Action Trackchair ST User manual

Revised ~ Nov. 3, 2016

Page | 1

Action Trackchair® Owner’s Manual

Including Models ST, NT, PT, TR, & PR

Revised Nov. 3, 2016 Page | 2

Helping the Disabled to be Enabled®

Action Manufacturing

1105 Lake Road, PO Box 620

Marshall, MN 56258

507-532-5940

www.actiontrackchair.com

Table of Contents

Forms

Triplicate Registration Form………………………………………………………………………………………………………..

Table of Contents……………………………………………………………………………………………………................................. 2

Introduction .................................................................................................................................................. 3

Safety ............................................................................................................................................................ 4

Operating the Action Trackchair................................................................................................................... 5

Comfort Adjustments.................................................................................................................................... 6

Batteries and Charging……………..……………………………………………………………………….……………………...........7 & 8

Track Adjustment for NT model……………………………………………………………………………………………………………….9

Blank Page……………………………………………………………………………………………………………………………………………. 10

Repair and Maintenance………………………………………………………………………………………………………………………. 11

Warranties .................................................................................................................................................. 12

Specifications…………………………………………………………………………………………………………………………….....13 & 14

Table 1: Hand Control Fault & Warning Indicators.............................................................................15 & 16

Strapping Methods with Trackchair Carrier................................................................................................ 17

Rocker Switch Override Instructions…………………………………………………………………………..............................18

Law, Regulation and Policy for Wheelchair/Mobility Device Use in “Federally Designated Wilderness………………….19

Revised Nov. 3, 2016 Page | 3

Introduction

Welcome to Action Trackchair. We at Action Trackchair want to make your experience the best

it can be. Enclosed in this owner’s manual you’ll find information to use and maintain your

Action Trackchair. With any questions please contact us at:

Action Manufacturing

1105 Lake Road

PO Box 620

Marshall, MN 56258

507-532-5940

Revised Nov. 3, 2016 Page | 4

Safety Guidelines

Only one person should be on the Trackchair at any time.

Seat belt is recommended.

Do not navigate Trackchair/Trackstander on more than a 20 degree slope

Trackchair will climb inclines enough to tip over in any direction.

When climbing over small logs or curbs approach incline at an angle, not directly at 90°

Make sure controls are in the off position before sitting in Trackchair and before getting out

of seat.

Always have a backup plan, “What if…?”

Do not ride the Trackchair during loading or unloading from vehicle or carrier.

Do not attempt to climb stairways.

Action Manufacturing Inc. does not recommend driving the Trackstander in the upright

position other than flat and stable terrain

Failure to know the limits can cause personal injury or equipment damage

Revised Nov. 3, 2016 Page | 5

Operating Your Action Trackchair

When you are ready to drive the Trackchair, make sure controls are in the off position

before sitting in Trackchair.

When operating your Trackchair, make sure you are securely fastened in with either the lap

belt or 4 point harness.

Your Trackchair can be programmed by your distributor/dealer to have the option of locking

the joystick or not, ask them about the availability for this option

If your Trackchair has a locking control, it can be unlocked in this way. Turn control on, hold

joystick forward until you hear a beep or three seconds, then joystick back until you hear a

beep or three seconds. It is now unlocked and ready for operation.

When locking the control, (if this option is selected by the distributor/dealer/customer) it is

done in this way. After the control has been turned off, hold the on/off button until the

control has cycled both on and then off. Control is now set in the locked mode.

The Action Trackchair control has five speeds, one-five and can be changed with the up and

down arrows.

Battery indicator is on the main screen on controls. Battery charge will last up to six hours,

depending on battery condition and type of use the Trackchair is subject to. Action

Trackchair has a built-in battery charger that plugs into 110 volt outlet.

Optional lighting is available and is controlled on the joystick control panel.

If your Trackchair has no separate Tilt–On-The-Fly rocker switch, tilting of the chair is

possible by pushing the “M” button on controls, and then moving joy stick forward or

backward to tilt chair. Cancel by pushing “M” again or moving joystick to the left.

If for some reason it is necessary to pull the Trackchair. Disengage the brakes on the motors

with the levers on back of motors. Push levers to the outsides on both motors. Do not pull

Trackchair more than 5 MPH

Action Trackchair does not recommend operating your Trackchair in the salt water,

although our Trackchairs are powder coated to the highest quality with very durable

powder coat, salt water is very corrosive and causes problems with powder coat and metal.

