ACTUATECH GD15 User manual

EN - 1

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD1920 AND GS15 - GS960

EN - 2

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

INDEX:

Pag.

1. GENERAL FEATURES 3

2. WORKING CONDITIONS 3

3. OPERATION AND ROTATION DIRECTION 6

4. SAFETY INFORMATION 9

5. INSTALLATION INSTRUCTION 9

6. MATERIALS AND THEIR DURABILITY 17

7. MAINTENANCE 19

8. ATEX SPECIFICATION 22

9. SPECIAL VERSIONS 23

10. STORAGE 25

11. TROUBLESHOOTING 25

12. DISPOSAL OF PRODUCTS AT THE END OF THEIR LIFE CYCLE 26

13. DECLARATION OF CONFORMITY 26

Environmentally friendly: under the green leaf icon you can nd the instructions for

a correct and environmentally friendly handling of the product.

ACTUATECH will be free to change all the specications and data included in this manual at any time, so as to improve the quality

and the performance of its products.

EN - 3

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

FOREWORD

The present User’s Installation and Maintenance Manual has been edited in conformity with:

- 2006/42/EC Directive “Machinery”;

- 2014/34/UE Directive “Equipment and protection systems designated to be used in potentially explosive atmospheres” (ATEX).

The following standards/technical specications also apply:

- EN 15714-3:2009 Industrial valves: Actuators – Pneumatic part-turn actuators for industrial valves.

- IEC 61508:2010-1/7 Functional safety of electrical/electronic/programmable electronic safety-related systems. Part 1 :7

- UNI CEN/TS 764-6:2005 Pressure equipment Part 6: Operating instructions structure and contents.

Below you will nd the safety instructions, the minimum information for storage / warehousing, the installation, the commissioning, the

maintenance and the instructions for disposal of products at the end of their life cycle for the pneumatic actuators:

ACTUATECH disclaims any liability for damage caused by improper use, even if partial, respect to the information contained in this

manual.

1. GENERAL FEATURES

ACTUATECH manufacture a wide range of part turn pneumatic actuators for valve remote control.

The actuators are available on Double Acting “GD” and Spring Return “GS” versions.

- The principle of the actuator application is to open and close the connected valve, without the manual operation with lever or hand

wheel, by means of an electric-pneumatic connection on remote control.

- Scotch – Yoke is a mechanical system that allows to transform the linear force into a rotary torque.

ACTUATECH applies the scotch - yoke system for its actuator production to transfer the pistons linear force to a driving shaft torque.

This system provides a long working life and best performance with the minimum energy consumption.

- ACTUATECH Scotch-Yoke system with its oblique grooves produces a torque curve with the highest torque at the start opening

operation in order to overcome the valve breakaway torque.

The maintenance should be done by ACTUATECH trained personnel only.

This instruction manual contains important information regarding the ACTUATECH Scotch-Yoke pneumatic actuator operation, instal-

lation, maintenance and storage. Please read carefully before installation and keep it in a safe place for further reference.

2. WORKING CONDITIONS

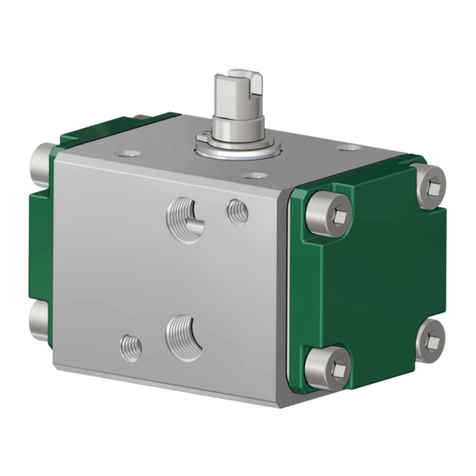

a) Construction

Standard ACTUATECH actuators are suitable for indoor and outdoor installation. The laser marking or a printed label on the actuator

body gives the actuator technical characteristics: type, size, operating pressure, output torque, operating temperature, ange con-

nection, product code and production date (see drawing pag.5).

