The Solo Pure Water System Operation and Maintenance Manual - 5

12. Troubleshooting

11. Storage

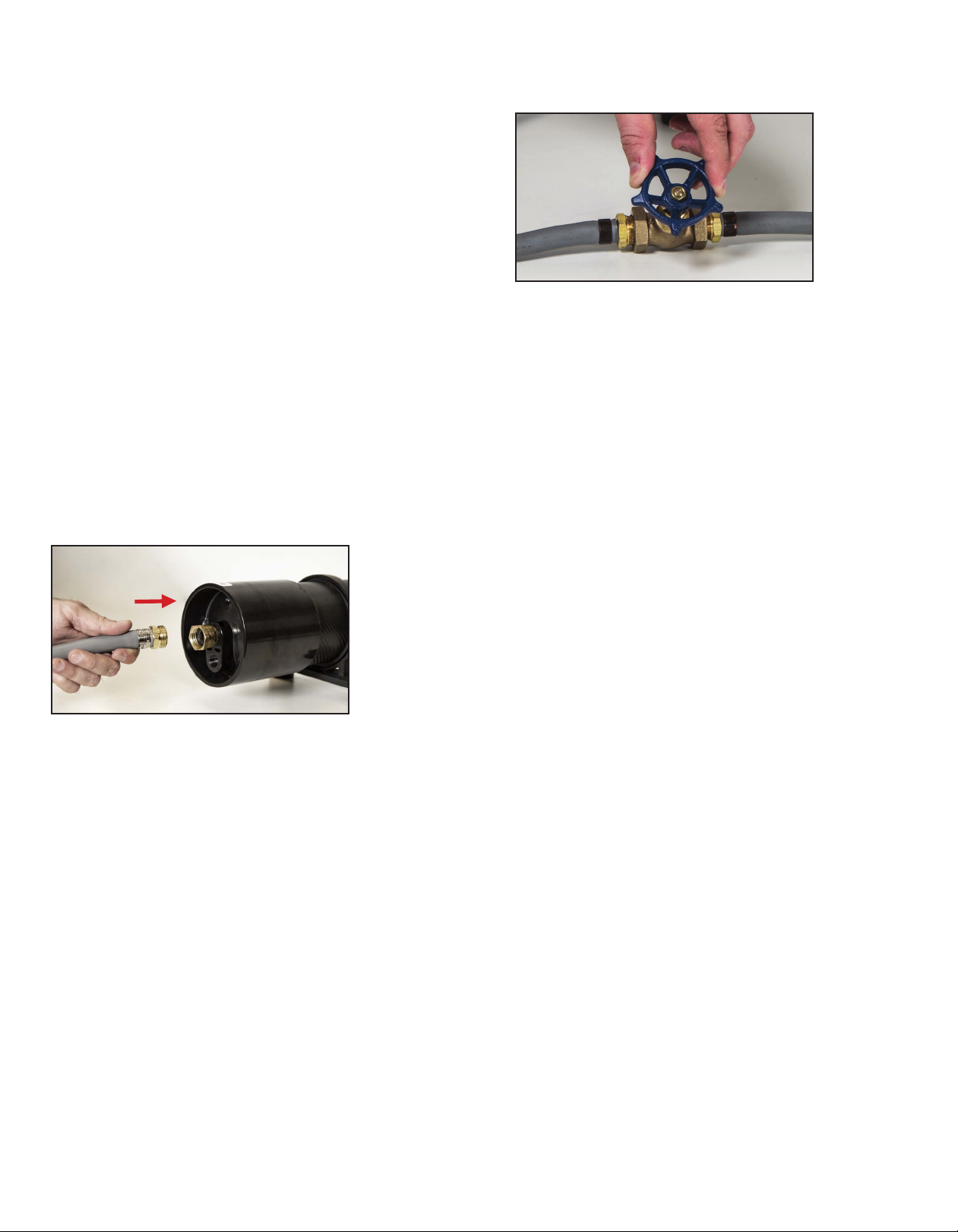

1. Low tap pressure is one of the most common causes

of low ow of pure water. Source water pressure is the

primary driver of system performance. Even sources that

appear to have plenty of ow out of the tap may not have

enough PSI to push water through the RO membrane.

