--jacketed cable having concentric neutral wires or copper tape

shielding. The elbow provides a voltage test point and an operating interface for connecting to an 12/20 (24)kV 250ampere

deadbreak bushing or accessory device. Designed with a fold down extension on the cable entrance for sealing to the jacket of

jacketed cable. When other types of UD cable are to be terminated, an appropriate Elastimold cable shield or grounding device

must be used.

DANGER

All apparatus must be de--energized during installation

or removal of part(s).

Do not touch or move energized products in the work

area.

These instructions do not attempt to provide for every

possible contingency.

Failure to follow these instructions will result in

damage to the product and serious or fatal injury.

This product should be installed only by competent

personnel trained in good safety practices involving

high voltage electrical equipment. These instructions

are not intended as a substitute for adequate training or

experience in such safety practices.

All apparatus must be installed and operated in

accordance with individual user, local and national

work rules and electrical standards.

For loadbreak products follow operating instructions.

All deadbreak connectors must be de--energized before

operating. All 250A deadbreak connectors must be

mechanically secured with bails when connected.

If this product is supplied with a protective shipping

cover(s), remove this shipping cover(s) and replace

with the appropriate HV insulated cap(s) or

connector(s) before submerging or energizing the

circuit.

Inspect parts for damage, rating and compatibility with

mating parts.

Excess distortion of the assembled product may result

in its failure.

FOR MORE INFORMATION ON PARTS, INSTALLATION RATINGS AND COMPATIBILITY, CALL THE NEAREST ELASTIMOLD OFFICE.

Limited Warranty:

1. T&B warrants that its products will be free from defects in materials or workmanship for a period of two (2) years, except for tools which are warranted

separately (see warranty accompanying those products). Fisher Pierceproducts and ElastimoldReclosers are warranted for three years; and Joslyn

VBT and VBU capacitor switches are warranted for four years or 40,000 operations whichever occurs first. Upon prompt notification of a warranted defect,

T&B will, at its option, repair or replace the defective product.

2. In no event shall T&B be liable for any consequential, indirect or special damages, nor will T&B be liable for transportation, labor, or other charges arising

out of the removal or reinstallation of its products. Liability for breach of warranty is limited to the cost of repair or replacement of the warranted product

only.

3. Misuse, misapplication or modification of T&B products immediately voids all warranties.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY

DISCLAIMED.

IMPORTANT

1. Read entire installation instruction before starting.

2. Check contents of package to ensure they are complete

and undamaged.

3 Check elbow housing cable entrance size and

compression lug size to ensure proper fit with cable.

4. Check threads by threading probe into compression lug.

If resistance is encountered prior to full assembly, check

for damage and replace damaged component.

