LOCK ON/OFF

The lock mode is useful for continuous monitoring of

temperatures. Scroll through MODE until the icon

flashes and press the Up or Down buttons to turn on or

off the LOCK mode. Press the measurement trigger to

confirm the lock measurement mode.

‘LOCK on’ allows for continuous measurement reading,

beyond the 8-second automatic time-off.

Continuous measurements are taken without the trig-

ger being pressed. Pressing the trigger will cancel the

HOLD command. [The IR Thermometer will continuously

display the temperature until the measurement trigger

is pressed again.]

“Lock off’ means the IRT2 will automatically turn off

after 8 seconds on non-use.

Emissivity can be adjusted while in ‘LOCK on’ mode by

pressing the Up or Down button.

ALARM – HIGH & LOW TEMPERATURE

The High / Low Alarm settings allow for the audio and

visual alarm turned on or off and for the high and low

temperatures to be adjusted according to your needs.

The audio alarm is a continuous beep. The visual alarm

is a flashing red backlight and flashing icon for a

high reading, or icon for a low reading.

9

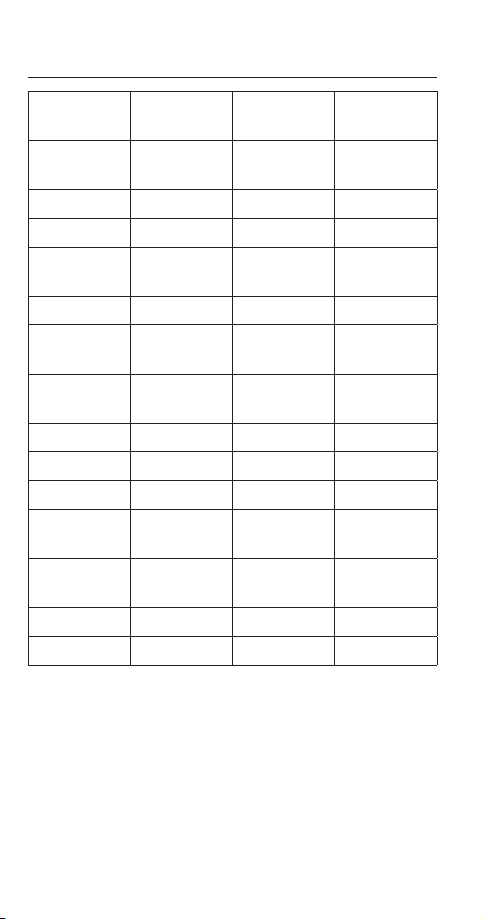

MODE

SCAN

MINMAX LOG AVG

=

C

o

F

o

HL

RT

MODE

SCAN

MINMAX LOG AVG

=

C

o

F

o

HL

RT

MODE

SCAN

MINMAX LOG AVG

=

C

o

F

o

HL

RT

MODE

SCAN

MINMAX LOG AVG

=

C

o

F

o

HL

RT