Hiniker 8605 User manual

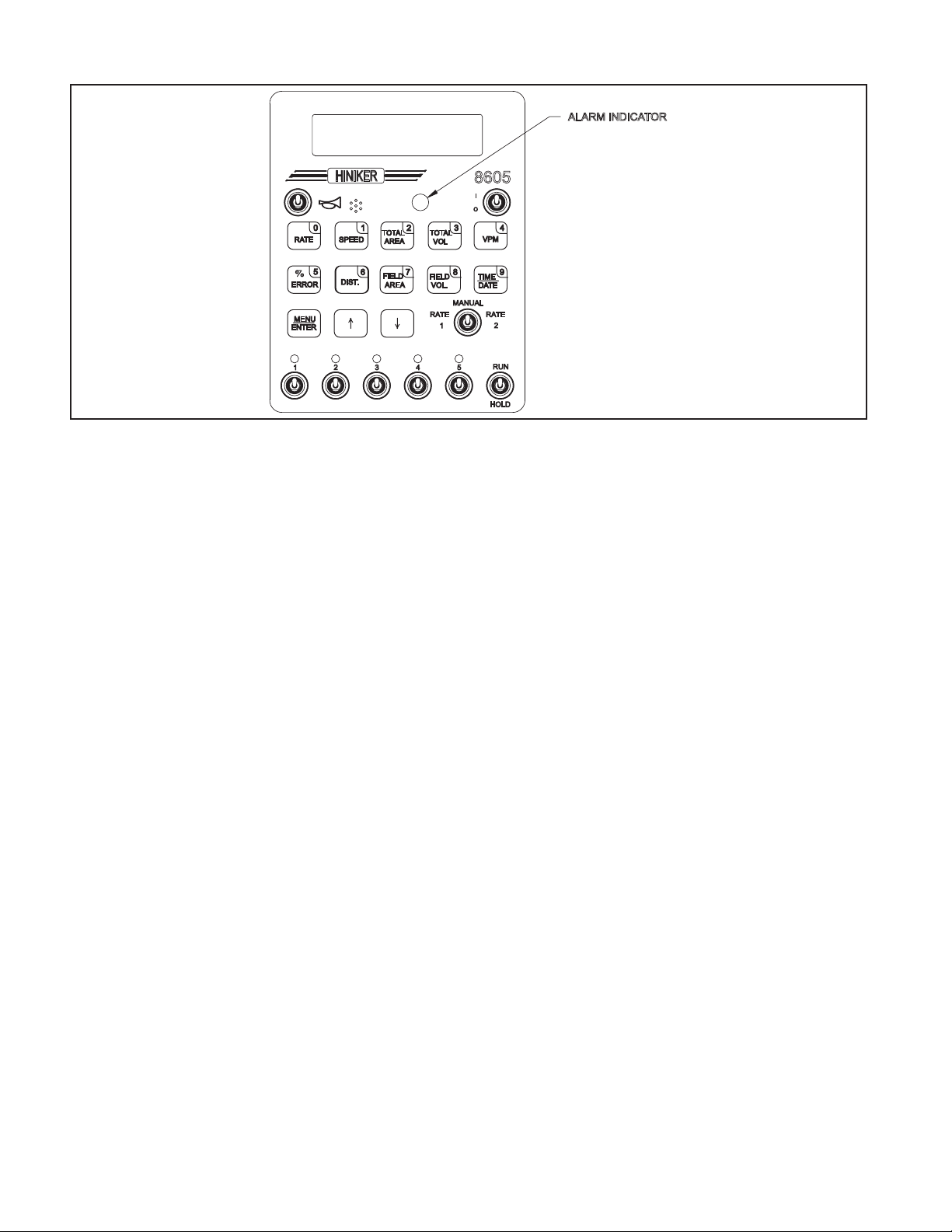

8605 CONTROLLER

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 39300018 Rev. E

TITLE

TABLE OF CONTENTS

39300018 Rev. E 9/11 Manual/39300018RevE

SAFETY ........................................................................................................................................ 3

TO THE PURCHASER.................................................................................................................. 4

OPERATION ................................................................................................................................. 5

SYSTEM OVERVIEW ............................................................................................................ 5

