aci AAR Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 1.0

I0000467

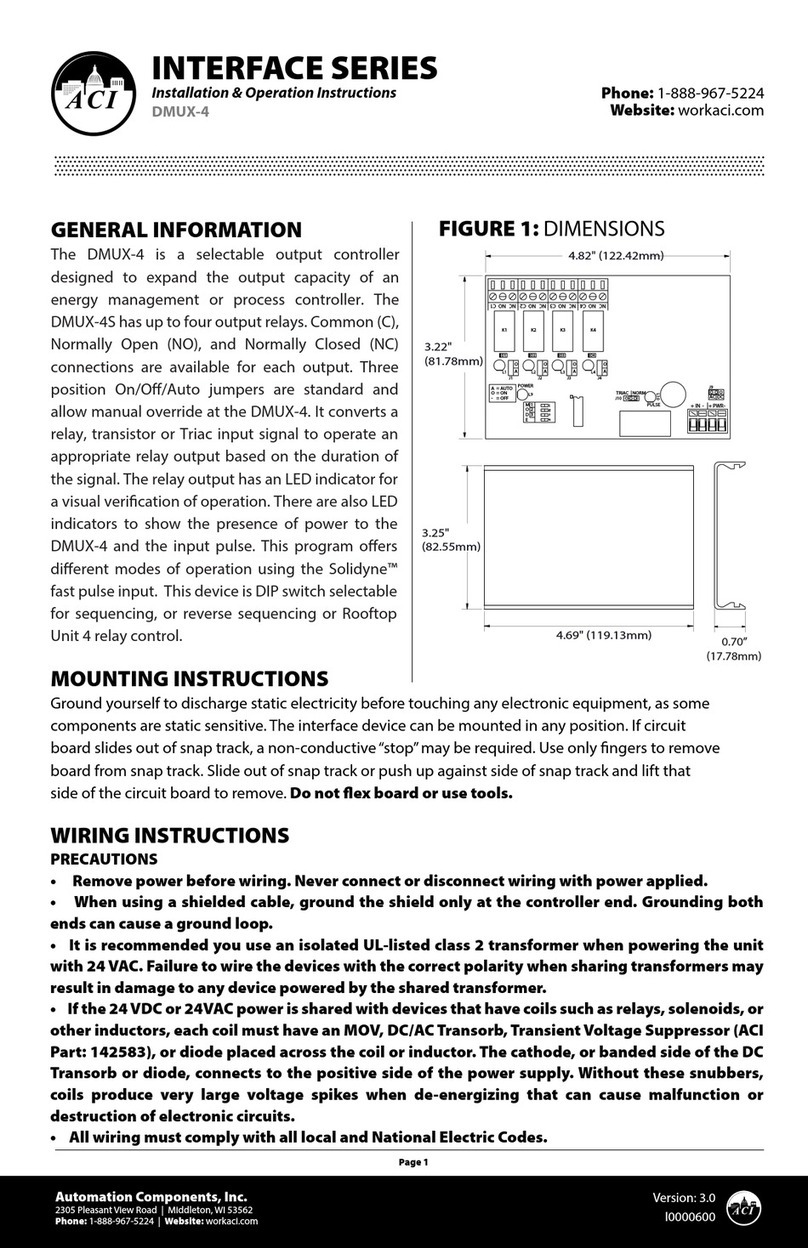

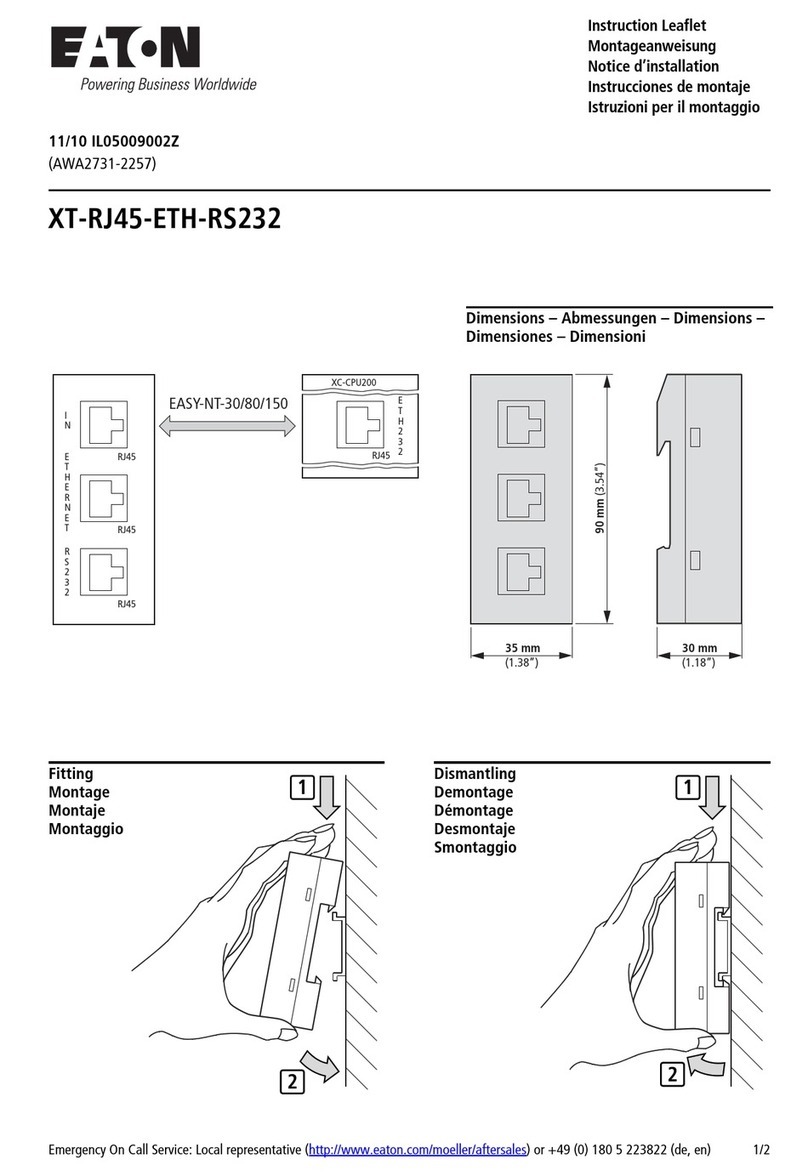

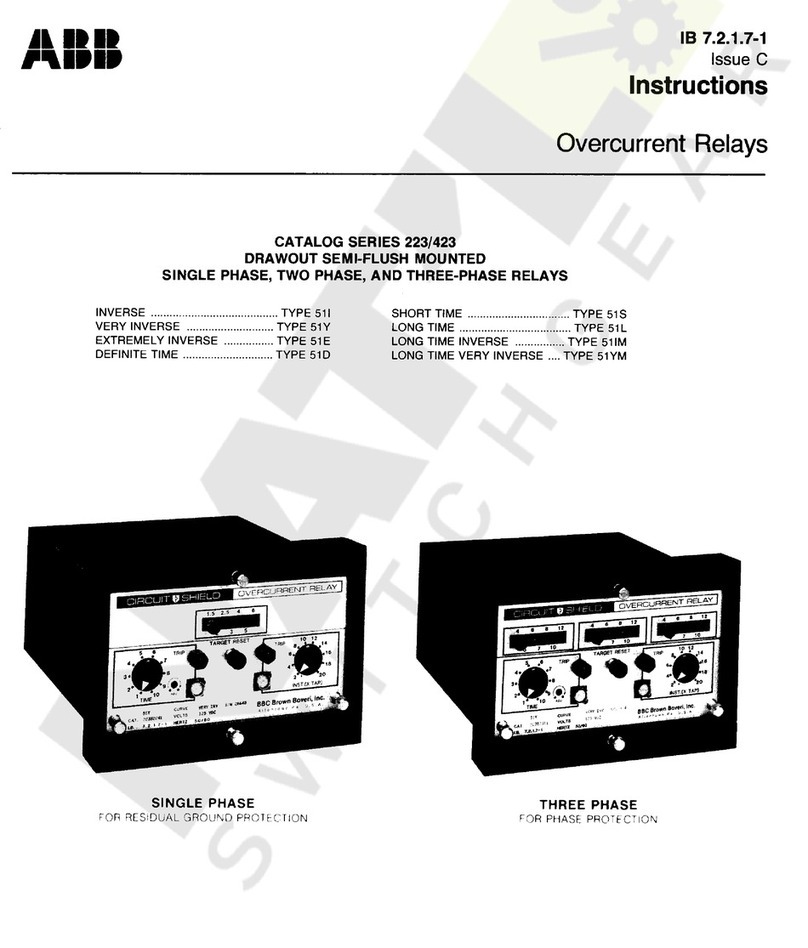

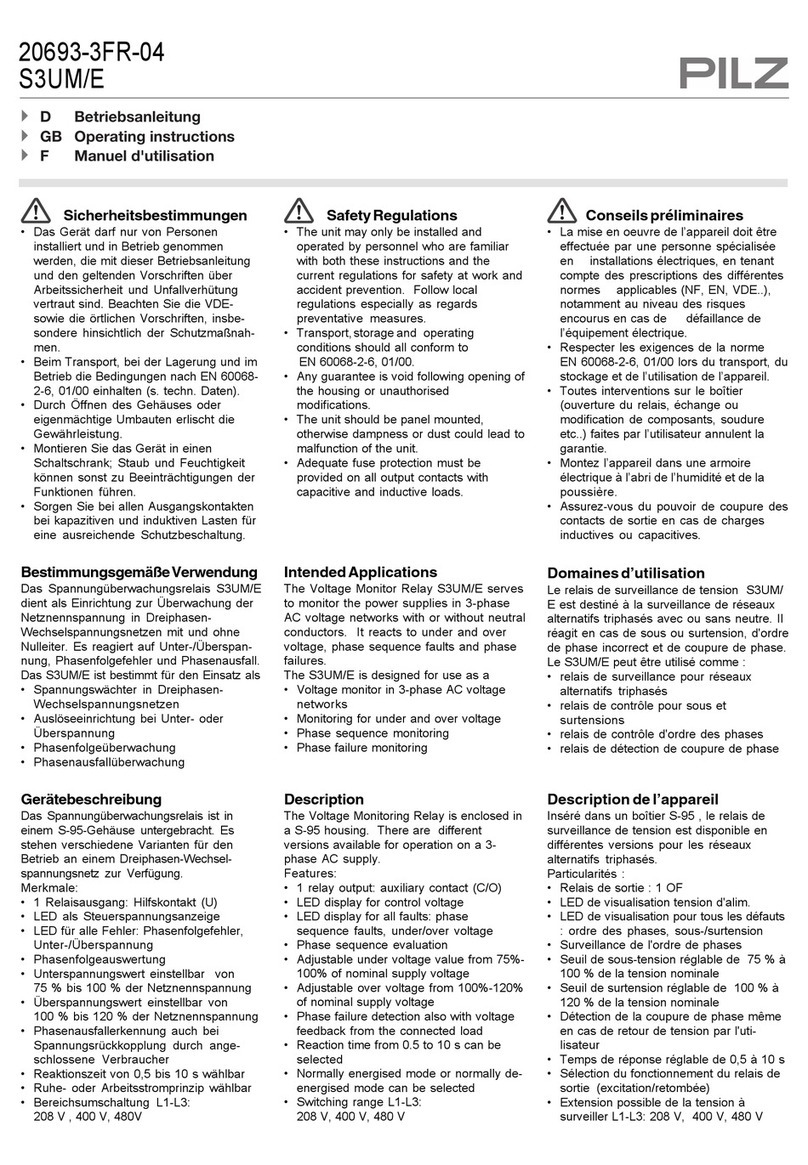

FIGURE 1: DIMENSIONS

ANALOG TO RELAY

INTERFACE SERIES

Installation & Operation Instructions

AAR

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The AAR is controlled by a single analog input signal

with two potentiometers controlling each output

relay. The two 10 amp output relays can be

independently set to xed or adjustable deadband.

“Fixed”, the relay will turn “ON” at the level set by the

Low pot and will turn“OFF”at a xed 3% of the input

signal below the turn-on level. “Adjustable” allows a

exible range of deadband adjustment using both

the High and Low potentiometer. The

edge-connector feature allows signal and power

connections to be extended to the next board. This

allows the installer to wire the rst unit, then slide

additional units together by plugging into a power,

and signal bus without the need to strip and

terminate additional wires. The AAR is eld

calibratable, however, factory calibration is available

upon request for an additional charge. Relay trip

points can be factory calibrated, saving installation

time and expense.

