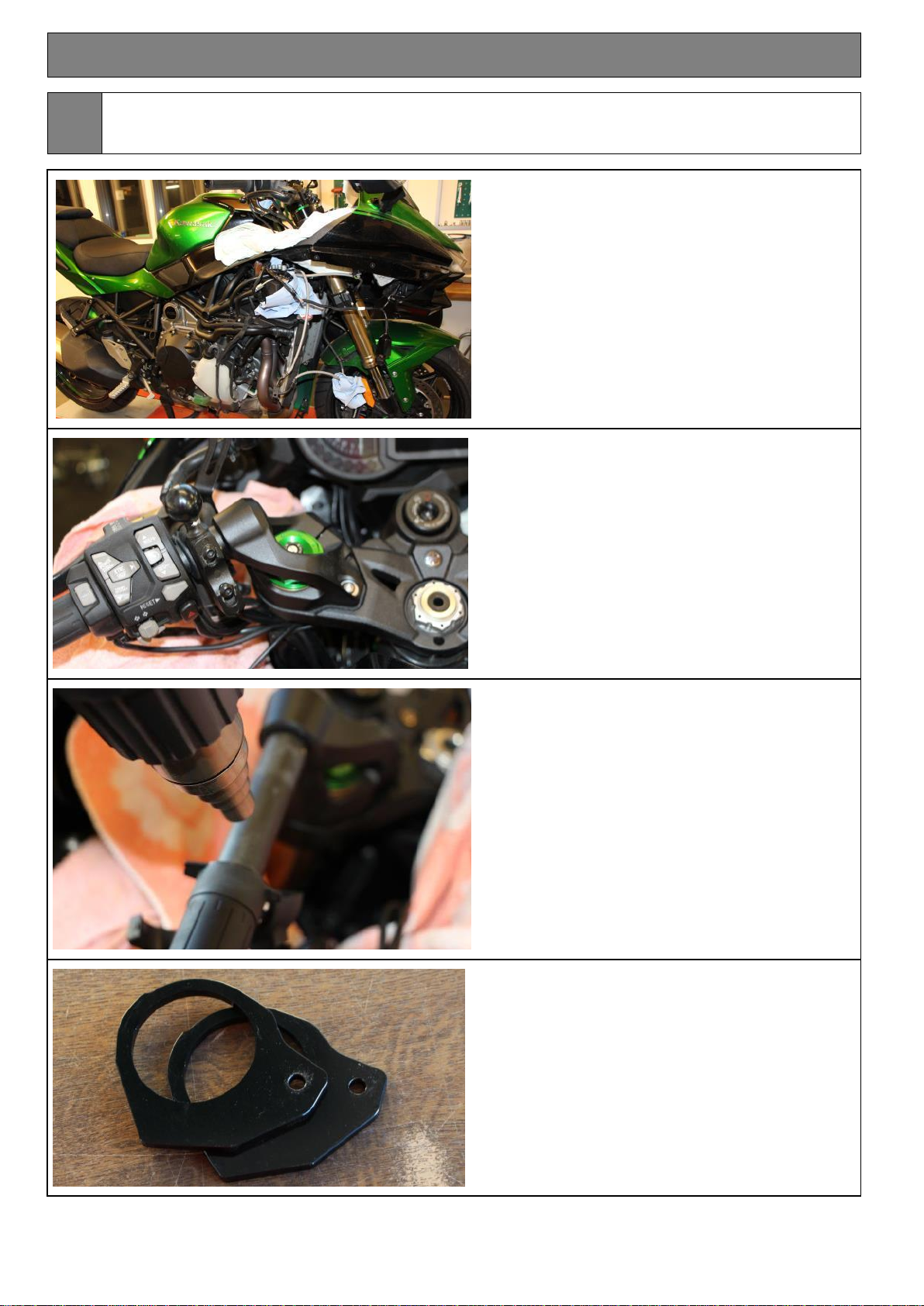

Installation manual Superbike™for Kawasaki Ninja H2 SX 2018-

• Revision: 00 • 13/02/2019 • © ABM Fahrzeugtechnik GmbH Page 2 of 8

Caution

Important safety advice:

Work undertaken on the steering and the brake system poses a safety risk. This work may only

be carried out by appropriately qualified personnel. Faulty work can have serious consequences

and may pose a threat to life and health. Only undertake this installation if you are sufficiently

qualified and have an official workshop manual as well as all relevant service notifications

available. Otherwise, we strongly recommend that the installation is carried out or at least

checked in a specialist workshop.

Brake fluid is toxic and may damage the surfaces of the fairing and other components. Use

suitable means to protect all parts against damage. Please observe the safety information of the

brake fluid manufacturer.

Use only fresh brake fluid taken from a sealed container. Always use new sealing rings which

comply with the specifications of the brake lines manufacturer. Never combine copper sealing

rings with aluminium fittings.

ABS brake systems should be bled solely in a garage authorised by the vehicle manufacturer.