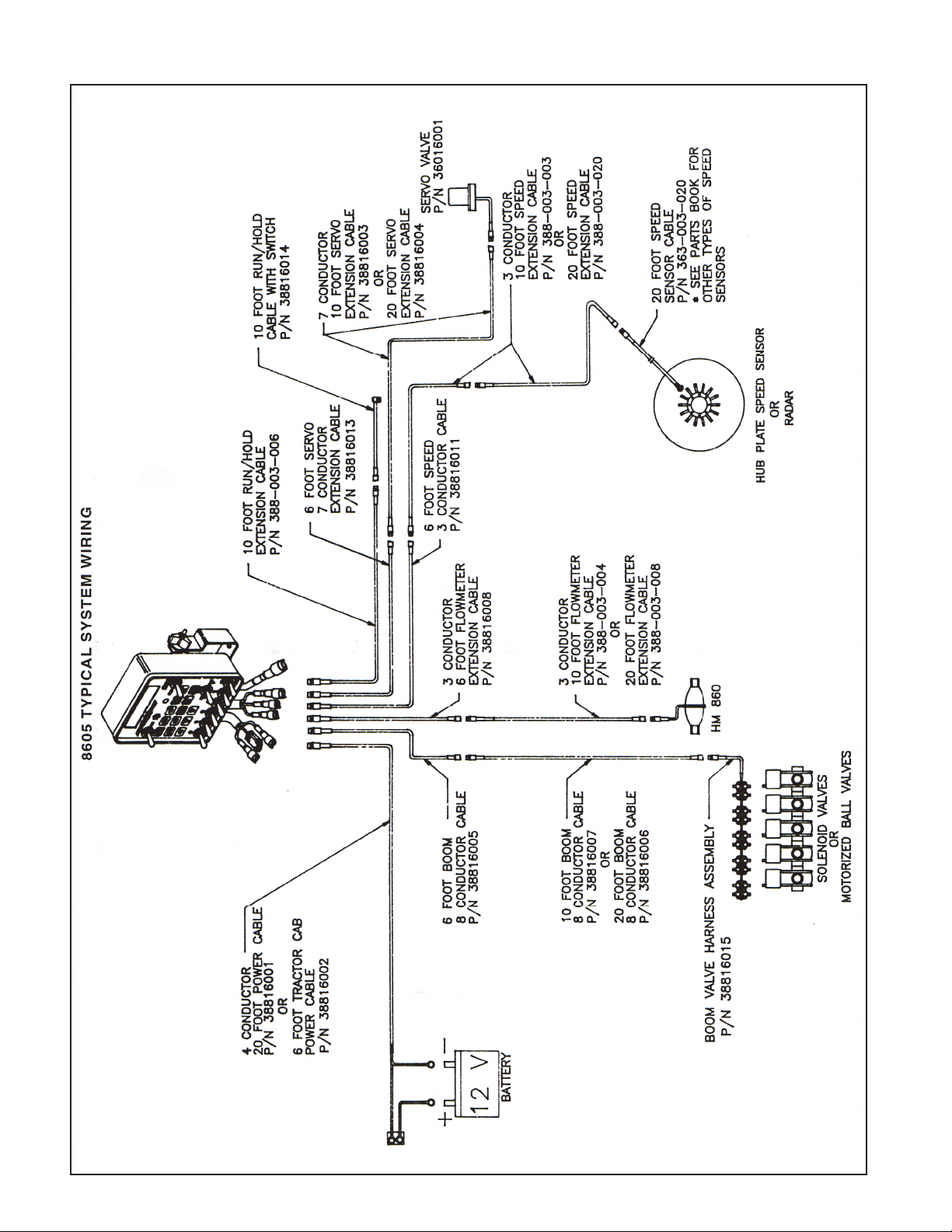

TYPICAL SYSTEM WIRING .................................................................................................. 6

POWER SWITCH................................................................................................................... 7

HORN..................................................................................................................................... 7

RUN/HOLD SWITCH ............................................................................................................. 7

RATE SELECTOR SWITCH .................................................................................................. 7

BOOM SWITCHES ................................................................................................................ 7

KEYPAD ................................................................................................................................. 8

TOTAL VOLUME .................................................................................................................... 8

TOTAL AREA.......................................................................................................................... 8

FIELD VOLUME..................................................................................................................... 8

FIELD AREA........................................................................................................................... 9

VPM........................................................................................................................................ 9

DISTANCE ............................................................................................................................. 9

SPEED ................................................................................................................................... 9

MENU/ENTER........................................................................................................................ 9

KEYS ............................................................................................................................. 9

TIME/DATE ............................................................................................................................ 9

RATE .................................................................................................................................... 10

% ERROR ............................................................................................................................ 10

DATA STORAGE.................................................................................................................. 10

DISPLAY ...............................................................................................................................11

GUIDELINES........................................................................................................................ 12

PRESYSTEM CHECK.......................................................................................................... 13

PRINTING REPORTS.......................................................................................................... 14

EXTERNAL INPUT............................................................................................................... 15

CALIBRATION ............................................................................................................................ 16

DISTANCE CALIBRATION................................................................................................... 16

GENERAL INFORMATION .................................................................................................. 16

CALIBRATION PROCEDURE - SPRAYERS ....................................................................... 17

MINIMUM FLOW RATE PROCEDURE ............................................................................... 19

CALIBRATION PROCEDURE - ANHYDROUS AMMONIA.................................................. 20

Table of Contents 1

2 Table of Contents

INSTALLATION........................................................................................................................... 22

Controller Mounting......................................................................................................... 22

Power Cable.................................................................................................................... 23

SPEED SENSORS............................................................................................................... 24

Hub Plate Speed Sensor................................................................................................. 24

Radar............................................................................................................................... 26

Adaptive Interface............................................................................................................ 27

GPS Ground Speed Sensor............................................................................................ 28

SPRAYER APPLICATION .................................................................................................... 30

Introduction...................................................................................................................... 30

Inline System................................................................................................................... 31

Bypass System................................................................................................................ 32

Flowmeter........................................................................................................................ 33

Servo Valve ..................................................................................................................... 34

REMOTE RUN/HOLD .......................................................................................................... 34

WIRING................................................................................................................................ 34

Motorized Boom Valves................................................................................................... 35

Solenoid Valves............................................................................................................... 35

ANHYDROUS AMMONIA APPLICATIONS.......................................................................... 36

TROUBLE SHOOTING............................................................................................................... 37

CONSOLE SYMPTONS AND POSSIBLE CAUSES............................................................ 38

CABLE AND CONNECTOR ................................................................................................. 39

SPEED SENSOR................................................................................................................. 41

FLOWMETER ...................................................................................................................... 41

FLOW METER CALIBRATION TEST................................................................................... 43

SERVO VALVE..................................................................................................................... 44

APPENDIX...................................................................................................................... 46-51

SERIAL COMMUNICATIONS SPECIFICATIONS................................................................ 46

SerialSpecications........................................................................................................ 46

PrinterSpecications....................................................................................................... 46

SERIAL PROTOCOLS .................................................................................................... 46-51

Hiniker Protocol........................................................................................................... 47-49

Generic Protocol.......................................................................................................... 49-51

WARRANTY..................................................................................................................Rear Cover

TITLE

SAFETY

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED

THESE SYMBOLS AND INSTRUCTIONS, OTH-

ERWISE DEATH, OR SERIOUS INJURY CAN

RESULT!

Operator safety is a principle concern in equip-

ment design and distribution. However, many ac-

cidents occur because a few seconds of thought,

and a more careful approach to handling, were

ignored.

Throughout this manual, and on all safety relat-

ed decals, a safety alert symbol, along with the

signal word CAUTION, WARNING, or DANGER

willbefound.Thesearedenedasfollows:

CAUTION: A reminder for proper safe-

ty practices and directs attention to

following them. Decals of this class

are yellow and black.

WARNING: A reminder for proper safe-

ty practices and what can happen if

they are ignored. This has a more seri-

ous consequence than CAUTION. Decals of

this class are yellow and black.

DANGER: Denotes the most serious

safety hazard. It is a reminder for ob-

serving the stated precautions and

what can happen if they are ignored. Decals

of this class are red and white.

CAUTION:For your own protection we

very strongly recommend that you

read, understand, and heed the follow-

ing information.

CAUTION: If you and your operator(s)

are not intimately familiar with proper

handling procedures for Anhydrous

Ammonia, contact your supplier for informa-

tion, and read all safety precautions found in

the “HINIKER ANHYDROUS AMMONIA MONI-

TORING AND CONTROL SYSTEM MANUAL”,

Refer to manual Part No. 360-000-246 Revi-

sion E or higher for Heat Exchangers man-

ufactured prior to 2007. These are painted

Gray.

or

Refer to manual Part No. 39300035 for Heat

exchangers manufactured in 2007 or after.

These are painted White Additional manuals

may be obtained from your local dealer.

ACCIDENTS CAN BE AVOIDED BY KNOW-

ING, AND FOLLOWING, THE PRECAUTIONS

CITED IN THIS MANUAL.

