Introduction

Thank you for your purchase of an AcraDyne®HT Series Pneumatic Nutrunner. These Nutrunners offer a reliable and dependable solution

for the installation and removal of heavy-duty fasteners in a variety of industries that require high torque capability, accuracy, power and

safety.

Safety Information

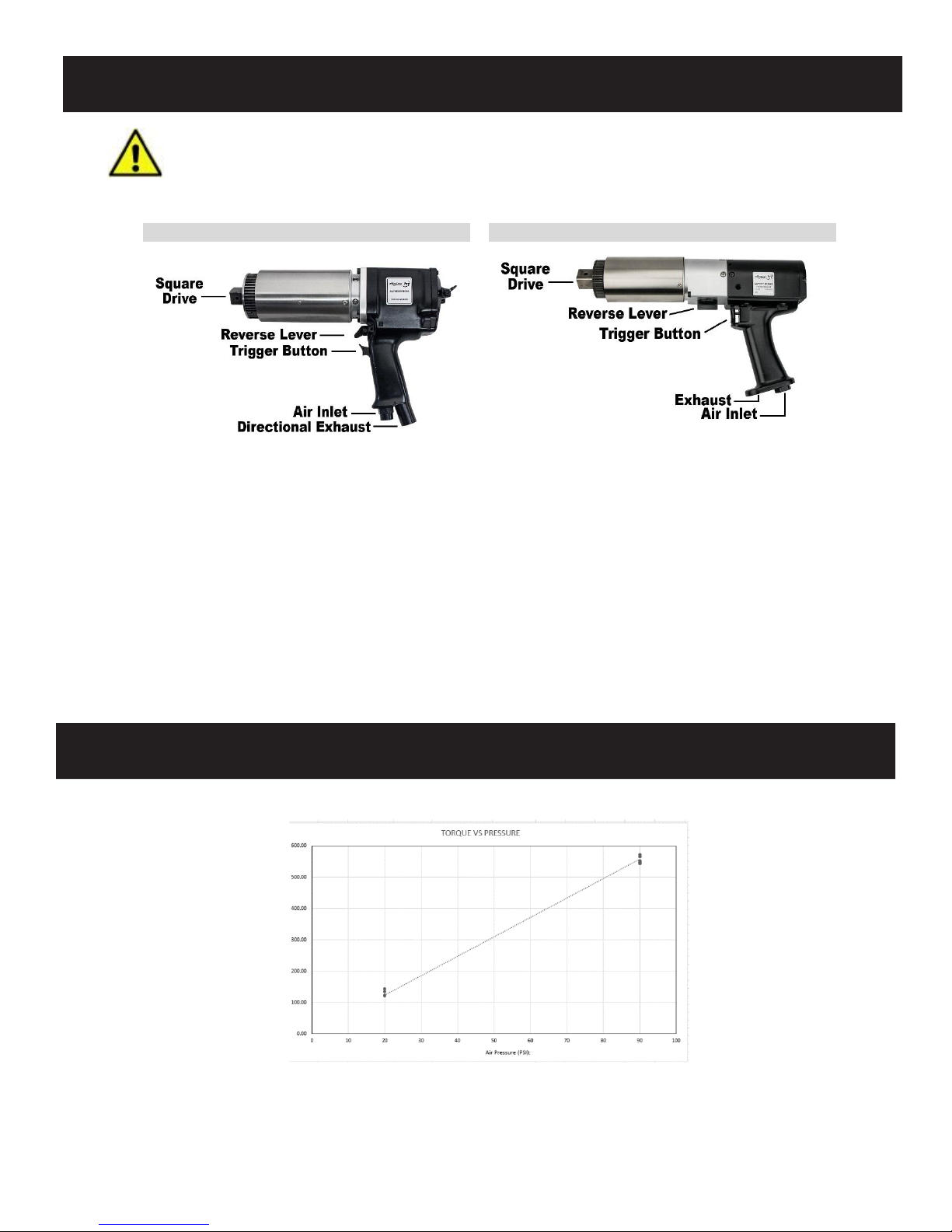

CAUTION –DO NOT USE THE ACRADYNE® HT NUTRUNNING SYSTEM WITHOUT FULLY READING THIS MANUAL AND HAVING A

COMPLETE UNDERSTANDING OF THE CORRECT USAGE OF AHIGH TORQUE DELIVERING TOOL AND ANY ASSOCIATED REACTION

BARS/ACCESSORIES.

SAVE THESE INSTRUCTIONS

1) WORK AREA

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tool in explosive atmospheres such as the presence of flammable liquid, gases or dust. Power tools create sparks which may ignite dust or

fumes. Ensure there are no cables or gas pipes that may cause a hazard if damaged by the tool.

c) Keep children and bystanders away while operating apower tool. Distractions can cause you to lose control.

d) Be aware of trip hazards such as air lines and electrical cords in the work area.

2) PERSONAL SAFETY

INDICATES CAUTION IS REQUIRED. FAILURE TO EXERCISE CAUTION AND CORRECT OPERATING TECHNIQUE CAN RESULT

IN SERIOUS PERSONAL INJURY, LOSS OF LIMB OR DEATH.

INDICATES WARNING RISK OF CRUSHING. FAILURE TO EXERCISE CAUTION AND CORRECT OPERATING TECHNIQUE CAN RESULT

IN SERIOUS PERSONAL INJURY, LOSS OF LIMB OR DEATH.

a) Only qualified and trained operators should install and adjust tool.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries. If the maximum duty cycle of the attached tool is exceeded or the tool temperature exceeds

50° C., then the operator should wear protective hand wear (gloves).

c) Avoid accidental starting. Ensure air is off before connecting to air hose. Carrying power tool with your finger on the throttle, or connecting to the air hose with

your finger on the throttle, invites accidents. Never carry the tool by air hose. Release throttle in case of an interrruption of the air supply.

d) Remove any adjusting key or wrench before turning the tool on. Awrench or akey left attached to arotating part of the tool may result

in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f) Dress appropriately for your environment. Do not wear loose clothing or jewelry. Keep hair, clothing, hands and gloves away from moving objects such as drives,

sockets and extensions. Loose clothing, jewelry, gloves or long hair can get caught in moving parts. Direct the tool’s cold exhaust away from you, your co-worker,

work surface and hands. Keep hands warm.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of these

devices can reduce dust-related hazards.

h) Ensure hose and fittings are securely fastened to prevent injury from disconnected whipping hose. Whenever universal twist coupllings are used, lock pins should

be installed and whip check safety cable shall be used.

i) Always shut-off air supply, drain air hose pressure and disconnect tool from air supply when not in use, before making changes to accessories or when in repair.

Air under pressure can cause severe injury.

j) Do not modify tool. Any modification of tool could result in personal injury.

k) Failure of the workpiece, tool or accessories can generate high velocity projectiles.

3) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for

which it was designed. Hold tool with a light, safe grip.

b) Do not use the power tool if the trigger does not turn it on and off. Any power tool that cannot be controlled with the trigger is dangerous and must

be repaired.

c) Tool is intended for the use on threaded fasteners with impact grade sockets. All sockets and extensions should be secured with pins and O-ring to the tool. Any

other use of this tool is strictly forbidden.

d) Inspect tool to ensure all markings are visible and legible.

e) Operator and maintenance personnel should physically be able to handle the bulk, wieght, and power of the tool. If not, the use of a balancer is reccommended.

f) Should the operator experience discomfort or pain in the hands, arm or shoulders, do not ignore it and seek the advice of a qualified medical professional.

3