5E-HUB 2.0 GETTING STARTED

E-Hub 2.0 performance

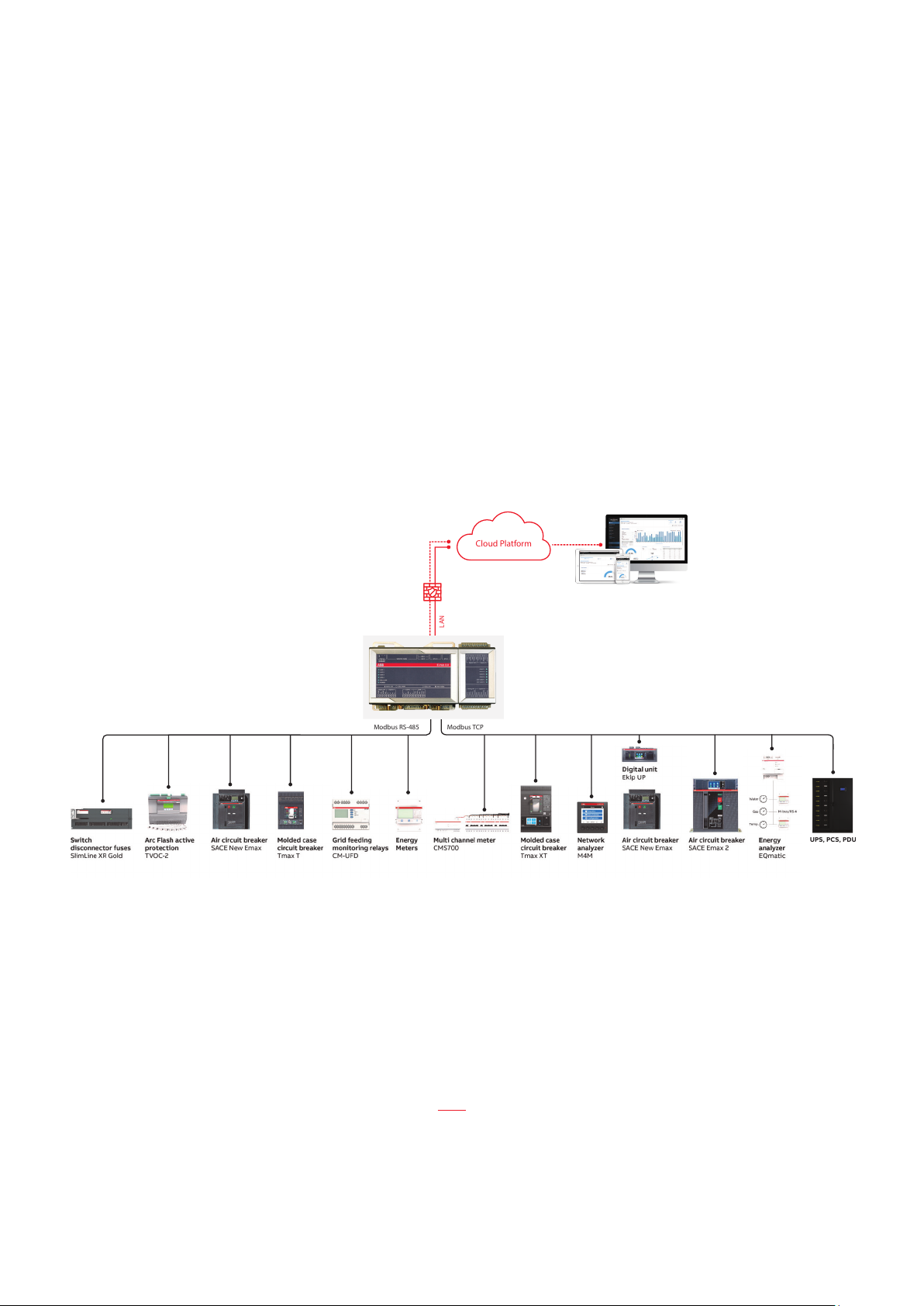

Each E-Hub 2.0 can connect up to 60 devices (total

Modbus TCP/IP and Modbus RS-485). More than 60

devices in total can decrease the performances of

the data logging.

• Up to 30 Modbus RS-485 devices can be con-

nected to the RS-485 interface , equally split be-

tween the two COM ports,

- Devices with Modbus address between 2 and

127 must be connected to RS-485 interface

COM 0.

- Devices with Modbus address between 128

and 247 must be connected to RS-485 inter-

face COM 1.

- Note that a total number of 30 Modbus RS-485

devices ensure an optimal data logging (30sec)

• Up to 30 Modbus TCP/IP devices to ETH1 port.

• Up to 4 channels of analog input supported.

- Analog Input 1 and 2 (AIN1 and AIN2) are for

current input. (4-20mA)

- Analog input 3 and 4 (AIN3 and AIN4) are for

voltage input. (0-36V)

• Up to 7 channels of digital input supported.

- Pulse meter and O/C contact can be selected

for different DI type.