GENERAL

1. If the Operator’s Manual is missing from this

equipment, obtain a replacement from your

HINIKER dealer. If you sell this equipment,

ensure the new owner acknowledges receipt

of this manual.

2. Read this manual thoroughly. Make sure the

operator understands it and knows how to

operate this equipment safely. Farm equip-

ment can kill or injure an untrained, or care-

less operator.

3. Do not attempt to handle and service this

equipment, or direct others to do the same,

unless you know how to do it safely.

4. Don’t be in a hurry.

Hiniker Company reserves the right to change

prices, standard features, specications or

designs, and options at any time without no-

tice and without incurring the obligation to

install such changes on machines previously

manufactured.

Safety 3

TITLE

Congratulations for joining the ranks of agribusi-

nessmen who acknowledge the importance of

accurate and controllable application of chemi-

cals.

This product will insure that the proper recom-

mended application rate is maintained. This will

not only save you money lost by overapplication,

but safeguard that your yields are not being ad-

versely affected by underapplication.

As an added bonus your operation will become

more environmentally responsible, by you be-

ing able to know that only the proper amounts of

chemicals required for your application are be-

ing used.

This product is designed and manufactured to

give years of dependable service, when used for

the purpose for which it was intended.

Never allow anyone to operate this equipment

until they fully understand the complete con-

tents of the manual. It is the responsibility of the

owner’s who do not operate this equipment, to

insure that the operator is fully instructed, and

is fully aware, and understands, the contents of

this manual.

Important information is contained in this manual

tohelpinsuresafeandefcientoperations.

If you have any questions about this manual,

or equipment discussed therein, contact your

HINIKER dealer.

4 To The Purchaser

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED

THESE INSTRUCTIONS, OTHERWISE DEATH,

OR SERIOUS INJURY CAN RESULT.

NOTE: All references to “LEFT” and “RIGHT”

are meant to mean viewing the equipment from

the rear and facing the tractor.

ALWAYS OBTAIN ORIGINAL HINIKER SER-

VICE PARTS BECAUSE SUBSTITUTE PARTS

COULD ADVERSELY AFFECT EQUIPMENT

PERFORMANCE AND WARRANTY.

Record the following information for later refer-

ence when obtaining service parts.

Purchase Date________________________

Name_______________________________

Dealer’s Name________________________

Console Serial No._____________________

Flowmeter Serial No.___________________

Servo Valve Serial No.__________________

TO THE PURCHASER

TITLE

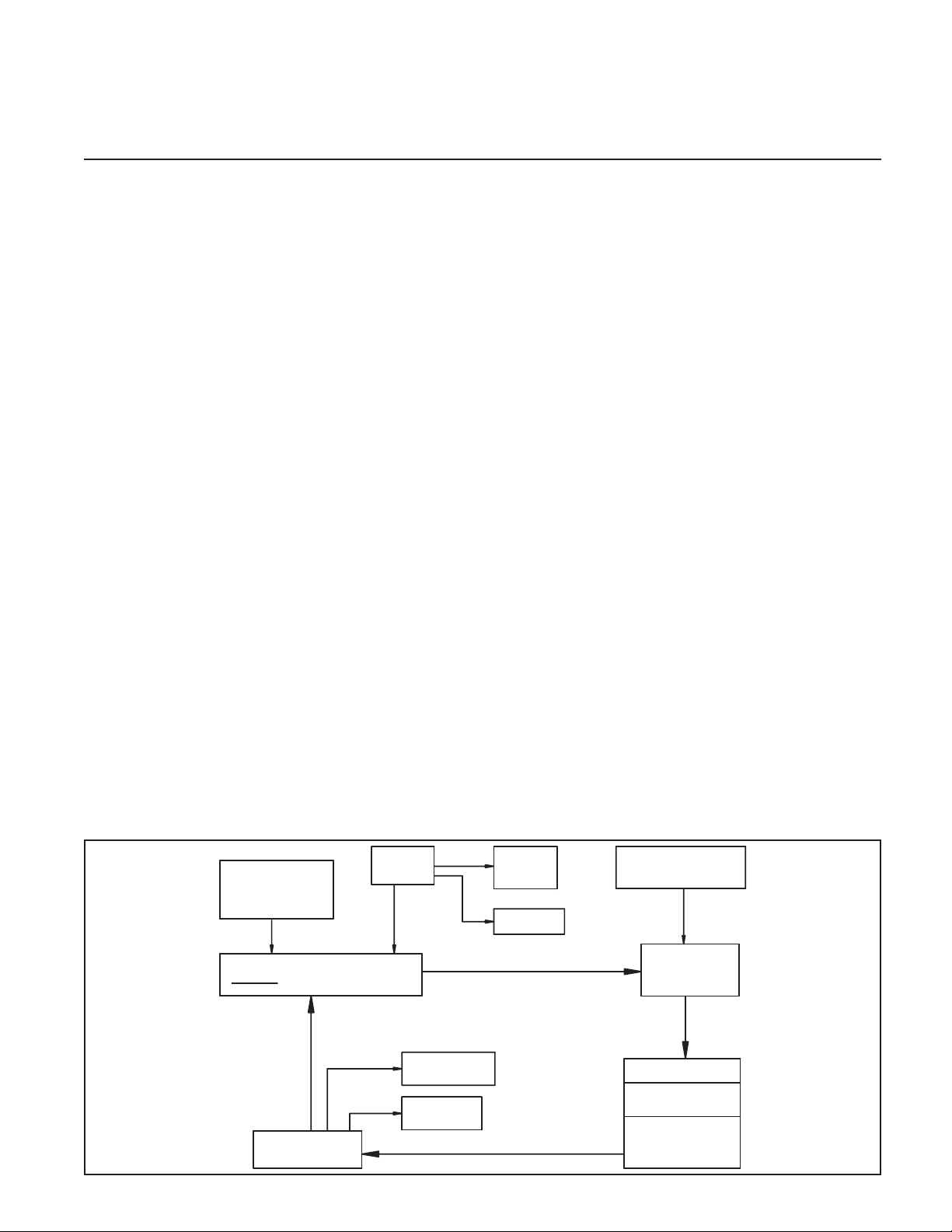

SYSTEM OVERVIEW

The Hiniker 8605 controller is a computerized sys-

tem that will enable you to apply liquid chemicals,

including Anhydrous Ammonia at any given rate.

The 8605 controller allows you to set up a system

individuallycalibratedtoyourspecicneeds.

