Configuration, Calibration, Changing Pass Code F20B, F22B

Calibration Preparation

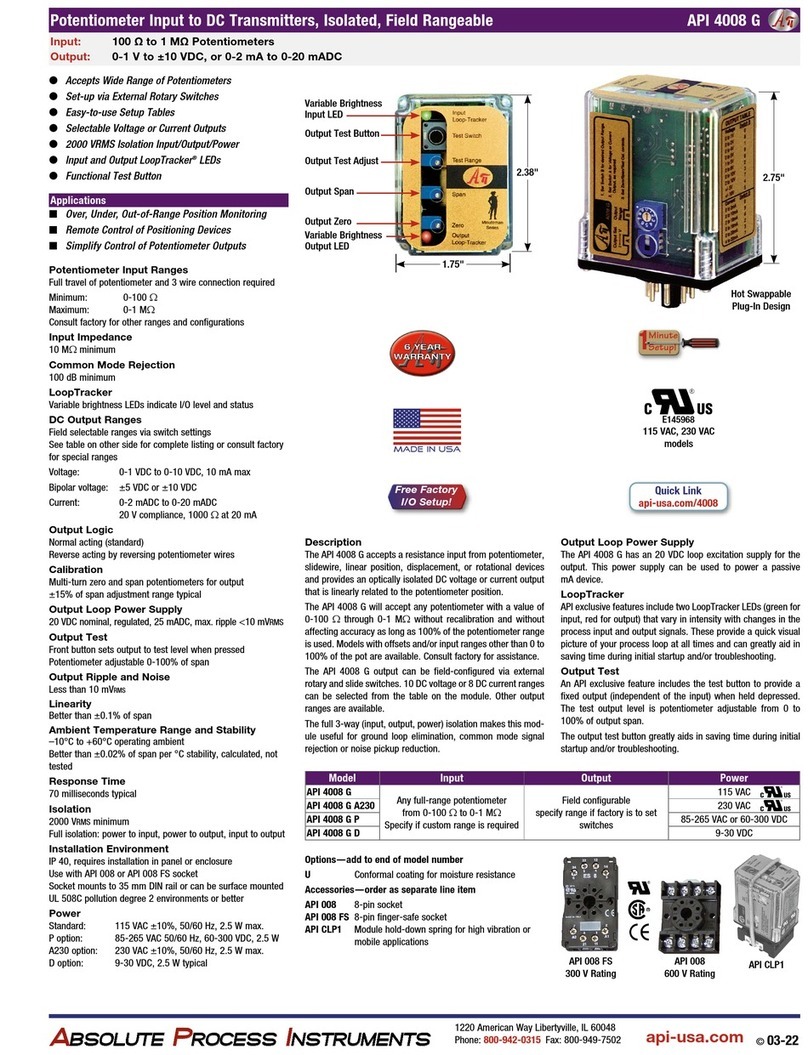

Gauges are factory calibrated at approximately 23°C using NIST

traceable calibration equipment. Calibration is not required before

using the gauge. Calibration intervals depend on your quality stan-

dards, but annual re-calibration is customary. Calibration should

only be performed by qualified individuals using appropriate cali-

bration standards and procedures.

The calibration system must be able to generate and measure

pressure/vacuum over the full range of the gauge and should be

at least four times more accurate than the gauge being calibrated.

A vacuum pump able to produce a vacuum of 100 microns (0.1 torr

or 100 millitorr) or lower is required for vacuum gauges.

Install fresh batteries and allow the gauge to acclimate to ambient

temperature for 20 minutes.

Entering Calibration Mode

With the gauge off, press and hold the tbutton. Then press the

Power button. Release all buttons when the display indicates CAL.

The display begins by indicating the full-scale positive pressure

rating of the gauge in the engineering units as configured by the

factory, and then shows all display.

Before the gauge enters the Calibration Mode, the display ini-

tially indicates _ _ _ _ with the first underscore blinking, and with

CALPC (calibration pass code) on the lower display.

Enter the 3510 pass code as described in the Configuration Pass

Code section.

Calibration Mode

The gauge enters and remains in the Calibration Mode until

restarted manually or power is removed. Features not related to

calibration are disabled and compound range models are set for the

same engineering units for pressure and for vacuum.

The calibration may be performed in any of the available engineer-

ing units as well as percent (PCT).

For greatest accuracy, use the sand tbuttons to select engi-

neering units for calibration with highest resolution (highest number

of display counts).

Press and release the Power button when the appropriate engineer-

ing units are displayed. Suggested units are listed below.