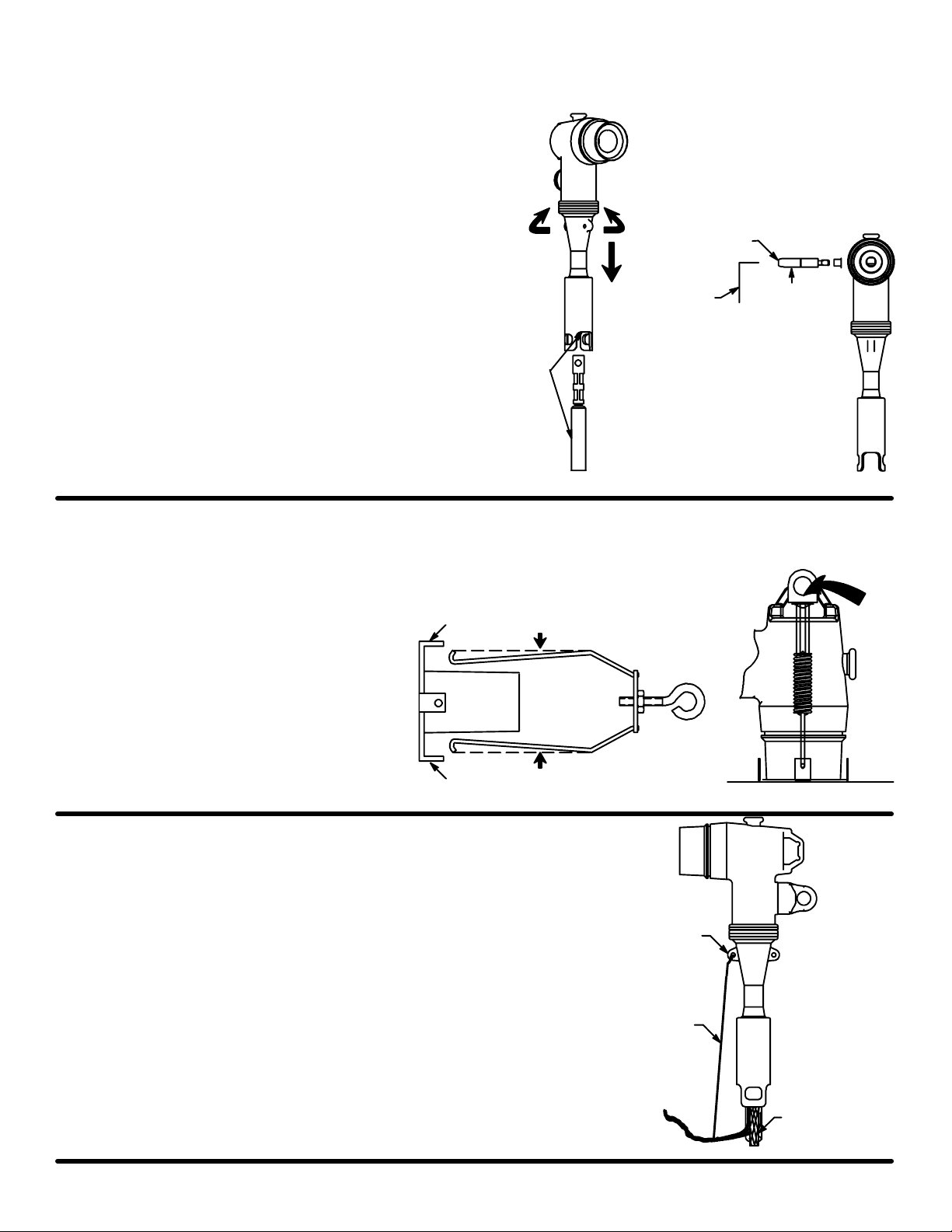

5. Unit Must be Bailed.

6. Have all required tools at hand and maintain cleanliness

throughout the procedure.

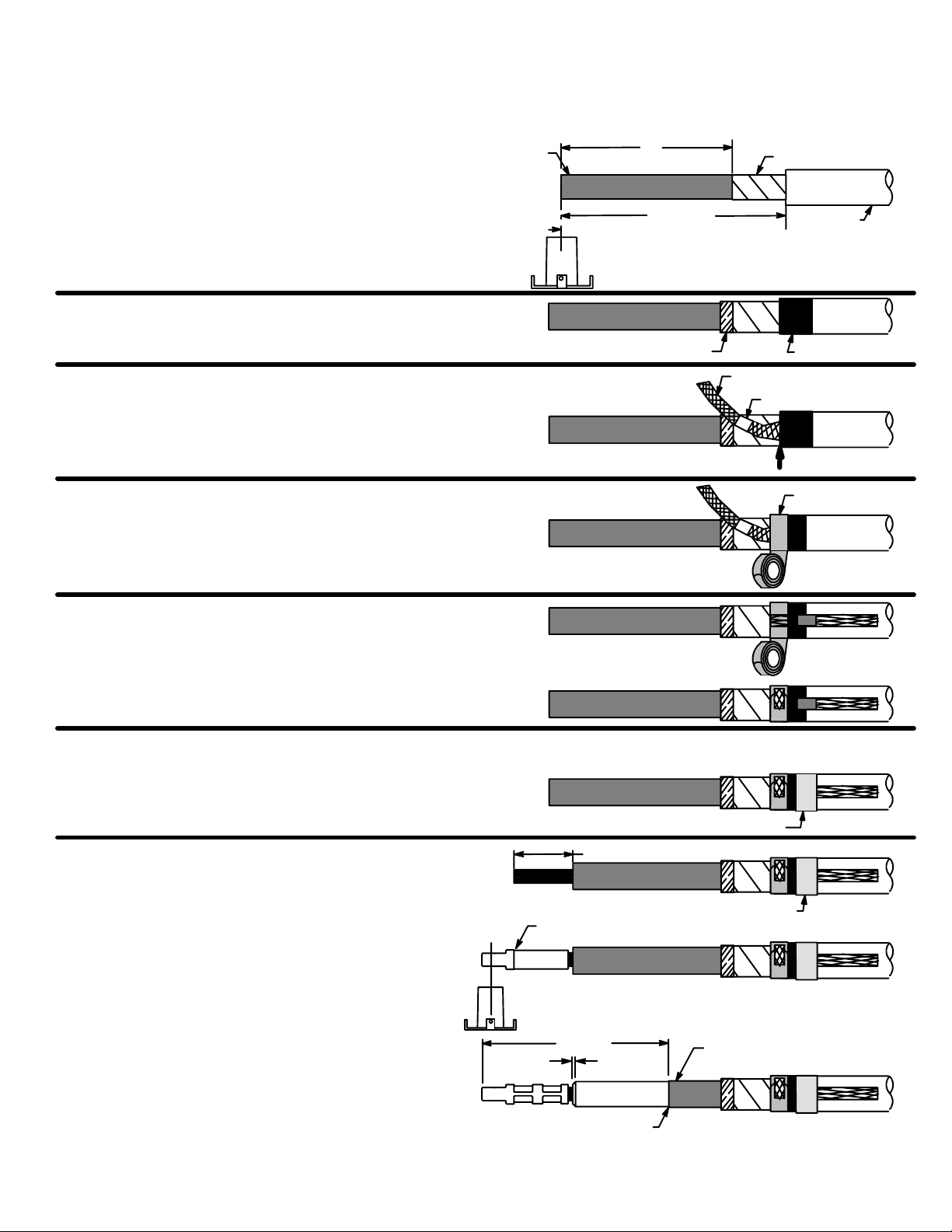

Compression Lug

Probe

Operating

Eye

ASSEMBLED ELBOW

Elbow Housing Test Point

Intergral Cable

Jacket Seal

Caution: If test point cap is not installed, lubricate cap and test point and install cap.

IS--1627

IS--252LRJS--IEC

Date: December 2017

Printed in U.S.A.

8155 T&B Boulevard, Memphis, Tennessee 38125

(800) 888--0211 Fax: (800) 888--0690