The 8605 controller in conjunction with a Speed Sen-

sor, Flowmeter, and Servo Valve performs the neces-

sary calculations to perform “on-the-go” adjustments

to the rate of application of chemicals.

Thecontrollerusestheinputsofactualow,speed,

and user selected functions to calculate the actual

application rate in GPA (Gallons Per Acre of liquid)

or PPA (Pounds Per Acre of nitrogen). This is then

compared to the target rate selected by the operator

to generate an adjustment amount. The adjustment

is sent to the Servo Valve which, in turn, adjusts the

actual ow. This process continues until the actual

ratematchesthetargetrate.Thefollowinggureisa

block diagram showing the basic operation.

The following is a list of features available with this

system.

- AnhydrousAmmoniaSystemConguration.

- InlineorBypassSystemConguration.

- Stepper Motor Valve Control.

- Uptovesectioncontrolofelectricsolenoidvalves

or motorized ball valves for individual boom control.

- Boom section widths may be individually set.

- Selection of Rate 1, Rate 2, Manual, or External

Rate Control.

- Adjustable Minimum Flow Limit.

- Adjust Rate 1, Rate 2, on the Go.

- Warning Lamp and audible alarm when the applica-

tion error is greater than 10%.

- Low battery indicator.

- Local Run/Hold.

- Remote Run/Hold Option.

- Dual line Sunlight Readable Display - any two selec-

tions displayed at once.

- Ten Display Selections are Available - Rate, Percent

Error, Speed, Distance, Volume per Minute, Field

Area, Total Area, Field Volume, Total Volume, and

Time/Date.

- SimpliedSystemDistanceCalibration.

- Easy Min./Max. GPM Determination.

- Non-Volatile Memory for setup data retention.

- Non-Volatilememoryforstorageofeldacres,eld

volume,anddate/timeforupto99eldsand16dif-

ferentchemicalspereld.

OPERATION

Operation 5

CALCULATE

ACTUAL GALLONS PER ACRE

SPEED

SIGNAL

TOTAL

ACRES

RATE 1/RATE 2/

MANUAL/VARIABLE

TOTAL

GALLONS

CALCULATE

GPA

% ERROR

INLINE/BYPASS

VALVE

RESPONSE

SERVO

VALVE

CONTROL

FLOWMETER

ACTUAL FLOW

SIGNAL

BOOM WIDTHS

BOOMS ON

DISTANCE CAL.

DISTANCE

INPUT

MINUTE

VOLUME PER

PULSES/GAL .

DWG. NO. 3138

6 Operation

DWG. NO. 3139B

The 8605 controller will enable you to set up and

controlasystemtailoredtoyourspecicneeds.

POWER SWITCH

The power switch is a two position toggle switch

used to apply power to the 8605 controller.

Placing the switch in the UP position applies

power and placing the switch in the DOWN posi-

tion removes power from the system. All calibra-

tion and application data is retained even with

power turned off.

HORN SWITCH

The horn switch is a two position toggle switch

used to control the audible alarm.

The horn is enabled with the switch in the UP

position and disabled when the switch is in the

DOWN position. Turning off the horn DOES NOT

turn off the visual alarm (yellow light).

RUN/HOLD SWITCH

The Run/Hold switch is a two position toggle

switch used to control power to the individual

boom valve control system.

RATE SELECTOR SWITCH

The Rate switch is a three position toggle switch

that is used to select Rate 1, Manual or Rate 2.

Operation 7

12

ERROR

MENU

ENTER

O5

O

RATE

3 4

HOLD

5RUN

AREA

FIELD FIELD

VOL.

AREA

TOTAL

TIME

DATE

SPEED

DIST.

TOTAL

VOL

HINIKER

I

O

8605

RATERATE

MANUAL

2

1

6 7 8

0 1 2 3 4

9

VPM

POWER SWITCHHORN SWITCH

RATE SELECTOR SWITCH

BOOM VALVE ON

INDICATORS

BOOM VALVE

SWITCH

SWITCH

RUN/HOLD/MASTER BOOM

DWG. NO. 3137A

The application rates for Rate 1 and Rate 2, are

set up in calibration mode and can be adjusted

“on the go” by pressing the Up, or Down arrow

keys.

When the Rate switch is in Manual (center posi-

tion), the Servo Valve can be adjusted manually

by pressing the Up, or Down arrow keys.

When in Rate 1, the 8605 controller supports the

use of an external application rate source, such

as GPS (Global Positioning Satellite) based

equipment. For specic details on serial com-

munications refer to the Appendix.

BOOM SWITCHES

Five separate Boom switches are available to

controluptoveelectricsolenoidvalvesormo-

torized ball valves.

The width of each Boom is set in the calibra-

tion mode. If any Boom is not needed, set its

width to zero or leave the Boom switch off. In

the Automatic and Variable Rate modes, the rate

is automatically adjusted as the Boom switches

are turned on and off. When all Boom switches

are turned off, the controller will stop automatic

control and be in the HOLD mode.

Acres are only calculated and counted for Boom

widths that are selected.

8 Operation

KEYPAD

The keypad is used for operator entry during Cali-

bration and operation. The number keys are used

for Calibration. The audible alarm is used with the

keypad to indicate data entry into the controller.

Each key press of the keypad results in a single

“beep” to signify acknowledgement of the key

press.

Keypad operation is described below.

TOTAL VOLUME

Press TOTAL VOL key to view the total gallons or

pounds of actual nitrogen applied. Total Volume

accumulates only when the console is in RUN. To-

tal Volume will not accumulate in HOLD.

Total Volume may be cleared to zero by depress-

ing the TOTAL VOL key for three seconds.

A solid tone will warn that Total Volume is about to

be cleared, release the key to abort. Total volume

is cleared at the end of the tone.

TOTAL AREA

Press TOTAL AREA key to view total acres.

Total Acres accumulate only when the console is

in RUN. Total Acres will not accumulate when in

HOLD.

The 8605 will automatically correct for the change

in implement width while calculating area when

any of the boom switches are turned off or on.

NUMERIC KEYS

12

ERROR

MENU

ENTER

O5

O

RATE

3 4

HOLD

5RUN

AREA

FIELD FIELD

VOL.

AREA

TOTAL

TIME

DATE

SPEED

DIST.

TOTAL

VOL

HINIKER

I

O

8605

RATERATE

MANUAL

2

1

6 7 8

0 1 2 3 4

9

VPM

DWG. NO. 3136A

Total Area may be cleared to zero by depressing

the TOTAL AREA key for three seconds.

A solid tone will warn that Total Area is about to

be cleared, release the key to abort. Total Area is

cleared at the end of the tone.

