Safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death,

or damage to the equipment can occur. If you are not a qualified

electrical professional, do not do electrical installation or maintenance

work.

• Do not do work on the drive, motor cable, motor, or control cables when the

drive is connected to the input power. Before you start the work, isolate the

drive from all dangerous voltage sources and make sure that it is safe to

start the work. Always wait for 5 minutes after disconnecting the input

power to let the intermediate circuit capacitors discharge.

• Do not do work on the drive when a rotating permanent magnet motor is

connected to it. A rotating permanent magnet motor energizes the drive,

including its input and output terminals.

1. Unpack the delivery

Keep the drive in its package until you are ready to install it. After unpacking,

protect the drive from dust, debris and moisture. Make sure that these items are

included:

• clamping plates, clamps and screws

• mounting template, integrated into the package

• quick installation and start-up guide.

Make sure that there are no signs of damage to the items.

2. Reform the capacitors

If the drive has not been powered up for a year or more, you must reform the DC

link capacitors. The manufacturing date is on the type designation label. Refer

to

Guide for capacitor reforming

(3AFE68735190 [English]).

3. Select the cables and fuses

• Select the power cables. Obey the local regulations.

•Input power cable: ABB recommends to use symmetrical shielded cable

(VFD cable) for the best EMC performance.

•Motor cable: Use symmetrical shielded cable (VFD cable) for the best

EMC performance. Symmetrical shielded cable also reduces bearing

currents, wear, and stress on motor insulation.

•Power cable types: In IEC installations, use copper or aluminum cables (if

permitted). In UL installations, use only copper cables.

•Current rating: max. load current.

•Voltage rating: min. 600 V AC.

•Temperature rating: In IEC installations, select a cable rated for at least

70°C (158°F) maximum permissible temperature of conductor in

continuous use. In UL installations, select a cable rated for at least 75°C

(167°F).

•Size: Refer to

Fuses and typical power cable sizes

for the typical cable

sizes and to

Terminal data for the power cables

for the maximum cable

sizes.

• Select the control cables. Use double-shielded twisted-pair cable for analog

signals. Use double-shielded or single-shielded cable for the digital, relay and

I/O signals. Do not run 24 V and 115/230 V signals in the same cable.

• Protect the drive and input power cable with the correct fuses. Refer to

Fuses and typical power cable sizes

.

4. Examine the installation site

The drive is intended for cabinet installation and has a degree of protection of

IP20 / UL open type as standard.

Examine the site where you will install the drive. Make sure that:

• The installation site is sufficiently ventilated and hot air does not recirculate.

• There is sufficient free space around the drive for cooling, maintenance, and

operation. For the minimum free space requirements, refer to

Free space

requirements

.

• The ambient conditions meet the requirements. Refer to

Ambient

conditions

.

• The installation surface is as close to vertical as possible and strong enough

to support the weight of the drive. Refer to

Dimensions and weights

.

• The installation surface, floor and materials near the drive are not flammable.

• There are no sources of strong magnetic fields, such as high-current single-

core conductors or contactor coils near the drive. A strong magnetic field

can cause interference or inaccuracy in the operation of the drive.

