AccuTemp EDGE Operating instructions

Made in U.S.A.

ELECTRIC SKILLET with MANUAL TILT - ALTES

OWNERS MANUAL AND INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Uncrating and Inspecting the Equipment 1

Important Warranty Information 2

Section II: Startup & Operation 3

Initial Cleaning 3

Control Functions 3

How to Start Cooking 4

Section III: Service & Maintenance 5

Servicing 5

Replacing Primary Thermostat 5

Hi-Limit Thermostat Replacement 5

Heating Elements 6

Actuator Maintenance and Adjustment 6

Actuator Replacement 6

Main & Worm Gear 7

Section IV: Caring for Stainless Steel 8

Sanitizing 8

Section V: Troubleshooting 10

Electrical Ratings & Field Wiring Requirements 11

General Parts List 12

Maintenance and Service Log 14

Wiring Diagrams 15

208-240 Volt /3Ph Delta Models ALTES-2430 15

208-240 Volt /3Ph Delta Models ALTES-2440 16

208-240 Volt /1Ph Delta Models ALTES-2440 17

440, 460 & 480 Volt/3Ph WYE Model ALTES-2430 18

440, 460 & 480 Volt/3Ph WYE Model ALTES-2440 19

Product Warranty (US & Canada Only) 20

Uncrating & Inspecting the Equipment

INSPECTION:

This appliance was carefully inspected before shipment from the factory. The transportation company assumes

full responsibility for safe delivery to the customer until customer acceptance of the package. Careful inspection

of the packaging and the appliance should be completed before acceptance from the transportation company.

CONTACT INFORMATION:

Toll Free 800 480-0415

Oce 260469-3040

Fax 260469-3045

Web Site www.accutemp.net

1

Important Warranty Information

The Accutemp Limited Warranty is valid in the Continental

United States and Hawaii and is void elsewhere. A complete

statement of warranty terms and conditions is included

in this manual. However, to ensure that you are familiar

with the installation, maintenance, and other important

warranty-related conditions, please study the following.

The instructions in this manual must be read thoroughly

before attempting installation, operation, maintenance, or

service. Accutemp reserves the right to render void any

warranty on equipment not installed in accordance with

the manual by a qualied technician, knowledgeable of

and experienced in the installation of commercial gas and

electrical cooking equipment.

Accutemp products are built to comply with applicable

standards of manufacturers. Many local codes exist and it

is the responsibility of the equipment owner and installer to

comply with these codes.

If the equipment has been changed, altered, modied, or

repaired by other than a qualied service technician during

or after the one year limited warranty period, Accutemp

shall not be liable for any incidental or consequential

damages to any person or to any property which may result

from the use of the equipment thereafter.

The Limited Warranty does not extend to:

1. Installation and start-up. Proper installation is the

responsibility of the owner/installer. Repair services for

the same will not be covered.

2. Malfunction as a result of improper maintenance.

3. Failure as a result of improper use or abuse of equipment.

4. Repair services initiated without prior authorization from

Accutemp.

5. Repair services for problems caused by inadequate gas

supply pressure or low voltage supply.

6. Repairs made by anyone other than qualied service

personnel recommended by Accutemp.

7. Damage caused in shipment.

8.Repair services for problems caused by routine

maintenance or cleaning.

9.Damage caused by tampering with, removing, or changing

a preset control or safety device.

10.Damage caused by hitting the cooking surface with

mplements or by rubbing or scraping the cooking

surface with abrasive materials.

11.Damage caused by simple adjustments, such as actuator

adjustments.

12.Lubrication of grease ttings or actuator springs and

gears. These parts should be greased at least once every

six months.

13.Moving other equipment to gain access to the unit.

14.Damages to any part of the unit as a result of cleaning

with high-pressure water or steam. Do not spray the

exterior of the equipment with water or steam!

15.Use of any replacement parts other than those supplied

or authorized by Accutemp voids all warranties and can

cause bodily injury to the operator and damage to the

equipment.

Refer to your warranty statement for those items that are

covered for only a 90-day period.

2

Section II: Startup & Operation

Warning:

Always disconnect power before cleaning (or servicing)

the unit.

The control console is not waterproof. Never spray the

control console, electrical controls, or connections with

water. Clean these areas by wiping them with a clean,

damp cloth.

When cooking, never allow water or foodstu to come in

contact with any electrical components.

Before operating your equipment, it must be cleaned

thoroughly. Refer to section IV: Caring for Stainless Steel

for instructions.

Important! Disconnect all electrical power before

cleaning the unit.

Clean the unit thoroughly with a mild detergent

solution. Always

“wipe”around the

control console

(never spray).

Never rinse control

consoles with

a spray hose or

let water come

in contact with

any electrical

and control

components.

For routine

cleaning, the

optional “Care Kit”

accessories help

you thoroughly

clean all surfaces,

including the

inside of the lid.

The stainless steel

Initial Cleaning We’ve already started the unit up during installation. Now

we’ll examine all control functions, step by step, for a full

understanding.

IMPORTANT: After installation or service and prior to

operating the unit, make sure the following are done,

otherwise the unit will not operate.

Make sure the ignition system control knob is in the

ON position.