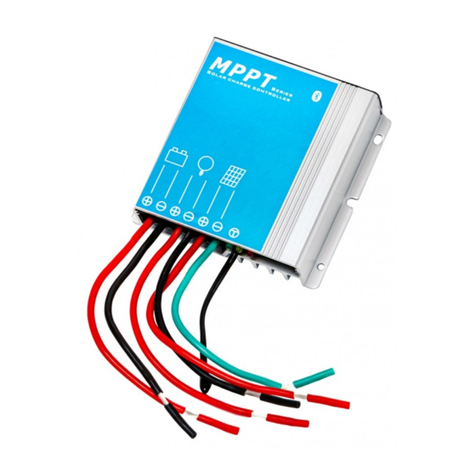

b) Motive energy

The operating media should be dry and ltered compressed air not necessarily lubricated or inert gases compatible with internal

actuator parts and lubricants.

The operating medium shall have a dew point equal to – 20 °C or, to be at least, 10 °C below the ambient temperature (ISO 8573-1,

Class 3). The maximum particle size shall not exceed 40 μm (ISO 8573-1, Class 5).

c) Supply operating media pressure

The maximum supply pressure is 8,4 bar (120 psi). Nominal supply pressure is 5,6 bar (80 psi), working pressure range from 2,5 bar

( 36 psi ) up to 8,4 bar (120 psi).

EN - 4

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

d) Operating temperature

Actuator standard working temperature range from –20°C (-4°F) to 80°C (176°F)

For low and high temperature versions please contact ACTUATECH. For high humidity and low temperature application are recom-

mended to use a supplementary protection (e.g. screens, sheds or integral painting)

e) Operating drive rotation

The part turn actuator rotation angle is nominally 90°. ACTUATECH actuator provides a stroke of 92° rotation, from –1° to 91°, with

standard stroke adjustment of –10°.

f) Cycle time

The cycle time is dependent on different operating and installation factors such as the supply pressure, the ow capacity, the con-

nection pipe size, the solenoid valve performance, the valve torque and characteristics, environmental temperature condition.

Actuator opening, closing and open/close cycle times (sec.).

The above time table is referred to a standard actuator working cycle at the following tests conditions:

Ambient temperature: 18°C – 25°C

Motive energy operating medium: compressed air at 5,6 bar

Nominal cycle: 90° in both directions

Load: free

GD actuators operate with solenoid valve 5/2 ISO 1-2. While the GS actuators with solenoid valve 3/2.

Time tested with Electronic Timer device.

NOTE: different working condition such as air pressure, piping connection, lters or solenoid valves, could change the timing of the

operations.

g) Lubrication

The actuators are factory lubricated for the standard working condition life.

During maintenance and reassembling ACTUATECH recommends using TECNOLUBE SYNTHY POLYMER 402, or equivalents.

Actuator size 0°-90° cycle time

SEC

90°-0° cycle time

SEC

GD15 0,04 0,04

GD30 0,06 0,07

GD45 0,08 0,09

GD60 0,10 0,10

GD106 0,12 0,13

GD120 0,15 0,15

GD180 0,20 0,21

GD240 0,28 0,25

GD360 0,38 0,36

GD480 0,46 0,4

GD720 0,64 0,59

GD960 0,81 0,73

GD1440 1,36 1,21

GD1920 1,59 1,44

Actuator size 0°-90° cycle time

SEC

90°-0° cycle time

SEC

GS15 0,13 0,09

GS30 0,14 0,10

GS53 0,20 0,17

GS60 0,25 0,22

GS90 0,31 0,33

GS120 0,40 0,37

GS180 0,58 0,44

GS240 0,65 0,53

GS360 0,96 0,72

GS480 1,16 0,9

GS720 1,65 1,49

GS960 2,60 2,14

EN - 5

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

h) Internal wear protection

The cylinder is lapped to obtain a surface with ne roughness and is protected with 20 μm technical oxidation. The pistons slide

supports are in P.T.F.E. or polyurethane only, no rubber in contact. The use of steel bearings on the Scotch-Yoke system ensures no

play and low friction during operation.

i) External protection

ACTUATECH standard actuators are suitable for indoor and outdoor installation. The aluminium body is external protected form cor-

rosion and wear with 20 μm technical oxidation. The cast aluminium end caps are polyester painted. Driving shaft and caps screws

are in stainless steel.

