OoeratinolnstruclionsandPartsIVanual

Assembly

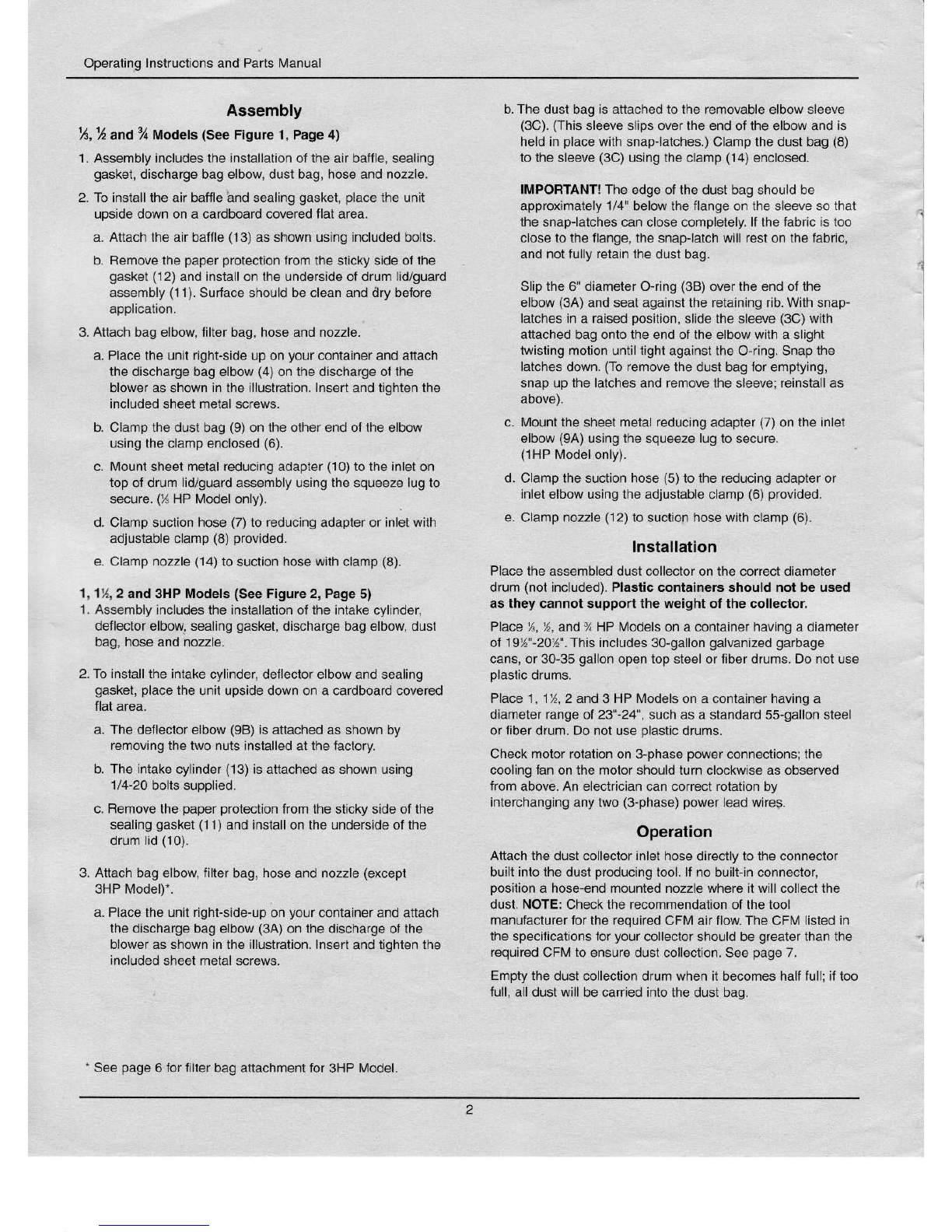

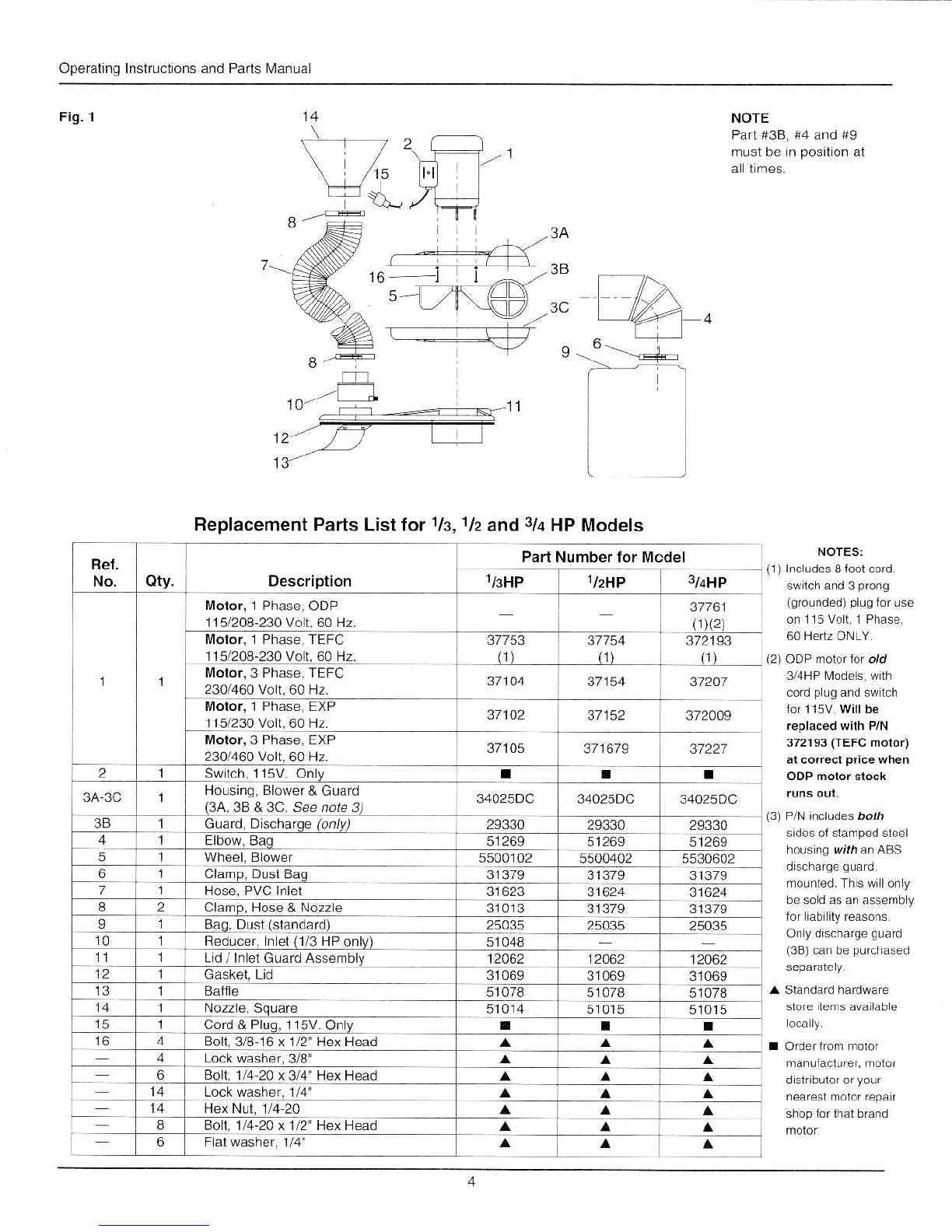

%,%and %Models (SeeFlgure 1,Page4)

1.Assemblyincludeslhe lnslallationoi the a r ballle,sealng

gaskel,

dischargebagelbow,dustbag,hoseandnozzle.

2. Toinstalltheairbafileirndsealing

gaskel,place

ihe unit

upsidedownona cardboardcoveredtlalarea.

a. Atiachlhe air balfle

(13)

asshownusingincludedbots.

b. Removethepaperprotection

from

the siickysde ofthe

gaskel(12)

andinstallon lhe undersideofdrumld/guard

assembly

{11).

