aci ANALOG RESCALING Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 3.0

I0000470

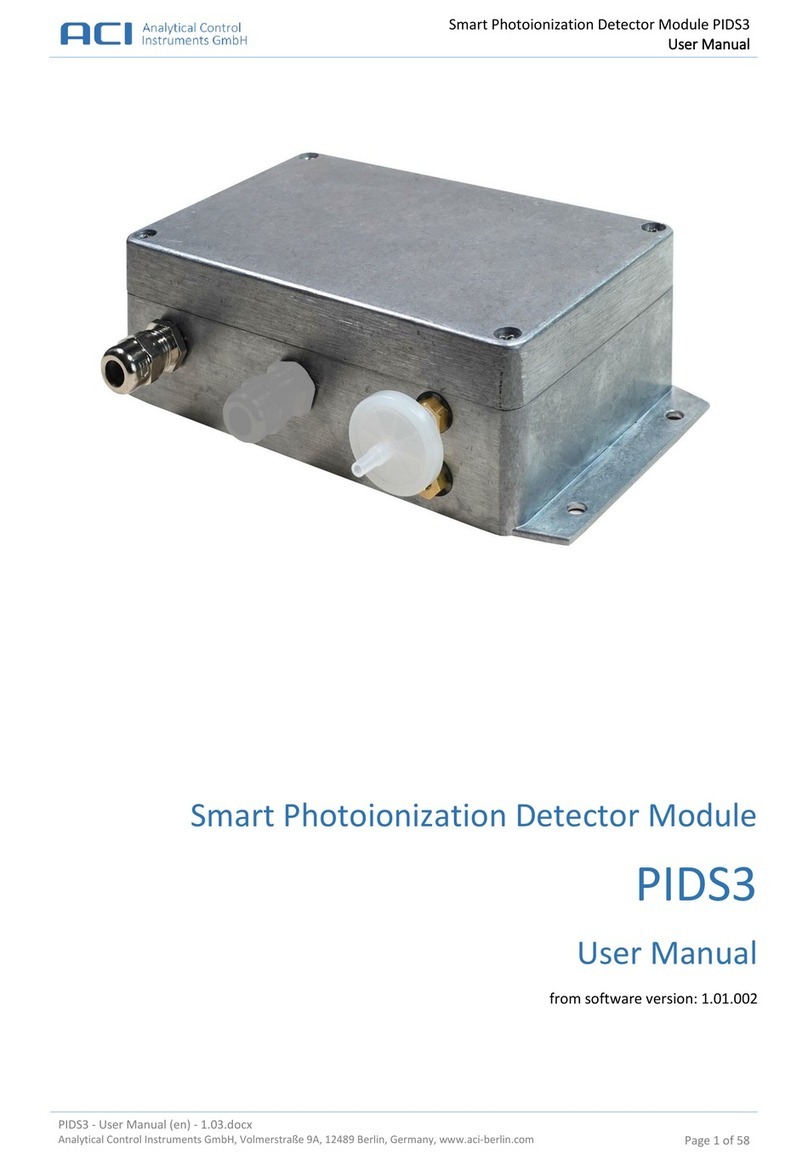

FIGURE 1: DIMENSIONS

ANALOG RESCALING MODULE

INTERFACE SERIES

Installation & Operation Instructions

ARM

Phone: 1-888-967-5224

Website: workaci.com

3.69” (93.82mm)

2.17”

(55.27mm)

0.70” (17.78mm)

2.30”

58.42mm)

2.70” (68.58mm)

BOARD

SNAP TRACK

GENERAL INFORMATION

The ARM is an analog rescaling module which

accepts an analog (voltage or current) input signal

and rescales it to another voltage or current output

signal. The top-adjust trimmer potentiometers can

be used to make ne adjustments to output ranges

for maximum exibility. This device can attenuate

an input signal to 100%. The ARM also has an

adjustable gain and oset. The output gain can be

adjusted from 1 to 25 times the input (gain will vary

depending on input). The oset of the output can

be adjusted anywhere from 0 to +/- 20 VDC. The

ARM also has the ability to reverse an input signal.

