Eaton A210 Manual

Other Eaton Controllers manuals

Eaton

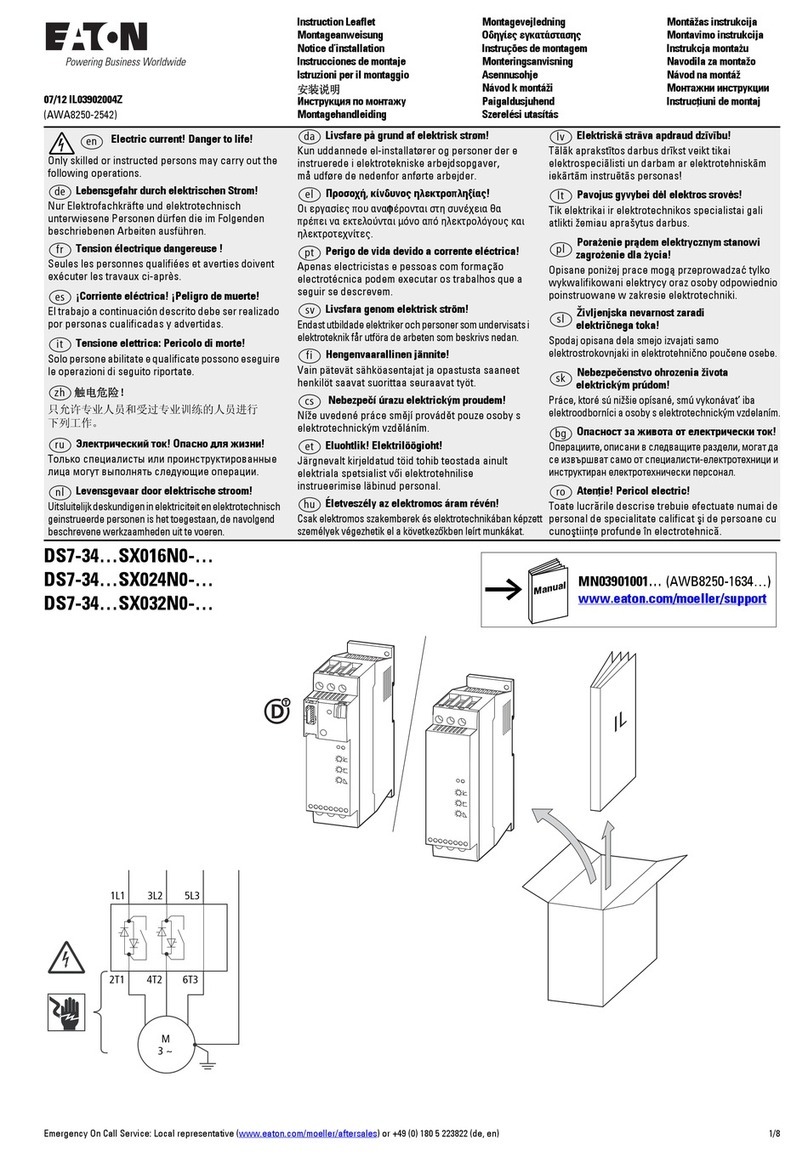

Eaton DS7-34 SX016N0 Series Manual

Eaton

Eaton Jockey lite User manual

Eaton

Eaton Cutler-Hammer S701X25N3BP Manual

Eaton

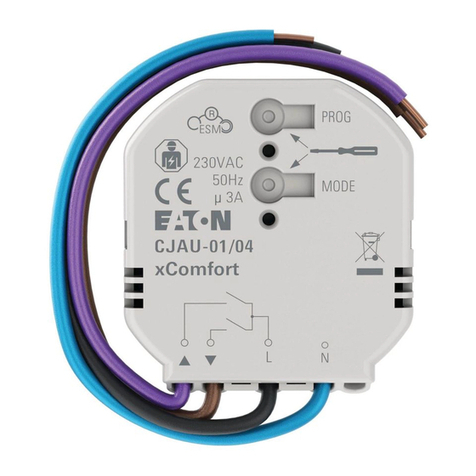

Eaton CJAU-01/04 Series Manual

Eaton

Eaton ATC-600 Programming manual

Eaton