If your Trackchair has been exposed to salt water, rinse the Trackchair completely with fresh

water and dry off.

Revised Nov. 3, 2016 Page | 6

Comfort Adjustments

There are few adjustments that are necessary. The foot rest can be moved up or down to fit the

rider’s needs. The chair itself can be leveled to the desired comfort of the rider. The armrest

can flip down or back for easier transferring into the chair. Electronic controls can be adjusted

at a servicing distributor/dealer as far as speed, acceleration, deceleration, braking, etc.

Revised Nov. 3, 2016 Page | 7

Batteries and Charging

Battery charge will last up to six hours, depending on battery condition, temperatures and

type of use the Trackchair is subject to (terrain and weight of rider). The Trackchair has a

built-in battery charger that plugs into 110 volts.

Operation after Applying AC Power to a ProSport Charger Connected to

Discharged Batteries

During the startup test the battery type LED will be illuminated and the red charge mode LED will flash indicating that the

unit is in a self-test mode. When complete and if there are no faults, the charger's system check OK indicator will illuminate

green and the ProSport's solid red charging LED will be ON indicating the charge process is initiated. Note: If there is a fault

the appropriate bank LED will illuminate and the charge process may not start, depending on the location of the fault. See

page 25 for further troubleshooting details.

If there are no Battery Faults, the Green System Check OK LED will illuminate and the following sequences will

proceed:

The red battery type LED (factory set for standard Flooded (lead-acid)/AGM batteries) will illuminate.

The red charge mode LED will illuminate indicating the charger has started its multi-stage charging process.

When the charge process is approximately 80% complete the red charge mode indicator will turn off and the amber

conditioning LED will turn on indicating the conditioning mode.

When the multi-stage charge process is completed you will observe the following: Battery type red LED goes OFF.

The red charging LED and the amber conditioning LED will be off and the green ready/maintain LED will illuminate indicating

your batteries are fully charged.

The only LEDs on after the multi-stage charge process is completed are the green system OK LED, blue AC power LED and

the green ready/maintain LED.

Multi-Stage Charging Overview

Stage 1 - System Check OK and Battery Analyzing: During this stage the ProSport red “Charge” LED will

flash indicating ProSport is analyzing all battery connections in addition to checking each battery is capable of being

charged. Upon completion the “System Check OK” indicator will illuminate green followed by Stage 2 Charging.

Stage 2 - Charging: During this mode the “Charging” indicator will be red. The ProSport Series will use all of

its available charging amps (as controlled by temperature) until the battery voltage is raised to 14.6VDC

(Flooded lead-acid factory setting).

Stage 3 - Conditioning: During this mode the “Conditioning” status indicator will be amber. Batteries will hold

at 14.6 VDC (factory set for Flooded lead-acid batteries) to complete charging while conditioning each battery

connected. Upon completion the ProSport will go into its Energy Saver Mode.

Stage 4 - Auto Maintain (Energy Saver Mode): During this mode the blue “Power” and green “Auto Maintain”

LED's will be on indicating Stage 2 charging and Stage 3 conditioning are completed. At this time ProSport will

initiate its Auto Maintain (Energy Saver Mode) which will monitor and Auto Maintain batteries only when needed

to maintain a full state of charge.

Stage 5 - Storage Recondition Mode: During this mode the ProSport “Storage Recondition Mode” green

indicator will illuminate with a slow fade in and out pulse. This indicates that while your batteries/boat are in storage

the ProSport will automatically recondition all batteries for up to 3 hours once a month extending battery life

and maximizing on the water battery power performance.

Revised Nov. 3, 2016 Page | 8

Batteries and Charging (Continued)

To get maximum daily use, the battery must be fully charged. This is accomplished by

having the Trackchair plugged in until the “READY LIGHT” comes on.

INDEPENDENT CHARGING BANK INDICATIONS

When your battery charging system is activated, each bank provides charging information utilizing five red

Light Emitting Diode (LED) indicators and one green Light Emitting Diode (LED) indicator.

The five red LEDs enable you to track the progress of the charge cycle on each battery as the voltage rises. (see

the following chart)

The charger can be left on for an extended period of time without harming the battery.