MOUNTING INSTRUCTIONS

The interface device can be mounted in any position. If circuit board slides out of snap track, a

non-conductive “stop” may be required. Use only ngers to remove board from snap track. Slide out of

snap track or push up against side of snap track and lift that side of the circuit board to remove. Do not

ex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both

ends can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

3.25” (82.55mm)

2.42”

(61.46mm)

0.70” (17.78mm)

3.25” (82.55mm)

2.70”

(68.58mm)

BOARD

SNAP TRACK

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 1.0

I0000467

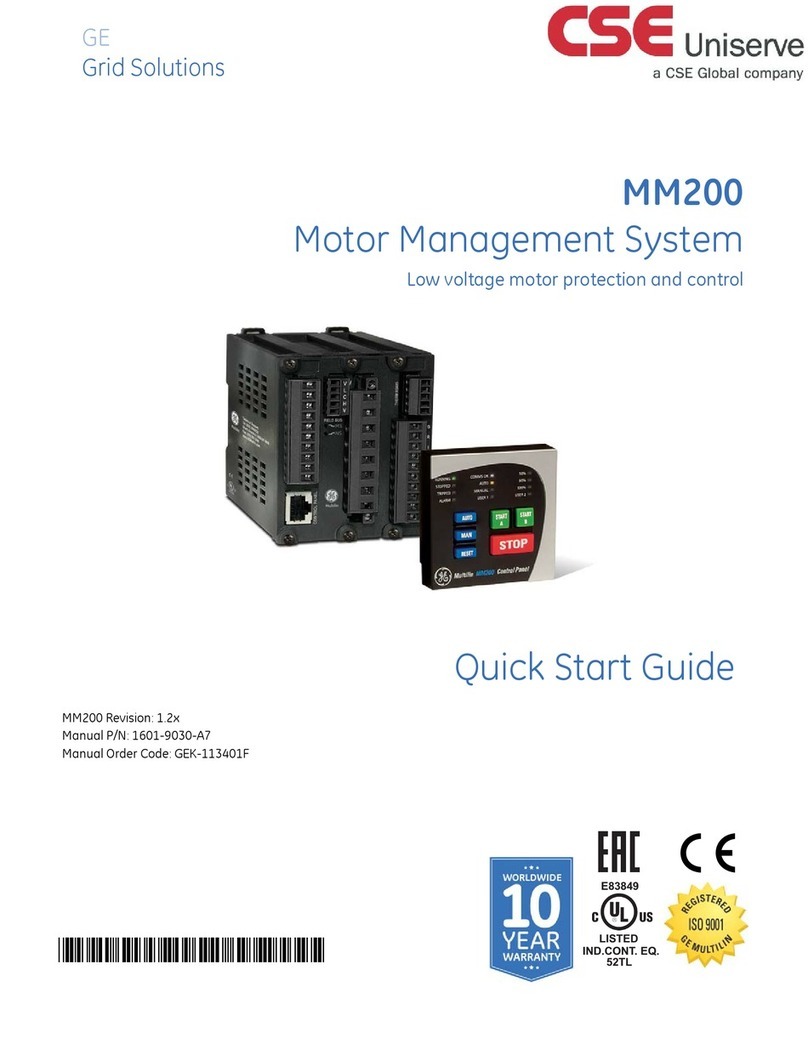

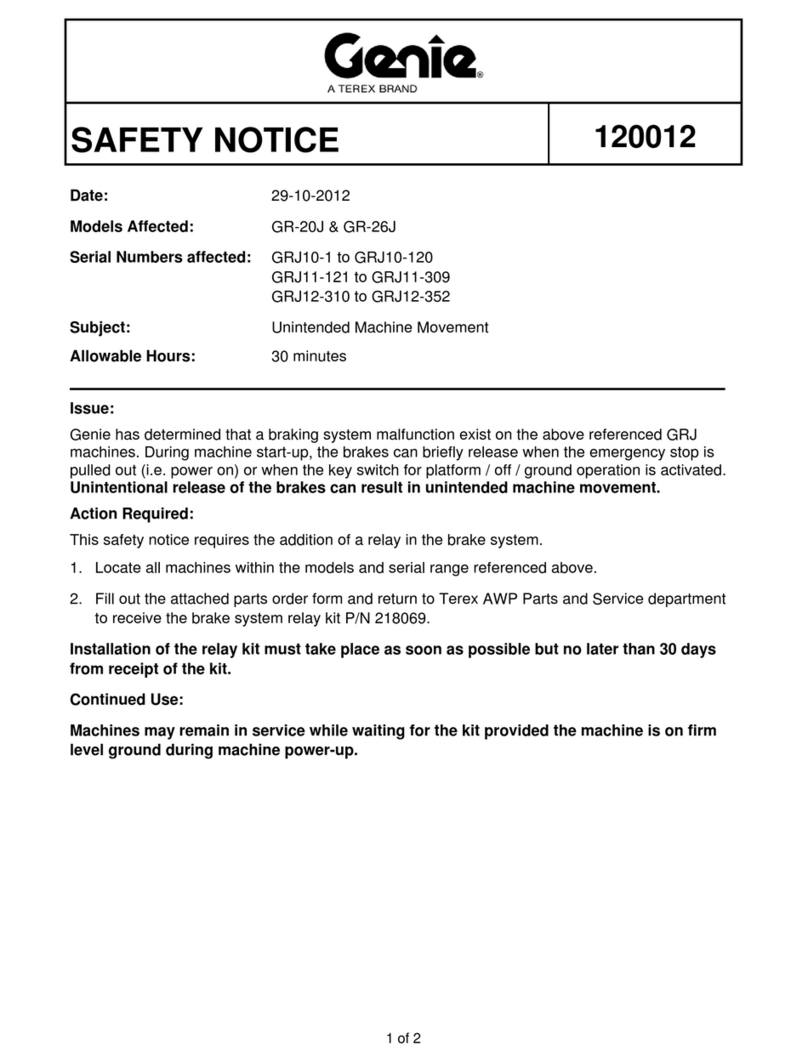

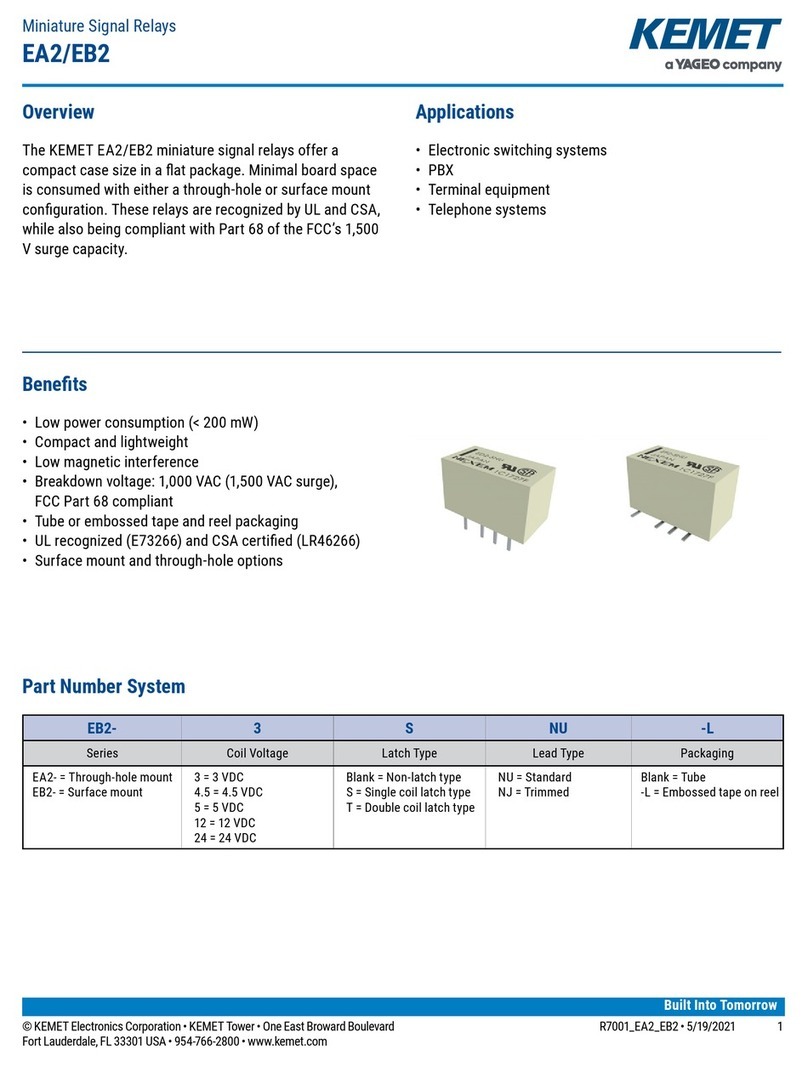

NC

C1

NO

NC

C1

NO

A

1F

A

J2

F

24

12

0-20mA

J1

IN

-

+H1

L1

H2

L2

2

NC

C1

NO

NC

C1

NO

A

1F

A

J2

F

24

12

0-20mA

J1

IN

-

+H1

L1

H2

L2

2

Snap together to extend signal and power

Analog

Input

Signal

(+)