For aggressive atmosphere and severe environmental condition select the required protection from the external nishes showed in

our catalogue or contact directly our technical department.

j) Functional Safety

The ACTUATECH S.p.A. pneumatic actuators are also suitable for installations which require high level of functional reliability, up to

SIL3, in compliance with the IEC 61508 standard.

k) Marking and classication

All ACTUATECH actuators bodies are marked with the Manufacturer name and address, the actuator Type code including the Series

and Size, and its range of Pressure and Temperatures working conditions and limits.

1. Name of the company in charge of marketing the product in the E.U.

2. Address of the company in charge of marketing the product in the E.U.

3. Model (with standard anging), operating pressure and temperature.

4. ATEX class of compliance with the rules and level of protection.

5. Name of Technical File deposited with a Notied Body.

6. Product code.

7. Month and year of production.

Supplemental marking according to ATEX Directive (see section 8)

Marking instructions where the temperature is different from the standard one:

- low temperature version: T. min.= -50°C T. max= 60°C

- high temperature version: T. min.= -20°C T. max= 150°C

EN - 6

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

3. OPERATION AND ROTATION DIRECTION

Double Acting.

The pistons of standard GD actuators are mounted as shown below. This provides the highest torque at the valve start opening for

valve clockwise to close. The pistons are then in their outermost position and the end travel stops can be ne adjusted.

The port 2 is in connection with the cylinder side chambers, supplying the pressurised air in port 2 the standard Double Acting actuator

drive shaft rotates counter clockwise to open, while the port 4 is in connection with the intermediate chamber and when pressurised

the drive shaft rotates clockwise to close.

Single Acting, Spring Return fail to Close.

The pistons of standard GS actuators are mounted as shown below. Although spring force is diminished, the geometry of the mecha-

nism provides a greater torque at the end of the spring stroke. When the actuator is in the valve open position, and the springs are

fully compressed, the end of travel stops can be ne adjusted.

Caution. In order to avoid suction of dust or dirt inside of the actuator chambers during the spring action, install a lter on the port 2.

The port 4 is in connection with the intermediate chamber and when pressurised the drive shaft rotate counter clockwise to open.

EN - 7

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Double Acting operation cycle (GD Type).

Simple Acting Spring Return fail to close operation cycle (GS Type).

EN - 8

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Important.

Special Double Acting version for ow dosing and Spring Return fail to open actuators with different piston positions have different rotation

to close and to open: please follow their special instructions.

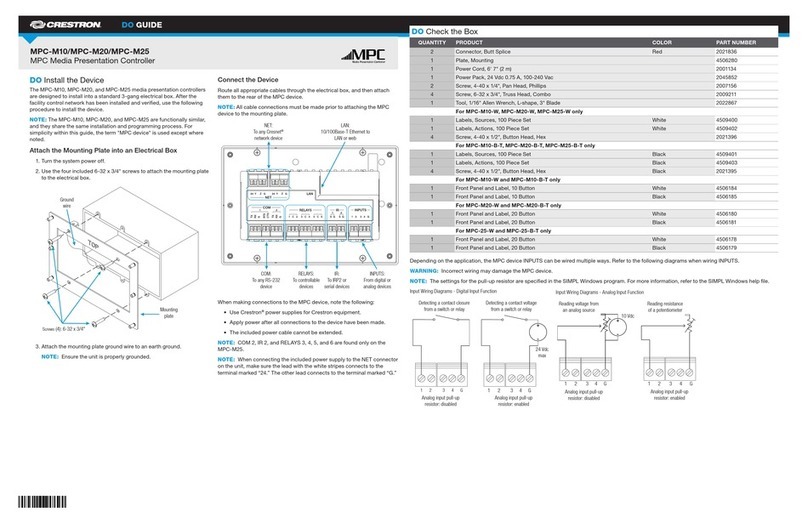

- Connection schema

Actuator operation functionality remote control should be done by means of direct solenoid valve connection to the actuator standard inter-

face VDE/VDI 3845 NAMUR, or by means of pipes screwed on the ports marked with the numbers 2 and 4 and connected to a separate

control cabinet.

Typical air connection schema

-Rotation direction.

In accordance with the international standard ISO 5599-2 the actuator air ports connection position, location, orientation and form shall be

clearly identied and marked with the numerate 2 and 4.

Standard Double Acting and Simple Acting Spring Return actuators shall be Clockwise (CW) direction to valve Close, and Counter Clockwi-

se (CCW) direction to valve Open.