Sensor Suggested units for calibration

3 PSI 6.920 FTH2O

5 PSI 5.000 PSI

15 PSI 775.7 MMHG or TORR

30 PSI 61.08 INHG

50 PSI 50.00 PSI

60 PSI 60.00 PSI

100 PSI 7.031 KG/CM2

200 PSI 407.2 INHG

300 PSI 610.8 INHG

500 PSI 3447 KPA

1000 PSI 6895 KPA

2000 PSI 4613 FTH2O

3000 PSI 6920 FTH2O

5000 PSI 5000 PSI

The display will then indicate the currently applied pressure in the

engineering units selected for calibration.

sand tButton Operation

Each time one of the sor tbuttons is pressed and released

quickly, a small change is made to the digitized pressure signal. It

may take more than one of these small changes to result in a single

digit change on the display.

To make larger changes, press and hold the appropriate button.

After about one second, the display will begin to change continu-

ously. Release the button to stop. Then make fine adjustments by

pressing and quickly releasing the buttons as previously described.

Gauge Reference Pressure Gauges

Apply zero pressure by venting the gauge port to atmosphere. The

character display will alternate between ZERO and CAL. Adjust

for a display indication of zero using the sand tbuttons.

Apply full-scale pressure. The character display will alternate

between +SPAN and CAL. Adjust for a display indication of

full-scale pressure using the sand tbuttons.

Apply 50% full-scale pressure. The character display will alternate

between +MID and CAL. Adjust for a display indication equal to

50% of full-scale pressure using the sand tbuttons.

Gauge Reference Vacuum Gauges

Apply zero pressure by venting the gauge port to atmosphere. The

character display will alternate between ZERO and CAL. Adjust

for a display indication of zero using the sand tbuttons.

Apply full-scale vacuum. The character display will alternate

between +SPAN and CAL. Adjust for a display indication of

full-scale vacuum using the sand tbuttons.

Apply 50% full-scale vacuum. The character display will alternate

between +MID and CAL. Adjust for a display indication equal to

50% of full-scale vacuum using the sand tbuttons.

Absolute Reference Gauges

Apply full vacuum to the gauge. The character display will alternate

between ZERO and CAL. Press the sand tbuttons to obtain

a display indication of zero.

Apply full-scale pressure. The character display will alternate

between +SPAN and CAL. Press the sand tbuttons to obtain

a display indication equal to full-scale pressure.

Apply 50% of full-scale pressure. The lower display will alternate

between +MID and CAL. Press the sand tbuttons to obtain

an indication equal to 50% of full-scale pressure.

Compound and Bipolar Gauges

In addition to the steps described above for pressure gauges, apply

full-scale vacuum. The character display will alternate between

-SPAN and CAL. Adjust for a display indication of actual applied

vacuum using the sand tbuttons.

For bipolar and –30.00inHg/+15.00psig compound range models

only, apply 50% full-scale vacuum. The character display will

alternate between -MID and CAL. Adjust for a display indication

equal to 50% of full-scale vacuum using the sand tbuttons.

Save Calibration

Press and hold the Power button until the display indicates - - - -

then release the button to store the calibration parameters in non-

volatile memory and restart the gauge.

Verify the pressure indications at 0%, 25%, 50%, 75% and 100%

of full scale.

Note: it is possible to do a zero calibration without affecting other

calibration points. After Zero calibration, press and hold the Power

button until the display indicates - - - - then release the button to

store the new zero point calibration and restart the gauge.

User-Defined Pass Code Configuration

The factory default pass code 3510 may be changed to a different

value for configuration and/or calibration.

Configuration Pass Code

With the unit off, press and hold the sbutton to view and/or

change the user configuration pass code. Then press the Power

button. Release all buttons when the display indicates CFG.

Calibration Pass Code

With the unit off, press and hold the tbutton to view and/or

change the user calibration pass code. Then press the Power but-

ton. Release all buttons when the display indicates CAL.

Change Pass Code Mode

Before the unit enters the view or change pass code mode, the

display initially indicates _ _ _ _ with the first underscore blinking,

and with CFGPC or CALPC on the character segments.

Note: The unit will automatically revert to normal operation if no

buttons are operated for approximately 15 seconds. To cancel and

return to normal operation, press and release the Power button

without entering any pass code characters.

Enter access code 1220:

Use the sand tbuttons to set the left-most digit to 1.

Press and release the Power button to index to the next position.

The 1 will remain, and the second position will be blinking.

Use the sand tbuttons to select 2.

Press and release the Power button to index to the next position. 1

2 will remain, and the third position will be blinking.

Use the sand tbuttons to select 2.

Press and release the Power button to index to the next position. 1

2 2 will remain, and the fourth position will be blinking.

