2

GENERAL INFORMATION

Accel Graphic Systems provides parts and service through its

authorized distributors and dealers. Therefore, all requests for

parts and service should be directed to your local dealer.

ThephilosophyofAccelGraphicSystemsistocontinuallyimprove

all of its products. Written notices of changes and improvements

are sent to Accel Graphic Systems' Dealers.

If the operating characteristics or the appearance of your product

differs from those described in this manual, please contact your

local Accel Graphic Systems Dealer for updated information and

assistance.

Always update your dampener when improvements are made

available, especially those related to safety.

Your authorized Crestline®AltraTM Series Dealer is:

The serial number of your

Crestline®AltraTM Series Dampener(s) is:

ATTENTION

CRESTLINE®

ALTRATM SERIES

DAMPENER

OWNER!

SAFETY

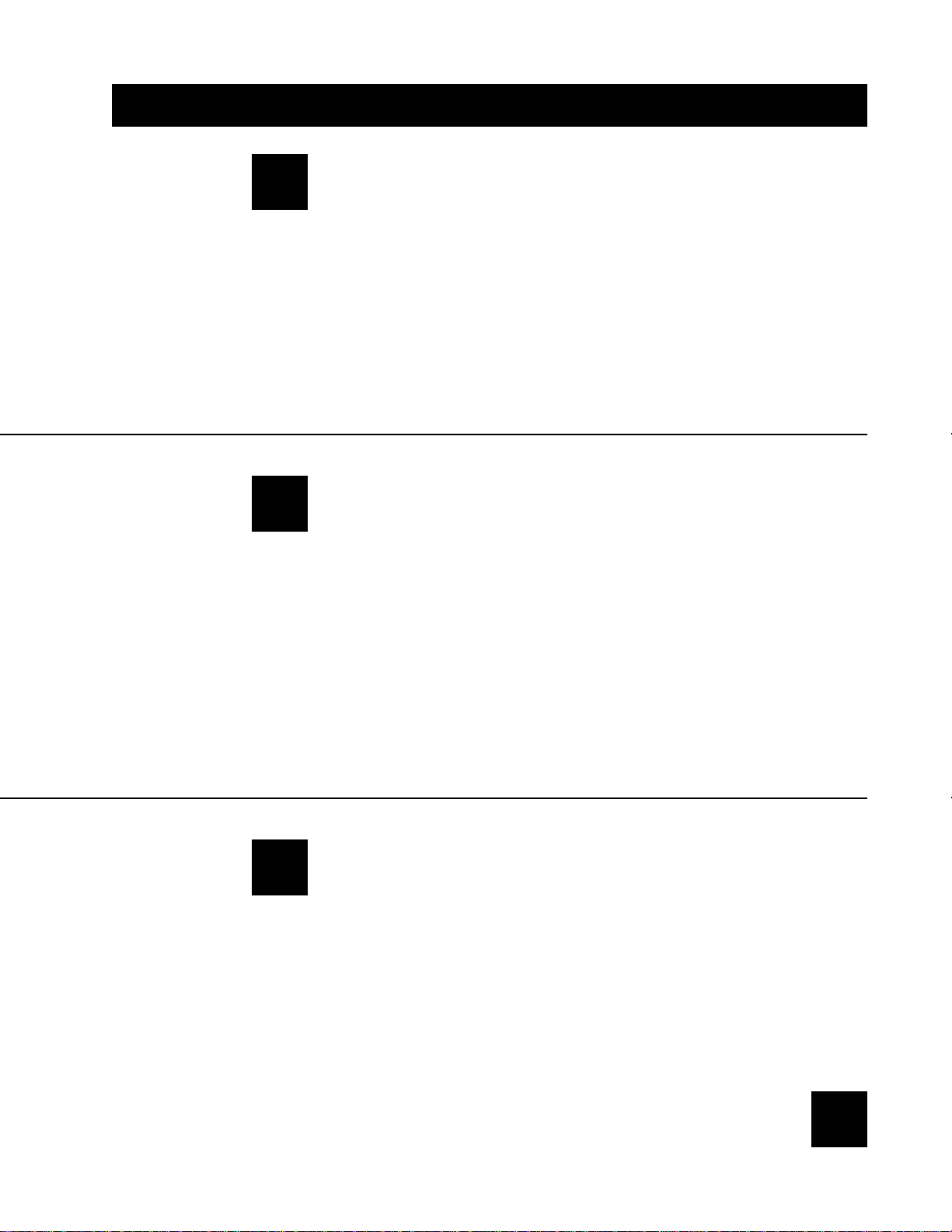

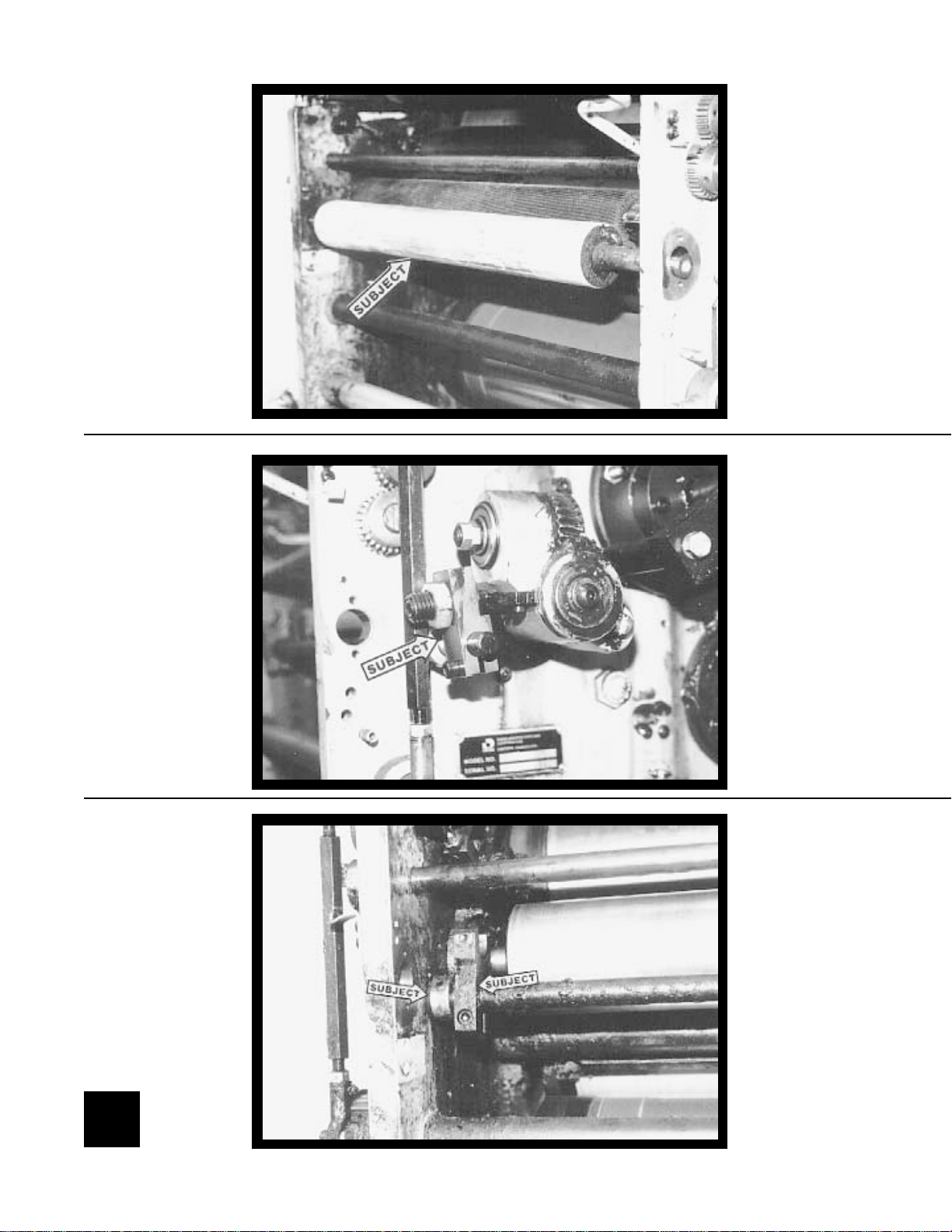

INFORMATION FOR YOUR SAFETY, DO NOT DISENGAGE OR REMOVE ANY

GUARDS FROM THE CRESTLINE®ALTRATM SERIES

DAMPENER. THE DAMPENER CONTAINS SOME INWARD

ROTATINGROLLERNIPSTHATCANCAUSEINJURYIFLEFT

UNGUARDED.

PRINTERS PARTS

800-543-1117 201-935-9595

fax 800-392-4072 201-935-5333

www.ppsnj.com