Eaton ELC-PH12NNDT User manual

Eaton

Eaton XV-102 Series User manual

Eaton

Eaton FD120 User manual

Eaton

Eaton OPTE9 User manual

Eaton

Eaton FDF120 Instruction manual

Eaton

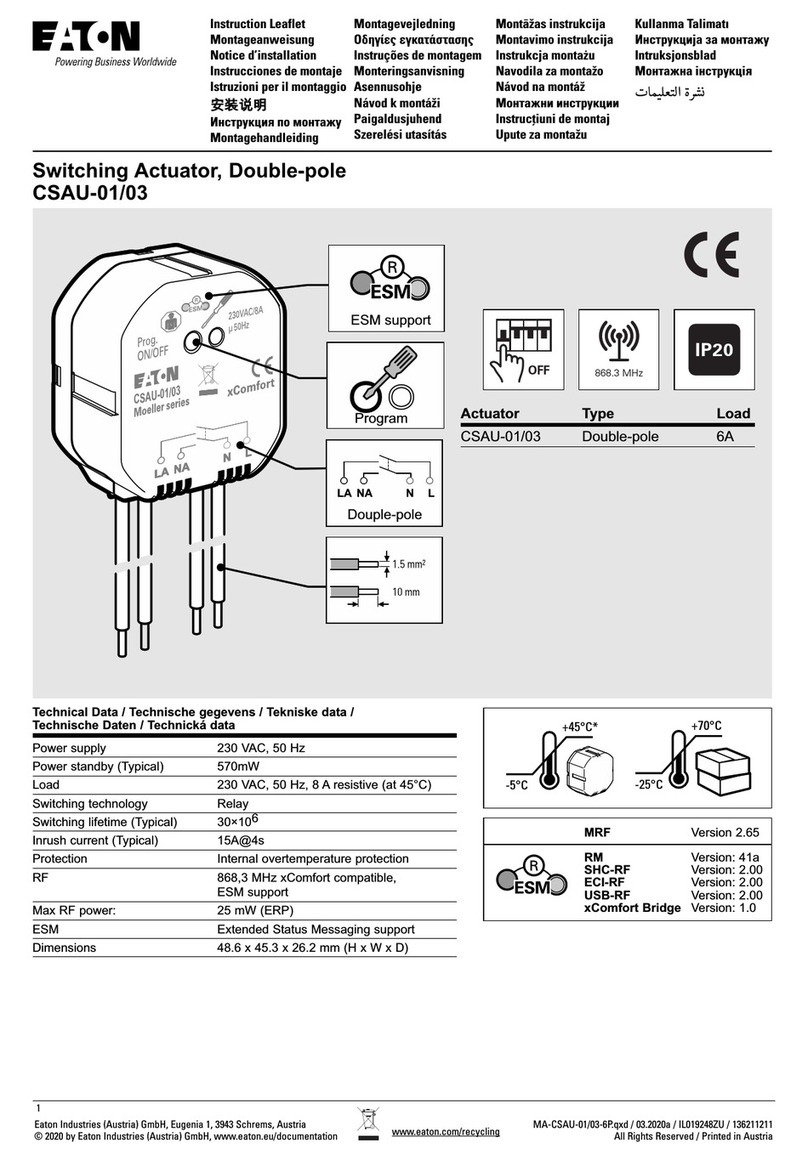

Eaton CSAU-01 Manual

Eaton

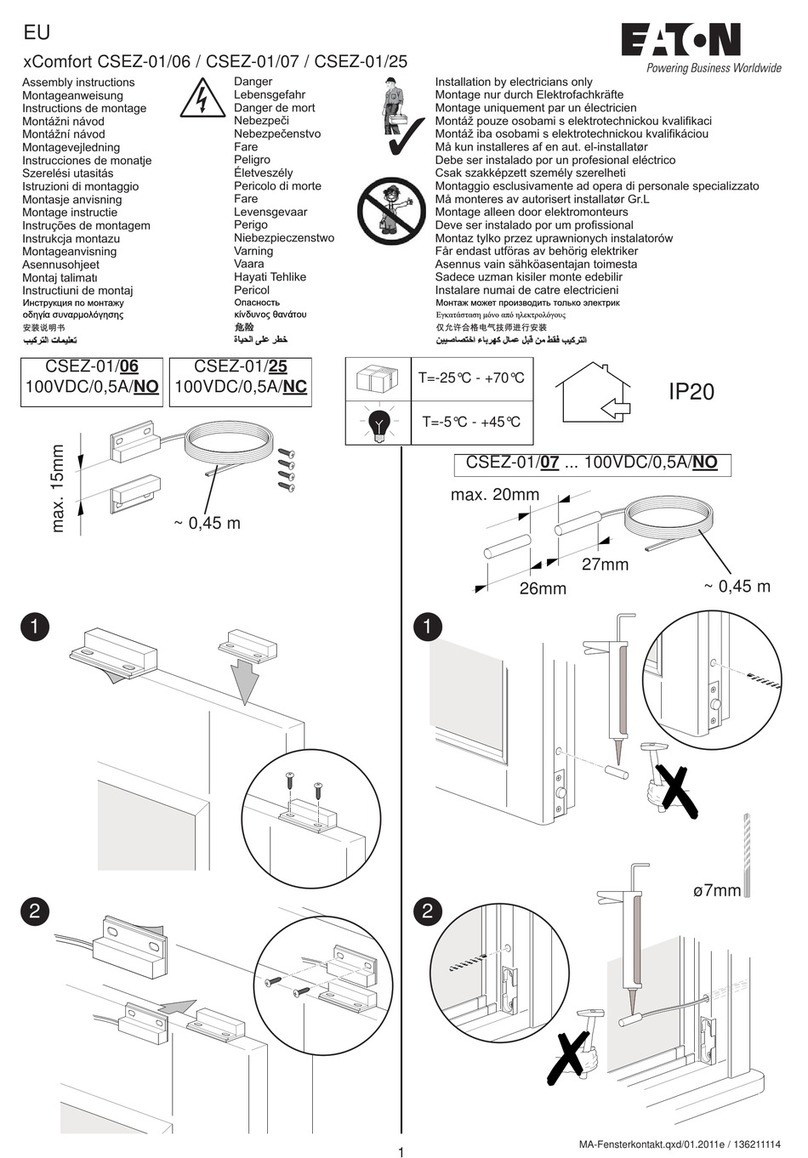

Eaton xComfort CSEZ-01/07 User manual

Eaton

Eaton DS7 Series Manual

Eaton