Use the sand tbuttons to select 0.

Press and release the Power button to proceed.

Note: If an incorrect access code was entered, the gauge will return

to the start of the access code entry sequence.

Change Pass Code

Once the access code has been entered correctly, the display will

indicate the existing user-defined pass code with CFGPC or

CALPC on the character segments.

Press the sor tbutton to select the first character of the new

pass code.

When the correct first character is being displayed, press and

release the Power button to proceed to the next pass code character.

Repeat above until the entire pass code is complete.

To exit the User Defined Pass Code change mode, press and hold

the Power button.

Release the button when the display indicates - - - - to restart

the gauge.

F20B Memory—M4 Versions

The M4 version allows recording pressure readings of up to four

tires. While in the memory mode the peak reading is captured.

The number 1 is shown on the upper

display. The lower display will indicate the

label for memory 1.

Use the sand tbuttons to select MEM 1,

or LF, RF, RR, or LR. The labels can be set

up in any order.

When the desired label for memory 1 is

displayed, press the Power button.

Repeat the steps for the other memory

locations. When the desired label for memory

4 is displayed, press and release the Power

button to save the user configuration and

restart the gauge.

I

Mem I

- or -

I

LF

ts

Zero/Clear Memory

ts

Zero/Clear Memory

*

*

*

F20B Memory—M8 Versions

The M8 version allows recording of up to eight pressure readings.

While in the memory mode the peak reading is captured.

The eight memory labels can be set for MEM

1 through MEM 8, or for 4 tires and 4 tire

inner liners used for auto racing.

After auto shutoff time selection, the number

1 is on the upper display. The lower display

will indicate the label for memory 1.

Use the sand tbuttons to select MEM 1,

or one of the 8 memory labels: LF, LF IN, RF,

RF IN, RR, RR IN, LR, LR IN. The labels can

be set up in any order.

When the desired label for memory 1 is dis-

played, press and release the Power button.

Repeat the steps for the other memory

locations. When the desired label for the last

memory location is displayed, press and release the Power button

to save the user configuration and restart the gauge.

I

Mem I

I

LF IN

ts

Zero/Clear Memory

*

*

- or -

ts

Zero/Clear Memory

*

F22BBL Backlight Time Selection

The lower display will indicate BL if the

display backlight is enabled or NO BL if

display backlight is disabled.

Use the sbutton to enable backlighting

and the tbutton to disable backlighting.

Press the power button to save the setting.

If NO BL was selected the user setup is

complete and the gauge will restart and be

ready for use with the new configuration.

If BL was selected the current backlight

auto shutoff time is displayed in minutes.

1 minute is the factory default.

Use the sand tbuttons to select the

minutes for backlight shutoff time.

A setting of zero disables the auto shutoff timer and the backlight

will be on whenever the gauge is on. The maximum setting is 255

minutes. The gauge auto shutoff time will override the backlight

time. When the desired time is displayed, press and release the

power button to save your selection and restart the gauge.

ts

Zero/Clear Memory

*

*

BL

- or -

No BL

ts

Zero/Clear Memory

2

BLTMR

*

*

- or -

cecomp.com

1220 American Way Libertyville, IL 60048

800-942-0315

CECOMPDiv. of

AABSOLUTEBSOLUTE PPROCESSROCESS IINSTRUMENTSNSTRUMENTS

Battery Replacement

A low battery indication will be shown in the upper left-

hand corner of the display when the battery voltage falls

sufficiently. The batteries should be replaced soon after

the indicator comes on or unreliable readings may result.

1. Remove the 6 Phillips screws on the back of the unit.

2. Lift up the battery holder.

3. Remove batteries by lifting up the

positive end of the battery (oppo-

site the spring) taking care not to

bend the battery holder spring.

4. Discard old batteries properly,

do not discard into fire, sources

of extreme heat, or in any haz-

ardous manner.

5. Always replace both batteries at

the same time with high quality

alkaline batteries.

6. Install batteries with correct orientation. Incorrect polarity will

damage the gauge. The negative (flat) end of each battery

should be inserted first facing the battery holder spring.

7. Replace battery holder face down being careful not to pinch the wires.

8. Replace the back cover, including the rubber gasket and rein-

stall the six screws.

Lift up the

battery holder

Disposal of Electrical & Electronic Equipment Applicable

in the European Union and other European countries.

This product should not be treated as household waste

when you wish to dispose of it. Please contact your local

waste disposal authority for information and collection

location for recycling electrical and electronic equipment.

You may also return this product via pre-paid shipping

to Absolute Process Instruments or your supplier for proper disposal.