FIELD VOLUME

Pressing the FIELD VOL key displays the current

Field and Chemical numbers along with the Date/

Time Stamp. After three seconds Gallons or actual

Nitrogen applied for the current selection will be

displayed.

Field volume may be cleared to zero by depress-

ing the FIELD VOL key for three seconds. This will

clear the Field Volume data accumulated to date

forthecurrentlyselectedeldandchemicalnum-

bers.

A solid tone will warn that volume is about to be

cleared, release the key to abort. Field Volume is

cleared at the end of the tone.

Clearing the Field Volume also signals that this is

the start of a new Field/Chemical application re-

cord. The record will be stamped with the current

date and time to indicate when the new application

record was started. If you are in NH3 mode, the

new record will be tagged as an NH3 record. The

printoutofNH3applicationrecordsshowtheeld

volume as pounds of actual nitrogen rather than as

gallons of liquid.

Field Volume accumulates only when the controller

is in Run. Field Volume will not accumulate in HOLD.

Operation 9

FIELD AREA

Pressing the FIELD AREA key displays the cur-

rent Field and Chemical numbers along with

the Date/Time Stamp. After three seconds Field

Acres for the current selection will be displayed.

Clearing Field Acres to zero may be done by de-

pressing the Field Area key for three seconds.

A solid tone will warn that Field Area is about to

be cleared, release the key to abort. Field Area

is cleared at the end of the tone.

Field Acres accumulate only when the control-

ler is in RUN. Acres will not accumulate when in

HOLD.

The 8605 will automatically correct for the

change in implement width when one or more of

the boom switches are turned off or on.

NOTE: The 8605 will accumulate volume and

acresforthecurrentelduntiltheeldnumber

or chemical number is changed. Changing the

eldnumbersavesthecurrentvaluesinmemory

and begins accumulating volume and acres for

theneweld.

VPM (Volume Per Minute)

Press the VPM key to view the current volume

perminute(owrate)ingallonsorpounds.VPM

will read 0 in Hold.

DISTANCE

The 8605 will calculate and display distance

anytime the DIST key is pressed. Accumulated

distance may be cleared by depressing the DIST

key for three seconds.

Distance does not accumulate in HOLD mode.

The distance must be calibrated before attempt-

ing to use the controller. An incorrect distance

calibration will affect all computations except

FIELD VOLUME and TOTAL VOLUME. It is rec-

ommended that the Distance Calibration be per-

formed prior to system Calibration.

SPEED

The 8605 will calculate and display speed in miles

per hour anytime the SPEED key is pressed. An

incorrect distance calibration factor will affect

speed calculations.

MENU/ENTER Key

Press the or keys to scroll through the fol-

lowingchoices:

Press the Enter key to choose a selection.

The MENU / ENTER key is used to view the

menu choices.

1. CHANGE FIELD & CHEMICAL # See steps

2 and 3, page 17.

2. CALIBRATION MODE See page 16.

3. DISTANCE CALIBRATION See page 16.

4. SET MINIMUM RATE See page 19.

5. VARIABLE RATE SETUP

6. PRINT RECORD See page 14.

7. PRINT ALL FIELD HISTORY See page 14.

8. CHANGE DATE & TIME

This is used to set date and time as follows. The

displaywillshowTIMEHH:MMandeitherAMor

PM.EnterthenewtimeinHH:MMformatwhere

HH=hours (01-12) and MM = minutes (00-59).

Note that setting the time requires that four dig-

its are to be entered (for example enter “0205”

for2:05).UsetheupArroworDownArrowkey

to change between AM and PM.

Press enter to advance to Date. The display will

show DATE MM/DD/YY Enter the new date in

MMDDYY format where MM=month (01-12), DD

= date (01-31), and YY = the last two digits of

the year (00-99). Note that setting the date re-

quires that six digits be entered (for example,

enter “010811” for January 8, 2011.

8. EXIT V3.00

This exits the menu and shows software version

number.

KEYS

The keys have four uses. In the Menu the

keys are used to scroll through the selections.

In Calibration the keys increment or decrement

calibration values. In Manual the keys adjust the

servo valve. When RATE or % ERROR is being

displayed the keys adjust the selected applica-

tion rate.

TIME /DATE

Press the TIME / DATE key to view the current

date and time. This key is a “toggle” key, press

it once and the time is displayed, press it again

and the date is displayed.

10 Operation

RATE

When RATE is selected, target and actual gallons

per acre or pounds of Nitrogen per acre being ap-

plied are displayed.

% ERROR

The purpose of % ERROR is to make it very easy

for the operator to see how close the actual ap-

plication rate is to the desired or target application

rate.

This function computes and displays the percent

error. Therefore, if the actual rate is exactly equal

to the desired rate, it will display 0% error. If, for

example, the actual rate was high by 5% then it

would display +5%. If the actual rate was low by

7% then it would display -7% (note the negative

sign).

A quick glance at the display using this mode will

let you know that it is working. Under normal con-

ditions the error will stay less than 10% (positive

or negative) which should be considered accept-

able. Quick speed changes such as shifting gears

onahillsidewillobviouslycauseasignicanterror.

However, the 8605 will immediately start correct-

ing and the “% ERROR” display will show this.

The 8605 will start making ow adjustments as

soon as the error reaches plus or minus 1%. If the

error exceeds 10% the alarm indicator will ash

and the audible alarm will sound.

The 8605 will then start driving the Servo Valve

at a much faster rate and will soon have the er-

ror less than 10% again. The alarm light will

stop ashing and the audible alarm will stop

“beeping” when the error is less than 10%.

ALARM INDICATOR

12

ERROR

MENU

ENTER

O5

O

RATE

3 4

HOLD

5RUN

AREA

FIELD FIELD

VOL.

AREA

TOTAL

TIME

DATE

SPEED

DIST.

TOTAL

VOL

HINIKER

I

O

8605

RATERATE

MANUAL

2

1

6 7 8

0 1 2 3 4

9

VPM

DWG. NO. 3135A

This is a handy feature since the operator can

“see” and “hear” when the error exceeds 10% and

“see” and “hear” when the 8605 automatically cor-

rects it.

The 8605 performs the Error (% Error) calcula-

tion very quickly. Therefore, it is normal to see this

modeuctuate,especiallyinroughgroundcondi-

tions where the speed naturally makes many small

changes. For example, a change of 1/4 MPH above

or below 5 MPH would be detected and correctly

computed as a 5% error. When the speed makes

these small changes, the % error display will usual-

ly show 1 or 2 positive error readings followed by 1

or 2 negative readings. It is easy to see that the av-

erageerroris0%andtheintermediateuctuating

readings should not be considered alarming. Both

the applicator and the 8605 are operating properly.

