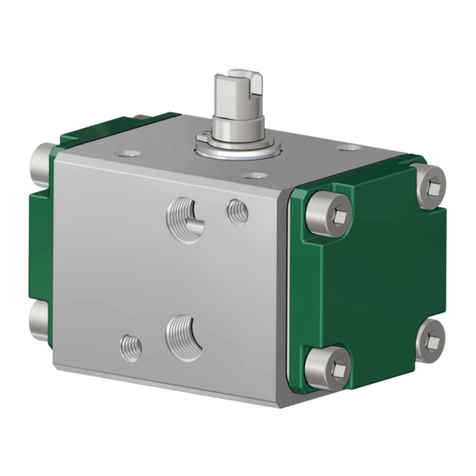

Scotch-Yoke part turn pneumatic actuator

Modification reserved. Rev.date 12.2003.

No guarantee for accuracy.

F.lli

Capponi,

126/128

25068

Sarezzo

(BS)

–

ITALY

Tel.

(+39)

0308908142

Fax

(+39)

0308908143

Page

2

of

24

1) General features

Actuatech manufacture a wide range of part turn pneumatic actuators for valve remote control, the actuators are available on

Double Acting “GD”and Spring Return “GS”versions.

- The principle of the actuator application is to open and close the connected valve, without the manual operation with lever

or hand wheel, by means of an electric-pneumatic connection on remote control.

- Scotch –Yoke is a mechanical system that allows to transform the linear force into a rotary torque.

Actuatech applies the scotch - yoke system for its actuator production to transfer the pistons linear force to a driving shaft

torque.

This system provides a long working life and best performance with the minimum energy consumption.

- Actuatech Scotch-Yoke system with its oblique grooves produces a torque curve with the highest torque at the start

opening operation in order to overcome the valve breakaway torque.

The maintenance should be done by Actuatech trained personnel only.

This instruction manual contains important information regarding the Actuatech Scotch-Yoke pneumatic actuator operation,

installation, maintenance and storage.

Please read carefully before installation and keep it in a safe place for further reference.

2) Working conditions

a)

Construction.

Standard Actuatech actuators are suitable for indoor and outdoor installation. The laser marking on the actuator body gives

the actuator technical characteristics: type, size, operating maximum pressure, output torque, operating max temperature,

flange connection, serial manufacture number (see drawing pag.4).

b) Motive energy

The operating media should be dry and filtered compressed air not necessarily lubricated or inert gases compatible with

internal actuator parts and lubricants. The filtration must grant a maximum particle size not exceeded 30µm. The air lubricant

must be compatible with the internal parts. The operating media should have its dew point not less than –20°C ( -4°F) in

normal condition, or at least the dew point should be 10°C below the ambient temperature.

c) Supply operating media pressure.

The maximum supply pressure is 8,4 bar ( 120 psi)

Nominal supply pressure is 5,6 bar ( 80 psi), working pressure range from 2,5 bar ( 36 psi) up to 8,4 bar (120 psi).

d) Operating temperature.

Actuator standard working temperature range form –20°C ( -4°F) to 80°C ( 176°F)

For low and high temperature versions please contact Actuatech.

e) Operating drive rotation.

The part turn actuator rotation angle is nominally 90°. Actuatech actuator provides a stroke of 92° rotation, from –1° to 91° ,

with standard stroke adjustment of –10°.

f) Cycle time.

The cycle time is dependent on different operating and installation factors such as the supply pressure, the flow capacity, the

connection pipe size, the solenoid valve performance, the valve torque and characteristics, environmental temperature

condition.