The ARM has a regulated 20 VDC power supply

output to power sensors. The ARM can also accept

a resistance input by using voltage divider

applications. The ARM is eld calibratable,

however, factory calibration is available upon

request for an additional charge. This will speed up

installation time for the end user.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If circuit board slides out of snap track, a nonconductive

“stop”

may be required. Use only ngers to remove board from snap track. Slide out of snap track or push against

side of snap track and lift that side of the circuit board to remove. Do not ex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both

ends can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids,

or other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the

DC Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 3.0

I0000470

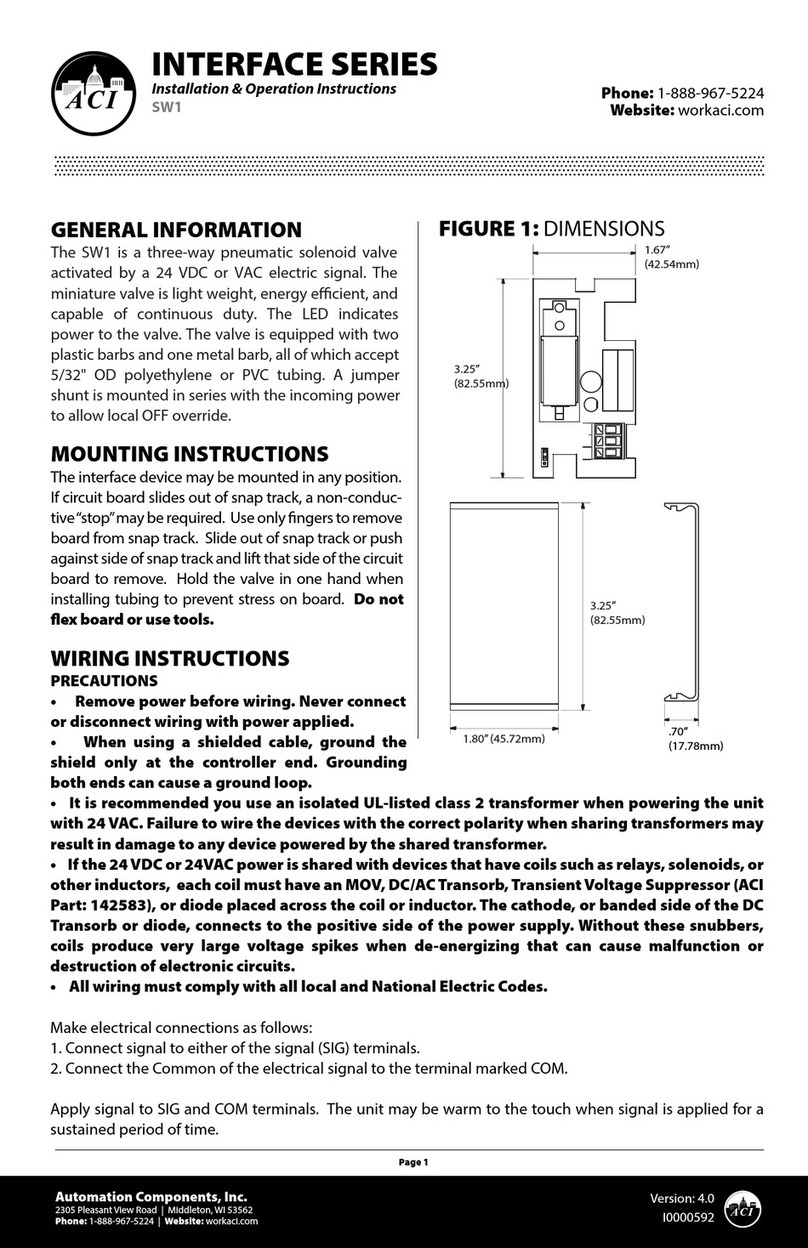

FIGURE 2: WIRING

Note: The ARM does NOT isolate the input signals from the

output. Use the Analog Isolation Module (AIM1, AIM2, or AIM3)

if you need to isolate the signal from the device being

controlled.