DATA STORAGE

The 8605 has the capability to store 1584 different

applications.Thesearedividedinto99eldswith

16chemicalspereld.FieldArea, Field Volume,

Time and Date are saved for each Field/Chemical

combination.

Field and Chemical numbers can be selected in

Change Field & Chemical # (Menu selection 1) or

in Calibration mode (Menu selection 2). The Field/

Chemical application record will be stamped with

the current date and time when Field Volume is

cleared to indicate when the new application record

was started. It will also be tagged as an NH3 re-

cord if Field Volume is cleared while in NH3 mode.

The print out of NH3 application records show the

eld volume as pounds of actual nitrogen rather

than as gallons of liquid. To view information on the

current Field/Chemical record, press Field Area or

Field Volume.

DISPLAY

During Calibration the display allows you to see

and adjust all calibration numbers. Upon comple-

tion of Calibration, the controller displays the “ini-

tializing Servo Valve” message and sets the valve

to a starting position that depends on the “Inline” or

“Bypass” location of the Servo Valve.

During normal operation any two of the ten func-

tion keys may be displayed. Pressing one of the

ten keys, % ERROR, RATE, VPM, TOTAL AREA,

TOTAL VOL, SPEED, DISTANCE, FIELD AREA,

FIELD VOL or DATE/TIME will display that select-

ed function on the bottom line of the display. The

previous bottom line function will now be shifted to

the top line of the display.

The following is a list of display messages and

their meanings.

HOLD

Reminds the operator that the 8605 is not automat-

ically controlling the sprayer, that all boom valves

are closed and the distance, acre and gallon coun-

ters have stopped accumulating. Hold is only dis-

played in Rate or % Error.

ERR

This stands for percent of error. The percent differ-

ence between the rate selected (RATE 1, RATE 2

or VARIABLE) and the rate being measured by the

combinationofspeedandowsignals.IftheRate

Selector Switch is in the Manual Position, MAN.

ERR will be displayed.

LOW BATTERY POWER

This is a warning that the battery power supplied

to the 8605 is less than 10 VDC. This condition

causes the 8605 to suspend operation. The 8605

will remain in this mode until battery power is 10

VDC or more.

NO-SPD

This is a warning that the speed signal is missing

or that the speed is too slow for the 8605 to oper-

ate in the RATE 1, RATE 2 or VARIABLE RATE

modes. Either increase your speed or switch to

manual operation. No-SPD is only displayed in

Rate or % Error.

ZERO WIDTH ENTERED

This is a warning that the Booms have zero en-

tered for implement width. Enter the correct width

values.

NO-FLO

Thisisawarningthattheowsignalismissingorthat

theowistoolowforthe8605tooperateintheRate

1,Rate2orvariableratemodes.Eitherincreaseow

by increasing speed or application rate or switch to

manualoperation.No-oisonlydisplayedinRateor

% Error.

TOT VOL

This is your total accumulated volume. This is mea-

sured as gallons or pounds of actual Nitrogen.

TOT AREA

This is your total accumulated area counter and is

measured in acres.

FLD AREA

Thisistheaccumulatedareaforthecurrenteld,and

chemical number. It is measured in acres.

FLD VOL

Thisistheaccumulatedvolumeforthecurrenteld

number and chemical number. It is measured in gal-

lons or pounds of actual Nitrogen.

SPEED

Displayed as “MPH” (Miles per hour).

DIST

This is your accumulated distance traveled in feet.

RATE (GPA or PPA)

This is your actual application rate measured in gal-

lons per acre or actual pounds of Nitrogen per acre.

The left side of the display shows the TARGET RATE

and the right side shows the ACTUAL RATE.

MIN

IndicatesMinimumowtotheboomscausedbythe

servo valve at the end. Displayed only during Rate or

% Error.

MAX

IndicatesMaximumowtotheboomscausedbythe

servo valve at the end. Displayed only during Rate or

% Error.

LIM

Limstandsforlimit.LIMisashedonthedisplayif

the Minimum Flow Rate feature has been enabled

andtheactualowratefallstothevalueset.Itisonly

displayed if RATE or % ERROR has been selected.

Operation 11

12 Operation

GUIDELINES

The purpose of this section is to provide some

general guidelines and recommendations for op-

eratingthe8605intheeld.

The 8605 has 13 keys labeled with 10 functions.

All of the functions are working at all times. How-

ever, only two can be displayed at a time. Press-

ing one of the ten function keys will display that

function. The operator is free to select whichever

function he or she desires, however, the follow-

ing is a list of recommendations.

Whenrstinstalled,itisimportanttoinsurethat

the 8605 is indeed controlling your sprayer prop-

erly.

The RATE and % ERROR keys will show this.

Pressing the RATE key will display the actual

application rate in gallons per acre (pounds per

acre). Pressing the % ERROR key will display

the actual error between the actual and target

rates. This is displayed as a percentage.

When the controller is in Hold then HOLD will

be displayed. The console must be in RUN and

actively working to show correct RATE and %

ERROR data.

TheError,Hold,No-spd,No-o,Min.andMax.

are only displayed when Rate or % Error is being

displayed.

It is important to remember that any errors less

than 10% are considered good. You will note,

however, that the 8605 will continue controlling

the Servo Valve until the error falls to zero. The

warninglightwillashandtheaudiblealarmwill

sound when the error exceeds ±10%.

The 8605 will automatically adjust the sprayer

owwheneverRate1 or Rate 2 isselectedor

when an external rate input is received. Putting

the Rate switch in the center position will turn

the automatic control off and the application rate

can then be adjusted manually.

Switching between Rate 1 and Rate 2 can be

done at any time and as often as desired. The

8605 will change to the new application rate and

maintain that rate.

The and keys will adjust the application rate

selected if Rate or % Error is being displayed.

Driving too fast or too slow will cause the servo valve

to end stop (either full open or full close).

When this happens, the pressure gauge will show

minimum or maximum PSI and the Controller will dis-

play either MAX or MIN. This indicates that you are

exceeding the limits of your applicator and the 8605

can no longer maintain a constant rate per acre.

Sometimes it is necessary to slow down to a very

slowspeedintheeldoronanendrow.(Smallarea

or rough spot, etc.) The 8605 will try to maintain a

constant rate lowering the pressure even though it is

far below the minimum acceptable pressure for the

nozzles. This will probably result in a trickle of spray

out of the nozzles causing very poor weed control.

