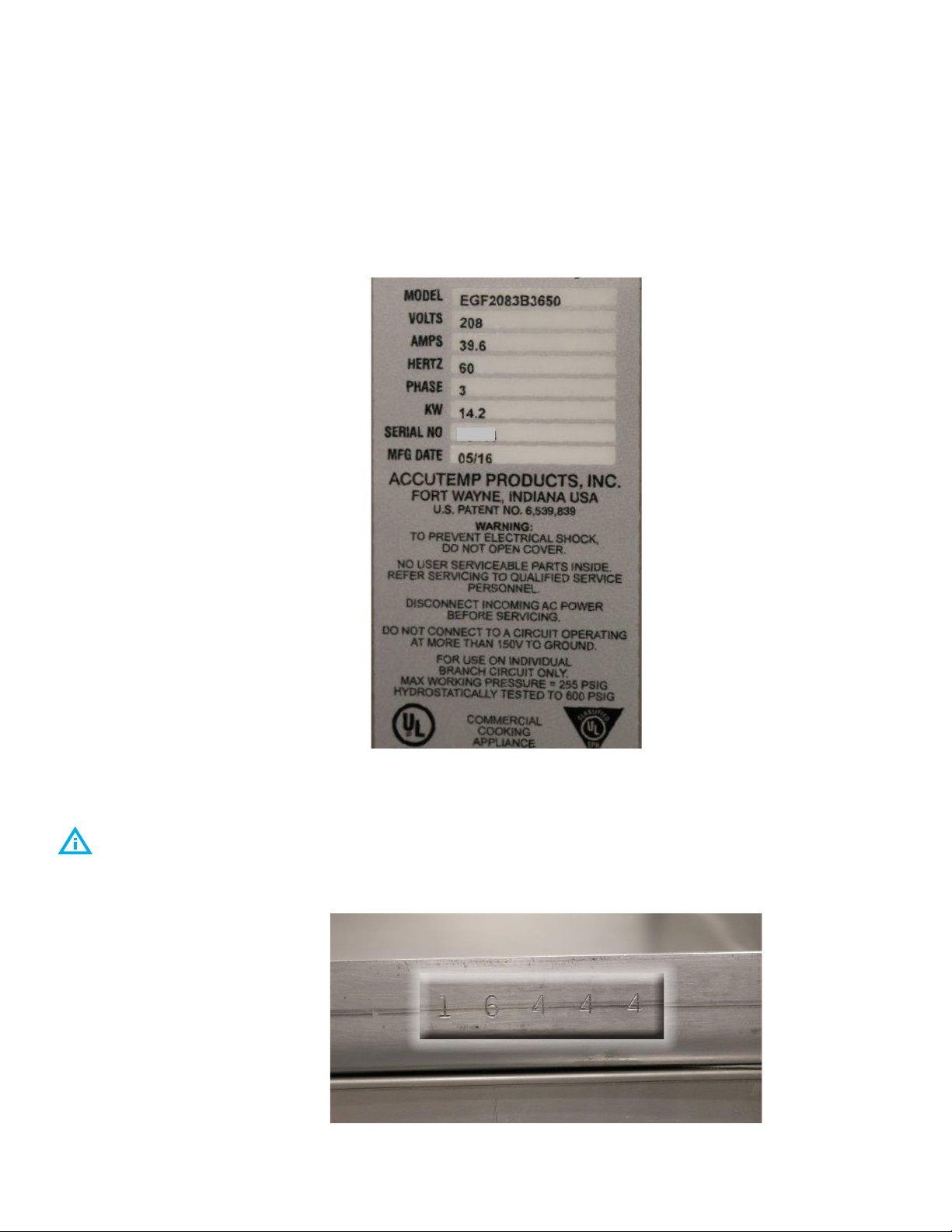

MP5018-1912 Accu-Steam Electric Griddle 4

I=mproper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing the equipment.

Intended for other than household use.

Plug the appliance into a properly

grounded electrical outlet of the correct

voltage, size and plug configuration. If they

do not match, contact a qualified electrician

to determine the proper voltage and size and

install the proper electrical outlet.

Do not connect to a circuit operating more

than 150V to ground

To avoid any personal injury or damage to

the unit do not pull the appliance by the power

cord.

To prevent any injury, discontinue any use

if power cord is frayed or worn.

To prevent any injury or damage this

commercial appliance must be installed by a

qualified electrician.

To avoid any injury, turn the power o,

unplug from the power source and allow to

cool before performing any maintenance.

To avoid electrical shock or personal injury,

do not steam clean or use excessive water on

this commercial appliance.

This product has no “user” serviceable

parts. To avoid injury or damage to the

commercial appliance use only Authorized

AccuTemp Service Agents and Genuine

Replacement Parts when service is required.

Genuine AccuTemp Replacement Parts are

specified to operate safely in the environments

in which they are used. Some aftermarket parts

or generic replacements parts do not have

the same specifications to operate safely in

AccuTemp equipment. It is imperative that to

use Genuine AccuTemp Replacement Parts

to avoid injury or damage to the commercial

appliance.

Always disconnect from power source

before cleaning or servicing.

Any in-the-field modification that bypass

the built-in safety features will result in personal

injury or death.

This appliance must be properly grounded,

in accordance with all National, State or local

electrical codes.

This appliance has a totally unique design

and is constructed unlike any other griddle

on the market today. Any modification may

permanently damage the appliance.

This appliance must be level for proper

operation and to reduce possible damage to

this commercial appliance.

This appliance is heavy, for safe handling,

the installer should obtain help as needed

or employ appropriate material handling

equipment to remove the commercial

appliance from the skid and move to the final

location in the building.

IMPORTANT: Read the following safety installation to avoid personal injury or death and to avoid

damage to the equipment or property

1.2 WARNING & CAUTION NOTES