Make sure the main electrical power and the gas

supply to the unit have both been turned on.

Fig. 2.1 Control Panel Features

Control Functions

surface of the unit may be polished with any reputable

commercial stainless steel cleaner or polish. Do not use any

abrasive materials or metal implements that might scratch

the surface, because scratches make the unit hard to clean

and provide places for bacteria to form & grow. Do not use

steel wool, which may leave particles imbedded in the unit’s

surface and cause eventual corrosion and pitting.

3

Section II: Startup & Operation

Rocker Switch (On - O). Energizes the unit for operation.

Primary Thermostat Dial (Temperature). Allows the user

to set the cooking temperature of the unit.

Unit Power On Indicator Light (Green). Illuminates upon

depressing the rocker switch to the ON position. This

indicates the unit has been energized.

Heater Power On Indicator Light (Red). Illuminates upon

turning the thermostat dial to show that the infrared

burners are operating. Note: If the temperature of the

unit is already above the set temperature, the red heater

power on light will not come on.

Overheat Indicator Light (Amber). It alerts the user

the primary thermostat has allowed the temperature

to exceed its maximum setting and the secondary

(automatice hi-temperature cut-o) thermostat has been

activated. The secondary thermostat, once engaged will

cut o power to the heating elements until the pan cools,

then the thermostat automatically resets and permits

normal operation to begin again.

Note: This unit is not intended for use as a fryer.

How to Start Cooking:

1. Make sure the main power supply to the unit has been

turned on.

2. Press the rocker switch to ON position, turn the primary

thermostat clockwise to the desired temperature. This

will cause the red indicator light to come on, showing that

the burner is operating.

3. Close the lid to speed up the heating process.

4. Once the unit has cycled (the red indicator light goes

out), you can start cooking immediately. However, to

guarantee the most even, stable heat you may want to let

it cycle several times.

5. If a new temperature is desired during a cooking

operation, simply turn the thermostat to the new

setting. Again, allow several cycles to ensure proper heat

stabilization.

Caution: Avoid dumping cold water into a very hot pan

to cool down. This can cause severe thermal shock,

which can crack welds or warp the pan.

5. To shut down the unit, turn the thermostat dial to OFF

and press the rocker switch to OFF.

Summary of Control Functions:

4

Section III: Service & Maintenance

Warning:

Always disconnect power before cleaning (or servicing)

the unit.

This section covers the basics of servicing and maintaining

your equipment. A “Maintenance and Service Log” is

included in this manual for your use in recording all

maintenance and service performed.

IMPORTANT: Service must be done by a qualied

technician experienced with commercial gas and electric

cooking equipment. Use only OEM supplied parts.

Unauthorized or generic parts can cause bodily injury and

equipment damage. If the unit ever needs repair during

the warranty period, prior authorization is required. A)

Replacing Primary and Secondary High Limit Thermostats

Servicing

Re-Calibrating Thermostats (Do Not Attempt)

IMPORTANT! If either thermostat is defective or not

working properly, it must be replaced (without breaking

the seal) and returned to Accutemp. The warranty is

voided if the seal is broken or any attempt is made to

recalibrate a thermostat. See below for replacement

instructions.

Replacing Primary Thermostat

1. Disconnect the unit from its power supply.

2. Remove the control console panel.

3. Disconnect and mark wire(s) connected to the normally

closed position with the enclosed tag marked normally

closed.

4. Disconnect and mark wire(s) connected to the common

position with the enclosed tags marked common.

5. Remove the thermobulb hold-down bracket, which

secures the thermobulb to the plate surface. Pull

thermobulb and capillary tube back through the access

port to remove the thermostat from the control console.

6. Remove the two mounting screws on the existing

thermostat from the front panel.

7. Use the existing hole locations for mounting the

thermostat. The two outer holes on the new thermostat

bracket are for mounting the thermostat and the two

inner holes are for mounting the bezel. With a marker,

mark the hole locations for drilling the bezel holes.

8. Drill holes through the front panel with the #32 drill

bit.9. Locate the new replacement thermostat on the

inside of the control box where the existing thermostat

is mounted. The thermostat should be mounted with

the at side of the dial stem facing the right side of the

unit and the common pole (“P” terminal) will be on the

left side. You will use the #6-32x1/4” round head slotted

screws provided to mount the thermostat in the two

outer holes.

10. After this has been completed, secure the bezel

in place with the #6 Type “F” x 5/16” pan head phillips

thread cutter screws provided in the two inner holes

which should have been drilled out in step 8. Note: The

triangular indicator marking on the bezel should be in the

3 o’clock position.

11. Reconnect the wires marked normally closed to

the normally closed position on the new replacement

thermostat with the piggyback push-on connector (if

more than one connection is needed) or a single push-on

connector (if only one connection is needed) as provided

in the installation package.

12. Carefully uncoil the capillary tube. Re-insert the

capillary tube and thermobulb through the access port

from which the old tube and bulb was removed and re-

install the thermobulb in the same location from which

the old thermostat thermobulb was removed.

13. Replace control console panel and secure in place.

Hi-Limit Thermostat Replacement

1. Follow steps 1 through 5 of the primary control

replacement procedure.

