6VD4 - INSTALLATION AND SERVICE INSTRUCTIONS

4.1 General

The VD4 are vacuum circuit breaker for indoor

installation.

For the electrical performances, please refer to the

corresponding technical catalogue code

1VCP000001.

For special installation requirements, please contact

ABB.

The following versions are available:

fixed

withdrawable for UniGear ZS1 switchgear

4.2 Reference Standards

The VD4 circuit breakers conform to the IEC 62271-

100, CEI - VDE - BS Standards are equivalent to IEC

Standards due to harmonization with IEC.

4.3 CLASSIC operating mechanism

VD4 circuit breakers are equipped with modular

CLASSIC spring operating mechanisms. The

operating mechanism is designed to cover the

specific range of 63 kA

4.4 Structure and function

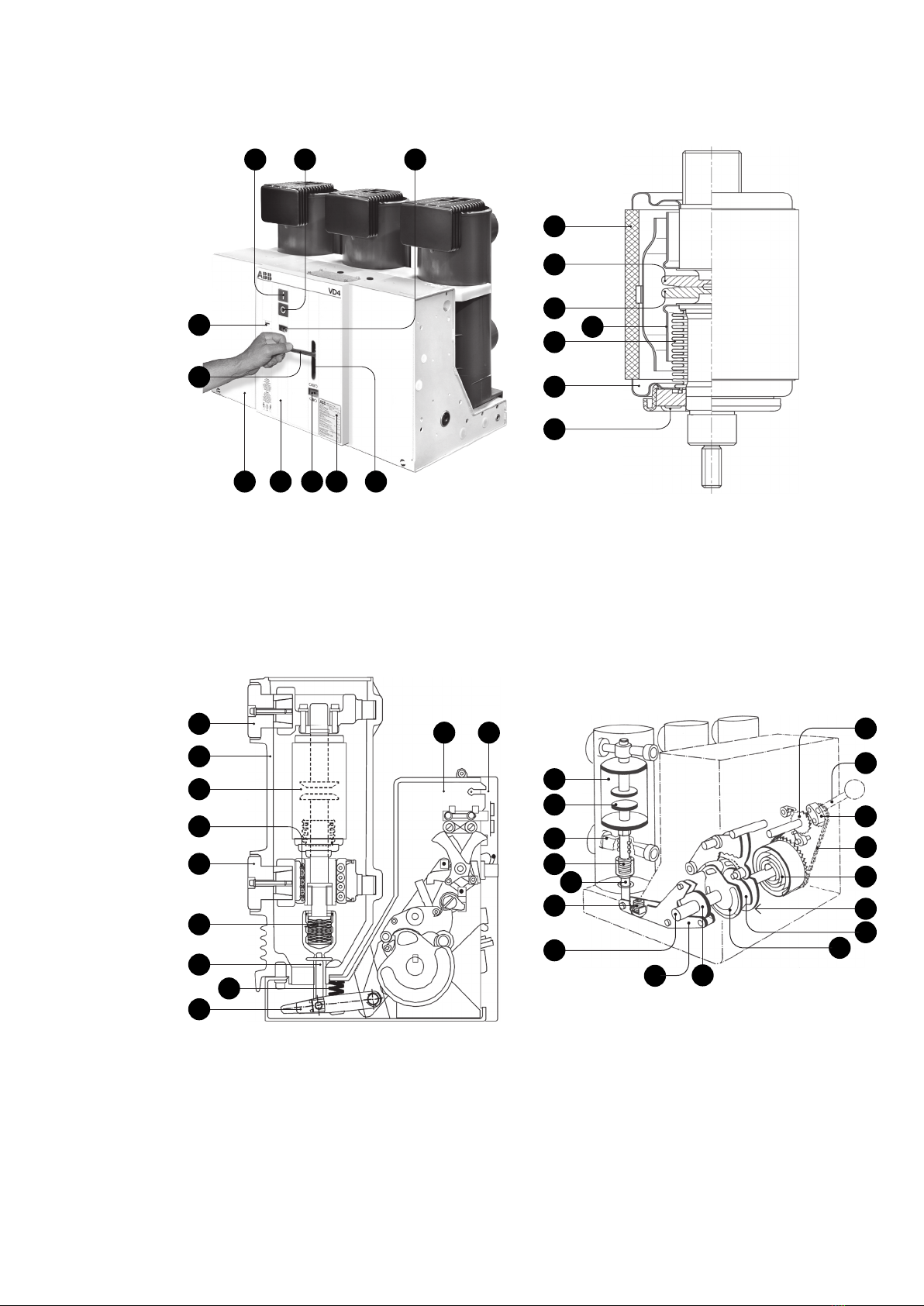

4.4.1 Structure of the breaker poles

(Figures 4/2, 4/3 and 4/4)

The basic structure of a vacuum circuit breaker and

a vacuum interrupter is explained in figures 4/2 and

4/3.

The poles, which are constructed in column form,

are mounted on the bracket-shaped rear part of

mechanism enclosure 1. The live parts of the breaker

poles are located in the insulating material pole

tubes 12 and protected from impacts and other

external influences.

With the breaker closed, the current path leads from

the upper breaker terminal 13 and a chamber holder

fixed in the pole tube to the fixed contact 15.2 in the

vacuum interrupter 15, then via the moving contact

15.3 and the roller contact 16.2, to the lower breaker

terminal 14. The switching motion is effected by

means of the insulated coupling rod 18 with internal

contact force springs 17.

4.4.2 Structure of the breaker operating

mechanism (Figures 4/1, 4/4 and 4/5)

The operating mechanism is of the stored-energy

spring type and acts on the three breaker poles. The

necessary operating energy is stored ready for

activation by charging the spring energy store.

The stored-energy spring mechanism essentially

consists of drum 33 containing the spiral spring, the

charging system, the latching and operating

mechanism and the linkages which transmit the

force to the breaker poles. In addition, there are

supplementary components such as the charging

—

4. Description

motor, releases, auxiliary switches and the controls

and instruments located on the front of the

mechanism enclosure 1.

The basic structure of a stored-energy spring

mechanism is explained in figure 4/4.

The operating mechanism is fundamentally suitable

for auto-reclosing and, due to the short charging

times, also for multi-shot auto-reclosing.