Sudaceshouldbecleananddrybelofe

3.Attachbagelbow,filierbag,hoseandnozzle.

a.Placethe unilright-side

uponyoLrr

conta

ner

andattach

thedischargebag

elbow

(4)

onthe dischargeol lhe

blowerasshown

inlhe illuslration.Insertandlightenlhe

includedsheetrnetalscrews.

b. CLamp

thedustbag(9)

ontheotherendoflhe elbow

usingtheclampenclosed

(6).

c. I\lo!nt sheelmelalreducing

adapler

(10)

to lhe inlel

on

iop ol drumlid/guard

assernblyusing

lhe squeeze

luglo

secure.

(x HP[4odelon]y).

d. Clampsuclionhose(7)10

reducing

adapteror inletwth

adjustableclarnp

(8)provided.

e. Clampnozzle

(14)to suction

hosewilh camp (8).

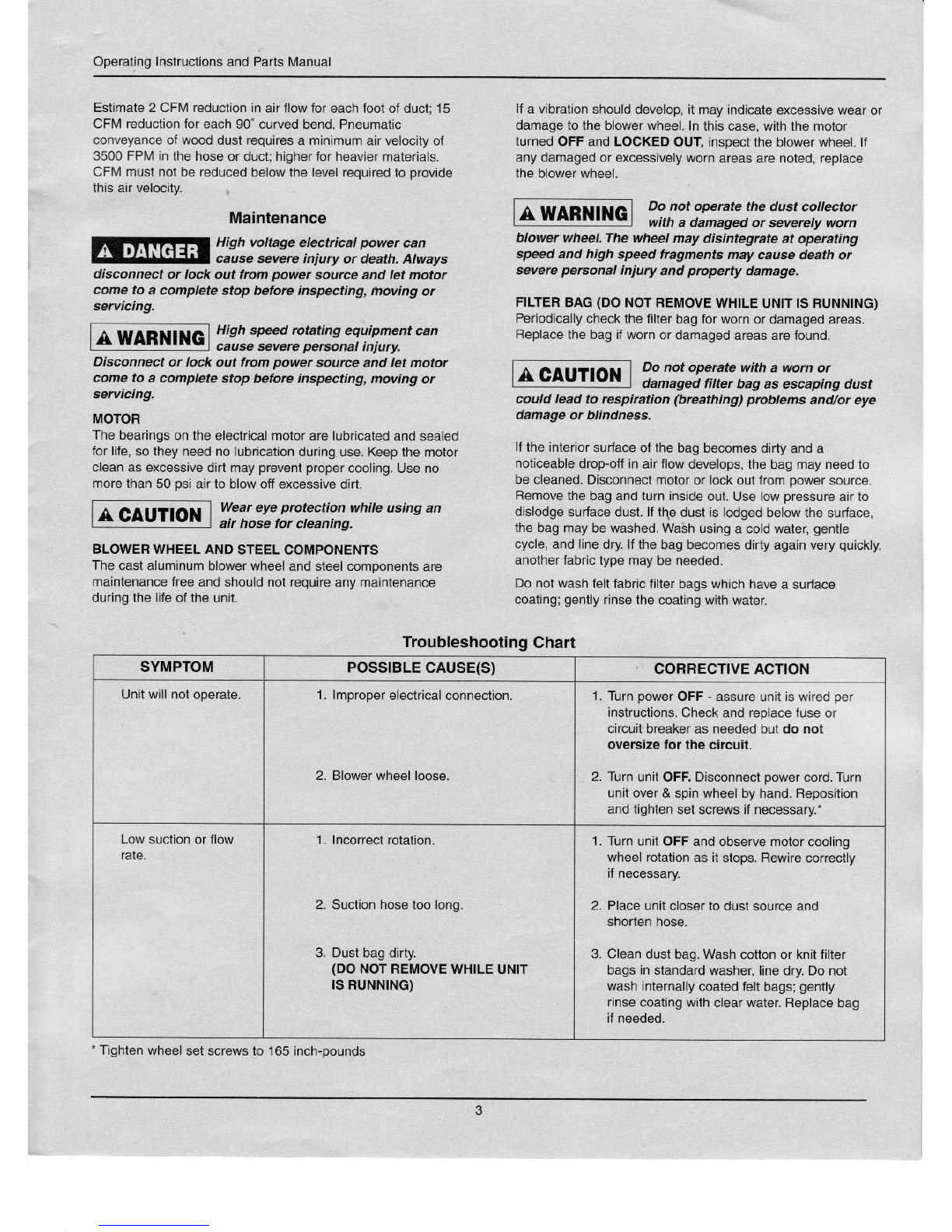

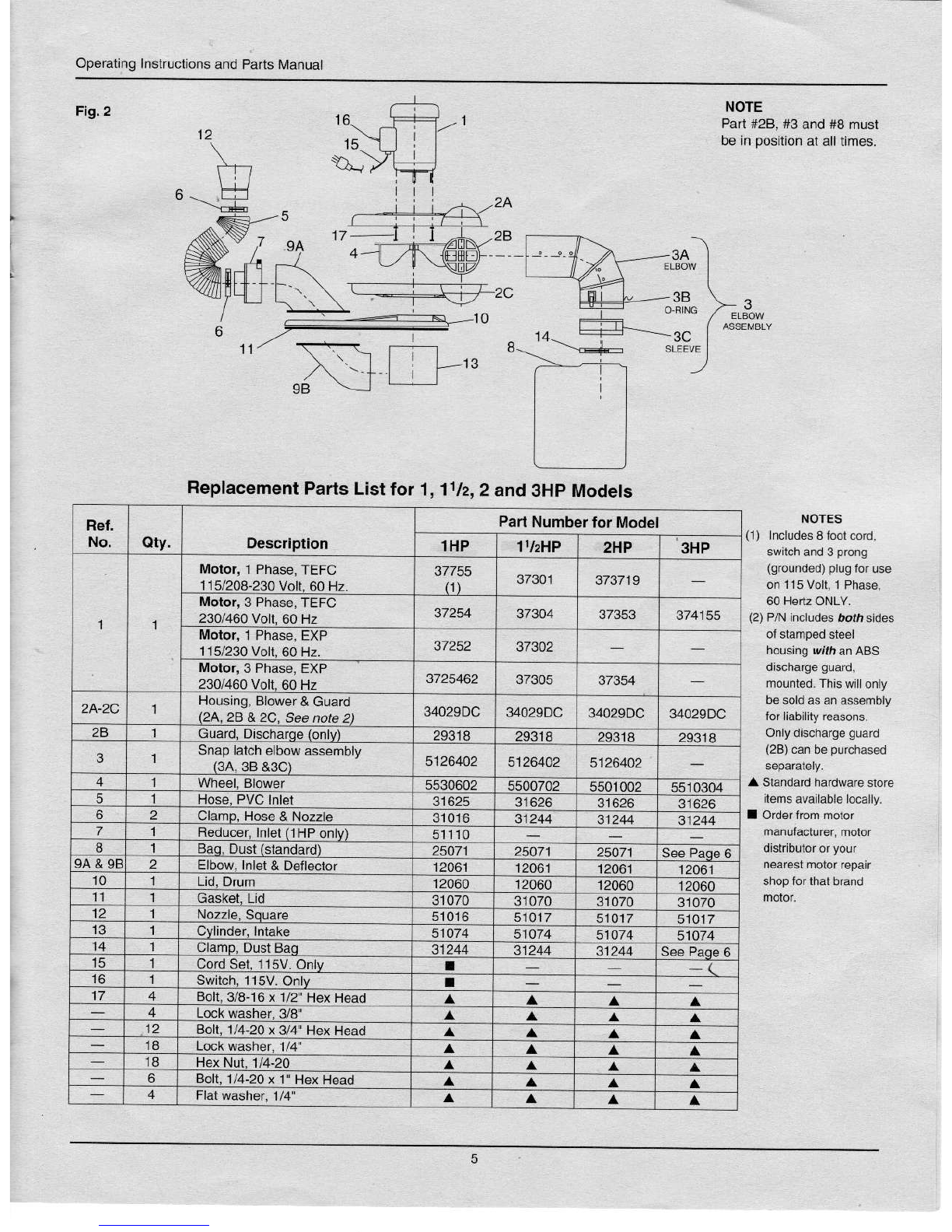

'1,

1x, 2 and 3HP Models(SeeFigure2,Page

5)

1.Assemblyncludesthe insrallationol lhe intakecylinder,

deflectorelbow,sealing

gaskel,

dischargebagelbow,dusl

bag,hoseand nozzle.