2. Remove the two mounting screws on the existing hi-

limit thermostat from mounting bracket.

3. Reconnect the wires marked normally closed to

the normally closed position on the new replacement

thermostat with the piggyback push-on connector (if

more than one connection is needed) or a single push-on

connector (if only one connection is needed) as provided

in the installation package.

4. Reconnect the wires marked common to the common

position (“P” terminal) on the new replacement hi-limit

thermo-stat with the piggyback push-on connector (if

more than one connection is needed) or a single push-on

connector (if only one connection is needed) as provided

in the installation package.

5. After wiring connections are complete, place the hi-

limit thermostat in the control console. Locate the new

replacement hi-limit thermostat on the mounting bracket

and secure in place using the 6-32x1/4” round head

5

Section III: Service & Maintenance

slotted screw.

6. Carefully uncoil the capillary tube. Re-insert the

capillary tube and thermobulb through the access port

from which the old tube and bulb was removed and re-

install the thermobulb in the same location from which

the old thermostat thermobulb was removed.

7. Replace control console panel and secure in place.

Heating Elements

Heaters can be checked by disconnecting the

labeled wires from the distribution block and

measuring the resistance (see electrical parts table

for resistance values) to be certain that they are

within specication. A replacement kit is available

with proper instructions to assure continued high

performance.

Other Component Replacement: All other

components are replaced by removing their

mounting screws. Make sure all covers are replaced

after all repairs are completed.

Actuator Maintenance and Adjustment

A) Actuator Tension Adjustment

The braising pan lid is designed to remain in position.

Should the tension need adjustment after shipping,

or at any time in the future, the following procedure

can be performed.

Raise the unit’s lid completely. Removal of the stop

nut may be needed to raise the lid completely.

Remove the tube closure cap on the actuator. With a

3/4”deep hex socket, turn the adjusting nut (located

inside the actuator sleeve) clockwise to increase the

tension or counterclockwise to decrease tension.

Rotate the nut one turn at a time and test the lid’s

operation. When the adjustment is complete,

replace the tube closure cap on the actuator sleeve.

B) Actuator: Re-Packing with Grease

The lid actuator(s) of your unit must be re-packed

with grease every six months to ensure proper

operation. Perform the following steps. Refer to

Figure 3.1.

1. Raise the lid of the unit fully.

2. Remove the tube closure cap.

3. Remove the self-locking 1/2-13 hex nut on the

actuator rod.

4. If the components inside the actuator sleeve do

not slide out easily, remove the bolt, which secures

the actuator sleeve to the frame lug. Put aside the

bolt, nut, and lock washer for re-assembly later.

5. Grasp the actuator sleeve and pull down away

from the actuator rod. The components inside the

actuator sleeve will slide out.

6. Pack the spring (or springs) with Bel-Ray No-Tox

Clear Grease #2. The grease must be liberally applied

between each coil.

7. After re-packing with grease, reassemble the

components back inside the actuator sleeve and

slide the sleeve back over the actuator rod.

8. Reconnect the actuator assembly to the frame lug

using the bolt, nut, and lock washer previously set

aside.

9. Adjust the tension of the actuators using the

procedure described earlier in this section.

C)Actuator Replacement

Should the actuators on your unit ever require

replacement, use the following procedure. Refer to

Figure 3.1 and to Figure 3.2.

1. Raise the lid of the unit fully.

2. Remove the tube closure cap.

3. Using a deep socket tool, loosen the self-

locking hex nut on the actuator rod (by turning

it counterclockwise) to eliminate pressure on the

springs.

4. From the pivot arm of the actuator, remove the

acorn nut, bolt, lock washer, and spacer and retain

them for mounting the new actuator(s).

5. From the frame lug (at the other end of the

actuator) remove the acorn nut, bolt, and lock washer

and retain them for mounting the new actuator(s).

6. Mount the new actuators using the bolts, nuts,

lock washers, and spacers set-aside in the above

steps.

Note: The actuator rod must be free to pivot during

use. Therefore, when tightening the hex bolt into

the acorn nut, tighten it completely, and then back

o a half turn.

6

Section III: Service & Maintenance

7. After the new actuator(s) are installed, adjust the

tension using the procedure described earlier in this

section.

Main and Worm Gear

Monthly, check the tilt mechanism (main and worm

gear) along with the trunnion support bearings for

adequate lubrication. If lubrication is needed, use

Bel-Ray No Tox Open Gear Grease or equivalent

edible grease. The tilt mechanism is in the right-

hand console. Trunnion bearings are in the left-

hand arm and between the right-hand console and

pan body.

7

Section V: Caring For Stainless Steel

This section provides specic guidelines for cleaning

and protecting the stainless steel surface of your

equipment.

Important!

Always disconnect power before cleaning (or

servicing) the unit. Never spray the control console,

electrical controls, gas controls, or connections with

water. Clean these areas by wiping them with a

clean, damp cloth.

The stainless steel can be cared for using any good

commercial stainless steel cleaner or polish. Contrary

to popular belief, stainless steel remains resistant to

corrosion only as long as its passive surface remains

intact. There are some basic rules to prevent the

breakdown of this surface.