FACTORY CALIBRATION

The ARM is set as follows:

•No Attenuation to the Input Signal

•Voltage Input Signal

•Voltage Output Signal

•Normal Acting Output Signal

•No Oset to the Output Signal

•Gain of 1 to the Output Signal (1:1)

The ARM can be ordered calibrated to your specications or you may follow the procedure below to set

your own calibration.

Be sure to check the input, output, GAIN and OFFSET specications of the ARM. It is possible that the ARM

cannot re-scale to your requirements.

Calibration

Complete the following steps to change the calibration of the ARM. You will need a digital volt/current

meter, a 24 VDC power supply and a voltage input signal simulator. (A 5K ohm or greater trim pot can be

used as a voltage input signal simulator by connecting one end of the trim pot resistance winding to the

(+) 24 of the power supply, the other end of the trim pot resistance winding to the (-) 24 of the power

supply and the wiper end of the trim pot to the “IN”terminal of the ARM).

EQUIVALENT CALIBRATION VOLTAGE

Use a voltage signal for your input signal during calibration: this makes both the procedure and the

explanation easier. If you will require a current input when you are nished, use the equation below to nd

the equivalent calibration voltage to use during the calibration procedure:

FINE GAIN OSET REV ATTN

PWR

L1

J1

J2

J3

OFFSET

RN

OUT

IN

IE

OUT

IN

P

+ 24 - O-+

Analog Output Signal

Note: 20VDC Regulated Accessory Power output used

for resistance to analog conversions

24 VAC/DC

Power Supply

Analog Input Signal

(+)

(+)

(+)

(+)

(-) (-)

OUT

IN

P

+ 24 -

24 VDC

24 VAC

Power

Supply

Loop

Powered

Sensor

(+) (-)

J3 OUT

IN

IE

Set IN to Current (I)

for Loop Powered

Sensor

20 VDC

at this

terminal

Input from 2-wire mA loop powered

sensor (using 20V ARM "P" terminal

for power)

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 3.0

I0000470

EQUIVALENT CALIBRATION VOLTAGE (Continued)

Equivalent Calibration Voltage = Required Input Signal Amps x 250

Example: 1 VDC is the equivalent calibration voltage for a 4 milliamp input signal (1 = .004

x 250) or 5 VDC is the equivalent calibration voltage for a 20 milliamp input signal (5 = .020

x 250).

Step 1) Trim Pot Presets Set all pots as follows to start (These are multi-turn trim pots with no hard stops;

they may make a slight clicking sound at either end of their range):

Turn the following pots full clockwise (25 turns): GAIN = gain of 1

FINE

OFFSET = 0 volts oset

REV = 0 volts reverse

Turn the following pot Full Counterclockwise (25 turns): ATTN = (no input signal attenuation)

Step 2) Jumper Shunt Presets

J1- NORMAL OR REVERSE ACTING: Set in “N” position for direct acting output signal. (If you require a

reverse acting output signal, you will set this shunt in the “R”position in Step 7).

J2 - OFFSET: Set in the “O”position for no oset to the output. (If you will require a“+” or“-” oset, you will

set this shunt in the appropriate position in Step 6).

J3 IN - INCOMING SIGNAL VOLTAGE OR CURRENT: Set in “E”position for voltage input . (If you require a

current input, you will set this shunt in the “I” position AFTER you are nished with the calibration

procedure).

J3 OUT - OUTGOING SIGNAL VOLTAGE OR CURRENT: Set in “E” position for voltage output (If you

require a current output, you will set this shunt in the “I” position AFTER you are nished with the

calibration procedure ).