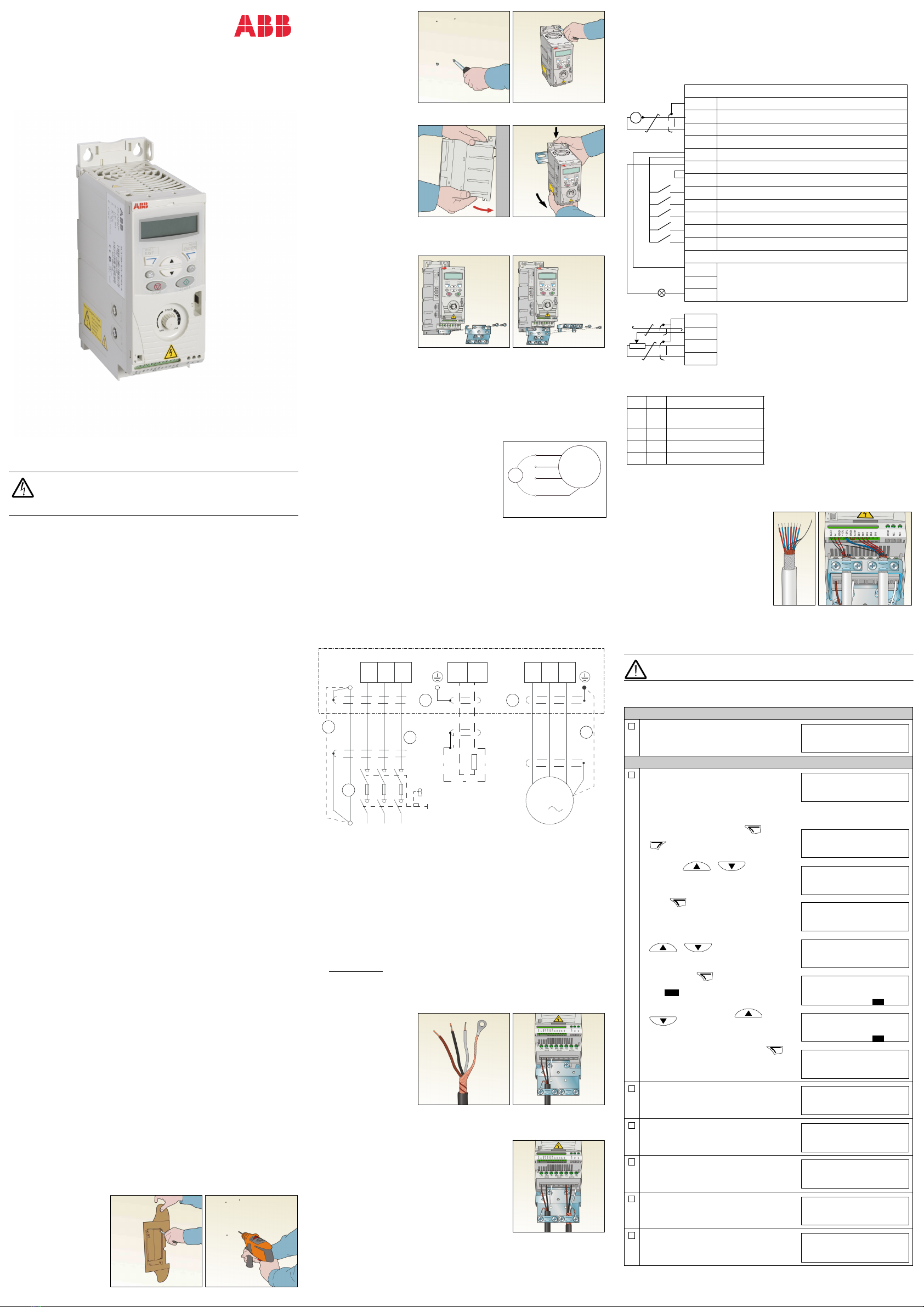

5. Install the drive

You can install the drive with screws, or to a DIN rail (top hat type, width × height

= 35 mm × 7.5 mm [1.4 in × 0.3 in]).

Do not install the drive upside down. Make sure that the cooling air exhaust is

above the cooling air inlet.

To install the drive with screws

1. Cut out the mounting

template from the

package and use it to

mark the locations for

the mounting holes.

2. Make the holes for the

mounting screws and

install suitable plugs or

anchors.

—

ABB MICRO DRIVES

ACS150 drives

Quick installation and start-up guide

3. Install the mounting

screws. Leave a gap

between the screw

head and mounting

surface.

4. Place the drive onto the

mounting screws.

5. Tighten the mounting

screws.

To install the drive to a DIN rail

1. Put the top of the drive

onto the DIN

installation rail at an

angle as shown in the

figure.

2. Put the drive against

the wall.

3. Make sure that the drive

is correctly installed.

4. To remove the drive,

press the release lever on top of the drive.

6. Attach the clamping plates

1. Attach the clamping

plate to the plate at the

bottom of the drive

with the provided

screws.

2. Attach the I/O clamping

plate to the clamping

plate with the provided

screws.

7. Measure the insulation resistance

Measuring the insulation is typically not required in North America.

Drive: Do not do voltage tolerance or insulation resistance tests on the drive,

because this can cause damage to the drive.

Input power cable: Measure the insulation of the input power cable before you

connect it to the drive. Obey the local regulations.

Motor and motor cable:

1. Make sure that the motor cable is connected to the motor and disconnected

from the drive output terminals U2, V2 and W2.

2. Use a voltage of 1000 V DC to measure the

insulation resistance between each phase

conductor and the protective earth conductor.

The insulation resistance of an ABB motor must

be more than 100 Mohm (at 25 °C/77 °F). For the

insulation resistance of other motors, refer to

the manufacturer’s documentation. Moisture in

the motor decreases the insulation resistance.

If you think that there is moisture in the motor,

dry the motor and do the measurement again.

8. Make sure that the drive is compatible with the

grounding system

You can connect all drive types to a symmetrically grounded TN-S system

(center-grounded wye).

Before you connect the drive to a corner-grounded delta system or IT system

(ungrounded or high-resistance grounded), remove the metal EMC filter

grounding screw. If the drive has a plastic EMC screw (drives with type code

ACS150-03U-…), it is not necessary to remove the screw.

