SI/RandC/001-EN Rev. A 08.2019

—

We reserve the right to make technical

changes or modify the contents of this

document without prior notice. With

regard to purchase orders, the agreed

particulars shall prevail. ABB does not

accept any responsibility whatsoever for

potential errors or possible lack of

information in this document.

We reserve all rights in this document and

in the subject matter and illustrations

contained therein. Any reproduction,

disclosure to third parties or utilization of

its contents – in whole or in parts – is

forbidden without prior written consent

of ABB.

© ABB 2019

—

ABB Limited

Measurement & Analytics

Howard Road, St. Neots

Cambridgeshire, PE19 8EU, UK

Tel: +44 (0)870 600 6122

Fax: +44 (0)1480 213 339

abb.com/measurement

ABB Inc.

Measurement & Analytics

125 E. County Line Road

Warminster, PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

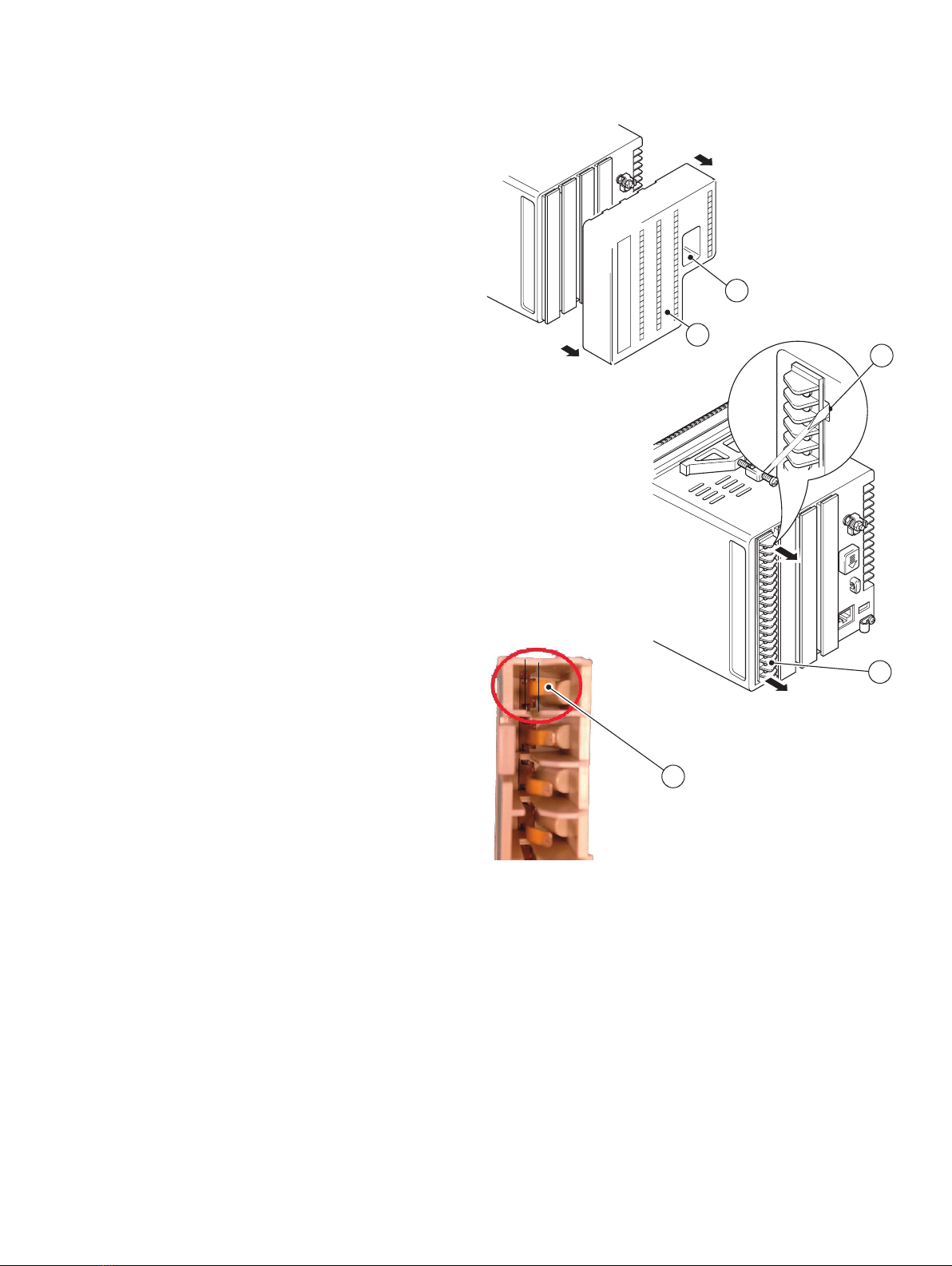

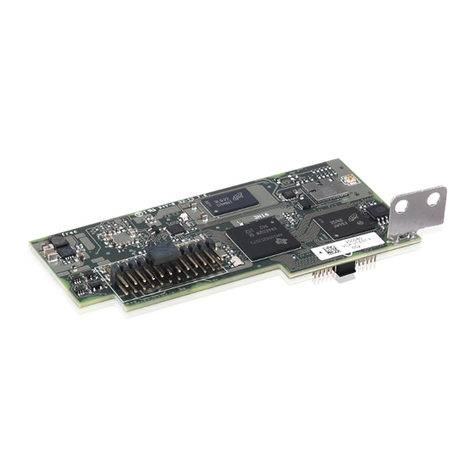

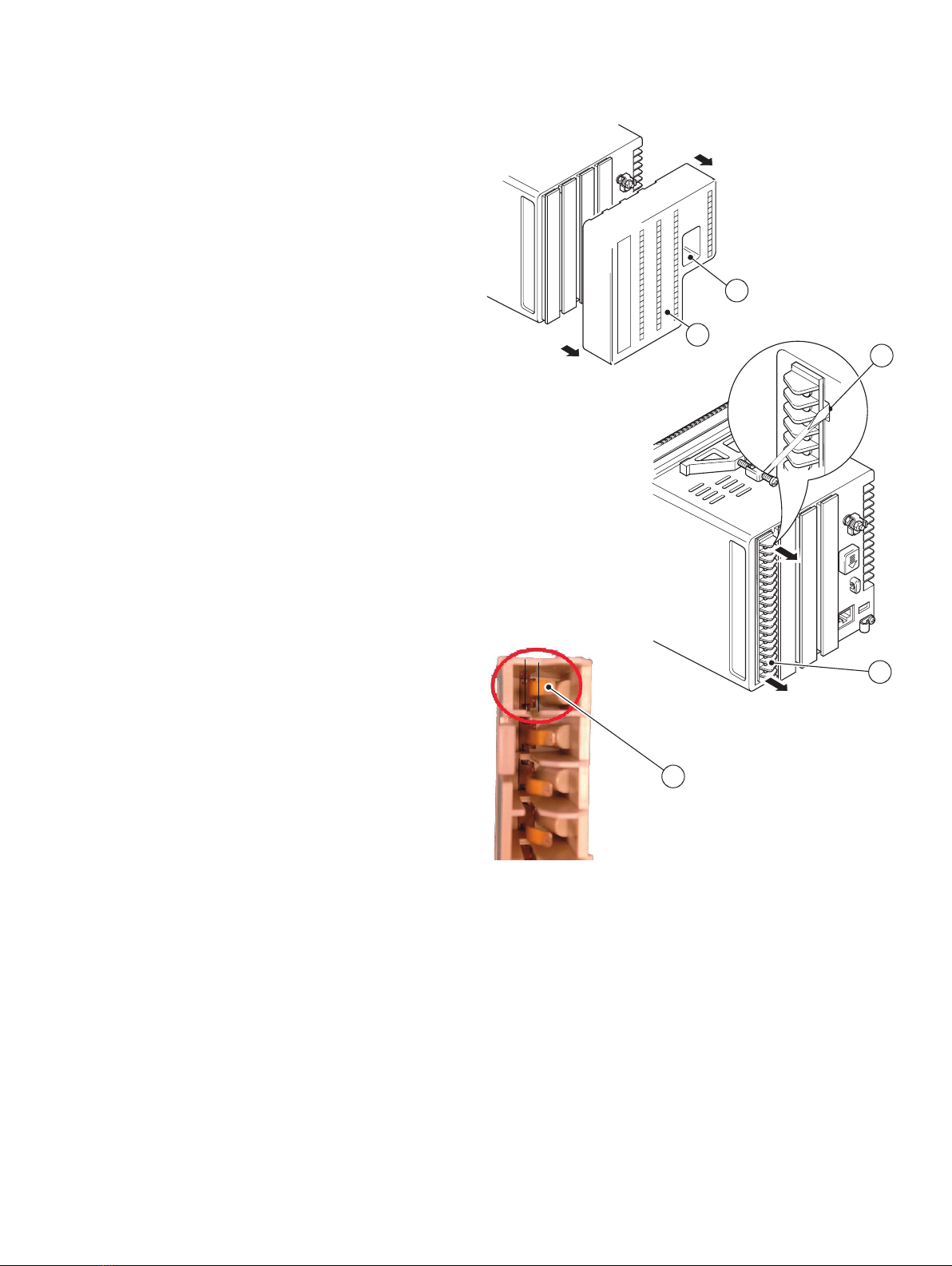

…4 Identifying failures

Referring to Figure 1:

1 Isolate the recorder from the power supply.

2 Press down into recess Aand pull terminal cover B

away from the case.

3 Insert a flat-bladed screwdriver into each slot Cin turn

(2 slots) to release the locking arm and pull terminal block

Daway from the case.

4 Check the position of spring contacts Ewithin the terminal

block assembly.

The correct position for the contacts is as shown in Figure 1

– each contact must be positioned a minimum of halfway

across the slot in which the module board fits.

5 If a contact is positioned incorrectly or is damaged, replace

the terminal block assembly.

6 Fit the terminal block.

7 Refit terminal cover B.

Figure 1 Examining the terminal block contacts

A

B

C

D

E