EN - 9

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

4. SAFETY NOTICE

- The actuator should be used within the pressure mentioned limits only, operating the actuator over the pressure limit will damage

the internal actuator parts.

- Operating the actuator over or under the temperature limits will damage the internal and external parts.

- Operating the actuator in corrosive environments without the required external protection will damage the actuator.

- Before installation, service or maintenance verify that the actuator is not pressurised, disconnect the air lines and make sure that

the air ports are vented.

- Do not remove the end caps while the actuator is installed in the line, or while the actuator is under pressure.

- Do not disassemble the caps end spring cartridge, this operation should be done by ACTUATECH trained personnel only, this ope-

ration could cause personal injury.

- Before mounting the actuator onto the valve make sure that the valve rotation is according with the actuator operating rotation, and

the upper shaft slot orientation is also correct.

- Before installing the actuated valve do cycling test for a wile to ensure the correct mechanical mounting and actuator/valve opera-

tions.

- The actuator installation shall be done according to and in observance with the local and national laws regulation.

- ACTUATECH cannot be responsible for any damage to people, animals or things due to an improper use of the product.

5. INSTALLATION INSTRUCTION

The principle of the actuator application is to open and close the connected part turn valve installed in a plant, without the manual

operation, by remote control by means of an electric-pneumatic connection.

The normal sizing of actuators requires a 20%-30% safety margin over the valve breakaway torque to handle valves. Plant design,

chemical and physical ow characteristics and environmental condition could increase the safety factor to apply to actuator sizing.

Before performing any installation operation, verify the actuator and valve conditions according to the safety notice above described.

Moreover, the utmost clearness is required during valve installation of the air supply connection to the actuator. All the connection

parts such as reductions, joints, plates, brackets and equipment must be clean and dirty free.

Before assembling the actuator onto the valve make sure that both items are correctly oriented, depending upon which direction of

rotation is required.

- Before starting the actuator installation, should be done a visual actuator control to verify its physical condition after transportation

and storage.

- Control trough the shaft slot or caps the actuator position

- Read carefully the ACTUATECH instruction sheet included in the cardboard box

- Read the actuator limits and performances marked on the actuator body to verify its suitability

- Remove the protection label stickers from the ports

Actuator control.

EN - 10

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

- Before tting the actuator on the valve, clean the valve and the actuator from the dust and dirt.

- Verify the valve position, close or open, and the rotation direction.

- Verify the actuator position and rotation according with the valve requirement and operation, especially for Spring Return installation

Fail to Close or Fail to Open.

- Spring Return Fail to Close actuators are always supplied in the close position.

- While Spring Return Fail to Open are always supplied in the open position.