Step 3) Wiring Connections

Make the following connections with the power OFF:

Connect a 24 volt AC or DC power supply to the ARM terminals “+24” and “-24”.

Connect the input signal common (-) and the (-) meter lead to the“-24” terminal. Connect (+) input signal

lead to the“IN” terminal.

Connect (+) meter lead to the“OUT” terminal.

Step 4) Power Up

Turn on the 24 volt power supply: the POWER indicator will light.

Step 5) Input/Output Signal Adjustments

In this step you will gure the desired voltage input signal span and the desired voltage output signal span

(see the section on Equivalent Calibration Voltage) and calibrate the ARM to these input and output signal

spans.

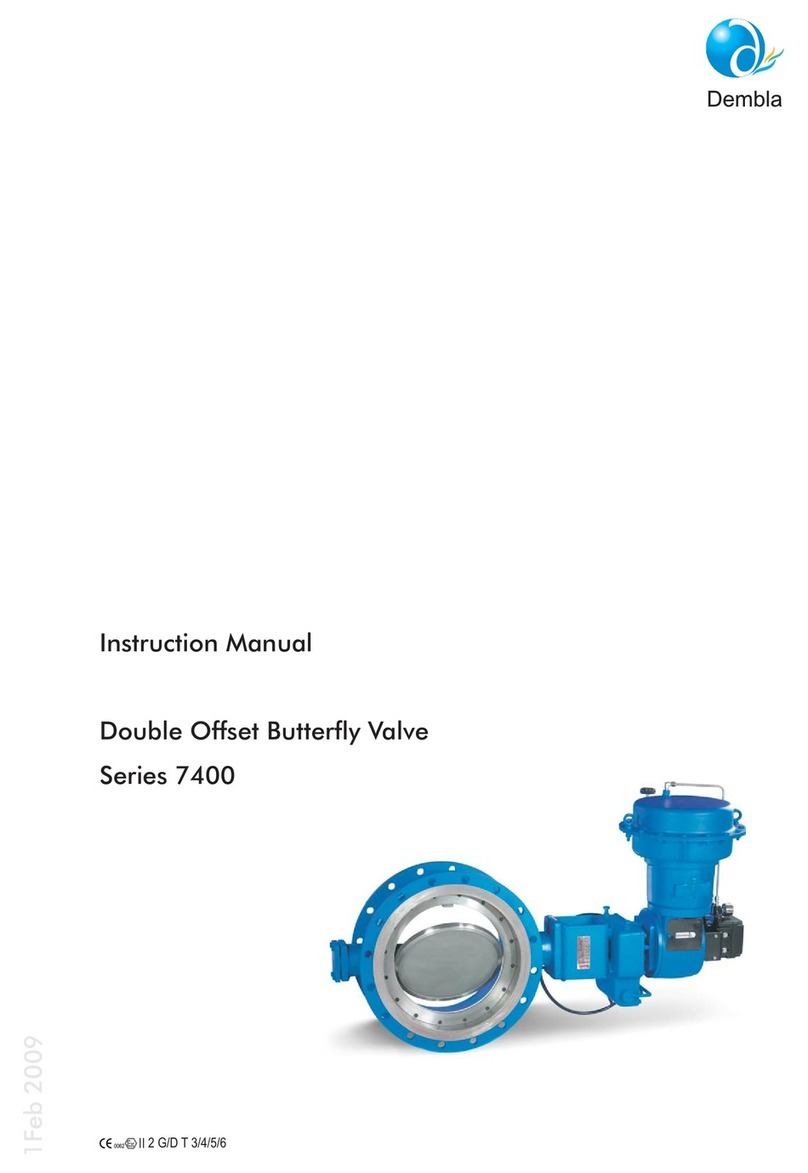

FIGURE 3: JUMPER SHUNTS

J2

OFFSET

O-+

J2

OFFSET

O-+

J2

OFFSET

O-+

No Oset - No

Output signal

span shift

Positive Oset

shifts Output

signal span higher

Negative Oset

shifts Output

signal span lower

Figure C

Shunt as shown selects Desired Output Oset

J3 OUT

IN

IE

J3 OUT

IN

IE

Sample Settings for Input

& Output Signal

Current IN/OUT Voltage IN/OUT

Figure B

J3 R N J3 RN

Sunt as shown selects

Desired Output Action

Direct Acting

Output increases

as Input increases

Reverse Acting

Output decreases

as Input increases

Figure A

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 3.0

I0000470

EQUIVALENT CALIBRATION VOLTAGE (Continued)

To calculate the voltage input signal span, subtract the minimum voltage input signal from the maximum

input signal (i.e. a 0 to 5 volt input signal will give you a 5 volt input signal span: 5-0=5).

To calculate the voltage output signal span, subtract the minimum voltage output signal from the

maximum voltage output signal (i.e. a 3 to 15 volt output signal will give you a 12 volt output signal span:

15-3=12).

Take the number for the voltage input signal span and apply this voltage to“IN”terminal.

Compare the output voltage reading on your meter with the voltage output signal span you calculated

above. If the meter reading is higher, adjust the “ATTN” trim pot until the meter reading drops to the

calculated output span. If the meter reading is lower, adjust the“GAIN”and “FINE”trim pots until the meter

reading increases to the calculated output signal span.

Step 6) Oset Adjustments

The oset adjustments simply shift the output signal range up or down from a “no oset” condition.