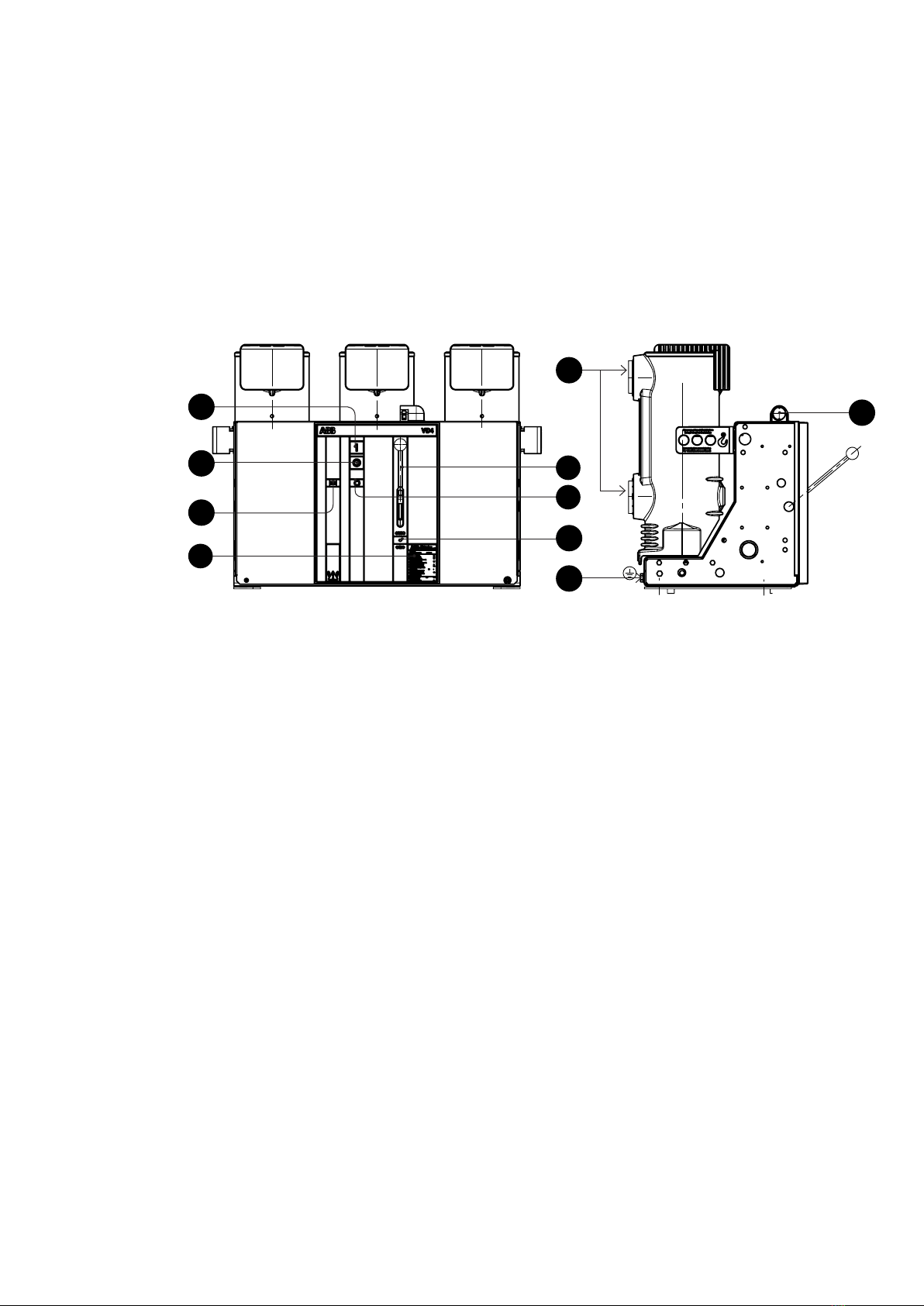

In the basic version of the circuit breaker, the spring

energy store is charged manually. The operating

mechanism can optionally be fitted with a charging

motor.

There is one rating plate with the main data of the

switch equipment on front plate 1.1, and another at

the lower front right in mechanism enclosure 1.

The basic version of the stored-energy spring

mechanism is fitted with the following auxiliary

equipment:

Shunt release OFF -MBO1

Five-pole auxiliary switch -BGB2 for annunciation

purposes 38

Auxiliary switch -BGB4 for fault annunciation

Mechanical ON push-button 2

Mechanical OFF push-button 3

Mechanical position indicator 4

Charging condition indicator 8 for the spring

energy store

Mechanical operating cycle counter 5

The following additional equipment can be installed:

Blocking magnet -RLE1 with auxiliary switch -BGL1

Shunt release ON -MBC

Second shunt release OFF -MBO2

Indirect overcurrent release -MBO3

Undervoltage release -MBU

Five-pole auxiliary switches -BGB1 and -BGB3

Charging motor -MAS 36

Five-pole auxiliary switch -BGS1 to switch the

charging motor.

4.4.3 Releases, blocking magnet and auxiliary

switches (Figures 4/1, 4/5, 9/1, 9/2, 9/3)

The releases and the blocking magnet are

mounted at the top left on the spring operating

mechanism.

The allocation of the auxiliary switches can be

seen in the wiring diagram.

The five-pole auxiliary switch -BGS1 is operated by

the charging condition indicator 8. It controls the

charging motor -MAS, serves as an electrical

interlock for shunt release ON -MBC when the

spring mechanism is not sufficiently charged, and

also provides an electrical switching readiness

signal.

Operation of the five-pole auxiliary switches

-BGB1, -BGB2 and -BGB3 is dependent on the

switching position of the circuit breaker.