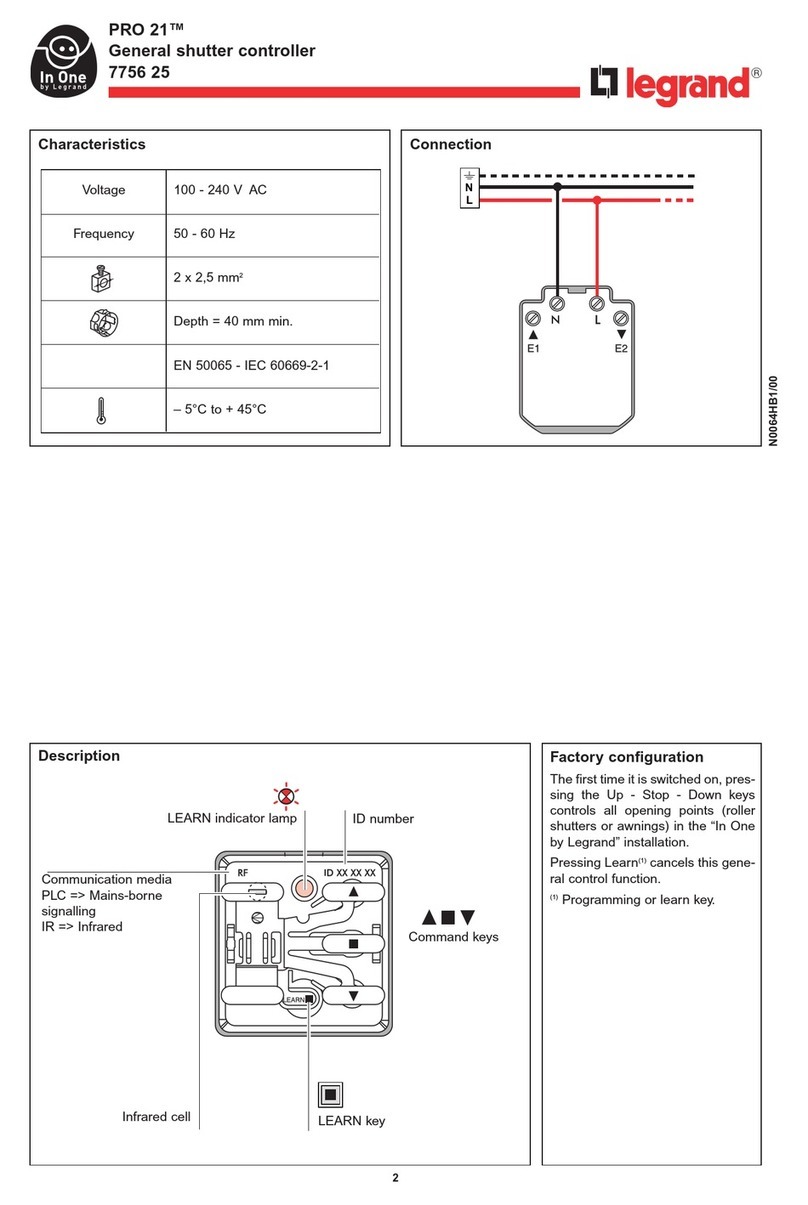

Valve/Actuator assembly: (A) direct-mount (B) plate-mount (C) bracket-mount.

EN - 11

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

A) Direct mounting.

Valve actuator Direct mounting is the best solution to avoid plays between valve stem and actuator drive shaft. For a direct mounting

you should have the same standard ange connection on valve and actuator as well as the valve stem dimensions that t perfectly

with the actuator drive. Before installation please verify that the actuator and valve ange ISO connections are the same size; verify

that the valve stem size and shape is suitable for direct mounting, if necessary, use a drive reduction.

Fit the valve stem into the actuator drive shaft connection, and bolt together the two ISO anges.

B) Mounting plate connection.

In case direct mounting is not possible cause of little differences in actuator/valve anges or drives sizes, mounting plates adapters

with suitable anges dimensions allows an easy connection living a sufcient space for the valve/actuator drive adapter.

C) Bracket & Joint connection.

Wherever for technical reason the plant installation requires a distance between actuator and valve, or the valve ange and/or stem

are not standard, and in any case, where the valve/actuator connection could not be possible, a bracket and joint is the right answer.

The Bracket is a steel bridge that allows to connect the valve with is own ange connection in one side and with the suitable actuator

connection onto the opposite side, living a space in between for a steel joint connection. The joint allows a drive connection between

the actuator and the valve stem indispensable in case of stem key drive and at head.

Chose the suitable ange bracket and the required joint connections to x the actuator onto the valve very tight without any plays.

ACTUATECH actuator with its draining channels system on the ange connection pattern is especially designed for valve

direct mounting. This system allows to drop away any possible ow coming from the valve stem that with valve/actuator

direct mounting could damage the actuator.

Screw torque wrench setting

Actuator/Valve rotation control and mounting.

Type: GD (Valve closed)

Size Torque Nm

M5 5-6

M6 10-11

M8 20-23

M10 45-50

M12 80-85

M14 125-135

M16 190-200

M20 370-390

EN - 12

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Type: GD (Valve open)

Type: GS (Valve closed)

Type: GS (Valve open)

EN - 13

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Stroke adjustment.

Both actuator versions, Double Acting and Spring Return, are provided as standard with 10° stroke adjustment.

a) GD Double Acting stroke adjustment instruction.

Close adjustment

The stroke adjustment on the actuator mounted on the valve should be done with the valve free of any ow pressure or friction impe-

diments, in addition the actuator shall be disconnected from the air supply and equipment.

This operation should be done with the valve/actuator held rmly in the pipeline or in a vice.

- Supply the air pressure to port 2 to open the valve, and to position the actuator pistons inward.