Only plastic scouring pads and soft cloths should be

used, since they will not damage the stainless steel

surface. Neveruseanythingthatwillscratchthesurface

such as steel pads, wire brushes, or scrapers. In the pan,

scratches make cleaning more dicult and provide

places for bacteria to collect and grow. Never use steel

wool since it can leave particles embedded in the pan

and can also lead to eventual corrosion and pitting.

Never let deposits from water, particularly hard water,

or deposits from food sit on the surface for extended

periods. Wipe up deposits and spills promptly. After

cleaning, rinse o the cleaning agents thoroughly

with water, wipe dry, and then allow the surface to air

dry. Oxygen actually helps maintain stainless steel’s

protective surface.

Never use cleaners

containing

chlorides (or

quaternary salts,

since they can

also contribute

to pitting and

rusting). Use only

alkaline, alkaline-

chlorinated, or

non-chloride

cleaners.

Tip: If you’ve been doing a lot of continued boiling

or steaming, you may notice a build-up of lime or

scale in the pan. This cleans up easily using vinegar, a

vinegar/water mixture, or any commercial de-liming /

de-scaling solution.

Sanitizing

Suggested Tools:

a. Cleaner, such as Klenzade HC-10 or HC-32 from

ECOLAB, Inc.

b. Kettle brushes in good condition

c. Sanitizer such as Klenzade XY-12.

d. Film remover such as Klenzade LC-30.

Procedure:

1. Clean food contact surfaces as soon as possible

after use. If the unit is in continuous use, thoroughly

clean and sanitize the interior and exterior at least

once every 12 hours.

2. Scrape and ush out food residues. Be careful not

to scratch the unit with metal implements.

3. Prepare a hot solution of the detergent/cleaning

compound as instructed by the supplier. Clean the

unit thoroughly. A cloth moistened with cleaning

solution can be used to clean controls, housings, and

electrical conduits.

4. Rinse the unit thoroughly with hot water, and then

drain completely.

5. As part of the daily cleaning program, clean soiled

external and internal surfaces. Remember to check

the sides of the unit and control housing.

6. To remove stuck materials, use a brush, sponge,

cloth, plastic or rubber scraper, or plastic wool with

the cleaning solution. To reduce eort required in

washing, let the detergent solution sit in the unit

and soak into the residue. Do NOT use abrasive

materials or metal tools that might scratch the

surface. Scratches make the surface harder to clean

and provide places for bacteria to grow.

7. The outside of the unit may be polished with a

stainless steel cleaner such as “Zepper” from Zep

Manufacturing Co.

8. When equipment needs to be sanitized, use a

solution equivalent to one that supplies 200 parts

per million available chlorine. Obtain advise on

sanitizing agents from your supplier of sanitizing

products. Following the supplier’s instructions, apply

the agent after the unit has been cleaned and drained.

Rinse o the sanitizer thoroughly.

9. It is recommended that each piece of equipment be

sanitized just before use.

8

Section V: Caring For Stainless Steel

10. If there is diculty removing mineral deposits

or a lm left behind by hard water or food residues,

clean the unit thoroughly and use a deliming agent,

like Lime-Away® from Ecolab, in accordance with the

manufacturer’s directions. Rinse and drain the unit

before further use.

NOTICE: NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL SURFACES LONGER

THAN 30 MINUTES. LONGER CONTACT CAN CAUSE

STAINING AND CORROSION.

9

Section V: Troubleshooting

The braising pan is designed to operate smoothly and eciently if properly maintained. However, in the event of a

problem, the following is a list of checks to be made by qualied personnel. The wiring diagram for the unit is located

behind the removable panel of the control console.

IMPORTANT: Service must be done by a qualied technician experienced with commercial gas and electric cooking

equipment. Use only OEM supplied parts. Unauthorized or generic parts can cause bodily injury and equipment damage.

If the unit ever needs repair during the warranty period, prior authorization is required.

Troubleshooting - General Problems

Symptom What to check for ..................hat

Pan will not heat, but indicator light comes on Heating elements for short circuit

Pan will not heat, indicator light does not come on That power supply is turned on

Loose or broken wires

Thermostat malfunctioning

Contactor(s) functioning

If automatic hi-temperature thermostat is engaged, wait

approximately 15 to 30 minutes for unit to cool down and

circuit will automatically reset.

Pan continues to heat after it reaches desired temperature Thermostat setting - too high

Primary thermostat malfunctiong

Contactor (s), to determine if it is de-energized.

Pan does not reach desired temperature Thermostat setting - too low

Heating element(s) for ground short or open (burnt out)

element

Primary thermostat malfunctiong

Contactor(s) functioning

Rapid clicking noise (chattering) Voltage, to see if it is too low

Contactor(s) for dirt or corrosion on the contacts.

Uneven cooking due to “cold spots” For burned out (open) or loose heating elements

Pan is hard to tilt Gears for foreign materials, lubrication and alignment.