Your system provides an equalization stage every 30 days while plugged in. If the charger is normally

disconnected from A/C after completing charge, equalization can be accomplished by plugging back into A/C

whenever this stage is desired. Battery manufacturers recommend that equalization is done once a month in

order to further reduce sulfation on the lead plates of a battery, which helps promote longer battery life. Note:

During this process the LEDs will go through their normal routine (Red counting up for % of charge) and the

Green Led will blink until the unit returns to the maintenance mode and a steady Green LED. (Not applicable to a

Gel Profile)

2 to 12.78 volts = 10%

12.79 to 13.25 volts = 10%, 30%

13.26 to 13.49 volts = 10%, 30%, 50%

13.50 to 14.04 volts = 10%, 30%, 50%, 70%

14.05 to 14.52 volts = 10%, 30%, 50%, 70%, 90% Green Flashing

{Finishing Stage} 14.52 to 15.49 volts

Dual Pro

Revised Nov. 3, 2016 Page | 9

Track Adjustment procedure for NT model Trackchairs

Track can be adjusted by loosening both bolts on the front idler wheels, inside and outside. Track

tensioners can be tightened with a 9/16 wrench by holding the lock nut and turning track tensioner bolts

clockwise an even amount. Adjustment is only needed if the track tension does not meet the below

spec. IT IS NOT NECESSARY TO OVER TIGHTEN THE TRACKS. Re-tighten front idler wheels, inside and

outside to 130 in./lbs.

Elevate Trackchair with suitable lift or blocks, here you

see the K&L model MC455 fat jack. (Purchase on-line)

Locate track lug over frame as shown

Press down on track with 10 to 15 lbs. of force and observe location

of track lug. When properly tensioned the lug at the blue arrow

should just contact the frame with 10 to 15 lbs. of force. Rotate

track to check measurement at 3 different locations around the

track to confirm measurement

Use suitable spring tension gauge purchased

from your distributor/dealer #80500

Revised Nov. 3, 2016 Page | 10

This page intentionally Blank

Revised Nov. 3, 2016 Page | 11

Repairs and Maintenance

All bearings are sealed and need no additional greasing.

Track can be adjusted by loosening both bolts on the front idler wheels, inside and outside.

Track tensioners can be tightened with a 9/16 wrench by holding the lock nut and turning

track tensioner bolts clockwise an even amount. Adjustment is only needed if the track

tension does not meet the below spec. IT IS NOT NECESSARY TO OVER TIGHTEN THE

TRACKS. Re-tighten front idler wheels, inside and outside to 130 in./lbs.

Cleaning your Trackchair/Trackstander

The Action Trackchair/Trackstander can be washed with a garden hose, do not use high

pressure wash to clean the chair. Always cover the joystick with a plastic bag to protect it

from getting moisture inside. THE JOYSTICK IS NOT WATERPROOF and should be covered

when washing, or stored outside or when transporting behind the vehicle open.

Do not spray water directly onto the motor controller under the seat.

Press down on track with 20 to 25 lbs. of force

and observe location of track lug. When properly

tensioned the lug should just contact “A" frame

at bottom right of picture with 20 to 25 Lbs. of

force. Note arrow

Rotate the track so an

internal lug is directly

above the “A” frame

cross support as shown

Use suitable spring tension gauge purchased

from your distributor/dealer #80500

Revised Nov. 3, 2016 Page | 12

Warranties

1 YEAR: The following components are covered against manufacture defects in

materials and workmanship for the period of one year.

oBatteries

oControl box and joy stick

oMotors

oAll sprockets and idler wheels

oSeats

oTilt Actuator

oAll other parts 1 year

Parts and Labor.

2 YEARS: The following components are covered against manufacture defects in

materials and workmanship for the period of two years.

oProSport battery charger (Trackchair)

1st Year- Parts and Labor 2nd Year- Parts Only.

3 YEARS: The following components are covered against manufacture defects in

materials and workmanship for the period of three years.

oDual Pro battery charger (Trackstander)

1st Year- Parts and Labor 2nd and 3rd Years- Parts Only.

Tracks

1st Year- Parts and Labor 2nd and 3rd Years- Parts Only.

Frame welding (Trackchair/Trackstander)

Warranty period starts @ delivery date to customer.

