7 |

SMART PIPETTE - USER GUIDE

Loading and Ejection Tips

Each SMART pipette is fitted with a tip ejector which helps eliminate

safety hazards associated with contamination.

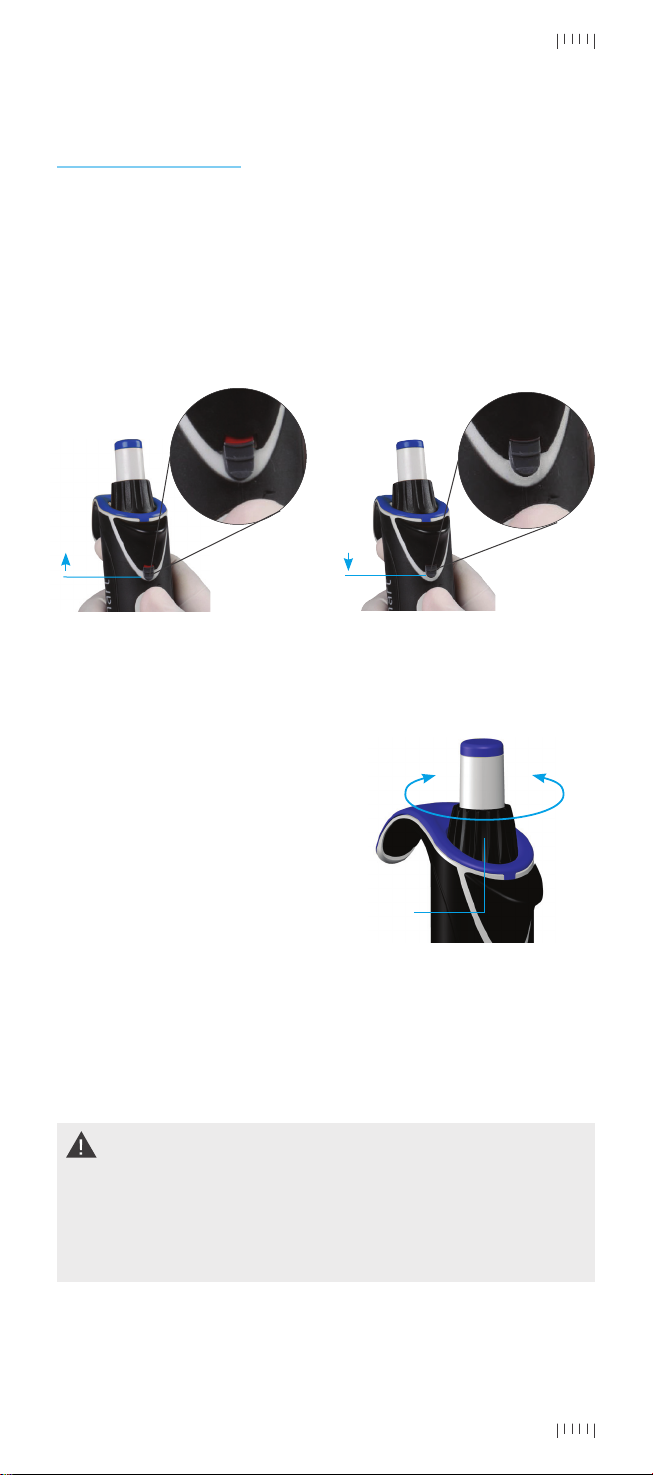

It is necessary to check that the tip cone is clean before fitting a tip.