10

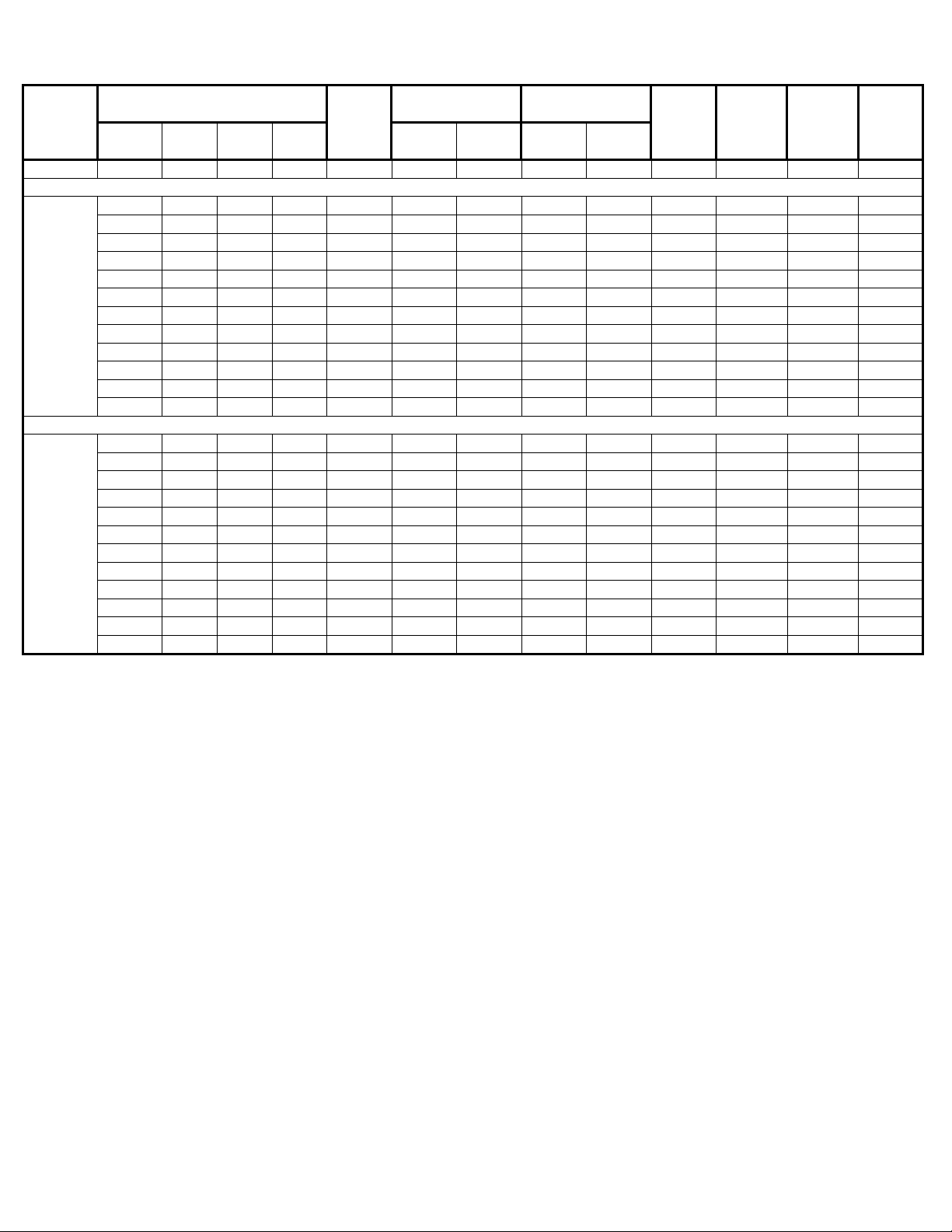

Electrical Ratings and Field Wiring Requirements

Supply

AWG Size

Volts Phase Amps kW kW Volts Number

Rating

Amps Min. AWG

208 151.4 10.7 61.97 219 260 8 6 42 1 3/32

208 329.7 10.7 61.97 219 240 12 10 42 7/8

240 149.2 11.8 61.97 240 260 8 6 42 1 3/32

240 328.4 11.8 61.97 240 240 12 10 42 7/8

380 131.1 11.8 61.97 380 240 10 842 1 3/32

380 317.9 11.8 61.97 219 225 14 12 42 7/8

415 128.4 11.8 61.97 415 240 12 10 42 7/8

415 316.4 11.8 61.97 240 225 14 12 42 7/8

440 126.8 11.8 61.97 440 230 12 10 42 7/8

440 315.5 11.8 61.97 254 225 14 12 42 7/8

480 124.6 11.8 61.97 480 230 14 10 42 7/8

480 314.2 11.8 61.97 277 225 14 14 42 7/8

208 172.1 15.0 91.67 219 275 4 3 168 1 23/32

208 341.6 15.0 91.67 219 250 8 6 42 1 3/32

240 162.5 15.0 91.67 240 275 6 3 168 1 23/32

240 336.1 15.0 91.67 240 240 8 6 42 1 3/32

380 139.5 15.0 91.67 380 250 8 6 42 1 3/32

380 322.8 15.0 91.67 219 225 12 10 42 7/8

415 136.1 15.0 91.67 415 240 8 6 42 1 3/32

415 320.9 15.0 91.67 240 225 14 10 42 7/8

440 134.1 15.0 91.67 440 240 8 6 42 1 3/32

440 319.7 15.0 91.67 254 225 14 10 42 7/8

480 131.3 15.0 91.67 480 240 10 842 1 3/32

480 318.0 15.0 91.67 277 225 14 10 42 7/8

Min

Junction

Box Size

Inches3

Min.

