1.0 Index

1.0 Index ................................................................................................................................. 2

2.0 Item List............................................................................................................................. 3

3.0 Specification ...................................................................................................................... 4

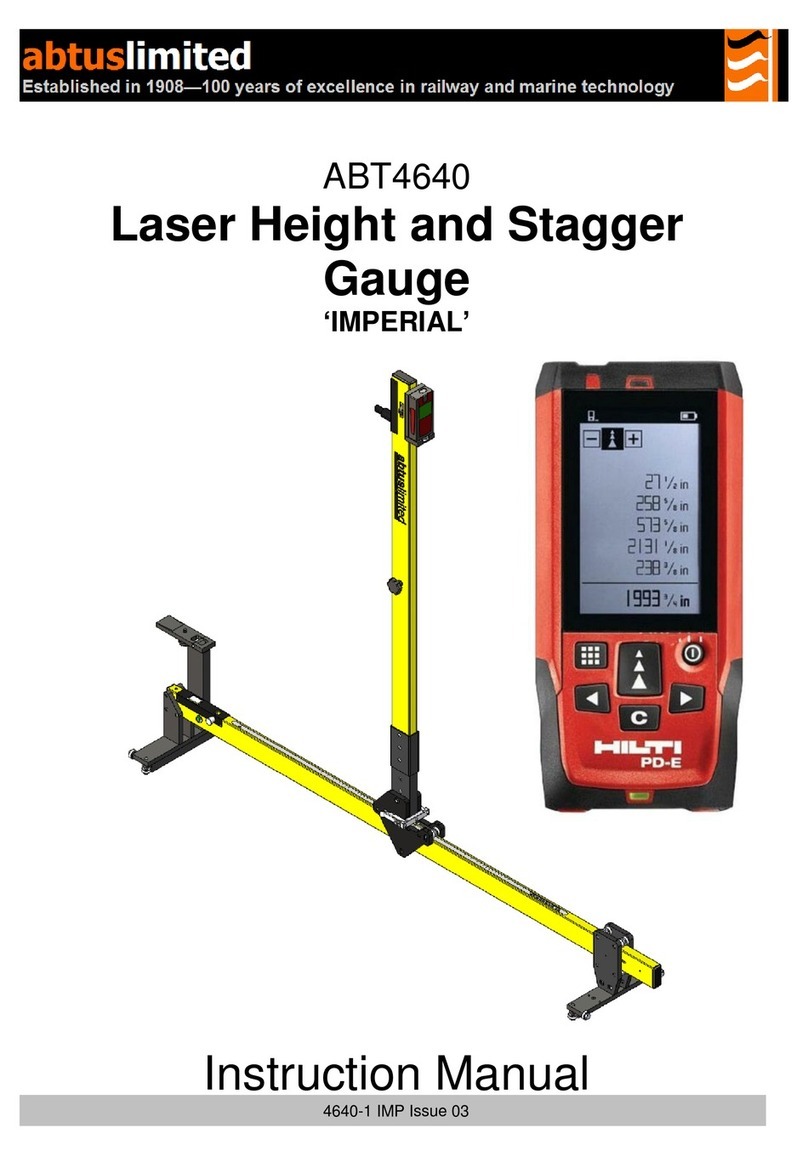

4.0 Getting Started................................................................................................................... 5

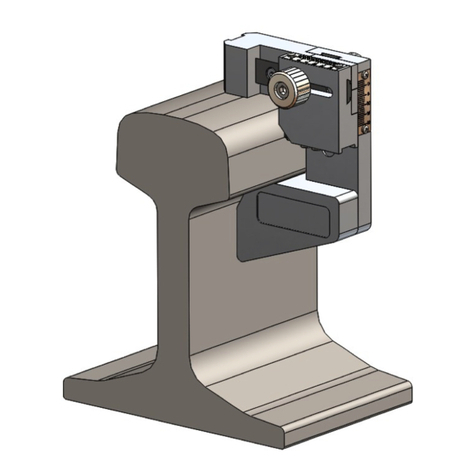

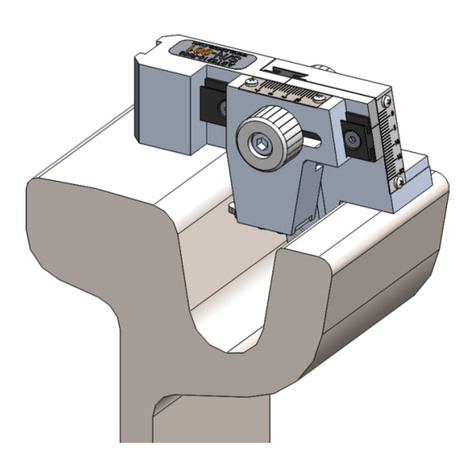

4.1 Overview ....................................................................................................................... 5

4.2 Assembly....................................................................................................................... 6

5.0 Maintenance .................................................................................................................... 12

5.1 Every 3 Months............................................................................................................ 12

5.2 Annual......................................................................................................................... 12

6.0 Measurement Characteristics ........................................................................................... 12

6.1 Cyclic Top Faults ......................................................................................................... 12

6.2 Gauge ......................................................................................................................... 13

6.3 Super-Elevation........................................................................................................... 13

6.4 Twist ........................................................................................................................... 13

6.5 Distance...................................................................................................................... 14

6.6 GPS ............................................................................................................................ 14

7.0 Transportation and Storage .............................................................................................. 14

8.0 Software Introduction........................................................................................................ 14

8.1 Cyclic Top Measurement Device Software.................................................................... 14

8.2 Initial Setup ................................................................................................................. 14

9.0 Before going on track ....................................................................................................... 15

9.1 Check Battery Levels................................................................................................... 15

9.2 Check Wireless Connection ......................................................................................... 15

9.3 Before Each Use.......................................................................................................... 15

9.4 Training and responsibilities......................................................................................... 16

9.5 Cyclic Top Fault Report from Measurement Train ......................................................... 17

9.6 Tools........................................................................................................................... 17

10.0 Step by Step Guide to Recording Cyclic Top Measurements on Track ............................... 18

11.0 Viewing a Recording......................................................................................................... 24

Step 1: View Cyclic Top Faults for a specific wavelength......................................................... 24

Step 2: Comparing results before and after maintenance......................................................... 25

11.1 PDF Recording Report................................................................................................. 29

12.0 Track Repairs................................................................................................................... 31

12.1 ‘Repair Track’ Screen................................................................................................... 31

12.2 Repair Report PDF ...................................................................................................... 32

13.0 Step by Step Guide to Recording Geometry Measurements on Track ............................ 34

14.0 Troubleshooting ............................................................................................................... 41

15.0 Using the Geode GPS as a stand-alone product................................................................ 42

15.1 When used as part of the CTMD .................................................................................. 42

15.2 To use the Geode GPS as a stand-alone product ......................................................... 42

16.0 Directive and standards.................................................................................................... 43