ABB TMC User manual

Other ABB Monitor manuals

ABB

ABB 8242 User manual

ABB

ABB CL Series Instructions for use

ABB

ABB IRC5 Compact User guide

ABB

ABB 8232 User manual

ABB

ABB M2238 Series User manual

ABB

ABB Industrial enabled Analyzer 9437 User manual

ABB

ABB AV410 User manual

ABB

ABB 7835 User manual

ABB

ABB 9438 User manual

ABB

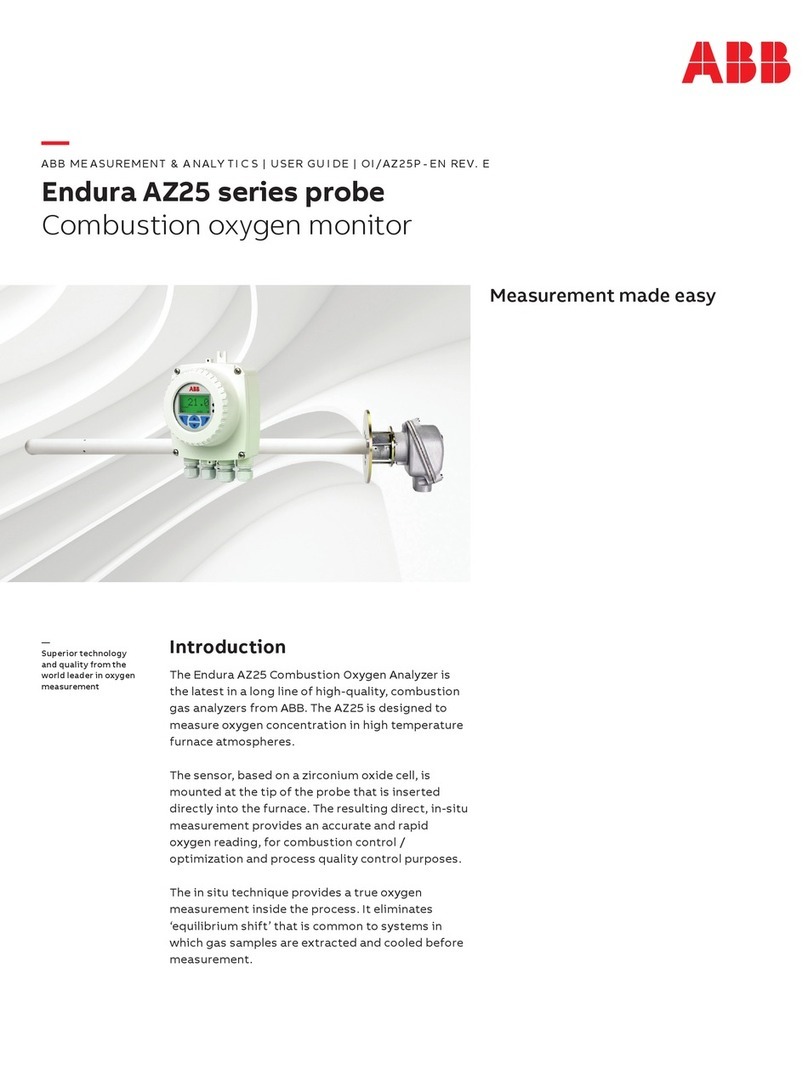

ABB Endura AZ20 series Operating manual