Knockout

Size (in.)

*ALTES-

2430

*ALTES-

2440

Model

Unit Electrical Ratings No. Of

Heating

Elements

Heating Element Contactors

Wiring to

Elements

& Pigtail

Min. AWG

11

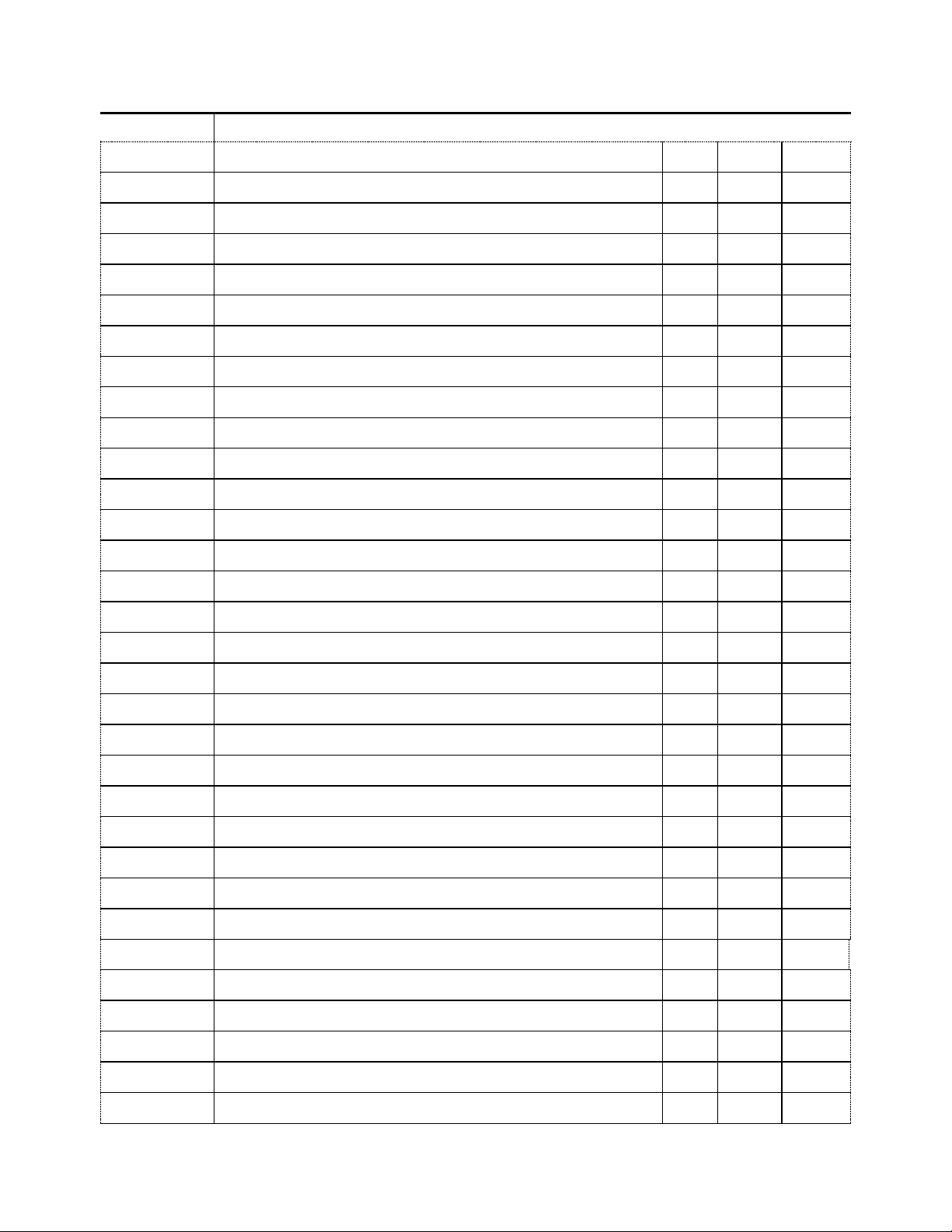

Part No.