Eaton S811+N37 series User manual

Eaton

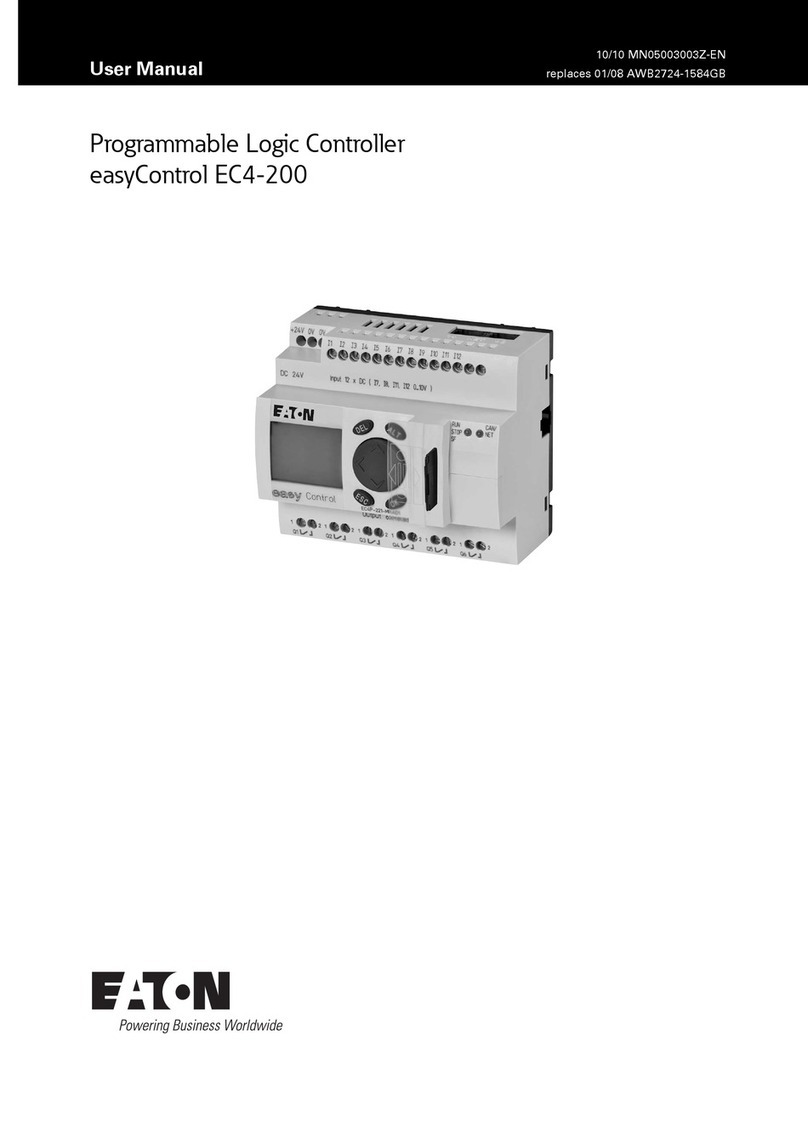

Eaton easyControl EC4-200 User manual

Eaton

Eaton xComfort Bridge Parts list manual

Eaton

Eaton ELC Series User manual

Eaton

Eaton SFX Series User manual

Eaton

Eaton Freedom 2100 Manual

Eaton

Eaton ER9.3-10 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions