ACTUATECH RP10 User manual

EN - 1

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

DOUBLE ACTING (DA) AND SPRING RETURN (SR)

RP10 - RP480

EN - 2

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

INDEX:

Pag.

1. GENERAL FEATURES 3

2. WORKING CONDITIONS 3

3. CONSTRUCTION FEATURES 6

4. CODING SCHEME 7

5. FUNCTIONNING 8

6. SAFETY NOTICE 10

7. INSTALLATION INSTRUCTION 10

8. OPENING AND CLOSING ANGLE SETTING 14

9. MATERIALS AND DURABILITY 18

10. MAINTENANCE 21

11. ATEX SPECIFICATIONS 29

12. ACTUATORS SPECIAL VERSIONS 30

13. STORAGE 30

14. TROUBLE SHOOTING 30

15. DISPOSAL OF PRODUCTS AT THE END OF THEIR LIFE CYCLE 31

16. DECLARATION OF CONFORMITY 31

17. ENVIRONMENT IMPACT 31

Environmentally friendly: under the green leaf icon you can nd the instructions for a correct

and environmentally friendly handling of the product.

ACTUATECH reserves the right to change, at any time, features and data of its own products, to better improve their quality and

lifetime.

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT) RP-300 ÷ RP-480 (GAS)

EN - 3

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

FOREWORD

Present User’s Installation and Maintenance Manual has been edited in conformity with:

- 2006/42/EC Directive “Machinery”;

- 2014/34/UE Directive “Equipment and protection systems designated to be used in potentially explosive atmospheres” (ATEX);

Following standards/technical specications also applied:

- EN 15714-3:2009 Industrial valves: Actuators – Pneumatic part-turn actuators for industrial valves;

- IEC 61508:2010-1/7 Functional safety of electrical/electronic/programmable electronic safety-related systems. Part 1÷7;

- UNI CEN/TS 764-6:2005 Pressure equipment Part 6: Operating instructions structure and contents;

1. GENERAL FEATURES

ACTUATECH manufactures a wide range of part-turn pneumatic actuators for valve remote control.

Actuators are available on Double Acting (DA) and Spring Return (SR) versions.

Main actuator purpose is to open and close valves using an electric-pneumatic connection on remote control, without any manual

operation (lever or hand wheel).

RP actuators use a Rack & Pinon kinetics to transform a rectilinear motion generated by pistons into a shaft rotational motion 0°÷90°.

Standard actuators (DA and SR) have a clockwise rotation (CW) direction to close the valves (0° closed valve, 90° opened valve), but

counter-clockwise rotation (CCW) versions (0° opened vale, 90° closed valve) are available too.

Double acting (DA) Rack & Pinon actuators have a double constant rectilinear torque curve, while Spring Return (SR) Rack & Pinon

actuators have a decreasing rectilinear torque curve.

The components for the actuator maintenance are supplied in the ACTUATECH spare part kit (see section 9 exploded views).

Actuators maintenance should be done by ACTUATECH or trained personnel only (see section 10).

This instruction manual contains important information regarding operation, installation, maintenance, and storage of ACTUATECH

actuators. Please read it carefully before installation and keep it in a safe place for further reference.

Actuators are components without dened and proper functionality.

Below you will nd the safety instructions, minimum information for storage / ware cylinder, installation, commissioning, maintenance

as well as instructions for products disposal at the end of their life cycle.

ACTUATECH disclaims any liability for damage caused by improper use, even if partial, respect to the information contained in this manual.

2. WORKING CONDITIONS

2.1 Installation

Standard ACTUATECH actuators are suitable for indoor and outdoor installation. Degrees of protection provided by enclosures accor-

ding to IEC 60529 - IP rating 66/67/68.Technical features such as type, size, operating pressure, output torque, operating temperature,

ange connection, product code and production date are readable directly on the product by a printed or a laser-graving label (see

section 3).

2.2 Operating medium

Use ltered compressed air not necessarily lubricated according to UNI EN 15714-3:2009 or inert gases compatible with internal

actuator parts and lubricants. Operating medium must have a dew point equal to -20°C (-4°F) or, at least, 10°C (50°F) below the

ambient temperature (ISO 8573-1, Class 3). Maximum particle size must not exceed 40 μm (ISO 8573-1, Class 5).

2.3 Supply operating pressure

Nominal supply pressure 5,5 bar (80 PSI) for Double Acting, 6 bar (87 PSI) for Spring Return RS60. Maximum supply pressure 8 bar (116 PSI).

EN - 4

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

2.4 Operating temperature

Standard working temperature range from –20°C (-4°F) to 80°C (176°F).

Actuators for Low or High temperature applications are available, please contact us.

Supplementary protection (e.g. screens, sheds, or integral painting) are strictly recommended for high humidity and low temperature

application.

2.5 Operating drive rotation

Part turn actuator rotation angle is nominally 90° with a ± 5° adjusting stroke: closing setting from -5° to +5° and opening setting from

85° to 95°.

2.6 Cycle time

Cycle time depends on different operational and installation factors such as supply pressure, ow capacity, pipe size connection,

solenoid valve performance, valve torque and characteristics, ambient temperature condition.

Double

Acting

0°- 90°

cycle time

(ms)

90°- 0°

cycle time

(ms)

RP10 23 21

RP20 73 47

RP40 131 110

RP60 160 120

RP80 189 130

RP120 137 125

RP160 183 177

RP240 304 288

RP300 383 354

RP480 522 455

Ambient temperature 18÷25°C (64,4÷77°F)

Supply pressure compressed air; 5,5 bar (80 psi) for double acting and 6 bar (87psi) for spring return

Operating drive rotation 90° in both directions

Load free

Spring Return

0°- 90°

cycle time

(ms)

90°- 0°

cycle time

(ms)

RP20 79 60

RP40 155 170

RP60 188 178

RP80 221 187

RP120 220 207

RP160 273 236

RP240 330 342

RP300 559 509

RP480 697 772

Actuator opening, closing and open/close cycle times

Above timetable refers to a standard actuator working cycle at the following tests conditions:

DA actuators operate with solenoid valves 5/2 ISO 1-2, while SR actuators operate with solenoid valves 3/2. Time tested by Electronic

Timer device.

Note: different working conditions such as air pressure, piping connection, lters, or solenoid valves, could change operations timing.

EN - 5

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

2.7 Lubrication

Actuators are factory lubricated for standard life-working condition.

During maintenance and reassembling, we recommend using, for standard version, TECNOLUBE SYNTHY POLYMER 402, or equi-

valents. For low and high temperature actuators contact us.

2.8 Internal wear protection

Cylinder inner part is lapped to obtain a ne roughness surface and it is protected by a 20µm technical oxidation layer. Pistons slide

supports are in P.T.F.E. or polyurethane material only, no rubber is in contact to cylinder inner surface.

2.9 External protection

ACTUATECH standard actuators are suitable for indoor and outdoor installation. Aluminium cylinder has an external corrosion pro-

tection realized by a 20µm technical oxidation layer. Casted aluminium end caps are polyester painted. The nickel-plated transmis-

sion shaft. Grub screw and caps screws are in stainless steel.

Actuators for aggressive or severe environment applications are available, please contact us.

2.10 Functional Safety

ACTUATECH pneumatic actuators are suitable for installations which require high level of functional reliability, up to SIL3, in com-

pliance with the IEC 61508 Standard.

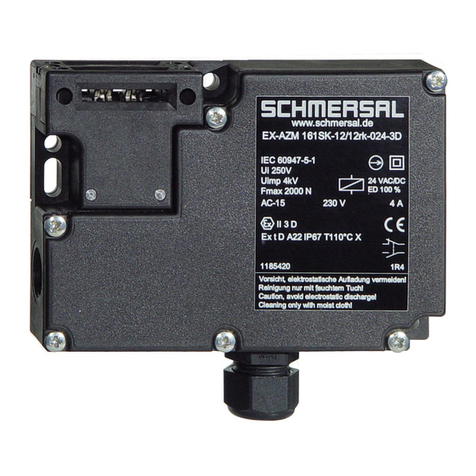

2.11 Marking and classication

Actuator body are impressed by laser marking or by an additional label (depending on the actuator model) as below indicated.

Manufacturer Name, Logo, Address

Product code and technical features

ATEX Directive marking (see section 11)

IC Symbol (SR type), fail to close, fail to open

Production date (yy/m)

1 4

2 5

3

Low temperature version marking T. min= -50°C (-58°F) T. max= +60°C (140°F)

High temperature version marking T. min.= -20°C (-4°F) T. max= 150°C (302°F)

1

3

4

5

2

EN - 6

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

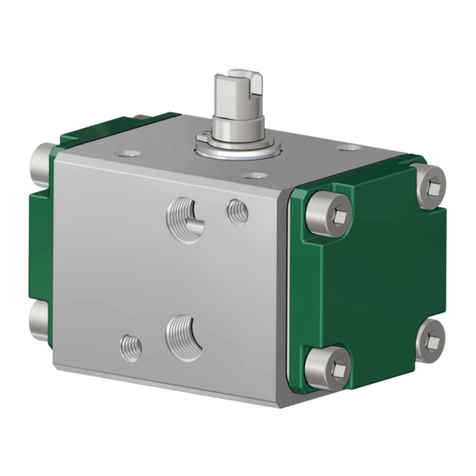

3. CONSTRUCTION FEATURES

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT) RP-300 ÷ RP-480 (GAS) RP-10 ÷ RP-480 RP-10 ÷ RP-480

Shaft (shaft slot indicates valve position; image shows a totally open position)

Inner chamber supply hole: GAS or NPT threading

Namur plate, for standard versions:

- GAS threading available from RP10 to RP240 (not available for RP300 and RP480);

- NPT threading available from RP10 to RP480;

Outer chamber supply hole: GAS or NPT threading

VDI/VDE 3845 Namur threaded connection holes:

- GAS threaded on the Namur plate from RP10 to RP240;

- GAS threaded on the cylinder for RP300 and RP480;

- NPT threaded on the cylinder from RP10 to RP480;

Threaded holes according to VDI/VDE 3845 to connect eventual accessories

Adjustment grub screw for closing and opening setting (± 5°):

- closing setting from -5° to +5°;

- opening setting from 85° to 95°;

Bi-square Drive

Valve connection ange

Evacuation grooves (in case of shaft leakages)

1

2

3

4

5

6

7

8

9

10

Customizations available, see section 4 or ACTUATECH catalogue.

For specic applications is available a wide range of actuators accessories on ACTUATECH catalogue.

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT)

61

32

4

5

RP-10 ÷ RP-480

7

RP-300 ÷ RP-480 (GAS)

1

6

4

25

10

8

9

RP-10 ÷ RP-480

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT)

61

32

4

5

RP-10 ÷ RP-480

7

RP-300 ÷ RP-480 (GAS)

1

6

4

25

10

8

9

RP-10 ÷ RP-480

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT)

61

32

4

5

RP-10 ÷ RP-480

7

RP-300 ÷ RP-480 (GAS)

1

6

4

25

10

8

9

RP-10 ÷ RP-480

RP-10 ÷ RP-240 (GAS)

RP-10 ÷ RP-480 (NPT)

61

32

4

5

RP-10 ÷ RP-480

7

RP-300 ÷ RP-480 (GAS)

1

6

4

25

10

8

9

RP-10 ÷ RP-480

EN - 7

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

4. CODING SCHEME

RP0160VAARS6007Q22G6

*Only on request.

N.B. For special versions contact ACTUATECH.

Example

A A B B B B C C D E F G G H H I J J K L

Types meanings Feature Reference

A A Brand RP Rack&Pinion

B B B B Size

0010

0020

0040

0060

0080

0120

0160

0240

0300

0480

C C Customer VA ACTUATECH

DRotation Angle

A90°

B* 180°

C* 120°

D* 135°

EClosing Direction RClockwise rotation

L Counter-clockwise rotation

FOperating Mode

SSpring Return Fail Close

O Spring Return Fail Open

DDouble effect

G G Springs used

00 No springs

20 2,0 bar springs

25 2,5 bar springs

30 3,0 bar springs

35 3,5 bar springs

40 4,0 bar springs

45 4,5 bar springs

50 5,0 bar springs

55 5,5 bar springs

60 6,0 bar springs

H H Smaller Flange Type

03 F03

04 F04

05 F05

07 F07

10 F10

12 F12

ILower shaft seat shape

(socket)

QStar shaft

D* Flat head shaft

J J Lower shaft seat size

(socket)

09 Shaft dimension 9mm

11 Shaft dimension 11mm

14 Shaft dimension 14mm

17 Shaft dimension 17mm

22 Shaft dimension 22mm

27 Shaft dimension 27mm

KAir connection

G Namur plate GAS

N Namur plate NPT

0Gas Thread on the cilynder

(no Namur interface)

INamur interface, integrated

Gas threads

LVersions

- Standard

6* Low temperature

4* High temperature

Types Features

RP Rack&Pinion

160 Model

VA ACTUATECH

A90° Rotation angle

RClockwise closing direction

SSpring Return Fail Close

60 6,0 bar springs

07 F07 F10 ange

QStar shaft

22 22mm squared socket

GNAMUR plate GAS

6Low temperature Version

EN - 8

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

5. FUNCTIONNING

Below described the main operating conguration. In case your product does not meet the following schemes, please look at

ACTUATECH catalogue or contact us.