Ensure that the tap pressure is sucient using a pressure

gauge ( TA-PG Sold Separately). Trying a dierent

source may lead to better performance. Also check all

hoses (incoming and outowing) for kinks or blockages,

Do not allow the lters or system to freeze. Failure to

do so could result in damage to your Solo system. Do

not allow the RO lter to dry out. A dry RO membrane

will develop cracks which allow more dissolved solids

to pass through. abc recommends that you run water

through your system once every 2 weeks or so, not only

to help keep your lters moist but to also wash out any

microorganisms that might try to grow in your lters. The

Solo needs to stay moist but does not need to be full of

water.

abc strongly recommends ushing out the system once

every 2-4 weeks to ensure the maximum lifespan of the

lter. This will ensure that the lter membrane does not

dry out and will reduce the chance that biological growth

will foul the lter elements while in storage.

If periodic ushing is not feasible, we recommend that

users seal the system by attaching the bypass hose to

the system inlet and then attach a closed shut o valve

to the system outlet. This will reduce the chance that

the lter dries out when in storage. Wrap lters tightly in

plastic wrap or plastic bags and then seal with tape.

Do not allow the system to dry out.

Store system indoors over the winter. Do not allow it to

freeze. Failure to do so could result in damage to your

Solo system. After the system has been stored this way,

it will need to be ushed thoroughly before use. Leaving

the system sealed for extended periods of time can

lead to biological fouling, which is why we recommend

periodic ushing.

Storage - Short Term (2-4 Weeks)

Low Pure Water Flow Out Of The Brush

Storage - Long Term (Winterizing)

especially hose reels that are wound too tight. Trying

a larger diameter hose (½”) or a shorter hose length

between the system and the tap can also improve ow.

Adding a pump, such as the ABC boost pump (WF1000-

BP Sold Separately), can help compensate for low source

pressure. Do not exceed 120 PSI when using a pump.

2. Mineral fouling of the RO membrane will lead to

reduced pure water production from your system.

Processing water through the RO membrane without

enough (or any) bypass ow will lead to increasing

mineral concentration within the RO housing. In minor

cases, this will result in a temporary drop in production

from the RO membrane. Flushing the excess minerals

from the housing will return the lter to normal production

rates if no fouling has occurred. In extreme cases the

mineral buildup will permanently reduce the ow rate of

the lter. These cases can only be xed by replacing the

lter.

3. Biologic fouling is another potential cause of reduced

pure water production from the RO lter. Algae, bacteria

and fungi can land and grow on the surface of the RO

membranes. These organisms eventually block o

pores in the membrane leading to reduced production

levels. Letting lters sit for long periods of time without

running any water through them increases the chances

of biological fouling. After long term storage, running a

series of long ushes will often return the RO membrane

to normal production levels. Fully open the bypass hose

and then shut o your system’s pure water outlet. Run

it like this for 10 minutes and then open your pure water

outlet and restrict your bypass to its normal running

setting. Test the water coming out of the RO (not the

bypass water). If levels are as expected, use the system

like normal. Doing this ushing process 2 or 3 times may

be required to return to normal production levels.

4. Expect decreased production rates when running your

RO with colder source water. The ideal temperature for

source water is 77°F. You can expect around half the ow

for water at 50 degrees that you would get at 75 degrees,

even if both sources are at the same PSI. Use your TDS

meter to measure the temperature of your source water

to determine if this is the cause of lowered ow rates.

5. Leaks in the system and the pole tubing can release

pressure and take ow away from the jets in your brush.

A couple of small leaks in the pure water lines can cut

pressure to the jets in half. Read the “leaks” section

below for more information on eliminating leaks in the

system.