EN - 16

ITENDEFRES

ACTUATECH S.p.A

Via

S.

Lorenzo

,

70

,

25069

Villa

Car

cina

(BS)

Italy

•

Ph. +39

0

30

8908142

•

Fax +39 030 8908143 • actuatec[email protected]om • www.actuatech.comRif. MAN80937 - 03/22

INSTRUCTION MANUAL

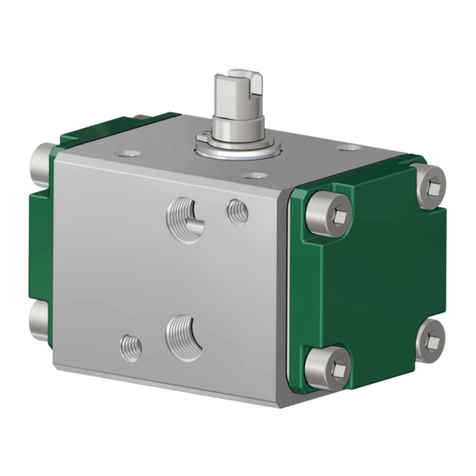

SCOTCH–YOKE PART TURN PNEUMATIC ACTUATOR

GD2880 - GD8000 AND GS1440 - GS4000

11. TROUBLESHOOTING

POTENTIAL EFFECT OF FAILURE POTENTIAL CAUSE OF FAILURE SOLUTION

Loss or reduction of the supplied

torque

Lack of supply Verify that the actuator has been con-

nected to the pneumatic line correctly

Air supply not enough to produce

required torque

Verify that the supply pressure value cor-

responds to the functioning requirements

(see actuator data plate)

Air leakage from seals Verify that the screws are completely

tightened

Leaks from the stem upper or lower

seals

Stem O-ring seal damage

Contact ACTUATECH for repairDamages on the body

Shaft damaged

Leakage form cylinder caps Seals damaged Replace the seals

(see “Maintenance” chapter)

Leakage from the ports after

manoeuvre

Damaged piston seal Replace the piston seals

(see “Maintenance” chapter)

Damaged body cylinder Contact ACTUATECH for repair

Insufcient valve rotation

Increase of valve manoeuvre torque Verify the valve release torque and the

possibility to replace with a new one

Air supply not enough to produce

required torque Increase the air supply

Mechanical stop (if there) not duty

adjusted Adjust the stops by increasing the stroke

Wrong connection between the actuator

and the valve stem

Check the connection elements between

the valve and the actuator

12. DISPOSAL OF PRODUCTS AT THE END OF THEIR LIFE CYCLE

The ACTUATECH products are designed so that when they are at the end of their life cycle they can be completely disassembled,

separating the different materials for the proper disposal and/or recovery. All materials have been selected in order to ensure minimal

environmental impact, health and safety of personnel during their installation and maintenance, provided that, during use, they are

not contaminated by hazardous substances.

The personnel in charge of the product disposal/recovery, must be qualied and equipped with appropriate personal protective equi-

pment (PPE), according to the product size and the type of service for which the device was intended. The management of waste

generated during the installation, maintenance or due to the product disposal, is governed by the rules in force in the country where

the product is installed, in any case, the following are general guidelines:

- The metal components (aluminium/steel) can be restored as raw material;

- Seals/sealing elements (NBR, FPM, FVMQ...), as contaminated by uids from other materials and lubrication, must be disposed of.

- The packaging materials that come with the product, should be transferred to the differentiated collection system available in the

country.

13. DECLARATION OF CONFORMITY

The ACTUATECH S.p.A. actuators have been designed, manufactured and tested to meet the requirements of the following Europe-

an standards and are marked, where provided, with the relative CE conformity marking:

- 2006/42/EC Directive “Machinery”;

- 2014/34/EU Directive “Equipment and protective systems intended for use in potentially explosive atmospheres” (ATEX).

- Regulation (EC) No 1907/2006 and successive concerning the Registration, Evaluation, Authorization and Restriction

of Chemicals (REACH).