Example: An output signal range in a“no oset“ condition is 3 to 15 volts. Adding an oset

of 2 volts would make the output signal range 5 to 17 volts or subtracting an oset of 2 volts

would make the output signal range 1 to 13 volts.

Apply the minimum voltage input signal and read the minimum output signal on the meter. With the

“OFFSET” jumper shunt “J2” in the “O” position (from Step 6), no oset voltage will be added or subtracted

from the output signal range.

If you need to shift the output signal range up, set the “OFFSET” jumper shunt “J2” in the “+” position and

adjust the “OFFSET” trim pot until you increase the voltage reading on the meter to match the desired

minimum output voltage. (Remember, this also increases the maximum output signal by the same

amount.)

If you need to shift the output signal range down, set the“OFFSET”jumper shunt “J2” in the“-”position and

adjust the “OFFSET” trim pot until you decrease the voltage reading on the meter to match the desired

minimum output voltage. (Remember, this also decreases the maximum output by the same amount.)

Step 7) Reverse Action Adjustments

If you will require your output signal to reverse act, set jumper shunt “J1” in the “R” position. Apply the

minimum voltage input signal and adjust the“REV” trim pot for the highest desired output signal.

Check the low, mid-scale and high signal points to insure proper calibration.

Step 8) Final Adjustments

If you require a current input, set the “J3” IN jumper shunt in the“I”position. If you require a current output,

set the “J3” OUT jumper shunt in the “I” position. Check operation of the ARM for desired signal re-scaling

and operation.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 3.0

I0000470

Page 4

ARM CALIBRATION WORK SHEET : Fill in and circle answers.

1. Input: minimum______maximum______ mA or VDC, Output: minimum______maximum______ mA or

VDC

2. Is the input VDC? Yes/No. Is the output VDC? Yes/No

a) If yes to both, set jumper J3 (IN/OUT) to E and skip to step 5.

b) If no to both, set jumper J3 (IN/OUT) to I and skip to step 5.

c) If yes to only one, continue to step 3.

3. Is current the input signal? If no, skip to step 4. If yes, perform the following:

a) Set J3 (IN) to I and (OUT) to E.

b) Multiply input minimum by 250 and enter value in “Input minimum” in step 5a.

c) Multipy input maximum by 250 and enter value in “Input maximum” in step 5a.