- Remove the cap nuts (part N° 18) and its O-ring (part N° 24).

- Screw in clockwise direction the screw adjustment (part N° 28) in one actuator side only.

- Supply the air pressure to port 4 to close the valve and to position the pistons outward and against the adjustment screw and check

the valve close position.

- In case the valve position is not correct, repeat the operation from the beginning.

- In opposite situation, if, with the air supply in the port 4, the valve is not sufciently closed, unscrew counter clockwise the adjustment

screw (part N° 28) backward counter clockwise until the required position has been found.

- Obtained the correct valve position, and with the air pressure to the port 4, screw the other adjustment screw up to piston pressing,

in this way both adjustment screws are working to stop the pistons simultaneously.

- Tightly screw the cap nuts (part N° 18) with its sealing O-ring (part N° 24) on the end caps to hold the adjustment screws in desired

position.

- The actuator is now ready to operate correctly.

ACTUATECH standard stroke adjustment is max 10° special longer screws are available on request.

EN - 14

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

b) GS Spring return Fail to Close stroke adjustment instruction.

Open adjustment

The stroke adjustment on the actuator mounted on the valve should be done with the valve free of any ow pressure or friction impe-

diments, in addiction the actuator shall be disconnected from air supply and equipment.

This operation should be done with the valve/actuator held rmly in the pipeline or in a vice.

- Remove the cap nuts (part N° 18) and its O-ring (part N° 24).

- Screw, clockwise direction, the screw adjustment (part N° 21) in one actuator side only.

- Supply air pressure to port 4, and due to the air pressure action, the pistons moves to the outward position up to the limits determi-

ned by the adjustment screw on the piston head.

- Check the valve open position, if the valve is to much open repeat the operation from the beginning.

- In opposite case, valve not sufciently open, with the air supply to the port 4, move the adjustment screw (part N° 21) backward

counter clockwise until the required position has been found.

- Obtained the correct valve position, and with the air pressure to the port 4, screw the other adjustment screw up to piston pressing,

in this way both adjustment screws are working to stop the pistons simultaneously.

- With pressurised air supply, tightly screw the cap nuts (part N° 18) with its sealing O-ring (part N° 24) on the end caps to hold the

adjustment screws in desired position.

- In this condition the actuator is ready to operate correctly.

ACTUATECH standard stroke adjustment is max 10°, special longer screws are available on request.

EN - 15

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Close adjustment

The stroke adjustment on the actuator mounted on the valve should be done with the valve free of any ow pressure or

friction impediments, in addiction the actuator must be disconnected from air supply and equipment.

This operation should be done with the valve/actuator well held in the pipeline or in a vice.

- Remove the cap nuts (part N° 18) and its O-ring (part N° 24).

- Supply the air pressure to port 4 to open the valve and position the actuator pistons outward.

- Unscrew, counter clockwise direction, both screws in same measure (part N° 21).

- Stop to supply air pressure to port 4, and due to the spring action, the pistons moves to the inward position up to the

limits determinate to the adjustment screws on the spring caps (part N° 22), ***WARNING

- Check the valve close position, if is over closed repeat the operation from the beginning until the desired valve closure

position is achieved.

- In opposite case, with the valve to much open, with the air supply to the port 4, move both adjustment screws inward,

clockwise in same measure.

- Without pressurised air supply, tighten the cap nuts (part N° 18) with its sealing O-ring (part N° 24) on the end caps to

hold the adjustment screws in desired position.

- In this condition the actuator is ready to operate correctly.

***WARNING. The Spring Return close adjustment is not a mechanical stop that act against the pistons travel or the shaft rotation,

but the screws limits the spring travel and the pistons without any force standstills. In this condition the shaft is not stopped and the-

oretically could be moved to the total closing position, adjustments of closing and opening cannot be performed both.

ACTUATECH standard stroke adjustment is max 10°, special longer screws are available on request.

EN - 16

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

This adjustment table represent the average drive variation angle α for each full turn of the adjustment screw β.

For each 1° of drive variation α 1 the adjustment screw is to be rotate as β 1.

*The below table data is referred to the standard stroke adjustment only (10°).

For longer screw adjustment please contact technical commercial department.