(-)

24 VAC/DC

Power Supply

(+)

(-)

24

12

0-20mA

J1

24

12

0-20mA

J1

0-20mA

0-12V

24

12

0-20mA

J1

0-24V

Signal Input Ranges

Set Jumper Switch for

A

1F

A

J2

F

2

Relay 1

Relay 2

FIGURE 2: WIRING

Calibration

1. Each relay can be individually set for a Fixed or Adjustable deadband. Place jumper shunts for relay 1

or 2 on A for adjustable or F for xed (or a combination of each).

Example: Relay 1 is set for an adjustable deadband. The turn on level is set with the High (H1)

potentiometer. The turn o level is set set wit the Low (L1) potentiometer (see Figure 2 for locaion of H1

and L1).

Relay 2 is set for a xed deadband, which allows a deadband of 3% of the input signal between the turn

on and turn o signal levels. Use the Low (L1) potentiometer to set the turn o level of the xed

deadband (the High potentiometer is out of the circuit).

2. Three input signal ranges can be selected. Set J1 to the desired type.

Note: If the rst board is to receive a 0-20 mA signal, then any attached boards must be set at the 0-12

VDC signal mode to operate correctly.

If the input signal is voltage, then set attached boards to same voltage as the rst board. Up to 6 boards

may be cascaded from same power supply. More can be connected if external power connection is

jumpered to every sixth board.

3. After jumpers are placed in the desired setting, turn on 24 volt power supply.

4. Turn all four potentiometers counterclockwise (these are approx. 20 turn pots).

5. Provide an input signal level equal to the desired turno point.

6. Adjust the L (low) potentiometer clockwise until the LED for the relay just turns OFF.

7. Turn the H (high) potentiometer for the relay clockwise (these are approx. 20 turn pots).

8. Provide an input signal level equal to the desired turn-on point.

9. Adjust the H potentiometer counterclockwise until the LED for that relay just turns ON.

10. Repeat steps 5 through 9 for each relay.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 1.0

I0000467

APPLICATION NOTES

Two unique uses for the AAR that may solve a problem for you.

Problem: From one analog signal I want to turn ON a load when the analog signal increases to a certain

value, and if it continues to increase, OFF again.

Solution: Set R1 to turn ON at 6 mA.

Set R2 to turn OFF at 10 mA.

As the signal input to the AAR increases to 6

mA the load will turn ON. As the signal input to

the AAR continues to increase to 10 mA, the

load will turn OFF.

Problem: From one analog signal I want to turn a motor ON at low speed when the signal increases to a

certain value, and to high speed if the signal continues to increase above the certain value.

Solution: Set R1 to turn ON at 6 mA.

Set R2 to turn ON at 10 mA.

When relays R1 and R2 are o, High and Low

speed are OFF.

When relay R1 is energized, Low speed is ON.

When R1 and R2 are ON, High speed is ON, Low

speed is OFF.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 1.0

I0000467

PRODUCT SPECIFICATIONS

24 VAC or 24VDC, (+/- 10%), 50/60 Hz

45 mA maximum

0 to 12 VDC @ 1M, 0 to 24 VDC @ 20,000

0-20 mA @ 499

Fixed or Adjustable – Jumper Selectable

Two SPDT Form “C” Relays

10A @ 120 VAC / 24VAC, 5A @ 240VAC

100,000 operations minimum

10,000,000 operations

90° Pluggable Screw Terminal Blocks

16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

Connect six AARs together using one connection, more if power is jumpered to

every sixth AAR

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

Polyvinyl Chloride (PVC)

UL94 V-0

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Voltage Signal Range (@

Impedance):

Input Current Signal Range (@

Impedance):

Deadband:

Digital Output Type:

Relay Contact Rating:

Relay Electrical Life:

Relay Mechanical Life:

Connections:

Wire Size:

Terminal Block Torque Rating:

Edge Connector:

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

Snaptrack Material:

Snaptrack Flammability Rating:

WARRANTY

The ACI AAR Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS

& TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Other aci Relay manuals