Example : minimum=4mA = .004 x 250 = 1 VDC and maximum=20mA = .020 x 250 = 5 VDC.

4. Is voltage the input signal. If no, skip to step 5. If yes,

a) Set J3 (IN/OUT) to E. Output jumper will be changed to I in later steps.

b) Multiply output minimum by 250 and enter value in “Output minimum” in step 5b,

c) Multiply maximum by 250 and enter value in “Output maximum” in step 5b.

Example : minimum 4mA = .004 x 250 = 1 VDC and maximum 20mA = .020 x 250 = 5 VDC.

5. Enter mA, VDC or equivalent values below. Note: Do not mix voltage and current.

a) Input minimum______ Input maximum______ maximum-minimum = Input span______

b) Output minimum______ Output maximum______ maximum-minimum = Output span______

6. Preset trimpots: 25 Turns until it clicks.

25 Turns Clockwise - Gain, Fine, Oset and Reverse

25 Turns Counter clockwise – Attenuation

7. Make all connections including signal generator and multimeter. Apply power (24 VAC or VDC).

8. Set jumpers J2 to 0 and J1 to N

9. First test: input a 50% signal. Is the input equal to or close to the output?

If yes, proceed to step 10.

If no, return to step 7.

Note: Min, max and span values are found in step 5.

10. Supply the “input span” signal or equivalent to the input. (Refer to step 5).

a) If the “input span” is less than “output span”, turn the gain or ne trim pot until the output is equal

to the “output span” signal.

b) If the “input span” is greater than “output span”, turn the attenuation trim pot until the

output is equal to the “output span” signal.

11. Setting the oset jumper:

a) If the “input minimum” is greater than “output minimum” Set J2 to (-). Skip to 12.

b) If the “input minimum” is less than “output minimum” Set J2 to (+). Skip to 12.

c) If the “input minimum” is equal to “output min” Leave J2 alone and skip to step 12.

12. Supply the “input minimum” signal or equivalent to the input. Adjust the oset trim pot until the output reads

the same as “output minimum”.

13. Is signal reverse acting? If not skip to step 14. If yes, refer to following:

a) Set J1 to R.

b) Supply “input minimum”, or equivalent, and adjust the Rev trim pot until reading is equal to output

maximum.

14. If the output is current. Set J3 (out) to I and reset meter to current. (Vout / 250 = mA).

15. Check the low, mid-scale and high signal points to check output for proper calibration. Fine calibration

adjustments may now be made.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 3.0

I0000470

ARM CALIBRATION WORK SHEET : Fill in and circle answers.

1. Input: minimum______maximum______ mA or VDC, Output: minimum______maximum______ mA or

VDC

2. Is the input VDC? Yes/No. Is the output VDC? Yes/No

a) If yes to both, set jumper J3 (IN/OUT) to E and skip to step 5.

b) If no to both, set jumper J3 (IN/OUT) to I and skip to step 5.

c) If yes to only one, continue to step 3.

3. Is current the input signal? If no, skip to step 4. If yes, perform the following:

a) Set J3 (IN) to I and (OUT) to E.

b) Multiply input minimum by 250 and enter value in “Input minimum” in step 5a.

c) Multipy input maximum by 250 and enter value in “Input maximum” in step 5a.

Example : minimum=4mA = .004 x 250 = 1 VDC and maximum=20mA = .020 x 250 = 5 VDC.

4. Is voltage the input signal. If no, skip to step 5. If yes,

a) Set J3 (IN/OUT) to E. Output jumper will be changed to I in later steps.

b) Multiply output minimum by 250 and enter value in “Output minimum” in step 5b,

c) Multiply maximum by 250 and enter value in “Output maximum” in step 5b.

Example : minimum 4mA = .004 x 250 = 1 VDC and maximum 20mA = .020 x 250 = 5 VDC.