Note:

All the AI and DI are set OFF as default.

• Data logging time and data refresh on the web

app is 30 seconds. However, performance could

decrease if a large number of devices (typically

more than 60) are connected to ABB Ability by

means of one single E-Hub 2.0.

Also, the type of devices that are connected and

the communication protocol used can affect the

performance. In order to ensure high data logging

performance, it is suggested to use more than

one E-Hub 2.0 when more than 30 devices have to

be connected via Modbus RS-485.

Internet data traffic

The estimated data traffic per connected device

amounts to 4 GB per year.

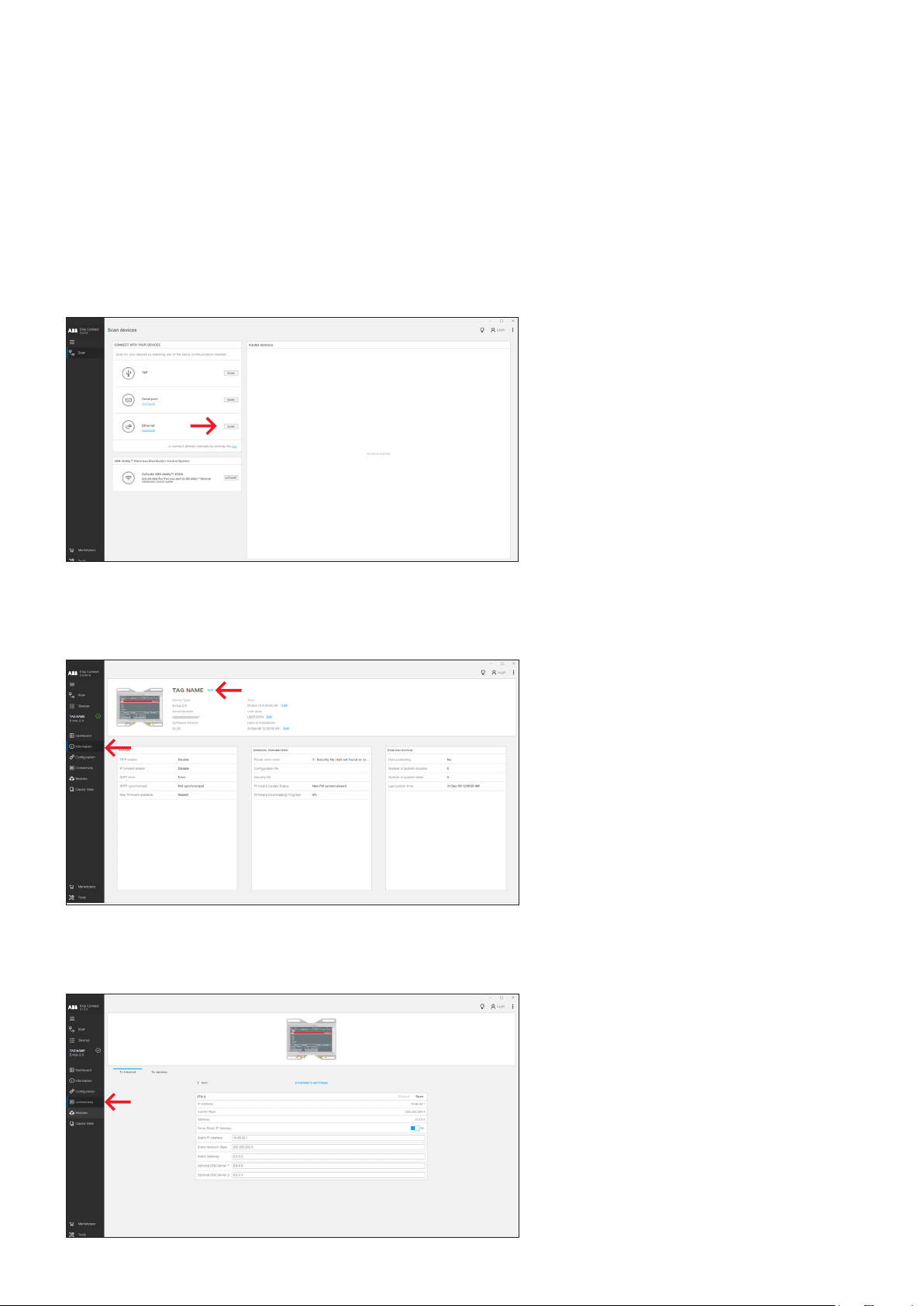

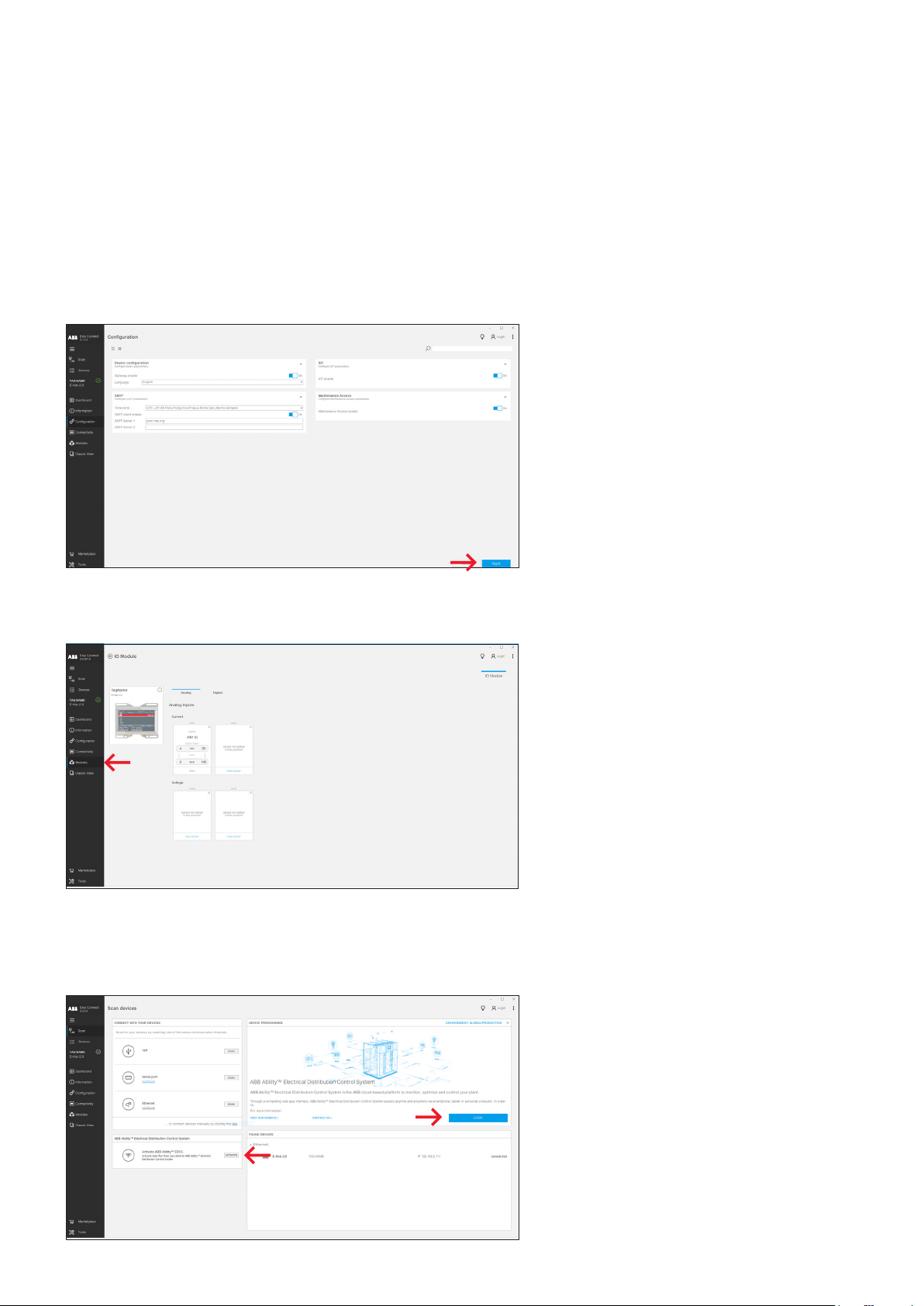

Configuring the system

The system configurations before provisioning

consist of four steps: E-Hub 2.0 Configuration,

Field Device Configuration, Network configura-

tion and Laptop Configuration.

E-Hub 2.0 Configuration

• E-Hub 2.0 ETH0 does not need a static IP ad-

dress, default configuration is DHCP client.

• E-Hub 2.0 Wi-Fi or 3G/4G has to be configured

using Ekip Connect 3. Please refer to the Ekip

Connect 3: Provisioning Steps.

• E-Hub 2.0 ETH1 default configuration is DHCP

server with the following parameters:

- Force Static IP Address: ON

- Static IP address: 192.168.2.1

- Static Subnet mask: 255.255.255.0

- DHCP Server IP Range Begin: 192.168.2.100

- DHCP Server IP Range End:192.168.2.255

- Enable DHCP Server: ON

Note:

If there is already one DHCP server on the ETH1 network, please be

sure to disable the existing DHCP server or disable the option "DHCP

enable" for the ETH1 port via Ekip Connect 3 to avoid conflict.

If you connect ETH0 to a network with an existing DHCP server, inter-

net connection should be guaranteed during the provisioning proce-

dure. Contact your network administrator in order to confirm.

For the configuration of the Digital Input and Analog Input of E-Hub

2.0 please refer to the Ekip Connect 3: Provisioning Steps.

Field Device Configuration

In case of connection via Modbus TCP, the down-

stream devices in the TCP network shall be con-

figured with the following parameters:

• Static IP address: ON

• Static IP address: select an address in the

192.168.2.2 … 192.168.2.99 range

• Subnet mask: 255.255.255.0

• Gateway: 192.168.2.1