1

CONTENTS

Section Page

1 INTRODUCTION .......................................................... 2

1.1 System Description ............................................ 2

1.2 AX400 Series Analyzer Options .......................... 2

2 OPERATION ................................................................. 3

2.1 Powering Up the Analyzer .................................. 3

2.2 Displays and Controls ........................................ 3

2.2.1 Key Functions ....................................... 3

2.3 Operating Page .................................................. 6

2.3.1 Single Input pH ..................................... 6

2.3.2 Dual Input pH ....................................... 7

2.3.3 Wash Function ...................................... 8

2.3.4 Single Input Redox (ORP) ..................... 9

2.3.5 Dual Input Redox (ORP) ...................... 10

2.3.6 Dual Input pH and Redox (ORP) ......... 11

3 OPERATOR VIEWS .................................................... 12

3.1 View Set Points ................................................ 12

3.2 View Outputs .................................................... 13

3.3 View Hardware ................................................. 13

3.4 View Software .................................................. 14

3.5 View Logbook .................................................. 14

3.6 View Clock ....................................................... 17

4 SETUP ........................................................................ 18

4.1 Sensor Calibration ............................................ 18

4.1.1 Set Buffer Type (pH Only) .................... 18

4.1.2 Set Up User Defined Buffers

(pH Only) ............................................. 20

4.1.3 Adjust Offset (Redox/ORP Only) .........21

4.1.4 Automatic and Manual, Single-

and Two-Point Calibration (pH Only) ... 22

4.1.5 Grab Calibration (pH Only) .................. 24

5 PROGRAMMING ........................................................ 25

5.1 Security Code .................................................. 25

5.2 Configure Display ............................................. 26

5.3 Configure Sensors ............................................ 27

5.4 Configure Alarms .............................................. 30

