PAGE 8

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 45302WK 24/02/17

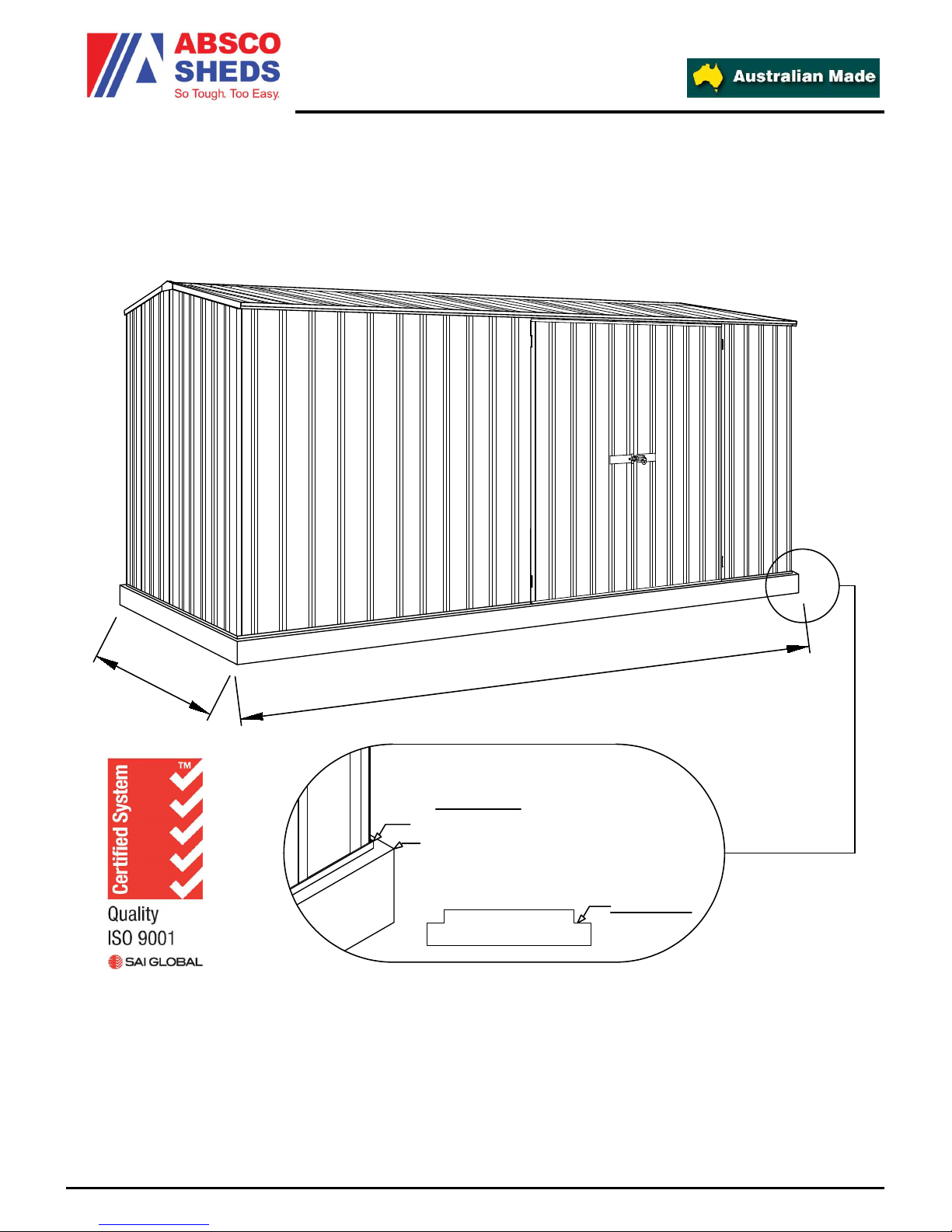

Absco Workshop Shed Model:

45302WK

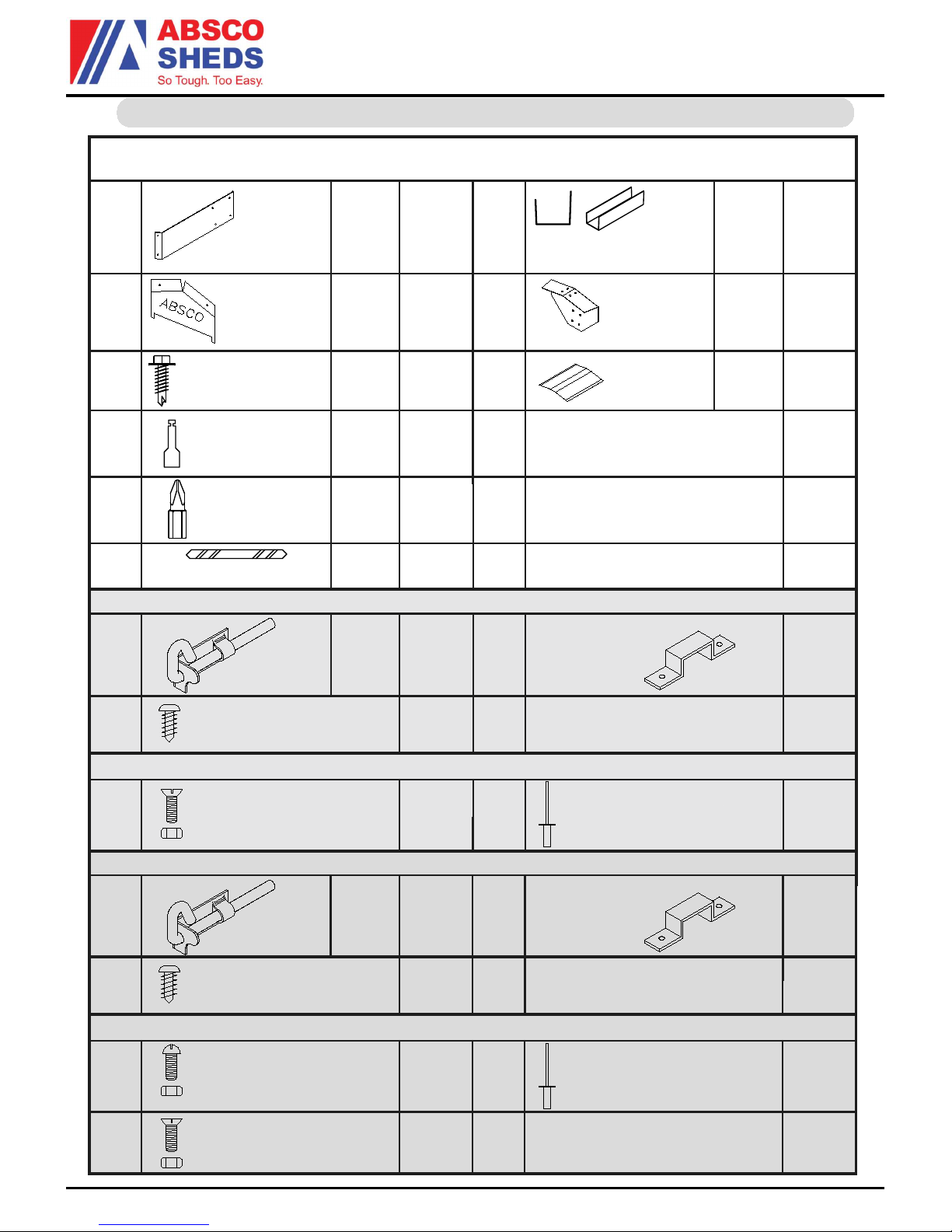

20mm

15mm

QTY = 10pcs.

CHANNEL

(0.79")

(0.59")