2.Toinsialltheintake

cylinder,delleclorelbowandsealing

gaskel,place

lhe unitupsidedo\,!nona cardboardcovered

a. Thedelleclorebow(98) isallachedas shownby

rcmovingthetwonuts nslalled

al lhelaclory,

b. The nrake

cyLinde'{13)is dhaLhedas shownLsirg

1/4-20

bollssupplied.

c.Bemovelhe paperproieciion

fromtheslickysideofthe

sealing

gaskel(11)

andinstallon lhe undersde of lhe

drumlld

(10).

3. Allachbagelbow,I lter

bag,hose

andnozzle

(excepl

3HPlVodel)'.

a.Placetheunitright-slde-up

onyour

containerandatlach

lhe discharcebagelbow

(3A)

on lhe dischargeoflhe

bower as showninthe illustration.Inserl

and

ilghlenihe

lncluded

sheelmelalscrews.

b.Theduslbag s atlachedlo lhe rernovable

elbowsleeve

(3C).(This

sleevesips

over

lhe endoftheelbow

andis

heldinplace

wilhsnap'atches.)Clarnplhe dusl bag(8)

tolhe sleev€

(3C)

usinglhe clamp

(14)

enclosed.

IMPORTANT!The

edgeof lhe dustbagshouldbe

approxirnately1/4'below lheflange

on lhe seeve sothat

thesnap-lalches

canclosecomplelely.

ltlheiabrlcistoo

closetotheflange,thesnap-latch

willrest

on iheiabric,

andnotfullyrerainrheduslbag.

Slipth€6 diamelerO-ring

(38)overtheendofthe

elbow

(3A)

andseatagainsllhe retainrngr b.Wilhsnap

latcheslna aised posilion,

slidethesleeve

(3C)wilh

attachedbagonlotheendoftheelbowwlh a slight

lwislingmorion

unliltghl aga

nsllhe oling. snap the

latchesdown.

(To

removelhe duslbaglorernptying,

snapuplhe lalchesandremoveihe seeve;reinsta

las

c. l,lounllhe sheel

meialreducngadapler

(7)

onthe inlet

elbow

(9A)

usingrhesqueezelugto secure.

(1HP

N4odelonly).

d. Clamplhe suclion

hose

i5) tothereducingadapleror

nletelbow

using

theadjustableclamp

(6)provided.

e. Clampnozzle

(12)to suclionhosewllhclamp

(6).

lnstallation

Pacelheassembleddusicollectoronrhe

correct

diameter

drum

(not

included).Plasticconlainersshouldnolbeused

aslheycannotsupportth€weightol lhe colleclor.

PaceX,l, andt1HPModelsonaconlainerhavingadiameter

ol19[''201'-Thisincludes3o-gallon

galvanizedgarbage

cans,or3035

gallon

openiopsieelorliberdrums.Donoluse

Place1,114,2and3 HPModelsonaconlainerhavinga

diameter€ngeof23"24',suchasastandard55-gallonsle€l

or

liber

drum.Donotuse

plastic

drums.

Checkmotorrotationon3-phase

power

connections;lhe

coolinglanonthemolorshouldtumclockwrseasobserved

ifom

above.Anelectriciancancoffectrolanonb?

interchanging

anytwo

(3-phase)

power

leadwlres.

Operation

Attachihedusicollectorinlelhosedireclytoiheconneclor

builtinlothedust

producing

lool.lfnobuilt-nconneclor,

poslion

a hoseendmounlednozzlewheret wil collecllhe

dusl.NOTE:Checklherecommendaionoflheloo

manufaclurerfor

therequiredCF[,4airllowTheCFMlisledin

lhespecificationslor

your

collectorshouldbe

greater

thanthe

required

CFI!'ltoensureduslcollection,See

page

7.

Emptythe

duslcollectiondrumwhenitbecomeshaffultiftoo

lull,

alldlst wlIbecarriedintothedustbag.

' See

page

6lorliler bagattachmentfor3HPlvodel.