5INTRODUCTION

—

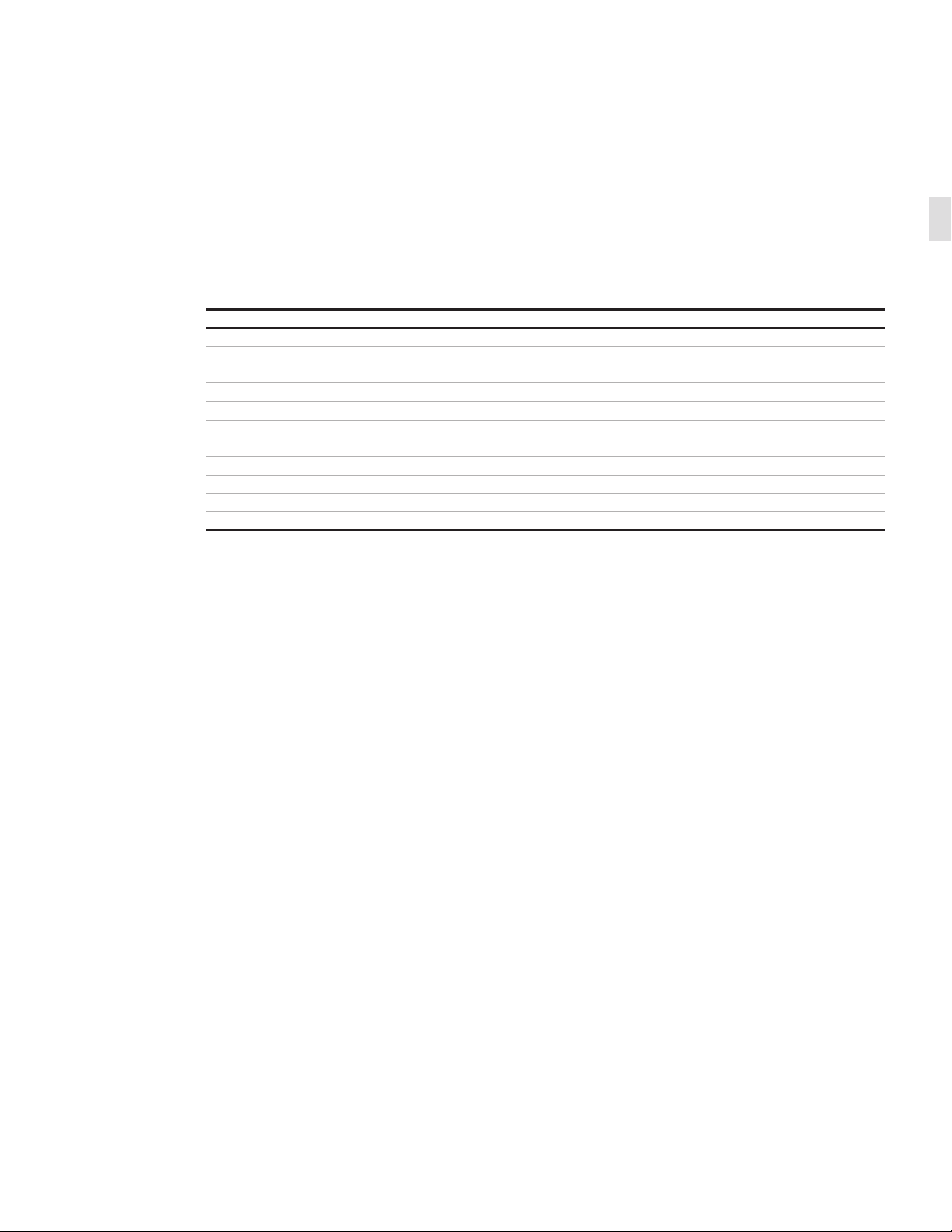

Raw material Recycle Environmental effects and reuse processes

Iron Yes Separate, use instead of new source (ore)

Stainless steel Yes Separate, use instead of new source (ore)

Copper Yes Separate, use instead of new source (ore)

Brass Yes Separate, use instead of new source (ore)

Aluminum Yes Separate, use instead of new source (ore)

Zinc Yes Separate, use instead of new source (ore)

Thermoplastic Yes Make granulate, re-use or apply as energy superior

Epoxy Yes Additive in refuse incineration

Rubber Yes Cut into pieces and use as high-grade energy

Packing foil Yes Cut into pieces and use for landfills

Wooden pallet Yes High-grade energy additive in refuse incineration

ABB is committed to complying with relevant

legal and other statutory requirements for

environmental protection according to the ISO

14001 standard. It is the duty of the end user

to facilitate end-of-life recycling and disposal

according to applicable regulations.

During disposal of the product, it is important

to follow all local legal requirements in force.

Disposal can be carried out either thermally in

an incineration plant or by storing on a waste site.

Following are the methods of recycle/disposal:

01

1.4. Product-related safety notices

The OVR-15, 27 and 38 reclosers should be installed

within the design limitations as described on the

unit’s nameplate and in these instructions. In

addition, always follow your company’s safety

procedures.

This recloser should not be used by itself as

the sole means of isolating a medium voltage

circuit. For the safety of personnel performing

maintenance operations on the recloser or

connecting equipment, all components should

be electrically disconnected by means of a visible

break and securely grounded.

This manual uses the terms “ground” and

“grounding” as per IEEE. These are equivalent

to IEC terms “earth” and “earthing.”

This manual contains terms and expressions

commonly used to describe this kind of equipment.

These instructions do not attempt to provide

the user of this equipment every possible answer

to questions that may arise in the application,

operation and maintenance of the product.

Detailed descriptions of standard repair

procedures, safety principles and service

operations are not included. It is important to note

that this document contains some warnings and

cautions against some specific service methods

that could cause personal injury to service

personnel or could damage equipment or render

it unsafe. These warnings do not cover every

conceivable method in which service (whether

or not recommended by ABB) may be performed.

Secondly, ABB cannot predict or investigate all

potential hazards resulting from all conceivable

service methods. Anyone using service procedures

or tools, whether or not recommended by ABB,

must be completely certain that both their personal

safety and the safety of the equipment will not be

jeopardized by the service method or tools

selected.

All information contained in this manual is based

on the latest product information available at the

time of printing. The right is reserved to make

changes at any time without notice.

Also, as improvements in assemblies and parts

are made, some parts may differ in appearance

than that depicted in illustrations; however,

functionality will be equivalent.