5.1 Double acting (DA) actuator

Supplying air into port (2) actuator shaft rotates counter-clockwise (CCW) to open the valve. Conversely, supplying air into port (4)

actuator shaft rotates clockwise (CW) to close the valve.

5.2 Spring Return (SR) FAIL TO CLOSE

Supplying air into port (2) pistons move outward compressing the springs and actuator shaft rotates counter-clockwise (CCW) to open

the vale. Closing action is realized stopping air feeding. Springs energy push pistons back and consequently shaft rotates clockwise

(CW).

To avoid dust or solid particles incoming, close port (4) using a cap. In case of explosive environment use protection caps in complian-

ce with National safety/technical Standards or Regulations.

Counter-clockwise

Rotazione antioraria

dell'albero

rotation of the shaf

t

2

Counter-clockwise

Rotazione antiorar

ia

dell'albero

rotation of the shaft

2

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

4

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

4

EN - 9

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

5.3 Spring Return (SR) FAIL TO OPEN

Supplying air into port (2) pistons move outward compressing the springs and actuator shaft rotates clockwise to close the valve.

Opening action is realized stopping air feeding. Springs energy push pistons back and consequently shaft rotates counter-clockwise.

To avoid dust or solid particles incoming, close port (4) using a cap. In case of explosive environment use protection caps in complian-

ce with National safety or technical Standards.

5.4 Connection diagram

Remote operation control should be done connecting a direct solenoid valve to VDE/VDI 3845 NAMUR plate or connecting a piping

system directly to ports (2) (4). Use an independent electric control cabinet.

According with ISO 5599-2 Standard, actuator ports connection position, location, orientation and form shall be clearly identied and

marked with numbers 2 and 4.

Standard Double Acting (DA) and Spring Return (SR) actuators shall be Clockwise (CW) direction for Closed valves, while Coun-

ter-Clockwise (CCW) direction for Opened valves.

Double acting Spring return FC

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

2

Rotazione antioraria

dell'albero

Counter-clockwise

rotation of t

he shaft

4

2

31

EN - 10

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

6. SAFETY NOTICE

! Actuator must be used within pressure limits only, submit it to overpressure will damage it;

! Actuator must be used within temperature limits only, overstep temperature limits will damage it;

! Operating actuator in corrosive environments without suitable and required external protection will damage it;

! During installation, service or maintenance activities actuator must be pressure-less, disconnect air feeding and make sure that

air ports have been completely vented;

! Do not remove any component if actuator is still under pressure or installed in the line;

! In case of a fall, actuators could generate serious injuries to operators, use suitable lifting equipment. Do not use air feeding

holes to hang up the product;

! Before connecting actuator and valve, make sure that valve rotation is according with actuator operating rotation and upper

shaft slot orientation;

! Before installing an actuated valve, carry out some cycling test to ensure correct connection and actuator/valve functionality;

! Actuator installation shall be done in compliance with National safety/technical Standards or Regulations;

!ACTUATECH cannot be considered responsible for any damage to people, animals or things due to an improper use

of the product.

7. INSTALLATION INSTRUCTIONS

Before actuator installation check its conditions to verify eventually failure during transport and/or storage.

Actuator purpose is a remote control of a valve (opening and closing actions) avoiding manual operations. Actuator uses air or gas

controlled by a mechanic, pneumatic or electropneumatic valve. Size actuator choice might be affected by system design, chemical/

physical ow and environmental conditions, consequently higher safety factor can be required.

- Carefully read this instruction manual and the handbook included in the box.

- Take care of actuator features limit indicated on the labels to ensure the suitability.

Please verify actuator/valve conditions according to the above safety warnings and strictly follow the below indications.