Revised Oct. 19, 2016 Page | 13

Specifications

ST Models TR Models Trackstander

ST16, ST18, ST20, ST22, ST24 TR1816, TR1820, TR2016, TR2020

Height 42” 43” lowered 64” raised

Width 37”, 37”, 39”, 41”, or 43”37” or 39”

Length 52 ½ “ w/ rear idlers 59” w/ rear idlers to front wheel kit

Weight 350 pounds estimate 470 pounds estimate

Seat height 23”25”

Seat Depth 16 ½” 16” or 20”

Tilt angle for chair 20° each way 5° forward/ 20° back

Track Size 6 ½” X 90” 6 ½” X 90”

Batteries Two 12 volt Wheelchair Batteries Two 12 volt Wheelchair Batteries

Controls Action Trackchair controls Action Trackchair controls

Motors 24 volt DC 24:1 ratio high torque 24 volt DC 24:1 ratio high torque

Speed 3-4 MPH 3-4 MPH

Turning Radius ZERO ZERO

Width between armrest 16”, 18”, 20”, 22”or 24”18”or 20”

Ground Clearance 3 ½” 3 ½”

Battery Charger 12 amp Std. 20 amp Optional 20 amp Std.

Range Variable up to 6 Miles Variable up to 6 Miles

Foot rest Adjustable Std. or Flip up Adjustable Std.

Accessory holders Two on each side and two on back of chair Two on each side and two on back of chair

Lap belt Std Four point harness Std.

Knee support N/A Std.

Revised Oct. 19, 2016 Page | 14

Specifications

PT Model PT14 PR1416

Between arm rest 14” 14”

Total Width 32” 32”

Height 42.5” 41” lowered- 56.5” raised

Track Type II is Std. Type II is Std.

Length 47.5” w/ rear idlers 39’—47.5 “ w/ rear idlers

Weight 375 pounds est. 375 pounds est.

Seat height 21.5”21.5”

Seat Depth Adjustable 9”-15” 15”

Track Size 6 ½” X 90” 6 ½” X 90”

Batteries Two 12 volt AGM Wheelchair Bat. Two 12 volt AGM Wheelchair Bat.

Controls Action Trackchair controls Action Trackchair controls

Motors 24 volt DC 24:1 ratio high torque 24 volt DC 24:1 ratio high torque

Speed 3-4 MPH 3-4 MPH

Turning Radius ZERO ZERO

Ground Clearance 3 ½” 3 ½”

Battery Charger 12 amp 12 amp

Range Variable up to 6 Miles Variable up to 6 Miles

Foot rest Adjustable Std. Adjustable Std.

Lap belt 4 point belt 3 point belt

Knee Support N/A Adjustable

Flip up Arm rest N/A Std.

NT Models

NT14, NT16, NT18, NT20, NT22

Between are rest 14”, 16”, 18”, 20”, 22” Motors 24 volt DC 24:1 ratio high torque

Width 29.5” Speed 3-4 MPH

Height 47” Turning Radius ZERO

Length 47.5” with rear idlers Ground Clearance 3.5”

Weight 380 pounds est. Battery Charge 12 amp standard

Seat height 25” Range Variable up to 10 Miles

Track size 6 ½” X 90” Foot Rest Flip up footrest standard

Batteries Two 12 volt AGM Wheelchair Bat. Flip up Arm rest Std.

Controls Action Trackchair controls Accessory holders two each side

Lap belt Std.

Revised ~ Oct. 19, 2016

15

HANDCONTROL LCD DISPLAY FAULT/WARNING REMEDY

Power Section Fault, or Current Sensor

Fault, or EEPROM Fault, or Main Relay

Fault, or Precharge Fault, or HW Failsafe

Fault.

1. Cycle power

2. Replace powerbase.

Handcontrol Fault, or Joystick Fault: 1. Return joystick to neutral and cycle power

Joystick out of center,

2. Recalibrate joystick.

Joystick stuck OOC, 3. Check joystick cable and cable connections.

Joystick Out-of-Range 4. Repalce joystick.

5. Replace hand control.

1. Check cable and cable connections.

2. Replace cable.

1. Check wiring.

2. Replace motor.

3. Replace powerbase.

1. Select drive or a different actuator;

fault may clear.

2. Check wiring.

3. Check that the seatback is not jammed.

4. Check actuator; replace if faulty.

5. Replace powerbase.

1. Select drive or a different actuator;

fault may clear.

2. Check wiring.

3.Check that the seat is not jammed.