ACTUATOR SIZE

ADJUSTMENT

SCREW ROTATION

ANGLE

SHAFT VARIATION

ANGLE AFTER

ADJUSTMENT

ADJUSTMENT

SCREW ROTATION

ANGLE

SHAFT VARIATION

ANGLE AFTER

ADJUSTMENT

βαβα

GD15 360° 3°34’ 101° 1°

GD30 360° 2°54’ 124° 1°

GS15 360° 3°7’ 115° 1°

GD45 360° 2°43’ 132° 1°

GD60 360° 2°18’ 156° 1°

GS30 360° 2°26’ 148° 1°

GD106 360° 1°55’ 187° 1°

GS53 360° 2° 180° 1°

GD120 360° 1°50’ 196° 1°

GS60 360° 2° 180° 1°

GD180 360° 2°14’ 160° 1°

GS90 360° 2°14’ 161° 1°

GD240 360° 2° 179° 1°

GS120 360° 1°54’ 187° 1°

GD360 360° 1°45’ 206° 1°

GS180 360° 1°40’ 216° 1°

GD480 360° 1°49’ 196° 1°

GS240 360° 1°54’ 190° 1°

GD720 360° 1°37’ 223° 1°

GS360 360° 1°45’ 206° 1°

GD960 360° 1°28’ 245° 1°

GS480 360° 1°57’ 184° 1°

GD1440 360° 1°31’ 237° 1°

GS720 360° 1°40’ 216° 1°

GD1920 360° 1°28’ 245° 1°

GS960 360° 1°33’ 230° 1°

EN - 17

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

6. MATERIALS AND THEIR DURABILITY

Life time 20 years or number of cycles as per EN15714-3 2009 (see table below).

(a)* Based on EN ISO 5211.

(b)* One cycle consists of nominal 90° angular travel in both directions (i.e. 90° to open + 90° to close). For angular travel other than

90°, the endurance shall be agreed between the purchaser and the manufacturer/supplier.

(c)* For thermoplastic actuators the minimum number of cycles shall be 250 000.

Should it be necessary to replace its pistons sealing, this operation must be done by ACTUATECH trained people with proper tools,

we recommend to return the actuator to ACTUATECH where the actuator will be overhauled and than tested for a correct replace-

ment.

On request ACTUATECH will be willing to provide its sealing Kits.

WARNING: ACTUATECH declines any responsibility for the products repaired by third parties.

Nominal torque (a)* Nm Piston or vane actuator Minimum

number of cycles (b)*

Maximum stroking time for testing,

based on 0-90° s

≤125 500 000 (c)* 3

≤1 000 500 000 5

≤2 000 250 000 8

≤8 000 100 000 15

≤32 000 25 000 20

≤63 000 10 000 30

≤125 000 5 000 45

≤250 000 2 500 60

EN - 18

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

Actuator components and material list.

* Parts included in the spare parts kit.

POS. Denomination Q. Materials Standards

1 Cylinder 1 Aluminium alloy EN AW 6063 Anodized

2Piston 2 Aluminium alloy EN AB 46100

3 Cap 2 Aluminium alloy EN AB46100 Painted

4Shaft 1Stainless steel AISI 303 - DIN 1.4305

5Scotch yoke 1Steel alloy UNI 90MnVCr8Ku - DIN 1.2842

Hardened

6Support bush 1Acetalic resin

7Shaft support 1Acetalic resin

8 Bush 2Steel alloy UNI 110w4Ku - DIN 1.2516

9 Rotative sleeve 2Steel alloy UNI 6364A - DIN 6325

10* Dynamic seal (piston) 2 Polyurethane

11* Piston’s support 4P.T.F.E. Carbo-Graphite lled

12* Piston o-ring 2 Nitrilic rubber

13 O-ring (upper sealing shaft) 1 Viton

14 External support ring 1 Aluminium alloy

15 Washer 1Stainless steel UNI 3653 - DIN 471

16 Seeger 1Stainless steel UNI 3653 - DIN 471

17 O-ring (low sealing shaft) 1 Viton

18 Nut 1 Aluminium alloy EN AB46100 Painted

19* Cap o-ring 2 Nitrilic rubber

20 Screw 8 Stainless steel AISI 304 - DIN 1.4301

21 Spring loading screw 2Steel UNI 3740/65 8G Galvanized

22 Spring cap 2Steel DIN 1.0315 Galvanized

23 Spring 2Steel DIN 1.7102

24* O-ring 2 Nitrilic rubber

25 External elastic pin of the yoke 1Steel DIN 1481

26 Internal elastic pin of the yoke 1Steel DIN 1481

27 Centering ring 1 Aluminium alloy DIN AIMgSiPb Anodized

28 Stroke adjustment screw 2Stainless steel AISI 304 - DIN 1.4301

EN - 19

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

7. MAINTENANCE

The ACTUATECH S.p.A. actuator, when installed and used properly, does not require maintenance, under normal use, as it’s provi-

ded with sufcient lubrication for standard duration.