- Check actuator position looking at shaft slot orientation;

- Double acting (DA) actuator is always supplied in opened position;

- Fail Close Spring Return (SR) actuator is always supplied in closed position;

- Fail Open Spring Return (SR) actuator is always supplied in opened position;

- Actuator position and rotation must be according to valve requirements and operations, especially for Spring Return (SR);

- Check valve position (open or closed) and its rotation direction;

- Before connecting actuator and valve, make sure that valve rotation is according with actuator operating rotation and upper shaft

slot orientation;

- Before installation, actuator, valve and accessories must be clean and free of dirt;

- Remove protective labels from air feeding ports;

EN - 11

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

7.1.2 Plate installation

If a direct installation is not possible because of discrepancy between actuators and valve anges or because of power transmis-

sion differences, is it possible to use plates. Adapting plates make the installation easier and offer more space for actuator/valve

installation.

7.1 Valve/Actuator installation

7.1.1 Direct installation

Direct installation is the best solution to avoid play or clearance between valve and shaft. Direct installation needs same anged

standard connection on valve and actuator as well as same dimension of valve stem and actuator socket.

Installation:

A. Pull reduction in valve stem (in case of reduction needs only);

B. Put valve stem into the actuator socket;

C. Verify correct connection to avoid play, clearance or interferences in between;

D. Place screws (1) and relevant washers (2) and screw them in compliance with below torque

indications;

E. After installation, check actuator rotation direction for Double acting (DA) actuators;

F. After installation, check actuator rotation direction and home position in case of Spring Return (SR);

G. In case of discrepancy contact us;

Installation:

A. Place plate (3) on valve ange;

B. Pull reduction in valve steam (in case of reduction needs only);

C. Put valve stem into the actuator socket;

D. Verify correct connection to avoid play, clearance or interferences in between;

E. Place screws (1) and relevant washers (2) and screw them in compliance with below torque

indications;

F. After installation, check actuator rotation direction for Double acting (DA) actuators;

G. After installation, check actuator rotation direction and home position in case of Spring Return (SR);

H. In case of discrepancy contact us;

EN - 12

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

7.1.3 Bracket & Joint Installation

Bracket & Joint installation is suitable in case of valves/actuator space requirements, in presence of non-standard valve ange or

valve stem, or generally in case of actuator/valve installation impossibility. Bracket is a stainless-steel drawn tubular with two holes

for Joint passage and several holes for valve/actuator installation. Joint allows the connection of actuator shaft and valve stem.

Bracket & Joint play or clearance must be as low as possible to ensure a correct actuator/valve power transmission.

Torque indication

ACTUATECH actuator, with evacuation grooves on connection side is purposely designed to a direct installation. Evacua-

tion grooves avoid any actuator damages caused by eventual draining uids coming from valve stem.

Installation:

A. Place Bracket (4) on valve ange, ribs must be perpendicular to the pipe;

B. Place screws (1) and relevant washers (2);

C. Place nuts (7) and washers (8) and in correspondence to the screws;

D. Lock the nuts using a wrench and screw them in compliance with below torque indications;

E. Put valve stem into the joint socket (3);

F. Put joint stem (3) into the actuator socket;

G. Verify correct connection to avoid play, clearance or interferences in between;

H. Place screws (5) and relevant washers (6) and screw them in compliance with below torque

indications;

I. After installation, check actuator rotation direction for Double acting (DA) actuators;

J. After installation, check actuator rotation direction and home position in case of Spring Return (SR);

K. In case of discrepancy contact us;

Flange type Torque (Nm)

F03 5 - 6

F04 5 - 6

F05 9 - 10

Flange type Torque (Nm)

F07 22 - 24

F10 46 - 50

F12 80 - 84

EN - 13

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

7.2 Actuator/Valve controls: Rotation direction check and installation

Double acting (DA)

Closed valve

Spring Return (SR) Fail Close

Closed valve

Double acting (DA)

Opened valve

Spring Return (SR) Fail Close

Opened valve

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

4

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

4

Cou nter-c lockw ise

Rotazio ne antiorari

a

dell'albe ro

rota tion of the s ha

ft

2

Counter-clockwise

Rotazione antiorar

ia

dell'albero

rotation of the shaf

t

2

EN - 14

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

Spring Return (SR) Fail Open

Closed valve

Spring Return (SR) Fail Open

Opened valve

8. OPENING AND CLOSING ANGLE SETTING

RP actuators rotation angle is nominally 90° with a ± 5° adjusting stroke: closing setting from -5° to +5° and opening setting from 85°

to 95°. Before any operation, take the pressure off, disconnect air feeding and make sure that air ports have been completely vented.