PUSH

PUSH

CHANNEL

CSJ

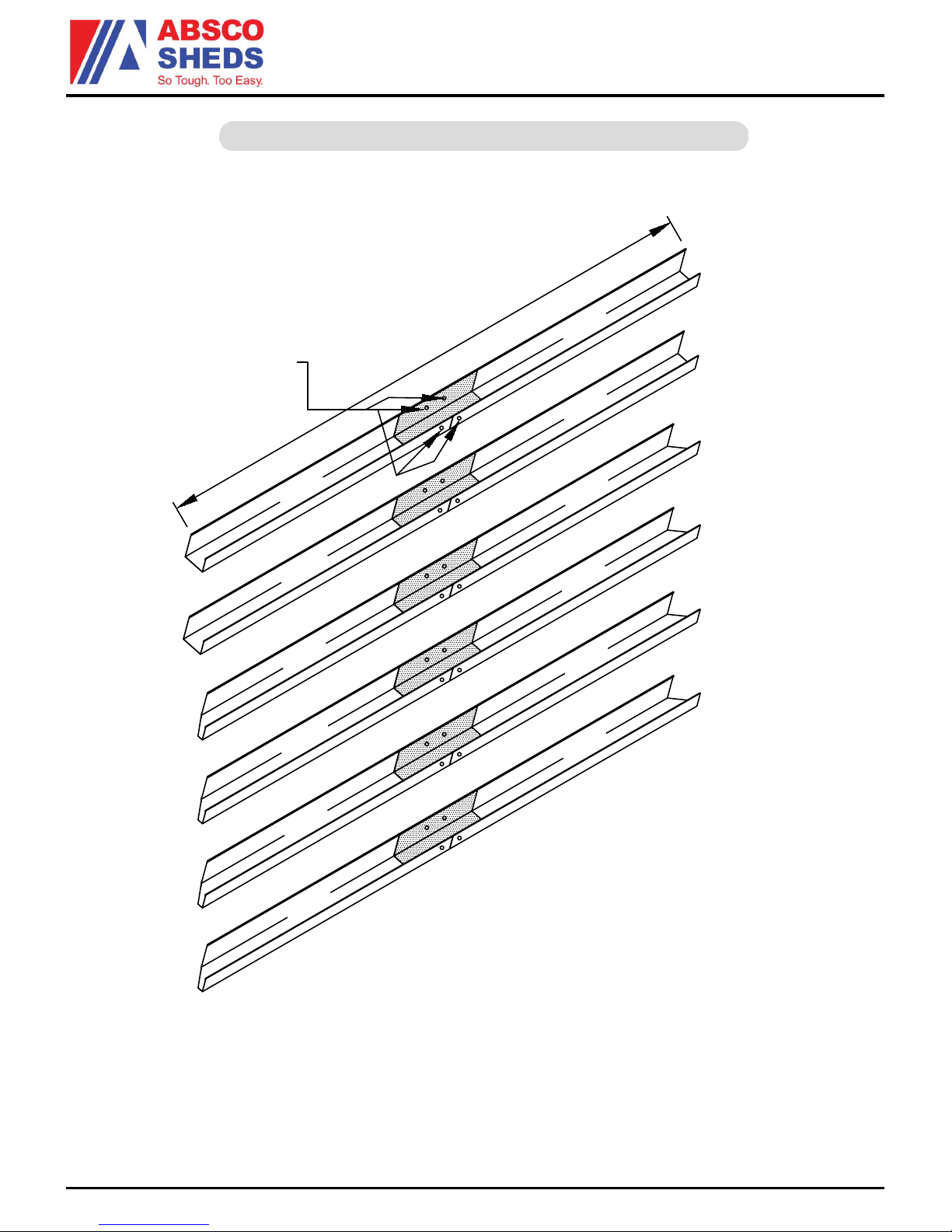

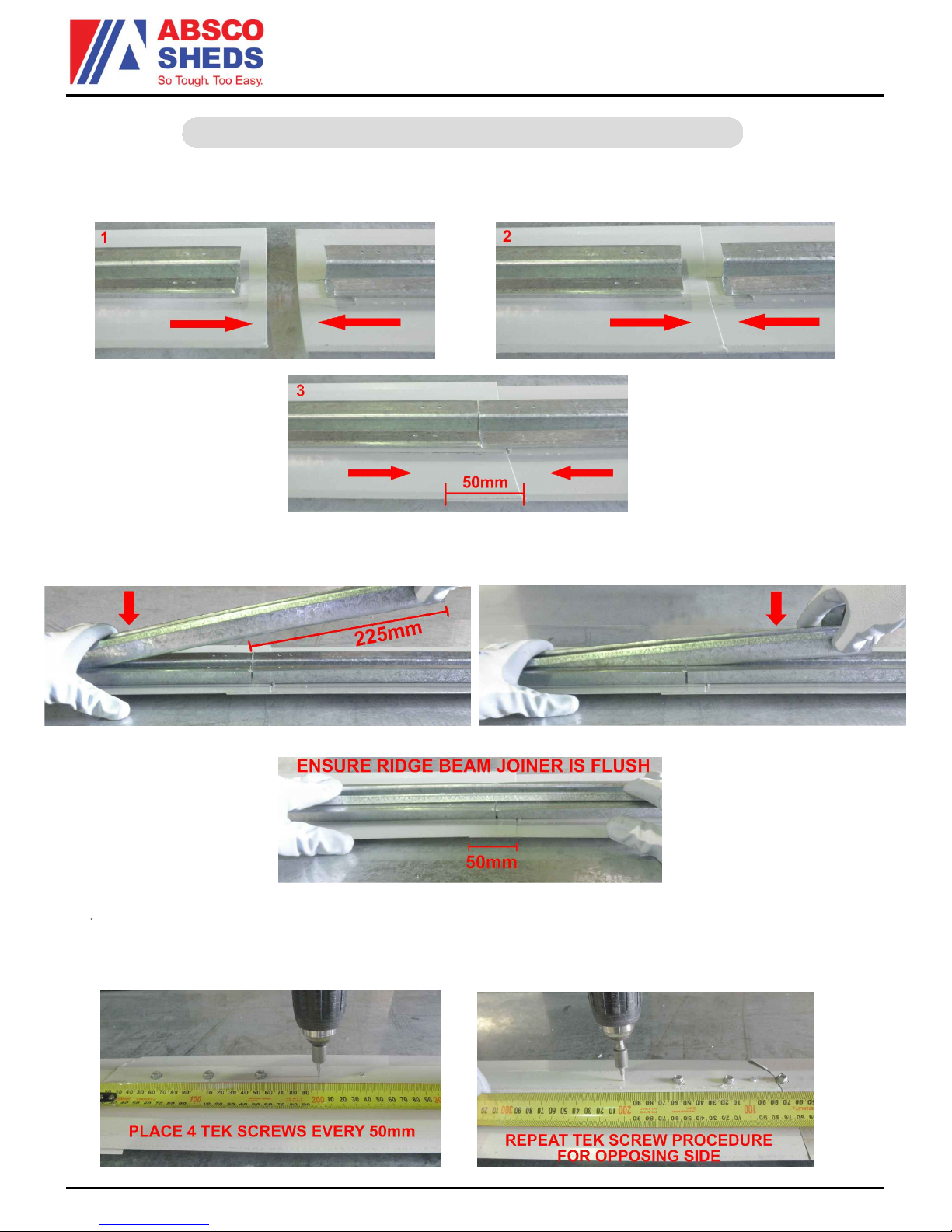

INSTRUCTIONS FOR JOINING SPLICED CHANNELS

CSJ

CSJ

HIGH-SIDE

CHANNEL

LOW-SIDE

CHANNEL

CSJ

CSJ

CSJ

= =

= =

==

=

=

STEP 1.

Position the channels and the CSJ

joiner channel so the center of the

CSJ is in line with the end of each

channel to be joined together.

STEP 2.

Join the first channel to the CSJ by inserting the center

of the CSJ (on an angle) to the end of the channel

where the JOIN>> text is marked. Push down one side

of the CSJ until you hear a 'click'.

STEP 3.

Join the second channel to the CSJ

by positioning the <<JOIN end of the

channel at the center of the CSJ

(on an angle). Push the CSJ into

the channel until you here a 'click'.

=

The joined channels should now

look like the picture above with the

CSJ positioned equally inside of the

joined channels.

FINISHED CHANNEL

=

NOTE: THE TEXT MARKED ON ALL PARTS MUST BE SHOWN ON THE SAME SIDE AS EACH OTHER.

JOIN>> <<JOIN JOIN>>

JOIN>> SJ

JOIN>>

<<JOIN

JOIN>> <<JOIN

J

CSJ

DRILL 4mm (0.16") x 3mm (0.12")

(2 PER A SIDE) HOLES TO

SECURE SECTIONS TOGETHER.

(THESE SCREWS MAY HAVE TO

BE TEMPORARILY REMOVED

AND REPLACED DURING LATER

ASSEMBLY)