4. Check actuator; replace if faulty.

5. Replace powerbase.

1. Select drive or a different actuator;

fault may clear

2. Check wiring.

3. Check that the leg rest is not jammed

4. Check actuator; replace if faulty.

5. Replace powerbase.

1. Recharge battery.

2. Replace old battery.

3. If this is happening frequently,

replace charger.

4. Check charger port on hand control; replace

if damaged.

1. Wait for voltage to come down

2. Replace old battery.

3. Check charger; replace if faulty

Under voltage warning

Overvoltage Warning.

Communications Fault

Brake Fault.

Seatback Actuator Driver Fault

Seat Actuator Driver Fault.

Leg Actuator Driver Fault

Revised ~ Oct. 19, 2016

16

1. If too hot, wait for controller to cool.

2. If too cold, drive chair in limited

current mode until controller warms up.

1. Check wiring.

2. Replace motor.

3. Replace powerbase.

1. Press Left Indicator button.

2. Replace Bulb.

3. If fault continues, check wiring.

1. Press Right Indicator button

2. Replace bulb.

3. If fault continues, check wiring.

1. Press Right or Left Indicator button.

2. Replace bulb.

3. If fault continues, check wiring.

1. Press Running Lights button.

2. Replace bulb.

3. If fault continues, check wiring.

1. Return seat to normal or upright position.

2. If fault continues, check all limit

switches and wiring.

* These icons indicate a problem only if they appear when they shouldn't.

Chair under attendant control. *

Battery charging; Inhibit. *

1. Wait for motor to cool.

1. Recharge battery.

1. Unlock the system.

1. Turn off attendant control (1742)

1. Unplug charger when charging is complete.

Right Indicator Fault.

Hazard Lights Fault.

Speed Limit Warning.

Running Lights Fault

Low battery

Locked Mode. *

Left Indicator Fault

Controller Over/Under temperature

warning.

Drive Thermal Warning

Open Motor Fault

Revised ~ Oct. 19, 2016

17

Strapping Methods

Proper strapping options for Trackchair to carrier

***Class III receiver hitch required for carrier, Check auto manufacturers

recommendation for hitch capacity***

Class III—2”-- Up to 6,000 pounds towing capacity, up to 600 pounds tongue weight

Revised ~ Oct. 19, 2016

18

Actuator not moving up or down?

First check the fuse in the black fuse holder located at the black & red, 16 gauge wire harness which

comes off the battery, fuse type is an ATC 20 amp.

If you suspect the actuator has failed and you have a “Tilt on the Fly” rocker switch, (not tilt through

the joystick) you can simply bypass the rocker switch as follows:

Locate wire coming out of the side of the actuator, unplug from the current plug it is attached to.

Plug lead from actuator into blue/yellow lead from the 14 pin connector which is located under the

seat.

Now turn joystick on and press the “M” button, move the joystick forward or reverse and the

actuator should move up or down.

If you find that the actuator does work, then the problem would be in the “Tilt on the Fly” rocker

switch or wiring to it.

Tilt on the fly wiring Tilt with joystick

Fuse holder

Rocker switch override instructions

Revised ~ Oct. 19, 2016

19

Law, Regulation and Policy for Wheelchair/Mobility Device Use

in “Federally Designated Wilderness (ADA Title V Section 508c, as amended in 2008)

(1) IN GENERAL –Congress reaffirms that nothing in the Wilderness Act prohibits wheelchair use in a wilderness

area by an individual whose disability requires its use. The Wilderness Act requires no agency to provide any form of

special treatment or accommodation or to construct any facilities or modify any conditions of lands within a wilderness

area to facilitate such use.

(2) Definition –for the purposes of paragraph (1), the term wheelchair means a device designed solely for use by a

mobility impaired person for locomotion, that is suitable for use in an indoor pedestrian area.” (per American with

Disabilities Act, Title V Section 508 (c)

Application: “Designed solely for use by a mobility-impaired person” means that the original design and manufacture

of the device was only for the purpose of mobility by a person who has a limitation on their ability to walk. “Suitable

for indoor pedestrian use” means the device would be allowed to be used inside a mall, etc.

A wheelchair or mobility device, even one that is a battery powered, that meets both parts of this definition is allowed

anywhere foot travel is allowed including in federally designated wilderness areas.

