January 4, 2017

MILLPWRG2 2 & 3 Axis

Release of Version R5

NOTE: HEIDENHAIN Corporation recommends making a backup of the control with the

included USB Recovery Drive before updating the control software. Please refer to the manual

included with the drive for the backup procedure

R5 is a complete software update.

If a special PLC for AMI functions was created for your MILLPWR system. The PLC for R5 may

need to be modified in the same manner. The PLC project has been updated, and rebased on

the Basic-NCK-V10 project. Any OEM/User customizations to the PLC will need to be

reintegrated into the new PLC project.

Users of auxiliary machine function interface (AMI) will need to first check two configuration

settings in their current system. Make note of the values described below so that they can be

restored manually after the R5 update, via the Machine Functions menu.

A special password provided by your authorized dealer is required to access the Advanced

Configuration from Installation Setup in order to view these settings:

System -> PLC -> CfgOemBool -> NP_MG_guard_inactive – [value]

If the setting is FALSE, then in R4SP1 they should set “Guards” to “Enabled”

Axes -> ParameterSets -> PS_1 -> CfgAxisAnalog – [unipolar]

If the setting is “off”, then in R4SP4 they should set “Polarity” to “Bipolar”

All users can verify your software version from the DRO screen by pressing SETUP. If one of

your soft keys is labeled More Commands, you have release 1 (R1) software. If one of your soft

keys is labeled Install Setup, press this key. Enter the password 8891 and press Enter. The

installed software version will be displayed at the bottom left of your screen.

If any issues are encountered, please contact your service representative for assistance.

You can download the software release update free of charge from our web site at www.acu-

rite.com. If you wish to purchase the software and operation manual from ACU-RITE, contact

your authorized dealer to place an order.

Installing the software onto your MILLPWRG2 system:

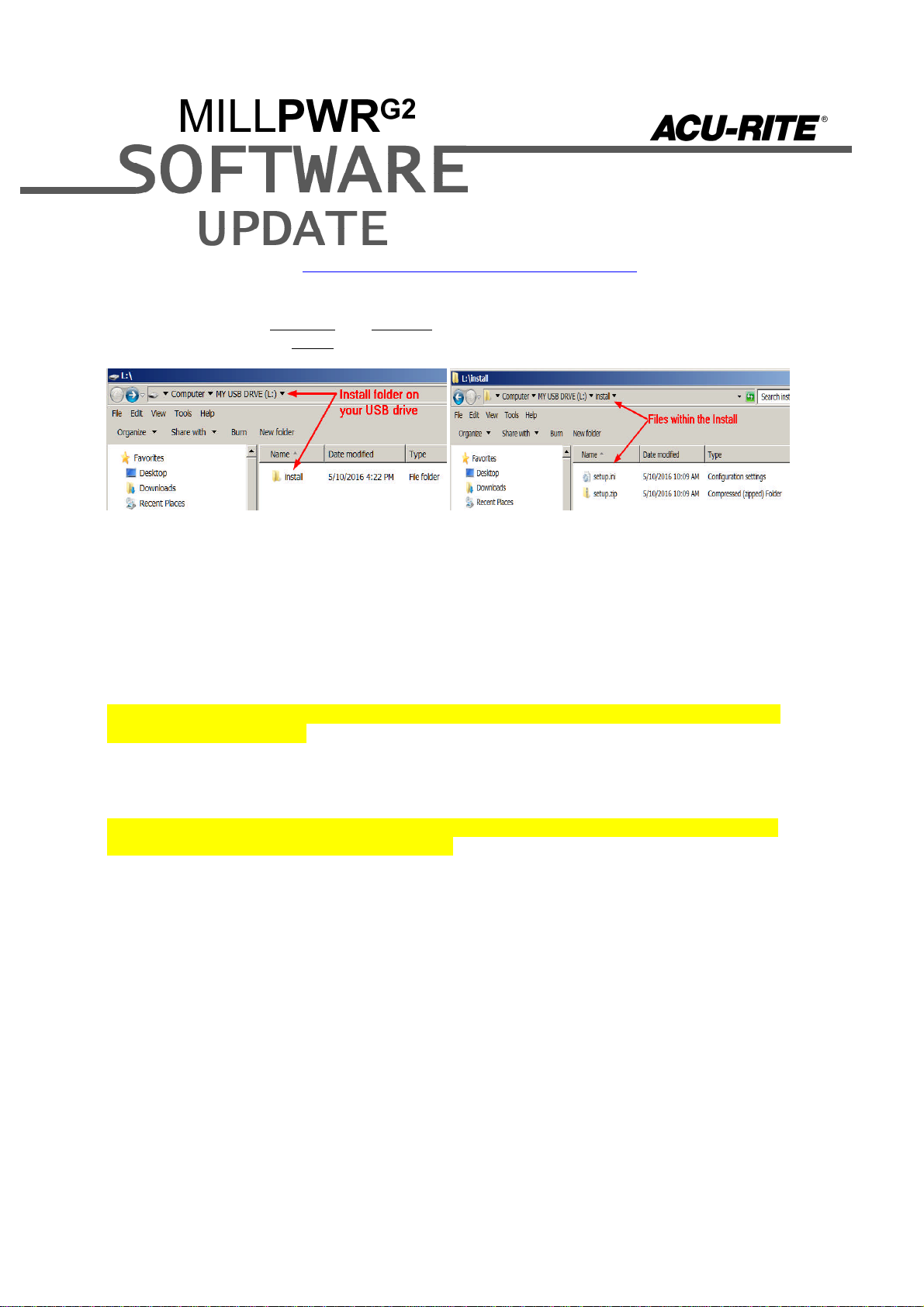

Use a blank USB memory stick (1 GB or larger) to update the software. Do not use any memory

stick with a smaller storage capacity. The software installation files are required for updating the

software. When a USB memory device in placed in a USB port prior to boot up with the update

files setup.zip, and setup.ini located within a folder named “install”, at boot up your G2 control

will detect the upgrade software files and proceed to install.

Procedure for downloading the update files and placing them on a USB drive.