3

4.4.10. Factory default......................................................................................................... 34

5. Test Mode................................................................................................................................ 35

6. Recloser Management............................................................................................................. 36

6.1. Firmware Information & backup ..................................................................................... 36

6.2. Firmware Upgrade........................................................................................................... 37

7. Communication ....................................................................................................................... 38

7.1. Wi-Fi parameters Configuration...................................................................................... 38

7.2 Station mode Configuration .............................................................................................. 39

7.3 Switching of communication modes ................................................................................. 44

7.4 Change Password for user roles ...................................................................................... 46

7.5 Forgot Password .................................................................................................................... 47

7.3 Security ............................................................................................................................ 48

7.3.1 General Security deployment guidelines................................................................. 48

7.3.2 TCP/IP based protocols and used IP ports............................................................... 49

8 Appendix.................................................................................................................................. 51

8.3 Appendix 1: Curve file format.......................................................................................... 51

8.4 Appendix 2: List of Events................................................................................................ 55

8.4.1 List of Internal or Device events .................................................................................. 55

8.4.2 List of External events.................................................................................................. 56

8.5 List of Security logs .......................................................................................................... 58

Table of Figures

Figure 1: EAGLE Open/Close Operation using the Mechanical lever ................................................ 6

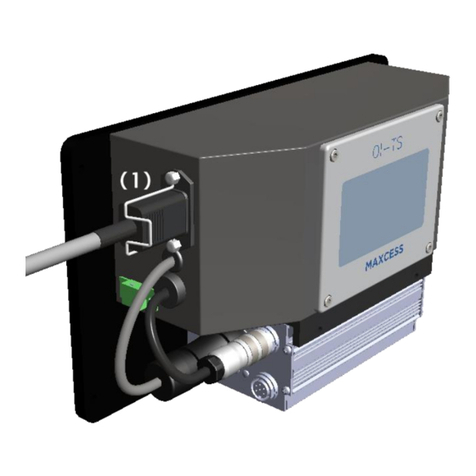

Figure 2 Parts of EAGLE Single phase recloser (Side View) ............................................................... 7

Figure 3 Parts of EAGLE (Bottom View)............................................................................................. 7

Figure 4: Location of for entering user credentials in Web-HMI....................................................... 9

Figure 5 EAGLE Web-HMI Dashboard in “Admin” mode in Access Point mode .............................. 12

Figure 6 EAGLE Web-HMI Dashboard in “Admin” mode in Station mode ...................................... 13

Figure 7: View of the Configuration-> General tab ......................................................................... 15

Figure 8: System time setting page ................................................................................................. 16

Figure 9 List of Events as seen in “Admin” mode............................................................................ 18

Figure 10: Live Data of the EAGLE as seen in “Admin” mode ......................................................... 19

Figure 11 Disturbance Records as seen in “Admin” Mode.............................................................. 20

Figure 12 Load profile as seen in “Admin” mode............................................................................ 21

Figure 13: Security log as viewed in “Admin” mode ....................................................................... 22

Figure 14. Eagle VG4 Life Curve....................................................................................................... 25