The following CFR and FSM apply in ALL areas of the National Forest System

36 Code of Federal Regulation (CFR) 212.1

“Motor Vehicle. Any vehicle which is self-propelled, other than:

(1) a vehicle operated on rails; and

(2) any wheelchair or mobility device, including one that is battery-powered, that is designed solely for use

by a mobility-impaired person for locomotion, and that is suitable for use in an indoor pedestrian area.”

Forest Service Manual 2353.05“Wheelchair or Mobility Device. A device, including one that is battery-powered,

that is designed solely for use by a mobility-impaired person for locomotion, and that is suitable for use in an indoor

pedestrian area. A person whose disability requires use of a wheelchair or mobility device may use a wheelchair or

mobility device that meets this definition anywhere foot travel is allowed.”

Application: “Designed solely for use by a mobility-impaired person” means that the original design and manufacture

of the device was only for the purpose of mobility by a person who has a limitation on their ability to walk. “Suitable

for indoor pedestrian use” means the device would be allowed to be used inside a mall, etc. A wheelchair or mobility

device, even one that is a battery powered, that meets both parts of this definition is allowed anywhere foot travel is

allowed

This manual suits for next models

4

Table of contents

Popular Wheelchair manuals by other brands

Trac About

Trac About IRV2000 owner's manual

HMN

HMN M2 Mini Standard user guide

Amiga

Amiga TravelMate Owner operational manual

Platinum Health

Platinum Health PHB3300 Assembly and instruction manual

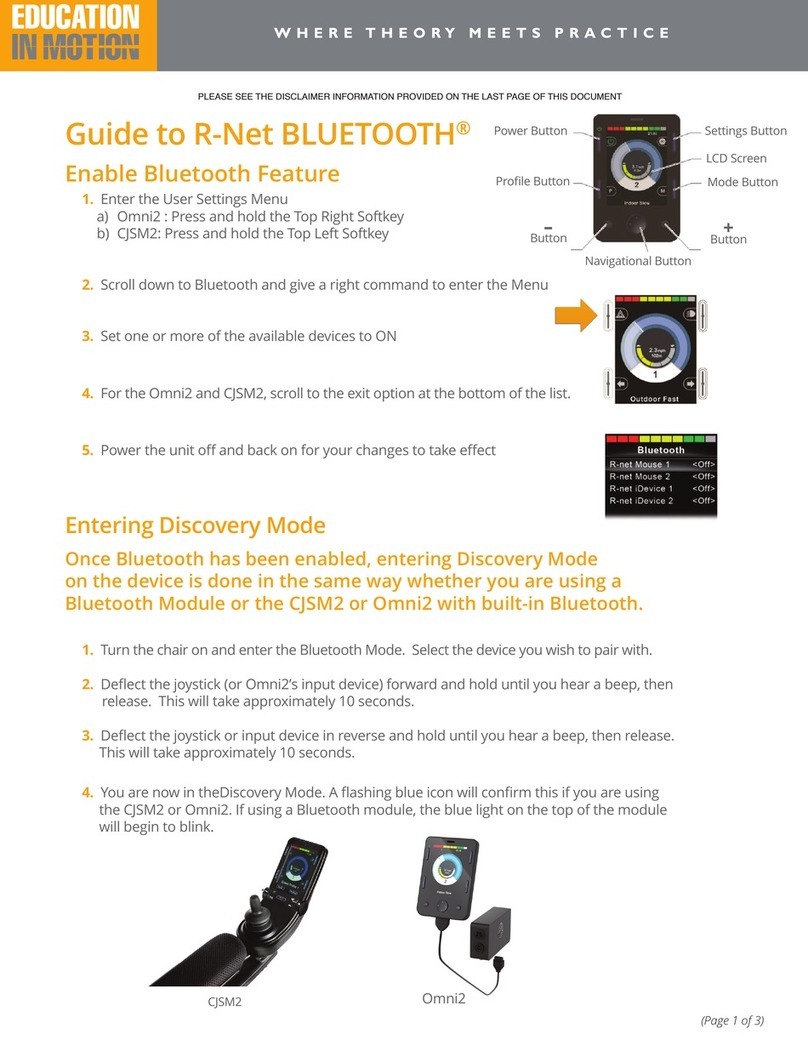

Sunrise Medical

Sunrise Medical R-Net BLUETOOTH Guide

Orliman

Orliman actius ACWC05#41 Instructions for use and care