5.4.1 Wash Cycle Configuration

(Applicable Only to Alarm 3) ................ 32

5.5 Configure Outputs ............................................ 34

5.6 Configure Clock................................................ 36

5.7 Configure Security ............................................ 37

5.8 Configure Logbook........................................... 37

5.9 Test Outputs and Maintenance ........................ 38

Section Page

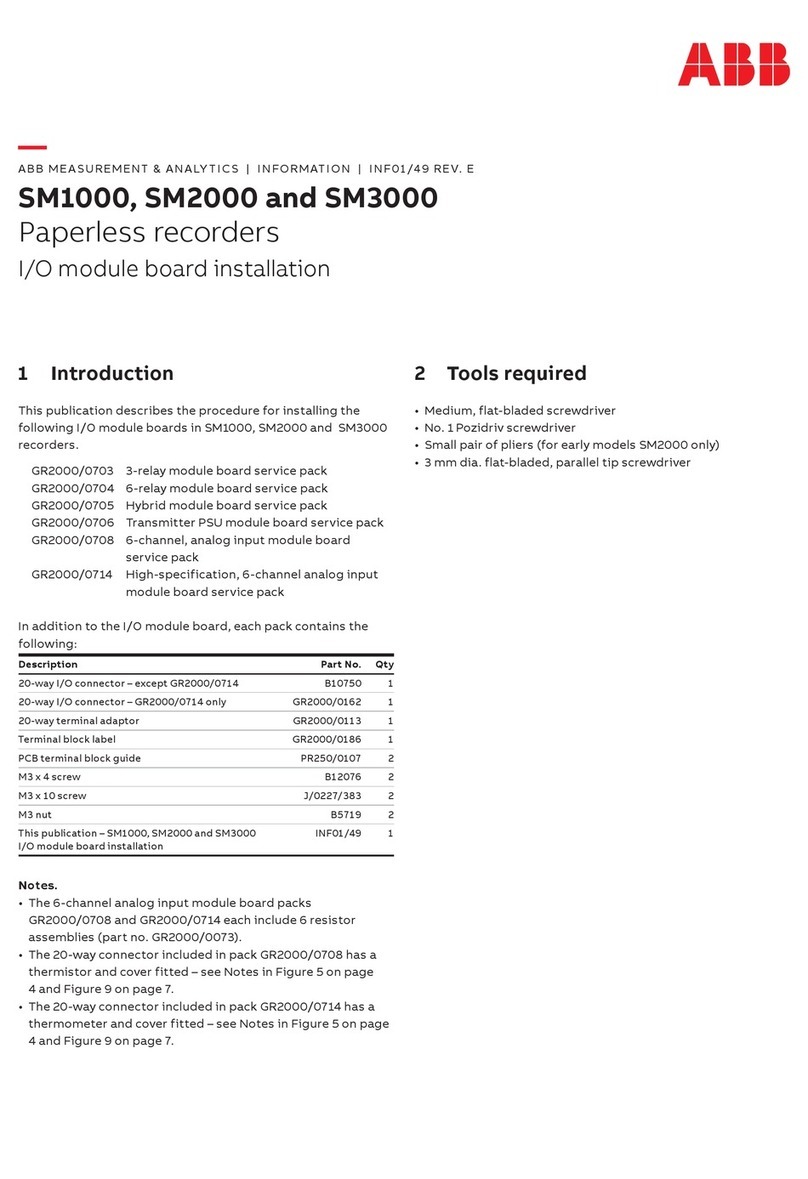

6 INSTALLATION ........................................................... 39

6.1 Siting Requirements ......................................... 39

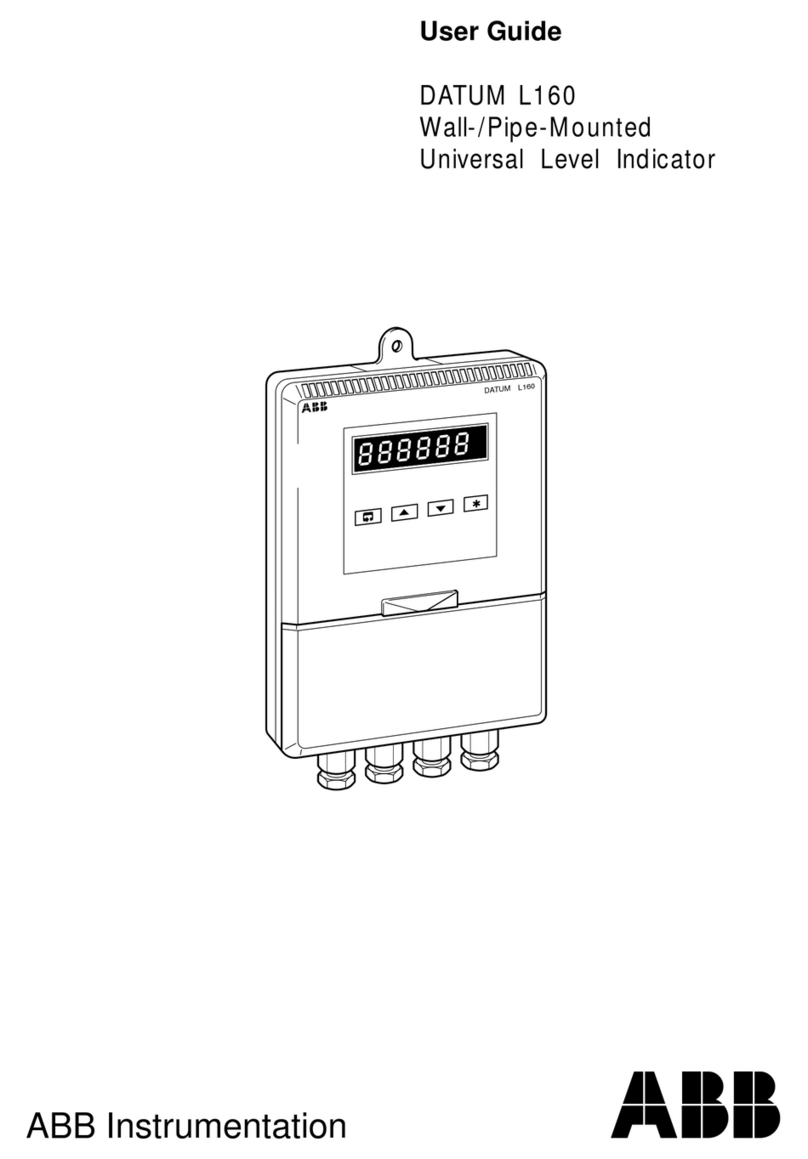

6.2 Mounting .......................................................... 40

6.2.1 Wall-/Pipe-mount Analyzers ................ 40

6.2.2 Panel-mount Analyzers ....................... 41

6.3 Connections, General ....................................... 42

6.3.1 Relay Contact Protection and

Interference Suppression .................... 43

6.3.2 Cable Entry Knockouts,

Wall-/Pipe-mount Analyzer ................. 44

6.4 Wall-/Pipe-mount Analyzer Connections ..........45

6.4.1 Access to Terminals ............................ 45

6.4.2 Connections ....................................... 46

6.5 Panel-mount Analyzer Connections ................. 47

6.5.1 Access to Terminals ............................ 47

6.5.2 Connections ....................................... 48

7 CALIBRATION ............................................................ 49

7.1 Equipment Required ......................................... 49

7.2 Preparation ....................................................... 49

7.3 Factory Settings ............................................... 50

8 SIMPLE FAULT FINDING ........................................... 55

8.1 Error Messages ................................................ 55

8.2 Calibration Fail Message or

no Response to pH/Redox Changes................ 55

8.3 Checking the Temperature Input ...................... 55

APPENDIX A ....................................................................... 56

A1 Buffer Solutions ................................................ 56

SPECIFICATION .................................................................. 59