Description

2424

2430

2440

407567-1 Thermostat, primary control 176 – 400°F (mechanical) 1 1 1

407567D Thermostat Knob 1 1 1

407770-B Bezel primary thermostat 1 1 1

407568-1 Thermostat, automatic high limit 1 1 1

407793 Grommet, primary control thermostat shaft 1 1 1

408497 Timer 120/240v (knob included) (optional) 1 1 1

407615 Rocker switch 1 1 1

407451 Indicator light red 240v 1 1 1

407452 Indicator light amber 240V 1 1 1

408580 Indicator light green 240V 1 1 1

406619 Fuse 2 amp 2 2 2

400780-2 Fuse block 2 pole 1 1 1

406578 Jumped terminal block 3 3 3

400749-1 Ground lug #14 to #6 1 1 1

430033 Transformer – All Voltages 1 1 1

407726 Power distribution block 1 1 1

408015-15 Contactor 15 Amp 600V 2 2 2

408015-25 Contactor 25 Amp 600V 2 2 2

408015-30 Contactor 30 Amp 600V 2 2 2

408015-50 Contactor 50 Amp 600V 2 2 2

408015-60 Contactor 60 Amp 600V 2 2 2

408015-75 Contactor 75 Amp 600V 2 2 2

408015-90 Contactor 90 Amp 600V 2 2 2

404440-219 Heater 219V x 1970 Watts NA 6 9

404440-240 Heater 240V x 1970 Watts NA 6 NA

404440-254 Heater 254V x 1970 Watts NA 6 NA

404440-277 Heater 277V x 1970 Watts NA 6 NA

456807-219 Heater 219V x 1670 Watts 6 NA NA

456807-240 Heater 240V x 1670 Watts NA NA 9

456807-254 Heater 254V x 1670 Watts NA NA 9

456807-277 Heater 277V x 1670 Watts NA NA 9

456973-219 Heater 219V x 1500 Watts 6 NA NA

12

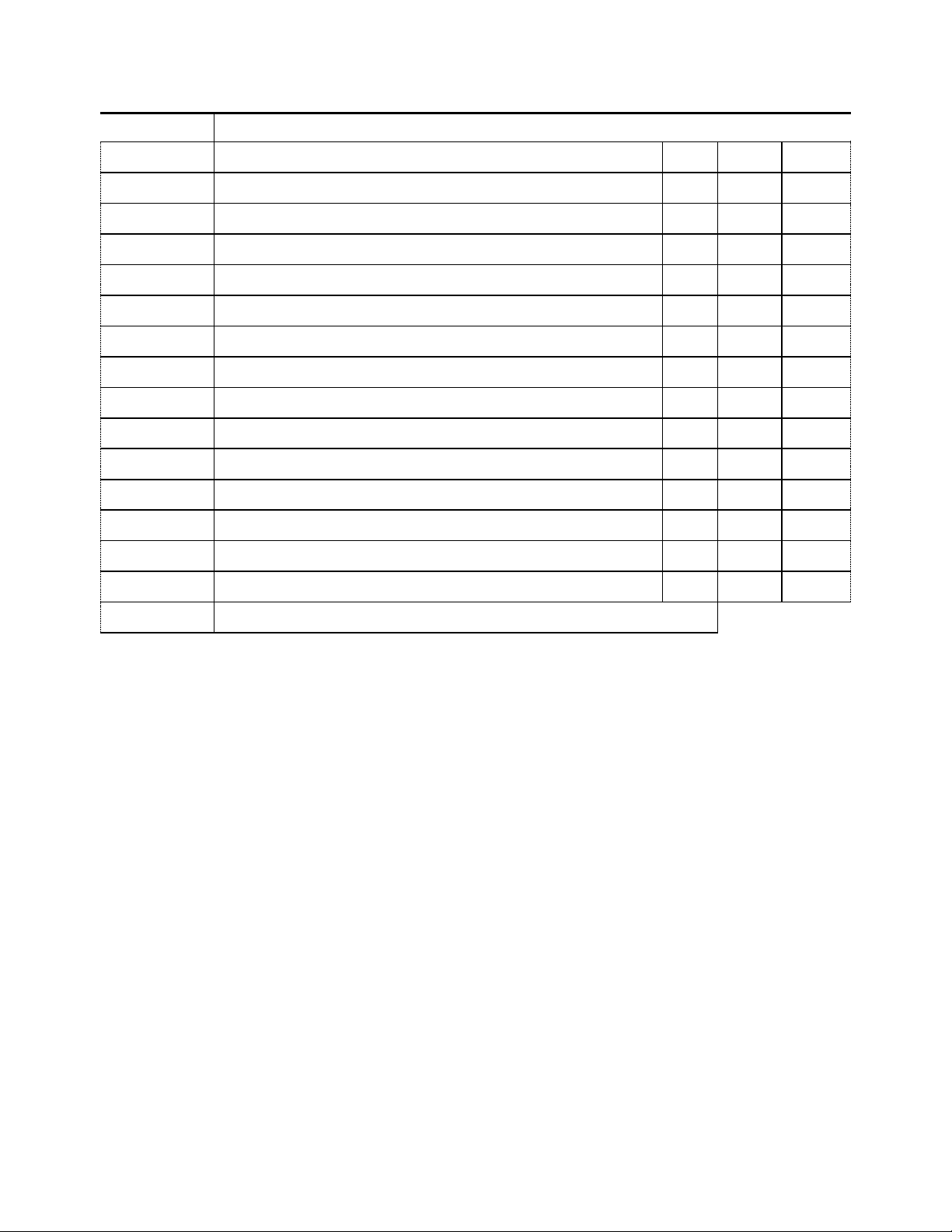

Part No.