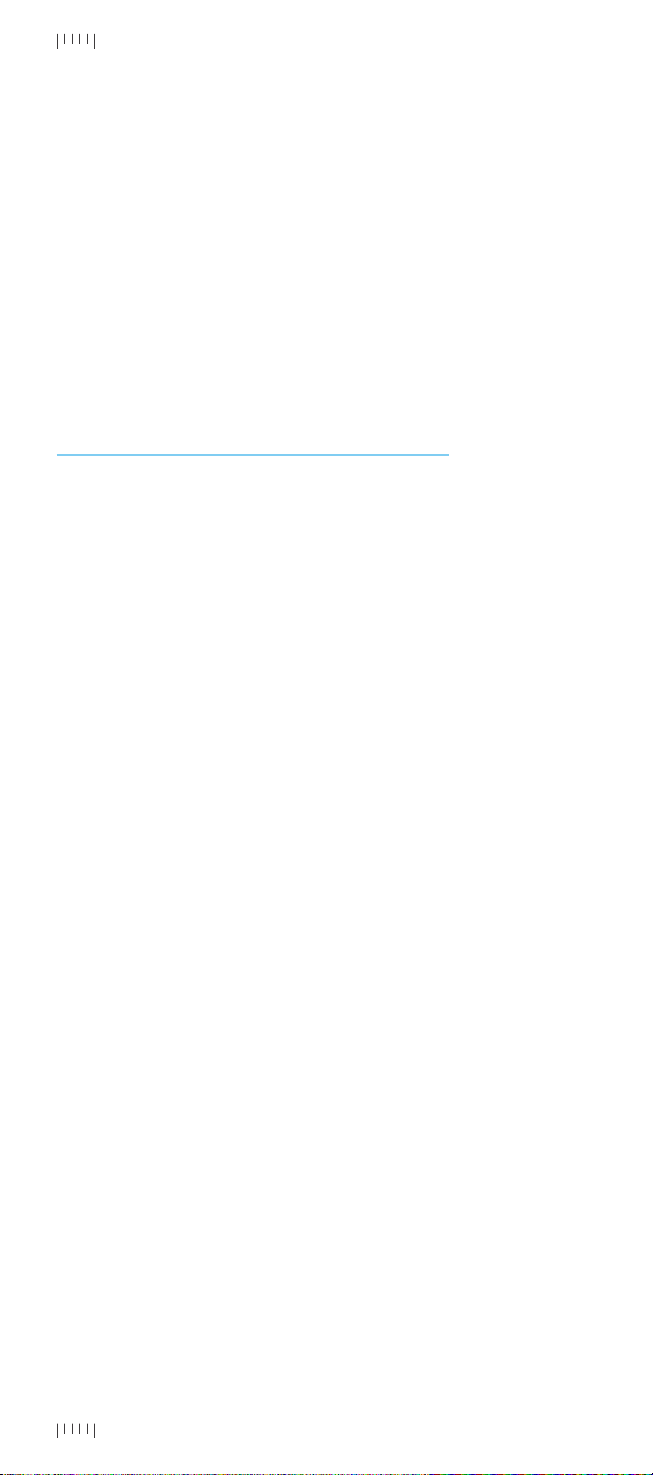

Press the tip on the cone of the pipette firmly to ensure an airtight

seal. The seal is set tight when a visible sealing ring forms between

the tip and the tip cone.

The tip ejector needs to be pressed downwards firmly with the thumb

to ensure proper tip ejection. Once the process is complete, make

sure that the tip is disposed of into a suitable waste container.

PIPETTING GUIDELINES

•While using the pipette make sure that operating knob has been

handled slowly and smoothly.

•Ensure that the tip is firmly attached on the tip cone. Please check

for foreign particles and remove if any, around the tip cone.

•Make sure that the temperature of tip, pipette and liquid are at

equilibrium.

•While holding the pipette, its main handle should be resting on your

index finger.

•While aspirating, hold the pipette in upright position and keep the

tip at a constant depth below the surface of the liquid.

•You should pre-rinse the tip before aspirating the liquid by filling

and emptying the tip 5 times. This is important especially when

dispensing liquids, which have a viscosity and density different

from water.

•For the volatile solvents you should saturate the air-cushion of your

pipette by aspirating and dispensing the solvent repeatedly before

aspirating the sample.

•When pipetting liquids with temperatures different to the ambient

temperature, pre-rinse the tip several times before use.

•After pipetting acids or other corrosive liquids that emit vapors,

remove the tip-cone and rinse the piston, O-ring and seal with

distilled water.

•Do not pipette liquids having temperatures above 70°C or below

4°C.

Make sure that liquids never enter the tip-cone, to prevent this:

•Never lay the pipette on its side when there is liquid in the tip.

•Press and release the push knob slowly and smoothly.

•Never turn the pipette upside down