Send the actuator directly to ACTUATECH S.p.A. for inspection or extraordinary maintenance

If the cap or piston seals need to be replaced, ACTUATECH S.p.A. can supply a kit containing spare parts.

WARNING: The seals must be replaced by qualied personnel and with the appropriate tools. ACTUATECH S.p.A. declines all re-

sponsibility for products that are repaired by third parties.

REPLACING THE SEALS

Disassembly.

Actuator disassembly operation must do with the actuator free from any pneumatic and electric connection and dismounted from the

valve.

Verify that the actuator is air bag free, and the spring return actuator is completely in its springs rest position.

Check that the air port 2 and 4 are absolutely vented.

Use proper tools only.

A) Loosen the end cap screws (part N° 20) in cross sequence to remove the end caps (part n° 3), in case of force on the screws that

means that the actuator is still under air or spring action and the operation should be discontinued until the action is removed. The

end caps contain a sealing O-ring (part N° 19) on its seat that should be checked before replacement.

Caution. The Spring Return end caps cartridges (Parts N° 3 + 18+24+19+23+22+21) are a safety device, where the preloaded spring

is set to avoid the dangerous spring jumping. Do not release the screw (part N° 21) to remove the spring from its seat, this operation

must be done by ACTUATECH technician only.

B) Hold the actuator in the vice and rotate the drive shaft until the pistons (part N°2) are released form the scotch-yoke groves (part

N° 5), then slip off the pistons from the cylinder (part N° 1). Do not use compressed air to remove the pistons from the body, this

operation could cause personal injuries.

EN - 20

ITENDEFRES

ACTUATECH S.p.A

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy • Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.com

Rif. MAN80515 - 07/22

INSTRUCTION MANUAL

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD15 - GD 1920 AND GS15 - GS960

C) The dynamic seal (part N° 10), O-ring (part N° 12) and supports (part N° 11) should be checked before replacement. Do not use

sharp tools to cut the dynamic seal and O-ring or remove the supports from the piston as this may cause furrows or marks.

D) When the components are disassembled, they should be properly cleaned, and wear checked prior to being greased and reas-

sembled. In case the sealing parts are too much worn out use new parts from the spare parts kit.

WARNING. Due to ACTUATECH scotch-yoke shaft blow-out security system the shaft disassembly operation must be carried out by

ACTUATECH technician only.

Assembly.

A) O-ring (part N° 12) and dynamic seal (part N° 10) shall be greased and mounted onto the piston seat using a proper conical tool

(see the drawing) that allows an easy and perfect slip-in of the items without any damages.

B) Push into its piston seats the P.T.F.E. supports (part N° 11).

C) Grease the pistons (part N° 2) on the replaced parts (parts N° 10+11+12), and the piston bearings (part N° 8).

D) Grease the internal cylinder surface (part N° 1).

E) Position the scotch-yoke shaft (part N° 5) in order to have the groves in position for the pistons insertion and the right shaft required

direction of rotation.

F) Insert the pistons (part N°2), using a proper conical tool (see the drawing), in the scotch-yoke grooves (part N° 5) and press simul-

taneously the two pistons inside of the cylinder (part N° 1). The ACTUATECH scotch-yoke system will avoid pistons misalignment.

Holding the actuator on a vice rotate the shaft to verify the shaft rotation direction and the easy movement.

G) Replace the sealing O-ring (part N° 19) on its caps seat (part N° 3) and grease it. Fit the end caps to the body screwing the screws

in cross (part N° 20).

N.B. For the screw torque wrench setting see pg. 11.

Other manuals for GD15

1

This manual suits for next models

25

Table of contents

Other ACTUATECH Controllers manuals