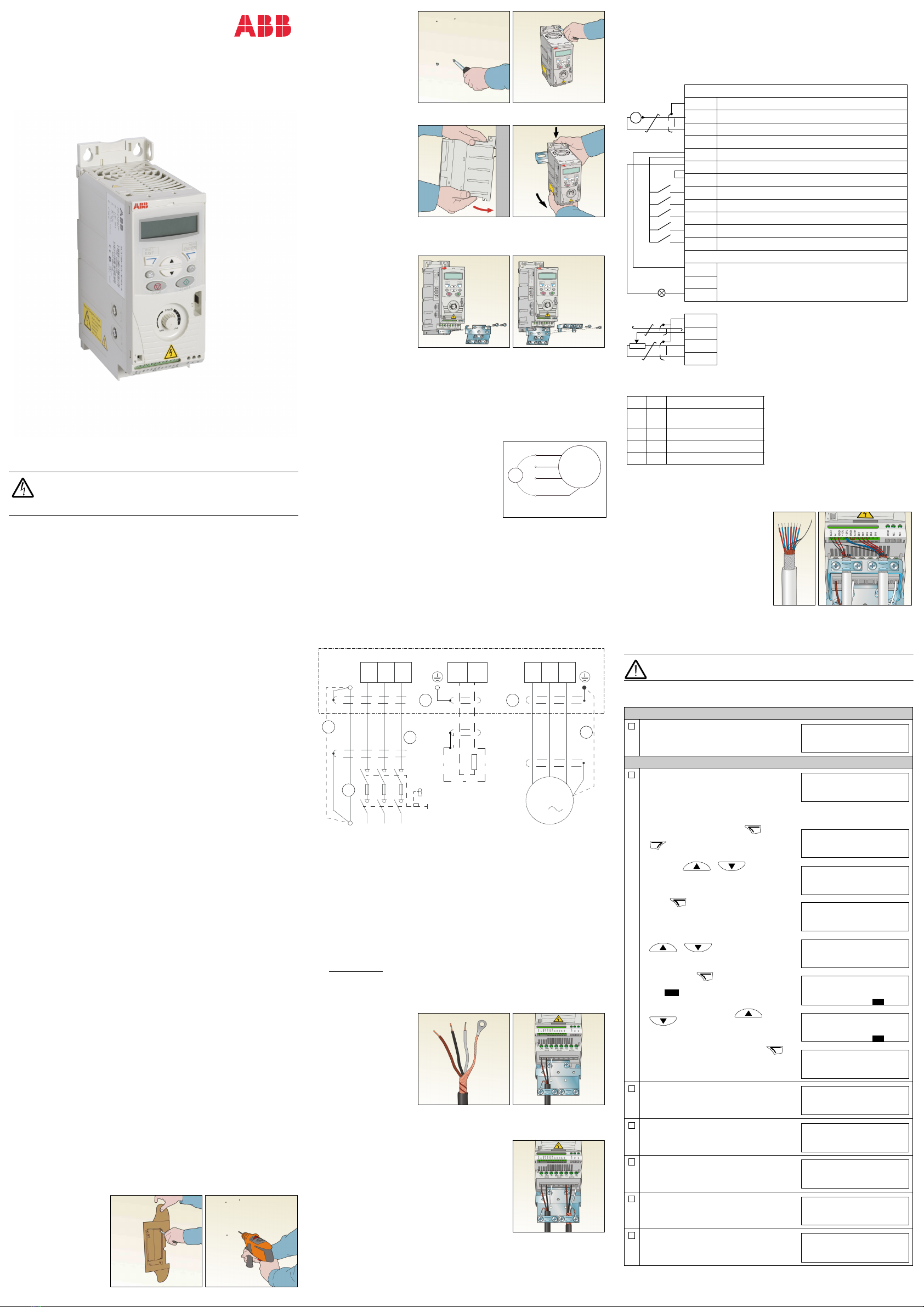

9. Connect the power cables

Connection diagram (shielded cables)

1. Two protective earth (ground) conductors. Drive safety standard IEC/EN/

UL 61800-5-1 requires two PE conductors, if the cross-sectional area of the

PE conductor is less than 10 mm2Cu or 16 mm2Al. For example, you can use

the cable shield in addition to the fourth conductor.

2. Use a separate grounding cable or a cable with a separate PE conductor for

the line side, if the conductivity of the fourth conductor or shield does not

meet the requirements for the PE conductor.

3. Use a separate grounding cable for the motor side, if the conductivity of the

shield is not sufficient, or if there is no symmetrically constructed PE

conductor in the cable.

4. 360-degree grounding of the cable shield is required for the motor cable and

brake resistor cable (if used). It is also recommended for the input power

cable.

5. 1-phase drives: Connect phase to U1 and neutral to V1. Keep W1

disconnected.

Connection procedure (shielded cables)

For the tightening torques, refer to

Terminal data for the power cables

.

