2

remove armature from movable arm.

5. Remove coil from magnet.

6. Replace coil.

7. Reassemble device by reversing

procedure.

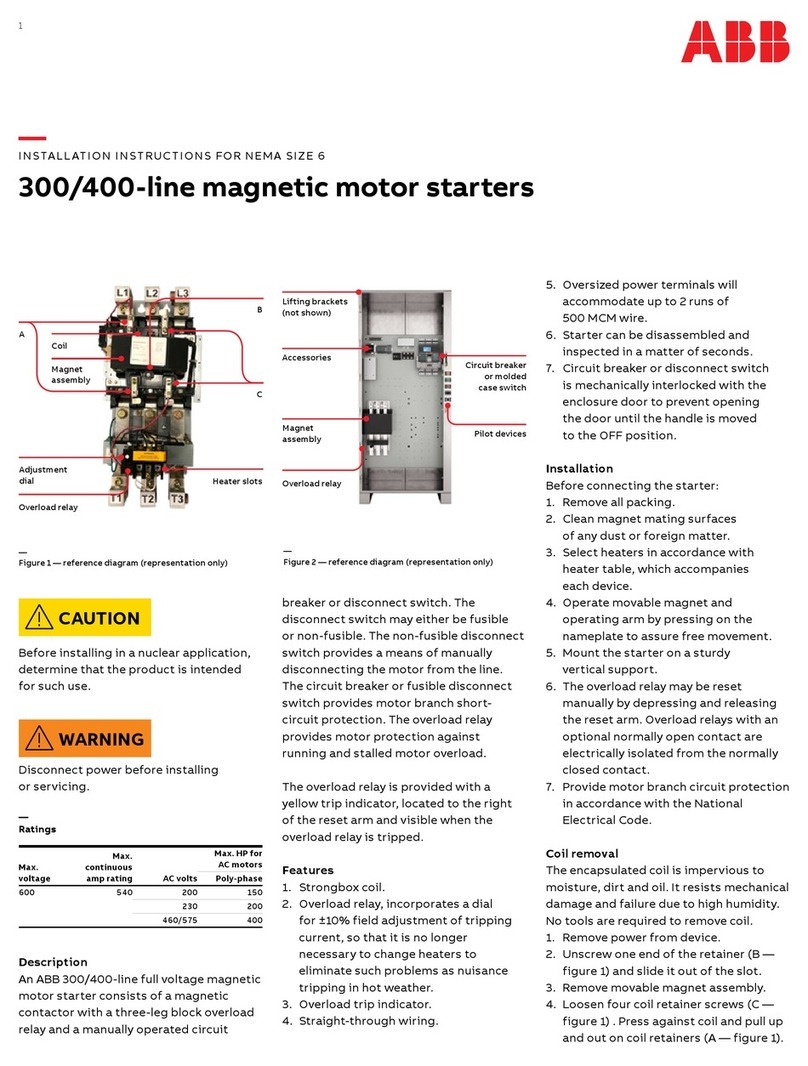

Contact removal

Movable contacts can be inspected

and replaced in seconds —without

tools (Figure 3).

1. Perform steps 1 through 5 under

“Coil removal.”

2. Remove magnet from molded cover

and movable arm.

3. Remove return spring from center

of movable arm.

4. Remove molded cover from movable

arm.

5. Depress and slide movable contact,

spring and spring seat from movable

arm.

6. Remove screws holding stationary

contacts in place and remove

stationary contacts

7. Reassemble device by reversing

procedure.

NOTE: Do not attempt to remove or

replace arc traps in arc chute cover.

chute cover will only fit one way and is

marked “TOP” in upper right-hand corner.

Magnet and movable arm will fit either

way but will be quieter if reassembled

the same way they were taken apart.

Check for welded contacts

in overload relay

This feature permits maintenance

personnel to check for welded relay

contacts by simply depressing the white

operator located at the top of the overload

the reset condition, an audible “click” will

be heard when the operator is depressed,

indicating that the contacts are operating

normally. A continuity check can also be

made by disconnecting the control wiring

from the terminals of the relay and placing

a bell set or a resistance measuring

instrument in the circuit. Connecting

either of these across the relay terminals

will indicate the relay contact is closed

until the contact-check operator is

depressed, opening the circuit. The

exclusive manual contact operation check

gives positive assurance that contacts

have not welded due to short circuits in

the control wiring.

Simple maintenance

require virtually no corrective

maintenance. Preventive maintenance

will assure many years of dependable

on-line service.

1. Always remove power from device

before performing any maintenance.

2. Keep magnet mating surfaces free

of accumulated dirt or dust.

mating surfaces.

4. Contacts are carefully designed for

maximum life. They need only be

replaced when nearly all the silver tip

is gone and the contact tip support is

exposed. DO NOT FILE the contacts.

Filing or otherwise dressing the

contacts only results in lost tip material

and reduces contactor or starter life.

5. The ultimate tripping current of the

installed relay heater can be adjusted

±10% by using adjustment dial.

—

Replacement coils

Frequency 115–120 V 200/208 V 230 –240 V – 460–480 V 575–600 V

–

Frequency 110 V – 220 V 380 V 440 V 550 V

–

—

Accessory kits

First NO auxiliary contact for contactor (right-side mounting)

First NC auxiliary contact for contactor (right-side mounting)

First NO-NC auxiliary contact for contactor (right-side mounting)

Additional NO auxiliary contact for all forms

Additional NC auxiliary contact for all forms

Pushbutton, START-STOP

Selector switch, H-O-A

Selector switch, OFF-ON

Indicating light

Control circuit fuse

Surge suppressor

—

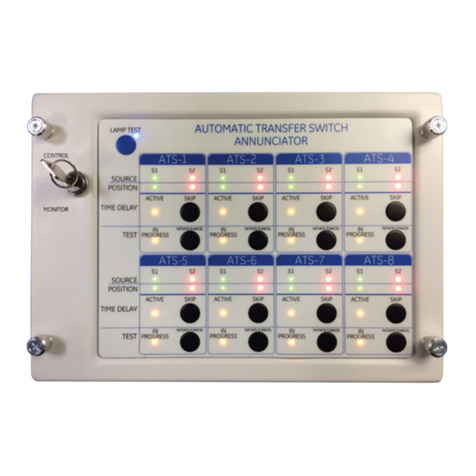

Figure 3 — reference diagram (representation only)

Stationary

contact

screws

Stationary

contacts

Movable

contacts

Movable arm

return spring

(not shown)

Spring seat

Spring