ACV PRESTIGE Solo 80 User manual

Other ACV Boiler manuals

ACV

ACV Prestige Guide

ACV

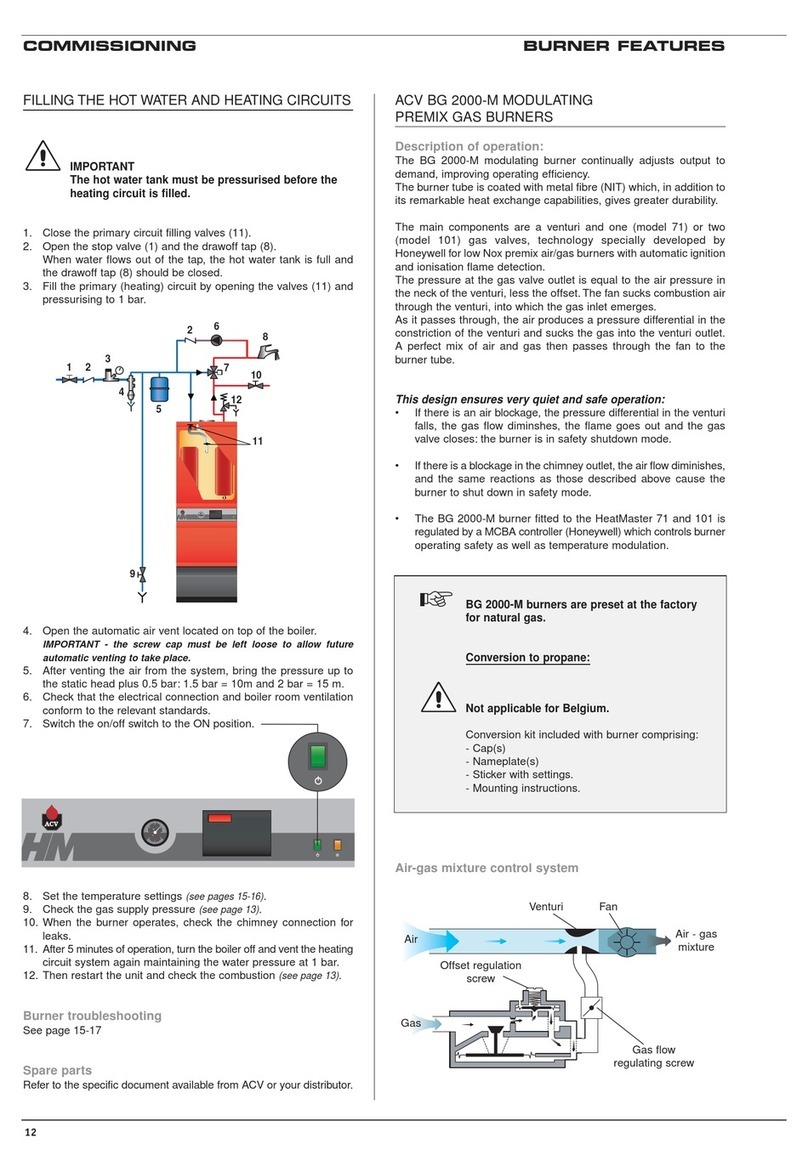

ACV HeatMaster 200N Booster User manual

ACV

ACV EVO S 40 Quick start guide

ACV

ACV HeatMaster 200N Booster Manual

ACV

ACV Smart Line SLE 130 Assembly instructions

ACV

ACV Prestige Solo 42 Manual

ACV

ACV delta pro rack Assembly instructions

ACV

ACV HeatMaster 201 Manual

ACV

ACV Compact A Series Owner's manual

ACV

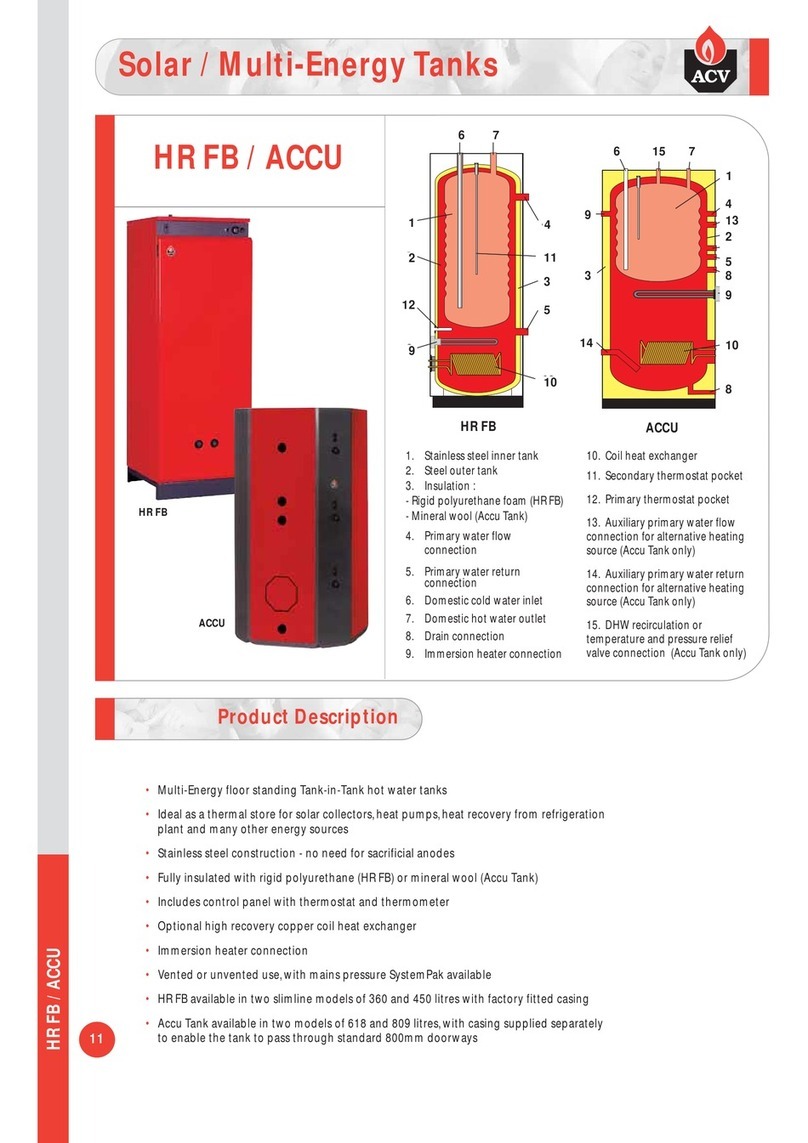

ACV ACCU B 600 Owner's manual

ACV

ACV HM 71 User manual

ACV

ACV Compact N1 User manual

ACV

ACV CC105 Instruction Manual

ACV

ACV Prestige 24 Solo User manual

ACV

ACV Alfa G Owner's manual

ACV

ACV HeatMaster 60 N User manual

ACV

ACV PRESTIGE Series Owner's manual

ACV

ACV Smart SL 100 Owner's manual

ACV

ACV Prestige 24 Solo User guide

ACV

ACV N-Mini User manual

Popular Boiler manuals by other brands

Immergas

Immergas VICTRIX ZEUS 26 2 ERP Instruction and recommendation booklet

Dunkirk

Dunkirk Plymouth Steam PVSB installation instructions

Glow Brand

Glow Brand C140 Installation & operation manual

Worcester

Worcester GREENSTAR 25Si Installation and servicing instructions

Buderus

Buderus Logano plus GB402 Installation and maintenance instructions for contractors

Stuart Turner

Stuart Turner Mikrofill ETHOS 70 Technical documentation

Slant/Fin

Slant/Fin GALAXY II GXHII-95 Installation and operating instructions

UTICA BOILERS

UTICA BOILERS UB95M-200 installation manual

Heatrae Sadia

Heatrae Sadia EXPRESS 7/1 Fitting instructions and user guide

U.S. Boiler Company

U.S. Boiler Company ALTA ALTAC-136 quick start guide

Mestek

Mestek 200i Installation and operation instructions

DOMUSA TEKNIK

DOMUSA TEKNIK LIGNUM NG Series Installation and operating instructions