A

B

A

B

GRANO

DADO

O-ring

RONDELLA

CAMMA

Adjusting screw nuts

Size Thread Grub screw key Nut key Torque (Nm)

RP 10

M6 ch.3 ch.10 10 - 11RP 20

RP 40

RP 60

M8 ch.4 ch.13 22 - 25RP 80

RP 120

RP 160 M10 ch.5 ch.16 38 - 43

RP 240 M12 ch.6 ch.18 85 - 90

RP 300

RP 480 M14 ch.6 ch.21 110 - 115

Rotazione oraria

dell'albero

Clockwise rotat

ion

of the shaft

2

Rotazione antioraria

dell'albero

Counter-clockwise

rotation of t

he shaft

4

EN - 15

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

8.1 Double acting (DA) angle setting instruction

Opening Setting instruction:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Act on the grub screw (see arrow);

C. Unloose counter-nut (A1);

D. Feed port (2) with a low pressure (for a small movement only) in order to put pistons in home position;

E. Using an Allen wrench, screw or unscrew grub screw (A) to obtain angle setting required (range ± 5°);

F. Once adjusted, lock the grub screw (A) using an Allen wrench and screw counter-nut (A1) according to torque indications;

Closing Setting instructions:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Act on the grub screw (see arrow);

C. Unloose counter-nut (B1);

D. Feed port (4) with a low pressure (for a small movement only) in order to put pistons in home position;

E. Using an Allen wrench, screw or unscrew grub screw (B) to obtain angle setting required (range ± 5°);

F. Once adjusted, lock the grub screw (B) using an Allen wrench and screw counter-nut (B1) according to torque indications;

Setting range

Setting range

Pistons home position

Pistons end position

EN - 16

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

8.2 Spring Return (SR) Fail Close angle setting instructions

Opening Setting instruction:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Make sure that on air port (4) has been assembled a lter and its conditions (lter must not be clogged);

C. Act on the grub screw (see arrow);

D. Unloose counter-nut (A1);

E. Feed port (2) with a low pressure (for a small movement only) in order to put pistons in end position;

F. Using an Allen wrench, screw or unscrew grub screw (A) to obtain angle setting required (range ± 5°);

G. Once adjusted, lock the grub screw (A) using an Allen wrench and screw counter-nut (A1) according to table torque indications;

Setting range

Pistons end position

Closing Setting instructions:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Make sure that on air port (4) has been assembled a lter and its conditions (lter must not be clogged);

C. Act on the grub screw (see arrow);

D. Unloose counter-nut (B1);

E. Using an Allen wrench, screw or unscrew grub screw (B) to obtain angle setting required (range ± 5°);

H. Once adjusted, lock the grub screw (B) using an Allen wrench and screw counter-nut (B1) according to table torque indications;

Setting range

Pistons rest position

EN - 17

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

8.3 Spring Return (SR) Fail Open angle setting instructions

Opening Setting instruction:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Make sure that on air port (4) has been assembled a lter and its conditions (lter must not be clogged);

C. Act on the grub screw (see arrow);

D. Unloose counter-nut (A1);

E. Using an Allen wrench, screw or unscrew grub screw (A) to obtain angle setting required (range ± 5°);

F. Once adjusted, lock the grub screw (A) using an Allen wrench and screw counter-nut (A1) according table torque indications;

Setting range

Pistons rest position

Closing Setting instructions:

A. Take pressure off, disconnect air feeding and make sure that air ports have been completely vented;

B. Make sure that on air port (4) has been assembled a lter and its conditions (lter must not be clogged);

C. Act on the grub screw (see arrow);

D. Unloose counter-nut (B1);

E. Feed port (2) with a low pressure (for a small movement only) in order to put pistons in end position;

F. Using an Allen wrench, screw or unscrew grub screw (B) to obtain angle setting required (range ± 5°);

G. Once adjusted, lock the grub screw (B) using an Allen wrench and screw counter-nut (B1) according to table torque indications;

Setting range

Pistons end position

EN - 18

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

9. MATERIALS AND DURABILITY

Number of cycles as per EN15714-3 2009 (see table below).

