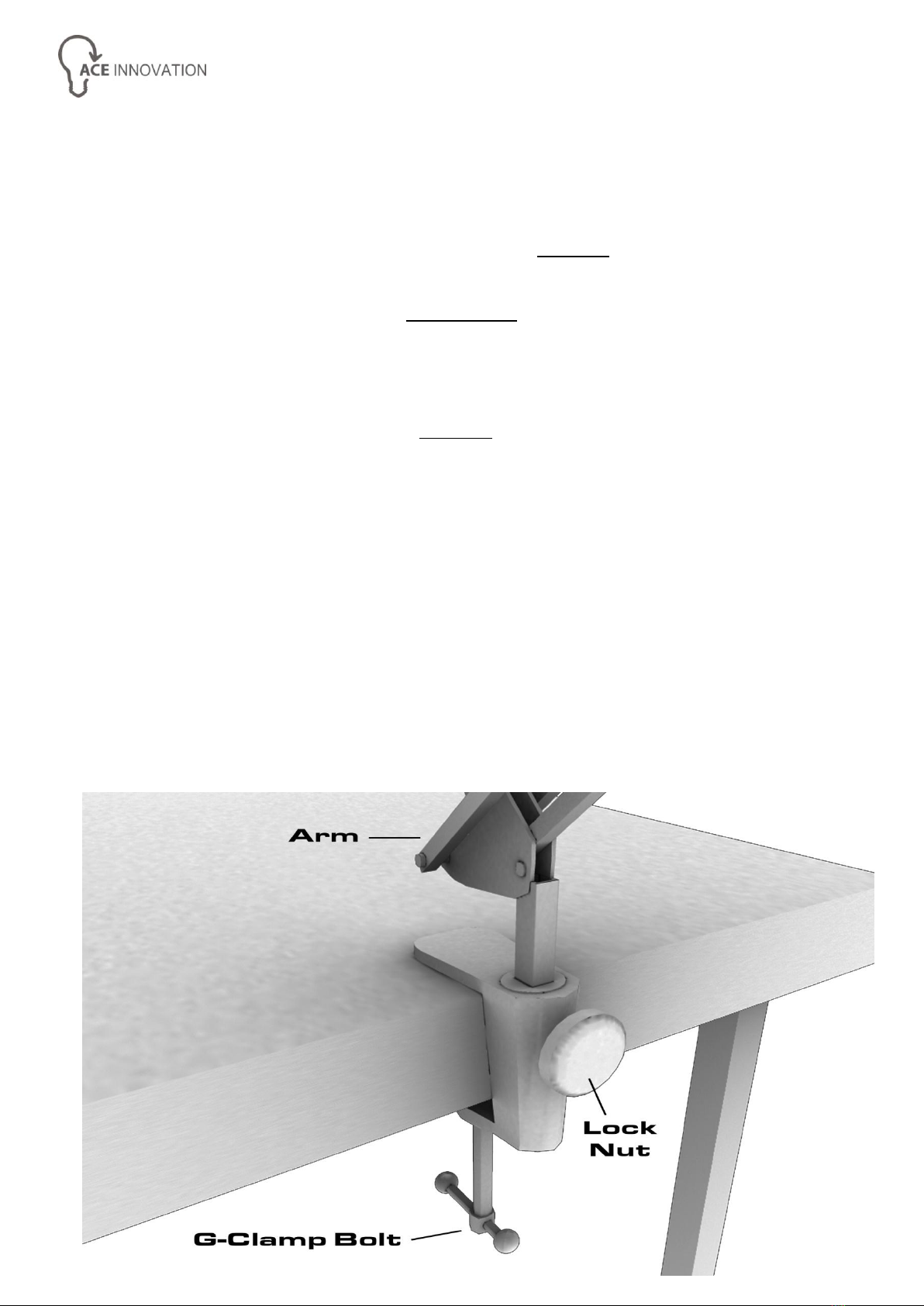

Fig 4

Warranty

Ace Innovation warrants the SuperVisor®, when purchased new, to be free from defects

in material and workmanship and will repair or replace, at Ace Innovation’s discretion, any

equipment which exhibits such defects; provided that the equipment has been installed

and operated under normal conditions and has not been tampered with by any persons

not authorised by Ace Innovation or its agents.

On no occasion shall Ace Innovation or its agents be liable for indirect, incidental or

consequential damages; the original user’s remedies being limited to repair or

replacement.

Ace Innovation makes no other or further warranty, express or implied, including

warranty of fitness for a specific purpose or warranty of merchantability.

This warranty is valid for a period of 12 months effective from the date of delivery.

Disclaimer

The Visor element of the SuperVisor® is made from a lightweight material which, during

manufacture and general use, may acquire superficial marks and indentations. This does

not affect the function, or impact on the operation of your SuperVisor® and is therefore

not covered by the warranty.

Note that this product is not designed for use by individual minors or unsupervised

children due to the mechanical operation of its components.

Due to the operating nature of this product care must be taken to ensure articles of

clothing or limbs do not foul the operating mechanism.

www.aceinnovation.co.uk

08455 199181