39Cabinet installation ..............................................................................

39Layout example, outside view ..............................................................

40Layout example, inside view ................................................................

41Mounting the control panel on the cabinet door .......................................

42Installation positions other than vertical ................................................

43Required free space ..............................................................................

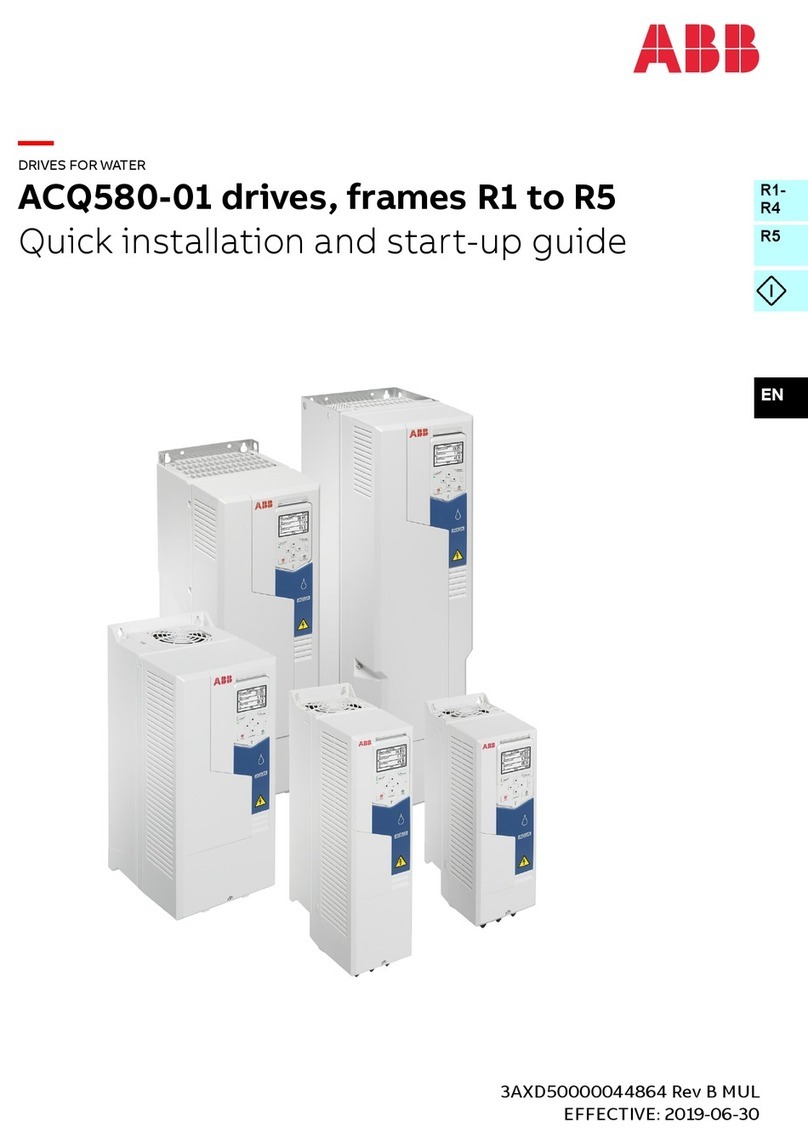

5 Mechanical installation

45Contents of this chapter ........................................................................

45Examining the installation site ................................................................

45Moving and unpacking the unit ................................................................

46Unpacking ......................................................................................

47Package drawings ............................................................................

49Examining the delivery .......................................................................

49Lifting ...........................................................................................

51Attaching alternatives ...........................................................................

51Attaching the drive module by the flange ...............................................

52Attaching the drive module by the heatsink ............................................

53Attaching the metallic shroud (standard) ...............................................

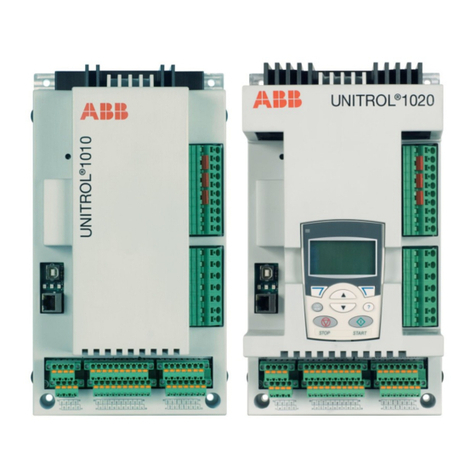

53Attaching the external control unit ...........................................................

54Attaching the external control unit to a mounting plate or wall ....................

54Attaching the external control unit vertically on a DIN rail ...........................

55Attaching the external control unit horizontally on a DIN rail .......................

6 Guidelines for planning the electrical installation

57Contents of this chapter ........................................................................

57Limitation of liability .............................................................................

57Selecting the main supply disconnecting device ..........................................

57European Union and United Kingdom ....................................................

58North America .................................................................................

58Other regions ..................................................................................

58Selecting the main contactor ..................................................................

58North America .................................................................................

58Other regions ..................................................................................

58Examining the compatibility of the motor and drive .....................................

59Protecting the motor insulation and bearings .........................................

59Requirements tables .........................................................................

59Requirements for ABB motors,

P

n< 100 kW (134 hp) ..............................

60Requirements for ABB motors,

P

n> 100 kW (134 hp) ..............................

61Requirements for non-ABB motors,

P

n< 100 kW (134 hp) ........................

62Requirements for non-ABB motors,

P

n> 100 kW (134 hp) ........................

62Abbreviations ..............................................................................

63Availability of d

u

/d

t

filter and common mode filter by drive type ..............

63Additional requirements for explosion-safe (EX) motors .........................

63

Additional requirements for ABB motors of types other than M2_, M3_, M4_,

HX_ and AM_ ................................................................................

63Additional requirements for braking applications .................................

63Additional requirements for ABB high-output and IP23 motors ................

63Additional requirements for non-ABB high-output and IP23 motors ..........

64Additional data for calculating the rise time and the peak line-to-line voltage .

65Additional note for sine filters ..........................................................

6 Table of contents