8

N O T E

Your amplier will not work if KEY-IN is not connected properly.

Transceiver producers give different names to this output, such as TX-GND, SEND, T/R-LINE, PTT,

etc. Some transceivers require that "ground on transmit" be implemented via a software command,

or by changing the setting of a switch on the rear panel or in the interior of the transceiver. Check your

transceiver manual. Consult with your dealer if you are having difculty.

The switching voltage presented from amplier KEY-IN socket to the transceiver “ground on transmit”

output does not exceed 13V (positive to the ground). The closed-circuit current is below 5mA.

e) The KEY-OUT socket on the rear panel provides an extra control signal from the amplier to the

transceiver. It can be used to improve the transmit/receive switching safety. The rating on this output

is very low current, so be certain that the load will not exceed 50VDC when it is open circuit and 20mA

when it is closed.

If your transceiver has a suitable input that disables transmission, we recommend that you connect it

with a cable terminated in a phono (RCA) connector to the KEY-OUT socket of the amplier. Transceiver

producers give different names to this input and they are for instance TX-INHIBIT, MUTE, LINEAR, etc.

Check your transceiver manual.

Your amplier will function normally if the KEY-OUT remains unused.

f) Preparation of wall outlet for the amplier.

W A R N I N G

If your amplier is only tted with one mains fuse, it is suitable for the European

Union ONLY. Your dealer will check that your amplier is correctly fused before

it is shipped to you, based upon your indicated location. Customers should

check with a qualied electrician if the amplier is to be used outside the country

for which it was purchased.

Your dealer will t the correct mains plug for your country, and will check that the amplier is correctly set

for the mains network applying there. If the amplier is to be connected to the mains network in another

country, check with your dealer or a qualied local electrician before use there.

W A R N I N G

Before connecting the amplier to your mains supply, be sure that the supply is

correctly wired, and that it is adequate for the current drawn by the amplier - up

to 16A from 200/240V and 20A from 100/120V. Make certain that the grounding

lead is connected properly in the wall outlet used for the amplier.

It is preferable that you use a wall outlet close to the power source. The power cord leads and associated

wiring should be at least 2.5mm2 (AWG 13 or SWG 15). Check if the respective fuses can handle current

up to 16A (20A for 120VAC) as well, and whether the voltage corresponds to the voltage for which the

amplier is set (S.2-2). If you connect the amplier to a different mains outlet, be sure that you check it

as well.

Make sure the main Power Switch on the rear panel is in the OFF position and insert the amplier's mains

plug into the wall outlet prepared for it. The amplier remains switched off at this time.

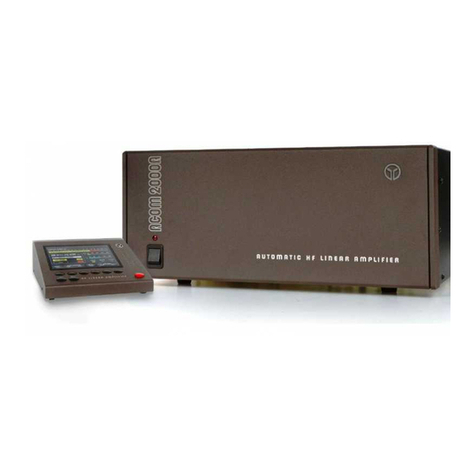

2-5. Installation of External Fan

This fan (Fig. 2-1) is not necessary in SSB and CW modes, or in continuous carrier modes (RTTY, SSTV

etc.) with a maximum carrier-down time of 5 minutes and a subsequent pause of 3 minutes. For higher

duty cycles such as continuous broadcast or increased ambient temperatures the fan is recommended.

The auxiliary fan (92x92x25mm or 92x92x38mm) must be a brushless type, 2...5W/24VDC. It may be

installed by your dealer or by the manufacturer on request.