Nominal torque a Nm Piston or vane actuator

Minimum number of cycles b

Maximum stroking time for testing,

based on 0-90° s

≤125 500 000 c 3

≤1 000 500 000 5

≤2 000 250 000 8

≤8 000 100 000 15

≤32 000 25 000 20

≤63 000 10 000 30

≤125 000 5 000 45

≤250 000 2 500 60

a Based on EN ISO 5211.

b One cycle consists of nominal 90° angular travel in both directions (i.e. 90° to open + 90° to close). For angular travel other than

90°, the endurance shall be agreed between the purchaser and the manufacturer/supplier.

c For thermoplastic actuators the minimum number of cycles shall be 250 000.

!In the case of maintenance, see section 10.

EN - 19

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

POS. Description Q. Row Material (standard actuator)

1 Cylinder 1 Aluminium alloy

2 Shaft 1 Steel alloy

3* Slide ring (upper shaft support) 1Acetal resin

4* Slide ring (lower shaft support) 1Acetal resin

5* O-Ring (lower shaft sealing) 1Nitrile rubber

6 Cam 1 Steel alloy

7* Internal support ring 1Acetal resin

8* External support ring 1Acetal resin

9 Washer 1Stainless-steel

10* Seeger 1 Stainless-steel

11* O-Ring** 2Nitrile rubber

12* O-ring (upper sealing shaft) 1Nitrile rubber

13 Namur plate** 1 Aluminium alloy

14 Screw** 2Stainless-steel

15* O-Ring 2Nitrile rubber

16* Washer (limit stroke) 2Stainless-steel

17* Nut (limit stroke) 2Stainless-steel

18* Grub screw (limit stroke) 2Stainless-steel

19 Piston 2 Aluminium alloy

20* Piston support leg 4Acetal resin

21* Dynamic seal 2 Polyurethan

22* O-Ring 2Nitrile rubber

23* End-cap O-ring 2Nitrile rubber

24 Cap 2 Aluminium alloy

25 Screw 8Stainless-steel

* Components of spare part kit. ** Not present for some models, see code table.

9.1 Actuator components and bill of materials

9.1.1 Double action actuator (DA)

EN - 20

ITENDEFRESRU

ACTUATECH S.p.A.

Via S. Lorenzo, 70, 25069 Villa Carcina (BS) Italy

Ph. +39 030 8908142 • Fax +39 030 8908143 • actuatech@actuatech.com • www.actuatech.com

Reference MAN81566 - 05/21

INSTRUCTION MANUAL

RP: RACK & PINION PART TURN PNEUMATIC ACTUATOR

RP10 - RP480

POS. Description Q. Row Material (standard actuator)

1 Cylinder 1 Aluminium alloy

2 Shaft 1 Steel alloy

3* Slide ring (upper shaft support) 1Acetal resin

4* Slide ring (lower shaft support) 1Acetal resin

5* O-Ring (lower shaft sealing) 1Nitrile rubber

6 Cam 1 Steel alloy

7* Internal support ring 1Acetal resin

8* External support ring 1Acetal resin

9 Washer 1Stainless-steel

10* Seeger 1 Stainless-steel

11* O-Ring** 2Nitrile rubber

12* O-ring (upper sealing shaft) 1Nitrile rubber

13 Namur plate** 1 Aluminium alloy

14 Screw** 2Stainless-steel

15* O-Ring 2Nitrile rubber

16* Washer (limit stroke) 2Stainless-steel

17* Nut (limit stroke) 2Stainless-steel

18* Grub screw (limit stroke) 2Stainless-steel

19 Piston 2 Aluminium alloy

20* Piston support leg 4Acetal resin

21* Dynamic seal 2 Polyurethan

22* O-Ring 2Nitrile rubber

23* End-cap O-ring 2Nitrile rubber

24 Cap 2 Aluminium alloy

25 Screw 8Stainless-steel

26 Spring 12 Steel alloy

27 Spring cartridge long 12 Acetal Resin

28 Spring cartridge short 12 Acetal Resin

29 Spring cartridge tube 12 Brass

* Components of spare part kit.

** Not present for some models, see code table.

The number of springs varies according to the model.

Excluded from the kit it is possible to request spare spring cartridge.

9.1.2 Spring Return actuator (SR)

This manual suits for next models

9

Table of contents

Other ACTUATECH Controllers manuals