To prevent a “MIN” message as you slow down the

8605 can automatically stop reducing the ow at

a preset minimum ow rate. This prevents a poor

spray pattern from your nozzles. This option can

be turned on and the Minimum Flow Rate set in the

main menu under Set Minimum Flow. This is only

available for the Spray Mode. Keep in mind that you

are OVER APPLYING to maintain a spray pattern at

verylow speeds. Whenevertheow isreducedto

theMinimumFlowlevel,thedisplaywillash“LIM”

toindicatethattheconsolewillnotreducetheow

any further.

NOTE: The following procedure can be used as an

alternative to using the Minimum Rate feature.

As you slow down, watch your pressure gauge.

When a minimum acceptable pressure (determined

by nozzle selection) is reached, switch the console

into MANUAL mode. (RATE 1 and RATE 2 switch in

center position.) This will freeze the servo valve at

that position and maintain the pressure at that MINI-

MUM amount instead of dropping it to zero.

After passing through the bad spot or making the

turn, simply switch back to Rate 1 or Rate 2 as you

again increase your speed.

Keep in mind that you are OVERAPPLYING to main-

tain a spray pattern at very low speeds.

It is highly recommended that the operator take ad-

vantageofthedualratecontrol.Signicantchemical

savings can be made if Rate 2 is programmed to a

higher rate for weedy spots, and ONLY used when

eldconditionsrequireit.Alltherestofthetimethe

operator can stay in the lower Rate 1 mode and save

chemicals.

Operation 13

PRE-SPRAYING SYSTEM CHECK

It is highly recommended that the following checklist

beusedbeforegoingtotheeldtospray.

1. Park sprayer, use clear water.

2. Select Rate and VPM. Turn booms on by select-

ing RUN.

3. Select Manual mode on the Rate Switch (center

position).

4. Hold the keyuntil the display ashes“MAX”.

(This will move the valve to the maximum pres-

sure position.)

5. Start the sprayer pump and run at operating

RPM.

6. Assure that all boom valves are operational.

7. Note Maximum Volume per Minute.

8. Note Maximum pressure.

9. Hold the key until the display starts to ash

“MIN”.

10. Note Minimum pressure.

11. Note Minimum Volume per Minute.

12. Perform “Minimum Flow Rate” procedure now if

using this feature.

13. Press the key until the pressure is at some typi-

cal amount or about the middle of the range.

14. Put controller in HOLD and turn pump off.

15. Setthedesiredeldnumberandchemicalnum-

ber. Double check that you have the correct target

Gallons Per Acre programmed in for RATE 1 and

RATE 2.

16. Clear both ACRE counts to zero, if desired.

17. Clear both VOLUME counts to zero, if desired.

Youarenowreadytogototheeldandbeginspray-

ing.

To adjust this maximum and minimum ow rate and

pressure, open or close any manual series valve, by-

pass valve, etc., to achieve a desired ow rate and

pressure range.

In general, a 4 to 1 pressure range can be used on

most nozzles. For example, 10 PSI to 40 PSI can be

used on ood-jet nozzles. Be sure to consult your

pressure nozzle charts. Using pressures that are too

low will generate a poor spray pattern. Very high pres-

sures will cause “misting” and also increase nozzle

wear-out rate.

A 4-to-1 change in pressure will only cause a 2-to-1

changeintheowrate.Therefore,thespeedchange

must be limited to 2-to-1. For example, a pressure

changeof10PSIto40PSI(4:1)willdoubletheow

rate. This means the speed can also double (4 MPH

to 8 MPH) and still maintain a constant GPA (gallons

per acre).

Minimum and Maximum speed can be calculated as

followsusingtheformula:

Speed = VPM x 495

Width (in feet) x Rate (in Gallons/Acre)

Example: Using an application rate of 20 GPA and a

widthof60feet,aminimumowrateof3.5gallons

per minute would allow a minimum speed of 1.44

mph.

Minimum Speed = Minimum VPM x 495

Width x Rate

Minimum Speed = 3.5 x 495

60 x 20

Minimum Speed = 1.4 mph

Changingtoamaximumowrateof70gallonsper

minute will allow a maximum speed of 28.8 mph.

Maximum Speed = Maximum VPM x 495

Width x Rate

Maximum Speed = 70 x 495

60 x 20

Maximum Speed = 28.9 mph

Calculation should be done for both Rate 1 and Rate 2.

REMEMBER, OPERATING OUTSIDE THE SPEED

RANGE FOUND IN THIS PROCEDURE (TOO FAST

OR TOO SLOW) MAY RESULT IN EXCEEDING

THE MINIMUM OR MAXIMUM RECOMMENDED

OPERATING PRESSURES FOR YOUR NOZZLE.

THIS COULD RESULT IN POOR WEED CONTROL,

ETC.

When a desired pressure cannot be obtained the

usual cause is low pump capacity. Other possible

problems are long runs of small diameter hose, low

capacityboomvalvesandexcessiveagitationow.

14 Operation

PROCEDURE FOR PRINTING 8605 REPORTS

The 8605 controller can send Field/Chemical re-

port information to a wide variety of serial print-

ers. The following describes the report printing

procedure in general. See Appendix A on serial

communications for details on printer specica-

tions. Information for an individual Field/Chemical

record can be printed by performing the following

steps:

1 . Press the Menu key and select the 4. PRINT

RECORD option.

2. Select the Field Number by entering it on the

keypadoradjustingthedisplayedeldnum-

ber with the Up or Down Arrow key.

3. Press Enter when Field Number selection is

completed.

4. Select the Chemical Number by entering it on

the keypad or adjusting the displayed chemi-

cal number with the Up or Down Arrow key.

5. Press Enter when Chemical Number selec-

tion is completed.

6. The printer should produce a report similar to

thefollowing:

Field/Chemical Application Record

Asof1:18pm,09/18/11

StartDate:09/18/11 Time:10:08AM.

Farm:................................................Field:01

FieldDesc:......................................................

Applicator:.......................................................

Chemical 01....................................................

AmountApplied: 00153.6 Gallons

Acres: 0016.4 Acres

WeatherConditions:......................................

Wind Speed/Direction...................../................

Temperature:............. Humidity:...................

NOTES:

.......................................................................

.......................................................................

Sample Field/Chemical Application Record Report

Information on all previously used Field/Chemi-

cal records can be printed by performing the fol-

lowingsteps:

1. Press the Menu key and select the 5. PRINT

ALL FIELD HISTORY option.

