ABB ACS560 Installation manual

Other ABB DC Drive manuals

ABB

ABB HP CP500 User manual

ABB

ABB ACS850-04 series User manual

ABB

ABB ACS355 series User manual

ABB

ABB ACQ80-04 Series Use and care manual

ABB

ABB 2000 Series User manual

ABB

ABB ACS880-07 User manual

ABB

ABB Baldor BC200 Installation instructions

ABB

ABB ACS2000 AFE 2MVA User manual

ABB

ABB HD4-HXA Operating and installation instructions

ABB

ABB ACQ550-x1-06A6-2 User manual

ABB

ABB ACS260-04 Series Installation manual

ABB

ABB ACS580-01 drives Installation manual

ABB

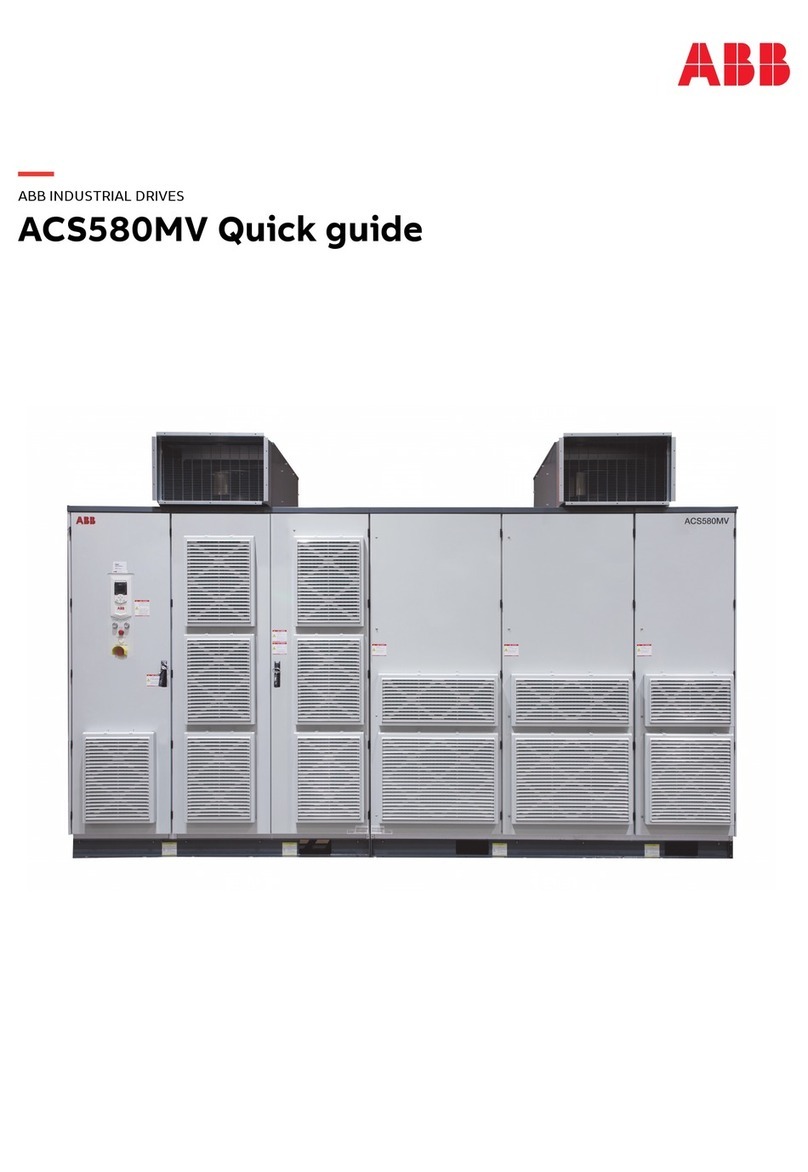

ABB ACS580MV User manual

ABB

ABB ACS580MV User manual

ABB

ABB ACS880-07C User manual

ABB

ABB ACS550 Series User manual

ABB

ABB ACS550-02 User manual

ABB

ABB ACQ580-07 User manual

ABB

ABB ACS 400V User manual

ABB

ABB ACS5000 User manual

Popular DC Drive manuals by other brands

Siemens

Siemens SINAMICS SM150 6SL3815-7NP41-0AA1 Operating instructions & installation instructions

SOMFY

SOMFY JR RU 30 instructions

Beckhoff

Beckhoff AX8911 Documentation

Lenze

Lenze 8200 vector Mounting instructions

Danfoss

Danfoss VLT DriveMotor FCP 106 Design guide

Danfoss

Danfoss VLT AQUA Drive FC 202 operating manual