Any work in relation to the installation, removal and tightening torque of original parts should

always be carried out in compliance with the workshop manual.

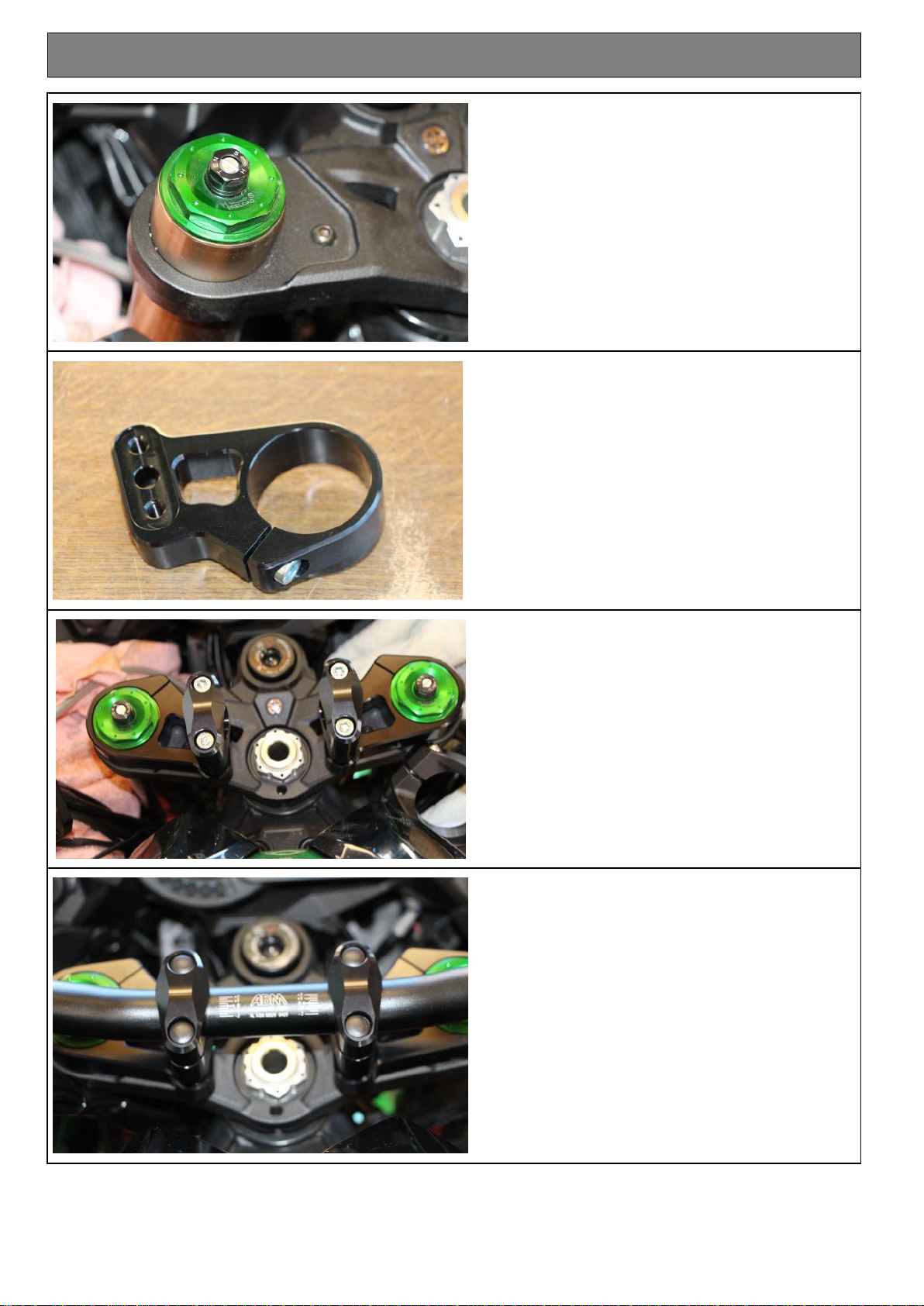

To ensure safe function, it is essential that all contact areas of clamp connections are clean, dry

and damage free during installation. Important: Make sure that nothing gets onto these contact

surfaces which decreases friction

(e.g. oil, silicone, care products, etc.).

It is essential that all clamp screws are tightened with the specified torque. The torque

specifications refer to dry screws and threads. The tight fit of all screw connections must also be

checked at every inspection.

It is your responsibility to check the product regularly and to determine if a service or

replacement is required.

Please remember that the yokes are safety-relevant parts of your vehicle. Check the handlebar

as well as the risers and yokes after a fall or collision and replace them completely at the

slightest indication of damage.

Never tie down the vehicle at the handlebar.

The Superbike Kit requires registration.

This product has been designed for a standard vehicle. ABM® Fahrzeugtechnik GmbH makes no

warranty or guarantee of any kind for any damages whatsoever arising out of the combination

with other component parts not tested by ABM, as a consequence of improper installation or

inadequate maintenance.