2. The printer should produce a report similar

tothefollowing:

Field/chemical History Report

Asof1:18pm,09/18/11

Field:1Area138.9Acres

Chemical:1Vol:1214.9Gallons

Date:09/18/11Time:10:08AM

Field:1Area92.2Acres

Chemical:2Vol:1182.4Gallons

Date:09/16/11Time:08:12AM

Field: 3Area22.1Acres

Chemical:1Vol:1214.9Gallons

Date:09/15/11Time:08:44AM

Field:6Area133.5Acres

Chemical:2Vol:1102.1Gallons

Date:09/10/11Time:09:11AM

Field:7Area44.3Acres

Chemical:1Vol:88.6Gallons

Date:09/01/11Time:09:16AM

NOTES:

.......................................................................

.......................................................................

Sample Field/Chemical History Report

Operation 15

USING THE 8605 CONSOLE WITH AN

EXTERNAL RATE INPUT

- The external rate input will override the pre-

programmed RATE 1 data.

- The external rate message protocol as ex-

plained in the Appendix. Your computer must

provide the variable rate data to the controller

in one of these formats.

- The controller will continue to apply at the

rate specied in the last received message

until it receives a new message specifying a

new application rate.

- Switching to MANUAL or RATE 2 on the con-

troller will override the external rate input.

- Entering CALIBRATION MODE will reset the

variable rate data to the RATE 1 data as dis-

played during Calibration step 4.

- The “Generic Protocol” is only available in

software version 3.0 or higher. If you have

earlier versions the 8605 will need to have

the software updated.

TITLE

16 Calibration

CALIBRATION

7. Your distance calibration is now complete,

you may now operate the system or perform

the Calibration procedure.

GENERAL

The Calibration procedure is used to set up the

controller to your particular system congura-

tion.

The Calibration Mode can be entered at any

time by pressing the MENU KEY and select-

ing CALIBRATION.

Before starting the calibration procedure please

familiarize yourself with the questions and any

number values required.

The controller has a memory retention feature

that saves calibration data during power off.

For Anhydrous Ammonia applications see Cali-

bration Procedures for Anhydrous Ammonia.

When all calibration steps are completed, the

8605 runs the servo valve to a home position,

therefore, the servo valve should be connected

to the controller during calibration. Failure to

have the servo valve connected will result in the

8605 displaying “Check Servo Valve” then exit-

ing calibration. This allows you to use the 8605

as a monitor if the servo valve is disconnected.

Field and chemical numbers can be changed

without performing the entire calibration proce-

dure by selecting menu selection 1. CHANGE

FIELD & CHEMICAL # and perfroming calibra-

tion steps 2 and 3.

DISTANCE CALIBRATION

The purpose of this step is to match the console

distance calibration factor to the distance mea-

suring device you are using, including RADAR.

This calibration process is extremely simple and

fast, involving nothing more than driving a pre-

measured distance with the Console in the DIS-

TANCE CALIBRATION mode.

Distance Calibration is not required when using

the Hiniker GPS Speed Sensor. Enter 2.00 as

the Calibration number.

Normally you will only have to do this procedure

once for each implement used, unless the same

implement is used in considerably different

ground condition. (Spring, summer and fall op-

erations). This procedure should be completed

prior to the Calibration procedure.

1. Measure500feetinyoureldandmarkstart

andnishwithags.

2. Stopat therstag. Lineupsome conve-

nientpartofthetractorwiththerstag.

3. Select Distance Calibration in the Main

Menu. Press Enter, the display will read

“Drive 500 Feet and Stop”.

4. Drive at normal speeds in a straight line with

the tank 1/2 full. Display will read “Press En-

ter Key When Done”.

5. Slowdownandstopwhenthesecondag

lines up. DO NOT BACK UP! Press the En-

ter Key.

6. The console now will compute the distance

calibrationfactoranddisplay:

THE NEW DIST CAL FACTOR = XX.XX

Where XX.XX is equal to your systems cali-

bration number.

This number is automatically stored in the

controller memory.

Calibration 17

CALIBRATION PROCEDURES - SPRAY APPLICATIONS

STEP DISPLAYED ACTION YOU TAKE

1

CALIBRATION MODE Select Calibration Mode from the Main Menu.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

2

FIELD NUMBER Usenumerickeystoentereldnumber.(1-99)or

Press key to increase number.

Press key to decrease number.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

3

CHEMICAL NUMBER Use numeric keys to enter chemical number. (1-16) or

Press key to increase chemical number.

Press key to decrease chemical number

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

4

APPLICATION:

1. SPRAY Press ,keys to make selection.

2. NH3Select 1. Spray

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

5

SERVOLOCATION: Press ,keys to make selection.

1. INLINE Select Inline if the servo valve is installed inline with the

owtothebooms.

2. BYPASS Select Bypass if the servo valve is installed in a return or

agitation line back to the tank or pump inlet.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

6

APPLY RATE 1

10.0 GAL/ACRE Use numeric keys to set value or

Press key to increase the gallon per acre for Rate 1.

Press key to decrease the gallon per acre for Rate 1.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

7

APPLY RATE 2

20.0 GAL/ACRE Use numeric keys to set desired value or

Press key to increase gallon per acre for rate 2.

Press key to decrease gallon per acre for rate 2.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

18 Calibration

STEP DISPLAYED ACTION YOU TAKE

8

VALVE RESPONSE 5 Set value for valve response in automatic 1 to 9.

Use numeric keys or the or key.

Larger number = faster response.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

9

FLOW METER

CALIBRATE 72.0

This number must match the pulses per gallon number on

thedecalontheowmeter.

Use numeric keys to set value or

Press key to increase number.

Press key to decrease number.

IMPORTANT:Makesureyouenterthepulses per gallon

calibration number.

17.0 PULSES/LB PULSES/Gal 72.0

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

10

DIST. CALIBRATION

FACTOR 2.00 Use numeric keys to set value or

Press key to increase calibration factor.

Press key to decrease calibration factor.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

If you have not performed the distance calibration procedures as outlined on page 16. You must do

so to determine what the distance calibration factor is. By performing the distance calibration on

page 16 the 8605 will automatically enter the distance calibration factor for step 10. If using a Hiniker

GPS Speed Sensor enter 2.00 as the Calibration number.

11

BOOM #1 WIDTH

240 INCHES Use numeric keys to set value or

Press key to increase the total width in inches for boom #1.

Press key to decrease the total width in inches for boom #1.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

12

BOOM #2 WIDTH

240 INCHES Use numeric keys to set value or

Press key to increase the total width in inches for boom #2.

Press key to decrease the total width in inches for boom #2.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

13

BOOM #3 WIDTH

240 INCHES Use numeric keys to set value or

Press key to increase the total width in inches for boom #3.

Press key to decrease the total width in inches for boom #3.

PRESS ENTER KEY TO ADVANCE TO NEXT STEP.

Table of contents

Other Hiniker Controllers manuals