Description

2424

2430

2440

456973-240 Heater 240V x 1500 Watts 6 NA NA

456973-254 Heater 254V x 1500 Watts 6 NA NA

456973-277 Heater 277V x 1500 Watts 6 NA NA

460101 Trunnion gear large 1 1 1

460102 Worm gear 1 1 1

404141-7 Assembly yoke & gear 7” deep pan 1 1 1

404141-9 Assembly yoke & gear 9” deep pan 1 1 1

404141-11 Assembly yoke & gear 11” deep pan 1 1 1

450466 Bullet feet w/flange 1 5/8” (Optional) 4 4 4

450751 Bullet feet w/o flange 1 5/8” (Standard) 4 4 4

408693-001 Actuator Assembly 1 1 1

405697 Handwheel 8” spoke 1 1 1

440057-01 Compression draw-off valve 1-1/2, (Optional) 1 1 1

440019-01 Compression draw-off valve 2”, (Optional) 1 1 1

440235-01 Compression draw-off valve 3”, (Optional) 1 1 1

407979-CKK CKK Care kit, (Optional)

13

Maintenance & Service Log

Model No.: Purchased From:

Serial No.: Date Purchased:

Purchase Order No.: Location Installed:

Date Installed:

Date Maintenance Performed: Performed By:

14

Jumped Term. Blk.

TB-3

Jumped Term. Blk.

TB-1

OVERHEAT

INDICATOR LIGHT

POWER ON

INDICATOR LIGHT

HEATER INDICATOR

LIGHT

ALTES-2430, 208, 240V, 3ø DELTA, 50/60 HZ, 3 WIRE PLUS GROUND R4 [010818]

FUSEBLOCKWITH

2 AMP FUSE

ON - OFF

ROCKERSWITCH

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

LIMITING

CONTACTOR

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

REGULATING

CONTACTOR

Jumped Term. Blk.

TB-2

COLOR KEYED GROUND

LUG

A-T1

A-T2

B-T1

B-T2

C-T2

C-T3

D-T2

D-T3

E-T1

E-T3

F-T1

F-T3

L1 L2 L3

TO POWER SUPPLY

LINE SIDE

LOAD

SIDE

THERMOSTAT PROBE

1

HIGH LIMIT CONTROL

PRIMARY

THERMOSTAT

POWER STUD BLOCK

15

Jumped Term. Blk.

TB-3

Jumped Term. Blk.

TB-1

OVERHEAT

INDICATOR LIGHT

POWER ON

INDICATOR LIGHT

HEATER INDICATOR

LIGHT

ALTES-2440, 208, 240V, 3ø DELTA, 50/60 HZ, 3 WIRE PLUS GROUND R4 [010818]

FUSEBLOCKWITH

2 AMP FUSE

ON - OFF

ROCKERSWITCH

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

LIMITING

CONTACTOR

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

REGULATING

CONTACTOR

Jumped Term. Blk.

TB-2

COLOR KEYED GROUND

LUG

A-T1

A-T2

B-T1

B-T2

C-T1

C-T2

D-T1

D-T3

E-T1

E-T3

F-T1

F-T3

G-T2

G-T3

H-T2

H-T3

J-T2

J-T3

L1 L2 L3

TO POWER SUPPLY

LINE SIDE

LOAD

SIDE

THERMOSTAT PROBE

1

PRIMARY

THERMOSTAT

POWER STUD BLOCK

HIGH LIMIT CONTROL

16

Jumped Term. Blk.

TB-3

Jumped Term. Blk.

TB-1

OVERHEAT

INDICATOR LIGHT

POWER ON

INDICATOR LIGHT

HEATER INDICATOR

LIGHT

ALTES-2440, 208, 240V, 1ø DELTA, 50/60 HZ, 2 WIRE PLUS GROUND R4 [062420]

FUSEBLOCKWITH

2 AMP FUSE

ON - OFF

ROCKERSWITCH

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

LIMITING

CONTACTOR

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

REGULATING

CONTACTOR

Jumped Term. Blk.

TB-2

COLOR KEYED GROUND

LUG

A-T1

A-T4

B-T1

B-T4

C-T1

C-T4

D-T2

D-T5

E-T2

E-T5

F-T2

F-T5

G-T3

G-T6

H-T3

H-T6

J-T3

J-T6

TO POWER SUPPLY

LINE SIDE

LOAD

SIDE

THERMOSTAT PROBE

1

PRIMARY

THERMOSTAT

HIGH LIMIT CONTROL

17

Jumped Term. Blk.

TB-3

Jumped Term. Blk.

TB-1

OVERHEAT

INDICATOR LIGHT

POWER ON

INDICATOR LIGHT

HEATER INDICATOR

LIGHT

ALTES-2430, 440, 460 and 480V, 3ø WYE, 50/60 HZ, 3 WIRE PLUS GROUND R4 [010818]

FUSEBLOCK WITH

2 AMP FUSE

ON - OFF

ROCKERSWITCH

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

LIMITING

CONTACTOR

NO

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

REGULATING

CONTACTOR

Jumped Term. Blk.

TB-2

COLOR KEYED GROUND

LUG

TRANSFORMER

TO POWER SUPPLY

LINE SIDE

LOAD

SIDE

THERMOSTAT PROBE

1

L1

L2

L3

AXT1

DXT1

BXT2

EXT2

CXT3

FXT3 TOHEATERS

HIGH LIMIT CONTROL

18

Table of contents

Other AccuTemp Kitchen Appliance manuals