3

1 General

1.1 Introduction

This MT5000 series is comprised of the MT5000, MT5100 and

MT5200 models. This manual provides an overview of the safety

aspects that must be observed for the installation and operation of

the device.

1.2 Product description

The MT-series of level transmitters is a modular range of field

mounted, microprocessor-based electronic transmitters, utilizing

guided wave radar technology. Accurate and reliable measurement

of liquid, solids and slurry level is provided in even the most difficult

and hazardous industrial environments. The MT-series can be con-

figured to provide specific industrial output signals, according to

4–20 mA with HART digital communication as well as FOUNDATION

Fieldbus protocol. The MT-series consists ofthree models: MT5000

(total level measurement), MT5100(total level and interface measure-

ment) and MT5200 (total level measurement with ULD mode for low

dielectric applications).

1.3 General safety information

The device is constructed in accordance with international and local

regulations and is deemed to be operationally safe. Additionally, the

device is tested and shipped from the factory in perfect working

condition. The information contained within this safety manual, as

well as all applicable documentation and certification, must be ob-

served and adhered to in order to maintain the factory-deployed

condition throughout the MT-series period of operation.

Full compliance with the general safety requirements must be ob-

served during handling, installation, maintenance or operation of the

device. In addition to providing general information, the individual

sections within this manual contain descriptions, processes and/or

procedural instructions with specific safety information for that

corresponding action.

Only by observing all of the safety information can the user minimize

the risk of hazards to personnel and/or the environment. The provid-

ed instructions are intended as an overview only and do not contain

detailed information on all available models or every conceivable

scenario that may arise during setup, operation and/or maintenance

work. This document shall be used in conjunction with the opera-

tion/instructions manuals.

For additional information, or in the event of specific issues not cov-

ered within these operating instructions, please contact the manu-

facturer. ABB declares the contents of this manual are not part of

any prior or existing agreements, commitments or legal relation-

ships and are not intended to amend those that are already in place.

In addition, the user must observe all relevant safety regulations

regarding the installation and operation of electrical systems and

the relevant standards, regulations and guidelines concerning explo-

sion protection.

1.4 Information on WEEE Directive 2002/96/EC (Waste Electrical

and Electronic Equipment)

This product/solution is not subject to the WEEE Directive 2002/96/

EC or corresponding national laws (e.g., the ElektroG-Electrical and

Electronic Equipment Act-Germany). Dispose of the product/

solution at a specialized recycling facility. Municipal garbage collec-

tion points should not be used for this purpose.

According to WEEE Directive 2002/96/EC, only products that are

used in private applications may be disposed of at municipal

garbage facilities. Proper disposal prevents negative effects on

both individuals and the environment and also supports the re-

use of valuable raw materials. ABB can accept and dispose of

returns for a fee.

1.5 Pressure Equipment Directive (PED) (97/23/CE)

This product conforms to the EC directives listed in the device-

specific EC declaration of conformity. It is designed in accord-

ance with safe engineering practices to meet state of the art

safety requirements, has been tested and left the factory in a

condition in which they are safe to operate.

1.6 Use of instruction

2 Installation in Hazardous Locations

2.1 Explosives atmospheres installation

For installation requirements in Explosives Atmospheres applica-

tions refer to IEC 60079-14 and any local Safety or Electric Code

regulations mandatory in your area.

For specific conditions for safe use refer to section 3.0 of this

manual.

WARNING - Bodily injury. The device can be operated

at high levels of pressure and with aggressive media.

As a result, serious injury or significant property

damage may occur if this device is operated incor-

rectly.

DANGER - Serious damage to health / risk to life

This symbol in conjunction with the signal word

“DANGER” indicates an imminent electrical hazard.

Failure to observe this safety information will re-

sult in death or severe injury.

WARNING - Bodily injury This symbol in conjunc-

tion with the signal word “WARNING” indicates a

potentially dangerous situation. Failure to observe

this safety information may result in death or se-

vere injury.

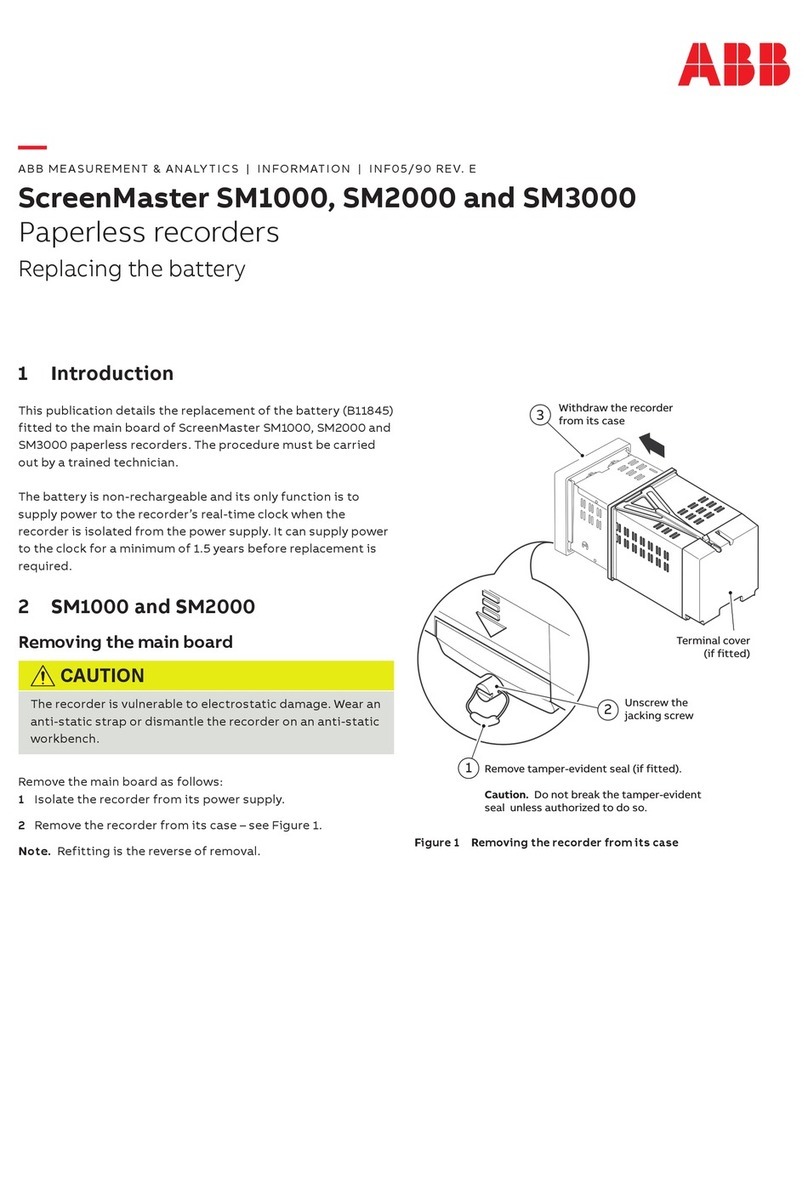

CAUTION - Minor Injuries This symbol in conjunc-

tion with the signal word “CAUTION” indicates a

potentially dangerous situation. Failure to observe

this safety information may result in minor or

moderate injury. This symbol may also be used for

property damage warnings.

NOTICE - Property Damage This symbol indicates

a potentially damaging situation. Failure to ob-

serve this safety information may result in damage

to or destruction of the product and / or other

system components.

IMPORTANT (NOTE) This symbol indicates opera-

tor tips, useful information or important infor-

mation about the product or its further uses. The

signal word “IMPORTANT (NOTE)” does not indi-

cate a dangerous or harmful situation.