5. Enter mA, VDC or equivalent values below. Note: Do not mix voltage and current.

a) Input minimum______ Input maximum______ maximum-minimum = Input span______

b) Output minimum______ Output maximum______ maximum-minimum = Output span______

6. Preset trimpots: 25 Turns until it clicks.

25 Turns Clockwise - Gain, Fine, Oset and Reverse

25 Turns Counter clockwise – Attenuation

7. Make all connections including signal generator and multimeter. Apply power (24 VAC or VDC).

8. Set jumpers J2 to 0 and J1 to N

9. First test: input a 50% signal. Is the input equal to or close to the output?

If yes, proceed to step 10.

If no, return to step 7.

Note: Min, max and span values are found in step 5.

10. Supply the “input span” signal or equivalent to the input. (Refer to step 5).

a) If the “input span” is less than “output span”, turn the gain or ne trim pot until the output is equal

to the “output span” signal.

b) If the “input span” is greater than “output span”, turn the attenuation trim pot until the

output is equal to the “output span” signal.

11. Setting the oset jumper:

a) If the “input minimum” is greater than “output minimum” Set J2 to (-). Skip to 12.

b) If the “input minimum” is less than “output minimum” Set J2 to (+). Skip to 12.

c) If the “input minimum” is equal to “output min” Leave J2 alone and skip to step 12.

12. Supply the “input minimum” signal or equivalent to the input. Adjust the oset trim pot until the output reads

the same as “output minimum”.

13. Is signal reverse acting? If not skip to step 14. If yes, refer to following:

a) Set J1 to R.

b) Supply “input minimum”, or equivalent, and adjust the Rev trim pot until reading is equal to output

maximum.

14. If the output is current. Set J3 (out) to I and reset meter to current. (Vout / 250 = mA).

15. Check the low, mid-scale and high signal points to check output for proper calibration. Fine calibration

adjustments may now be made.

Page 6

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 7

Version: 3.0

I0000470

PRODUCT SPECIFICATIONS

WARRANTY

The ARM Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS &

TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Page 6

24 VAC or 24VDC, (+/- 10%), 50/60 Hz

200 mA maximum

0 to 35 VDC @ 1M

0-44 mA @ 250

0 to 500,000

Multi-turn potentiometers

0.25 VDC minimum to 20 VDC maximum

44 mA maximum, Signal Gain 1 to 25 times (nominal) depending on input value

+/- 1%

0 to 100%

0.25 to 20 VDC

20 to 0.25 VDC (nominal)

750 @ 20 mA

3300 @ 20 VDC +/- 10% / 400 @ 10 VDC +/- 10%

20 VDC +/- 10%, 30 mA maximum

45° Captive screw Terminal Blocks

12 (3.31 mm) to 22 AWG (0.33 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

Polyvinyl Chloride (PVC)

UL94 V-0

RoHS2, WEEE

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Voltage Signal Range (@

Impedance):

Input Current Signal Range (@

Impedance):

Input Resistance Signal Range:

Field Adjustable Ranges:

Output Voltage Signal Range:

Output Current Signal Range:

Output Accuracy:

Output Signal Attenuation:

Output Signal Oset:

Output Signal Inversion (RA):

Output Current Load Impedance:

Output Voltage Load Impedance:

Regulated Power Output:

Connections:

Wire Size:

Terminal Block Torque Rating:

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

Snaptrack Material:

Snaptrack Flammability Rating:

Agency Approvals:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

Page 8

Version: 3.0

I0000470

This manual suits for next models

2

Table of contents

Other aci Control Unit manuals

Popular Control Unit manuals by other brands

Bray

Bray 19L Series Installation, operation and maintenance manual

ETAS

ETAS ES650.1 user guide

APARIAN

APARIAN J1939/B Series quick start guide

Carrier

Carrier 50CO Series Installation, operation and maintenance instructions

Honeywell

Honeywell S4567A 1001 instruction sheet

Vimar

Vimar Elvox RS15 Installation and operation manual