1. Strip the input power

cable. Ground the

cable shield (if any)

under the grounding

clamp. Twist the cable

shield into a bundle,

mark it accordingly

and connect it to the

grounding terminal.

Connect other

grounding

conductors (PE) to

the grounding terminal. Connect the phase conductors to the U1, V1 and W1

terminals.

2. Strip the motor cable. Ground the cable shield

under the grounding clamp. Twist the motor

cable shield into a bundle, mark it accordingly

and connect it to the grounding terminal.

Connect the phase conductors to the U2, V2 and

W2 terminals.

3. If used, connect the brake resistor cable to the

BRK+ and BRK- terminals. Use a shielded cable

and ground the shield under the grounding

clamp.

4. Mechanically attach the cables on the outside of

the drive.

PE

PE

U1 V1 W1 BRK+ BRK-

U1 W1

M

3

U2 V2 W2

V1

(L) (N)

L1 L2 L3

ACS150

Optional brake

resistor

1

23

4 4

5

10. Connect the control cables

Do the connections according to the default control connections of the

application macro that you select.

Default I/O connections (ABB standard macro)

The diagram shows the I/O connections when parameter

9902

is set to 1

(ABB STANDARD).

Connection procedure

To prevent inductive coupling, keep the signal wire pairs twisted all the way up

to the terminals.

1. Strip the outer insulation of the

cable and ground the bare shield

360 degrees under the clamp.

2. Connect the conductors to the

correct control terminals.

3. For double-shielded cables, twist

also the grounding conductors of

each pair in the cable together and

connect the bundle to terminal SCR

(1).

4. Mechanically attach the control

cables on the outside of the drive.

11. Start up the drive

WARNING! Make sure that it is safe to start the motor. Disconnect the

motor from other machinery, if there is a risk of damage or injury.

Before you start up the drive, make sure that the installation is completed and

that you have the motor nameplate data available.

Power-up

Apply input power. The panel powers up into the

Output mode.

Entry of start-up data

Select the application macro (parameter

9902

)

according to how the control cables are

connected. The default value 1 (ABB STANDARD)

is suitable in most cases.

The general parameter setting procedure in the Short parameter mode is described

below.

1. To go to the Main menu, press if the

bottom line shows OUTPUT. Otherwise press

repeatedly until you see MENU at the

bottom.

2.Press keys /until you see

“PAr S” on the display.

3.Press . The display shows a parameter

of the Short parameter mode.

4.Find the appropriate parameter with keys

/.

5.Press and hold for approximately two

seconds until the parameter value is shown

with under the value.

6.Change the value with keys /

. The value changes faster while you

keep the key pressed down.

7. Save the parameter value by pressing .

Enter the motor data from the motor nameplate.

• motor nominal voltage (

9905

)

• motor nominal current (

9906

)

• motor nominal frequency (

9907

).

Set the maximum value for external reference

REF1 (

1105

).

Set constant speeds 1, 2 and 3 (

1202, 1203, 1204)

.

Set the minimum value (%) corresponding to the

minimum signal for AI(1) (

1301

). Typical settings:

0% for 0 … 20 mA (or 0 … 10 V) signal.

20% for 4 … 20 mA (or 2 … 10 V) signal.

Set the maximum limit for the drive output

frequency (

2008

). This is equal to power line

frequency, typically (50 or 60 Hz).

I/O connection 4)

SCR Signal cable shield (screen)

AI Frequency reference: 0 … 20mA

GND Analog input circuit common

+10V Reference voltage: +10V DC, max. 10mA

+24V Auxiliary voltage output: +24V DC, max. 200mA

GND Auxiliary voltage output common

COM Digital input common

DI1 Stop (0) / Start (1)

DI2 Forward (0) / Reverse (1)

DI3 Constant speed selection 1)

DI4 Constant speed selection 1)

DI5 Acceleration and deceleration selection 2)

Relay connection 5)

COM Relay output

No fault [Fault (-1)]

NC

NO

Alternative connection for AI(1):

SCR If you use a voltage signal instead of current, switch the IU

selector to U (0 … 10 V voltage signal), and use this

connection instead the one shown above.

AI

GND

+10V

1) See parameter group 12 CONSTANT

SPEEDS:

2) 0 = ramp times according to parameters

2202

and

2203

. 1 = ramp times according to

parameters

2205

and

2206

.

3) 360 degree grounding under a clamp.

4) Tightening torque: 0.22 N·m (2 lbf·in)

5) Tightening torque: 0.5 N·m (4.4 lbf·in)

DI3 DI4 Operation (parameter)

0 0 Set speed through

integrated potentiometer

10Speed1(

1202

)

01Speed2(

1203

)

11Speed3(

1204

)

3)

1…10kohm